Patents

Literature

65results about How to "Reduce drainage costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System for forecasting mine water regime and intelligently controlling drainage

InactiveCN101979838AReduce drainage costsReduce testing costsMining devicesDrainageWater securityPit water

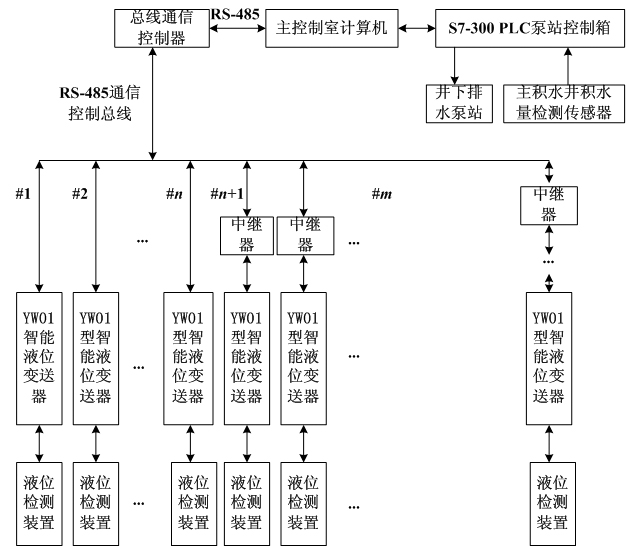

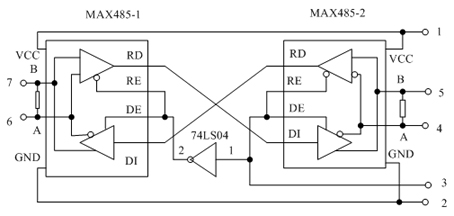

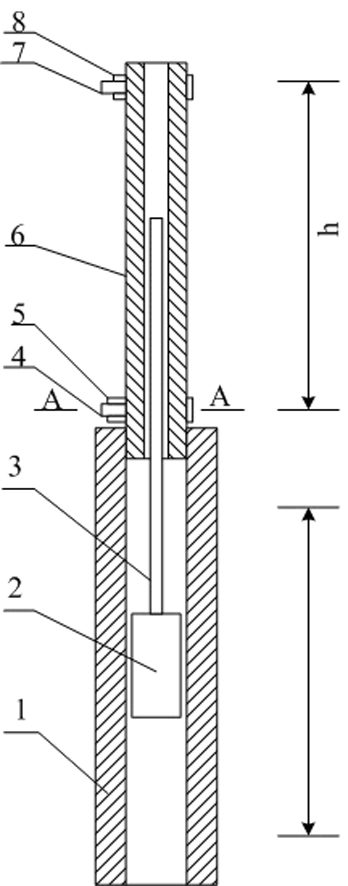

The invention relates to a system for monitoring and forecasting mine underground water regime and intelligently controlling drainage and belongs to the technical field of management of the mine underground water regime. The hardware devices of the system comprise an underground local accumulated water well accumulated water volume detection sensor group, a main accumulated water well accumulated water volume detection sensor, an RS-485 communication network module, a liquid level detection device, a master control room computer, an underground drainage pumping station and a pumping station master control box, wherein the RS-485 communication network module comprises an RS-485 communication control bus, a bus communication controller and a repeater. The system has the advantages of saving energy, reducing emission, reducing underground drainage cost, improving the safety of underground drainage, increasing the communication distance of an underground sensor, greatly reducing water level detection cost and improving system reliability. By the system, the underground water regime can be comprehensively known and controlled conveniently by a ground master-control room, and the safety of the underground water regime is improved.

Owner:JINZHOU HEAVY WATER PUMP

Foam tailings cemented filling material and manufacturing method thereof

InactiveCN101723622AIncrease profitReduce accumulationSolid waste managementCeramicwareFoaming agentFilling materials

The invention relates to a high-performance foam tailings cemented filling material and a manufacturing method thereof. The foam tailings cemented filling material consists of the following components in percentage by weight: 15.0 to 50.0 percent of cement, 40.0 to 85.0 percent of tailings, 0 to 30.0 percent of fly ash, 0 to 1.0 percent of water-reducing agent, and 0 to 0.3 percent of foaming agent. The manufacturing method of the filing material comprises: mixing the cement, the tailings, the fly ash and the water-reducing agent in the proportion at room temperature; adding water and stirring the mixture to be slurry; ensuring that the ratio of water to ash is less than 1.5; preparing the foaming agent in the proportion into foam; adding the foam to the mixture material stirred well and stirring again; uniformly distributing the added foam in the mixture material; and forming the foam tailings cemented filling material. The method has the advantages of greatly increasing the utilization rate of the tailings and effectively reducing the accumulation of the tailings on the ground. The filling material has the advantages of realizing self-flow transport of downhole pipelines and improving downhole operation environment, along with good fluidity, low water consumption and no material segregation.

Owner:GUANGDONG SHENGRUI TECH CO LTD

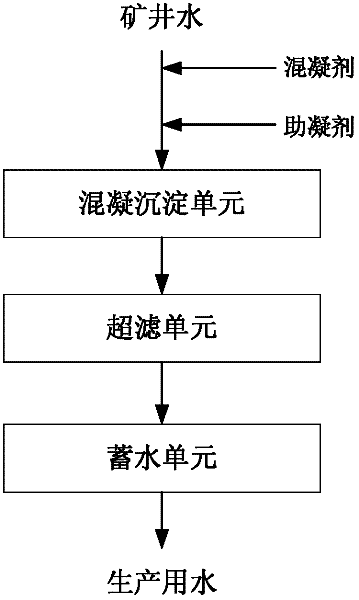

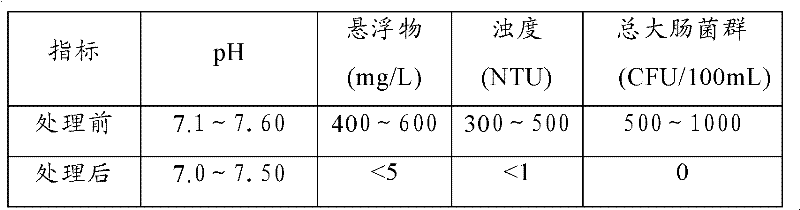

Coal mine water underground purification treatment device and method

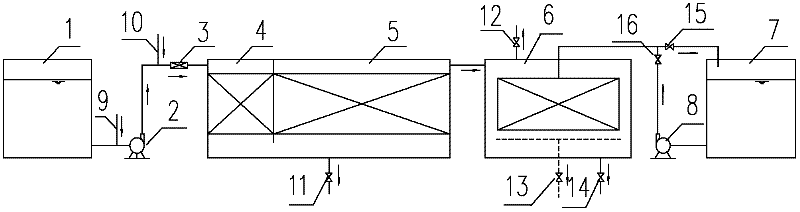

InactiveCN102336484AEasy to installEasy maintenanceWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentUltrafiltrationWater quality

The invention discloses a coal mine water underground purification treatment device and method. The coal mine water underground purification treatment device comprises a lifting unit, a coagulating sedimentation unit and an ultrafiltration unit which are connected in turn through pipelines, wherein a medicament adding unit is arranged before the coagulating sedimentation unit. The device has simple and compact structure; the treatment method is scientific and reasonable, and multiple defects of the prior art are overcome, the equipment is simple and is convenient to use and maintain; a sterilizing device is not required, power devices are fewer, the device has small floor area and is suitable for the narrow coal mine underground environment; and the device has the advantages of good purification effect and high effluent quality.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

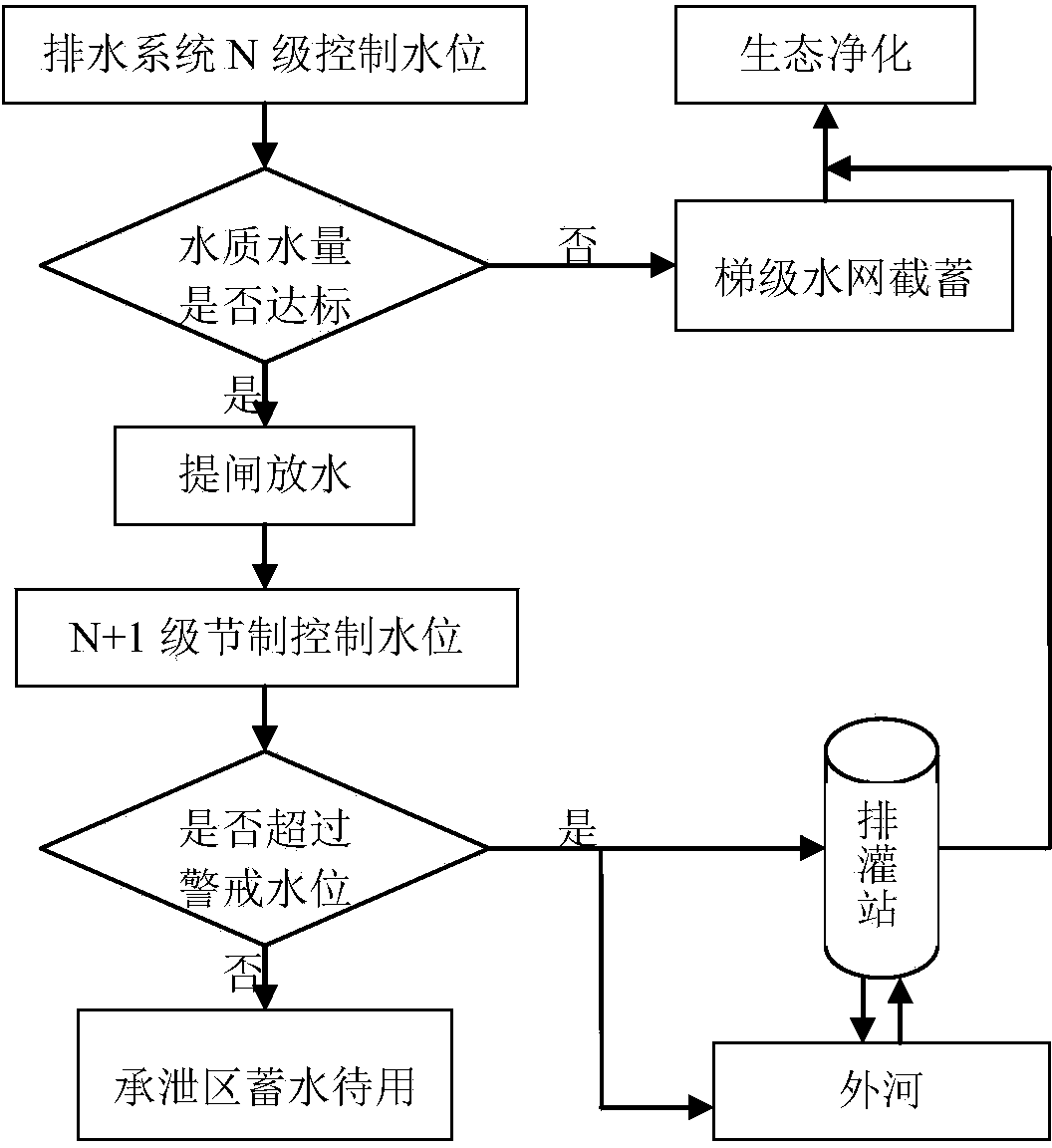

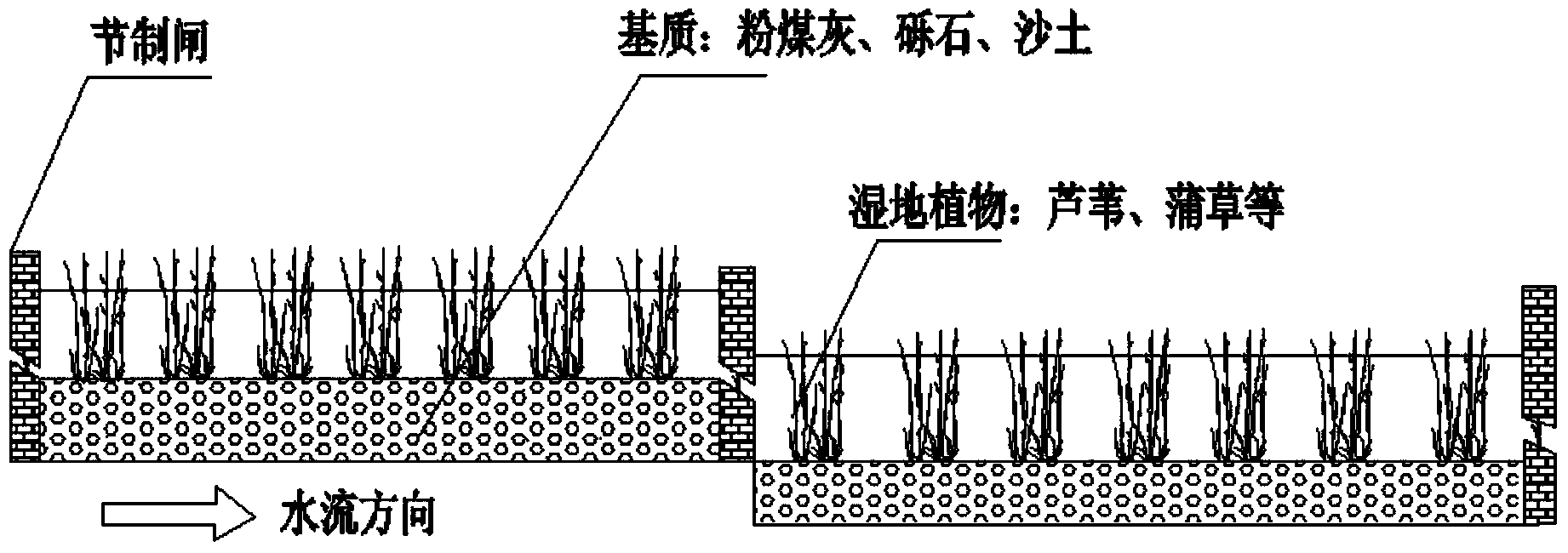

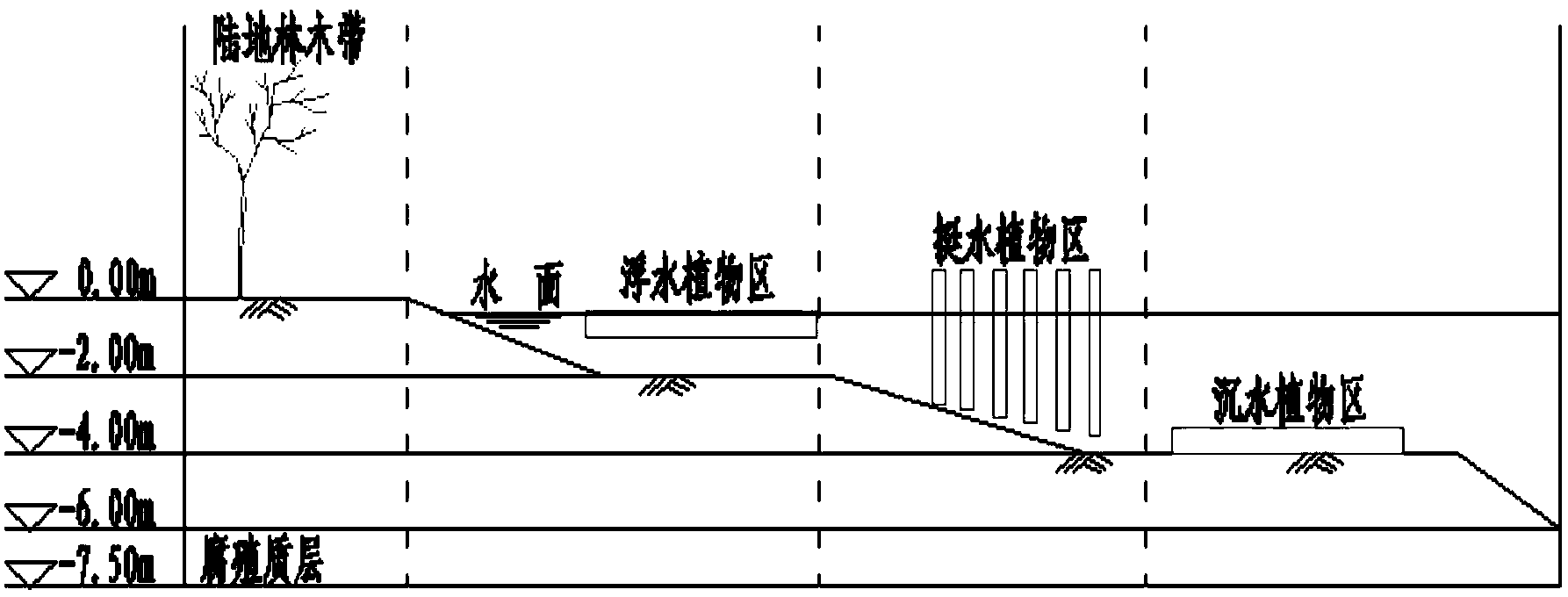

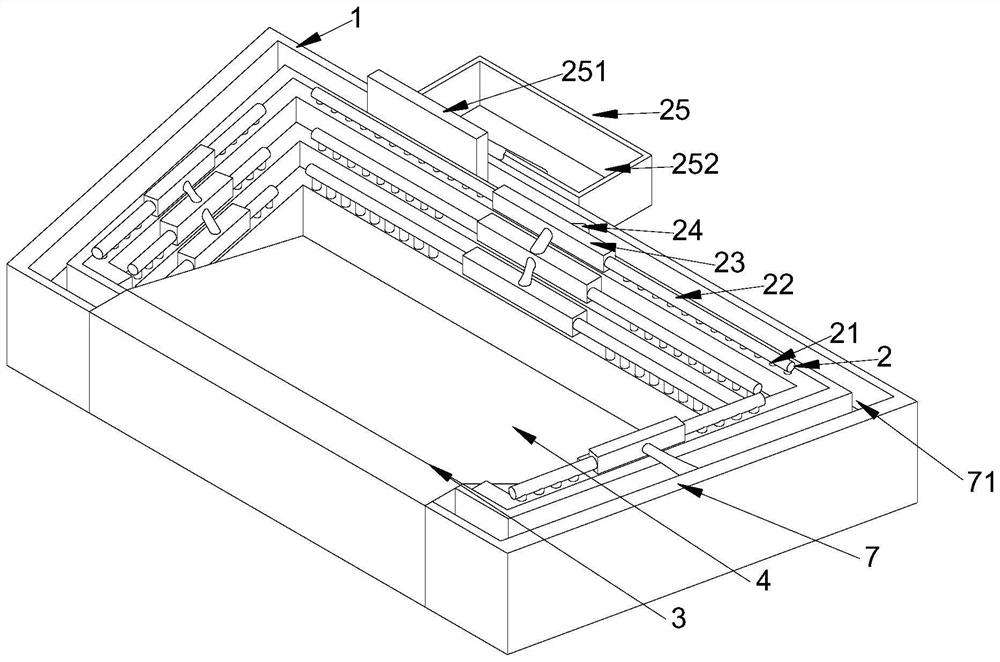

Method for water resource cascade adjustment control and water quality ecological purification in high groundwater level coal-mining subsidence area

InactiveCN103936163AChange the condition of space assignmentEvenly spacedSoil drainageHydraulic engineering apparatusHeavy metalsWater quality

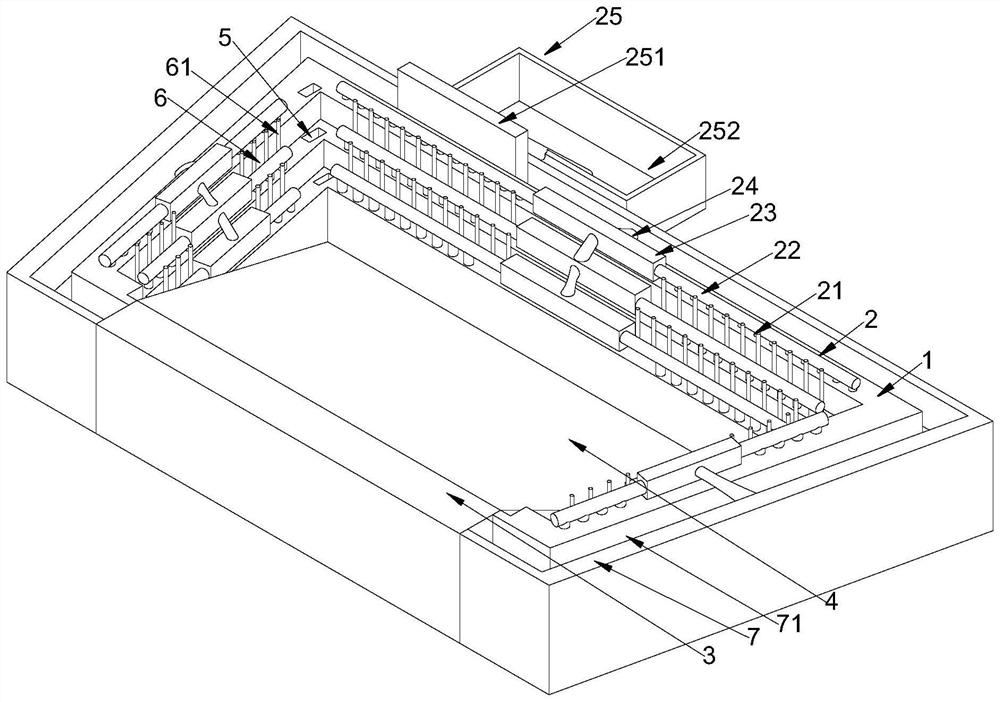

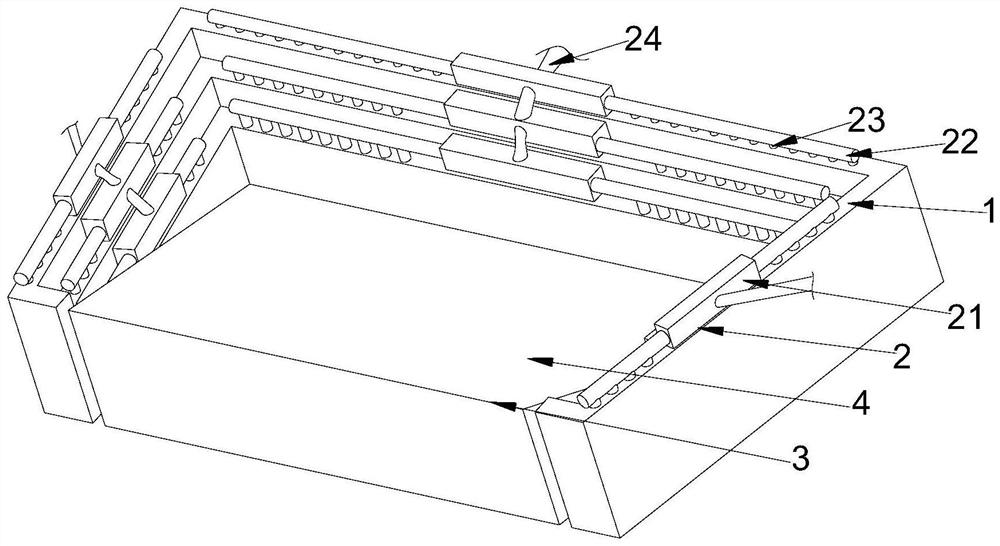

The invention discloses a method for water resource cascade adjustment control and water quality ecological purification in a high groundwater level coal-mining subsidence area, belonging to methods for water quality ecological purification in coal-mining subsidence areas. According to the method, after the high groundwater level mining area is mined, due to surface subsidence and high groundwater level, a large quantity of water is accumulated in the surface, the water resource utilization efficiency is low, the water quality is relatively poor, and the water quality of a water body in the mining area generally has the problems of heavy metal and sulfide pollution, water body eutrophication and the like according to existing analytical tests. The method is mainly used for solving the problems of water distribution of accumulated water in the mining subsidence area, water quality ecological purification and the like, the adjustment control of surface water resources is mainly realized through main rivers distributed in the mining area, N-stage control and Nstage water surface are established on the main rivers due to relatively large surface elevation difference after mining area subsidence, and pollutants and eutrophic substances in the water body are purified by corresponding three-dimensional distributed aquatic plants and animals according to test analysis results of the water quality of the water body so as to achieve the purpose of water quality purification of the water resources of the accumulated water in the high groundwater level mining area.

Owner:CHINA UNIV OF MINING & TECH

Novel water control method suitable for mine shafts

ActiveCN102425421AImprove construction conditionsProtection securityDrainageShaft liningEngineeringWater layer

The invention relates to a novel water control method suitable for mine shafts, which is characterized by firstly adopting grouting for water plugging at a water-bearing layer at the upper part of the shaft; arranging a wall seat at the boundary of the water-bearing layer and a water-resisting layer and arranging a bypass for water interception after the wall on the upper surface of the wall seat; arranging a dewatering orifice in the bypass and arranging a water guide pipe in the orifice, wherein the wall seat is wider than the bypass and the wide part of the wall seat is upwarped for water blocking; arranging a water collecting ring in the shaft at the upper part of an access road and draining water collected by the water collecting ring into the bypass after the wall, wherein a baseplate of the access road is 200-300mm higher than the bypass; and pre-burying a drainage pipe and enabling gushing water collected at the upper part of the bypass to self-flow into a water sump and be further drained to the ground through a drainage device. By adopting the novel water control method, the construction conditions of the mine shaft can be improved, the construction quality can be improved and the progress can be accelerated; furthermore, water damages can be effectively prevented during the production period of a mine, the safety of the mine shaft is protected, the drainage cost is reduced and the service life of the mine shaft is prolonged.

Owner:BLUESTAR LEHIGH ENG INST CO LTD

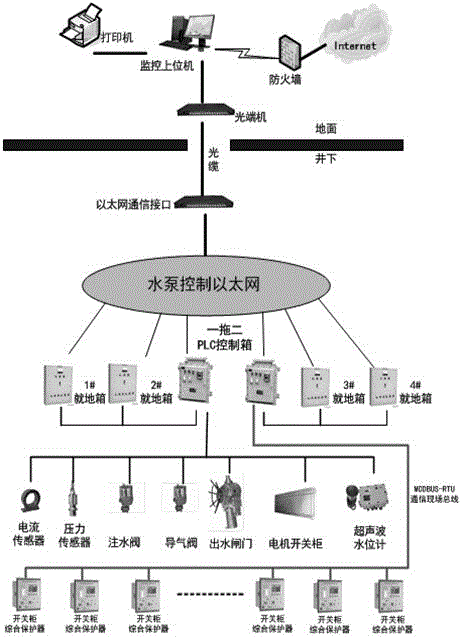

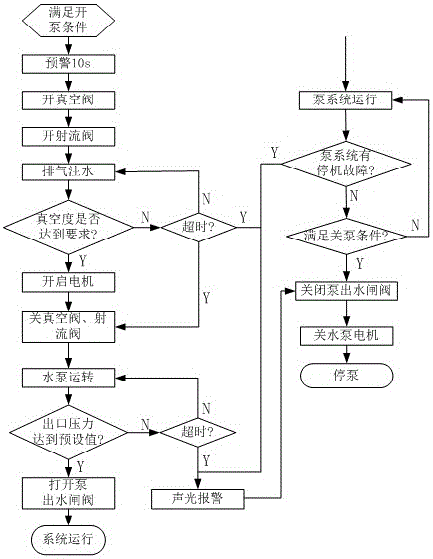

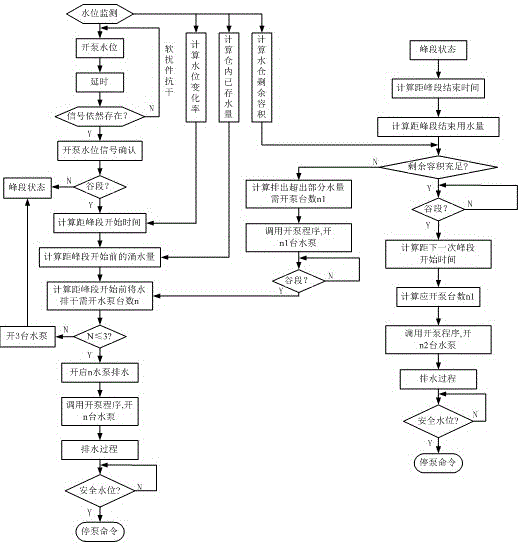

Intelligent control and energy conservation optimization algorithm for underground water pump

InactiveCN105952660AEasy to transformRealize intelligent drainageForecastingPump controlField dataEngineering

The invention relates to an intelligent control and energy conservation optimization algorithm for an underground water pump. The intelligent control and energy conservation optimization algorithm is particularly applicable to drainage of an underground water pump in a coal mine. The intelligent control and energy conservation optimization algorithm is characterized by comprising a PLC control cabinet, a field sensor, an upper computer, on-site operation boxes, a frequency converter and a detection instrument, wherein the PLC control cabinet and the upper computer are core parts of an intelligent control system, communicate with display screens of the on-site operation boxes, control the process of starting and stopping of the water pump, observe relevant parameters, and set a working mode of the water pump; and the field sensor and the detection instrument form a detection unit of the system used for acquiring field data.

Owner:CHINA UNIV OF MINING & TECH

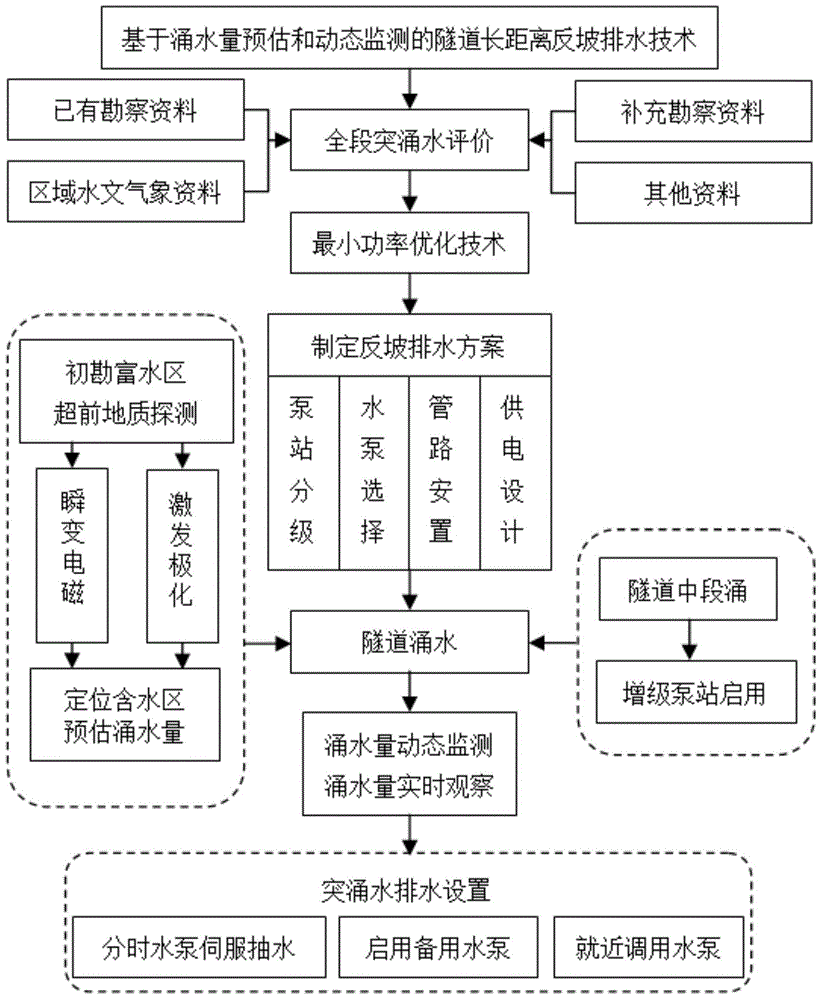

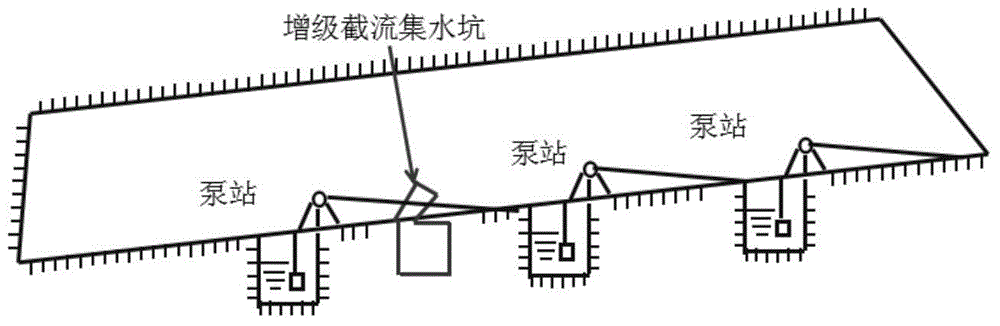

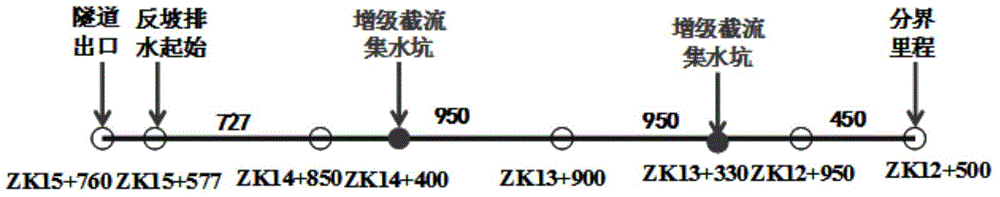

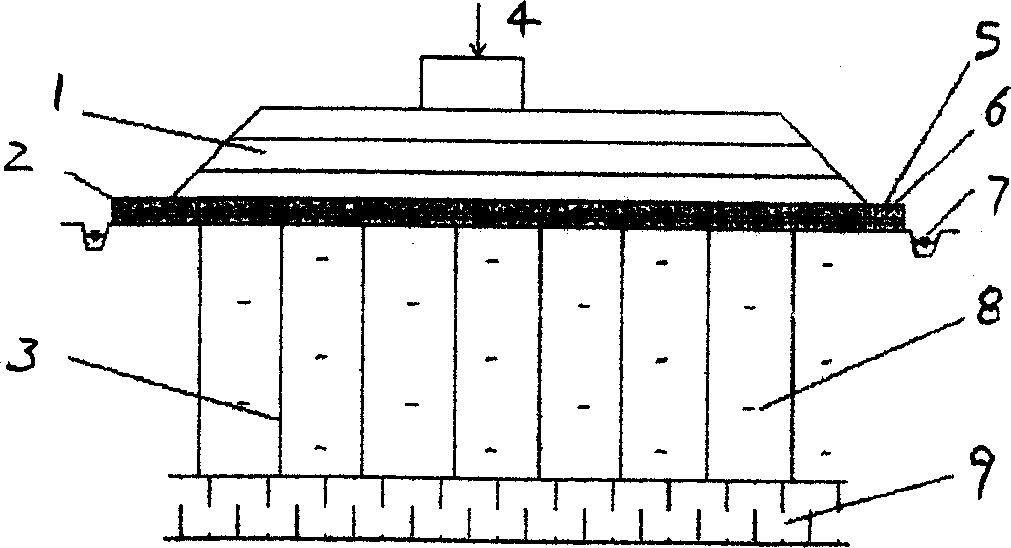

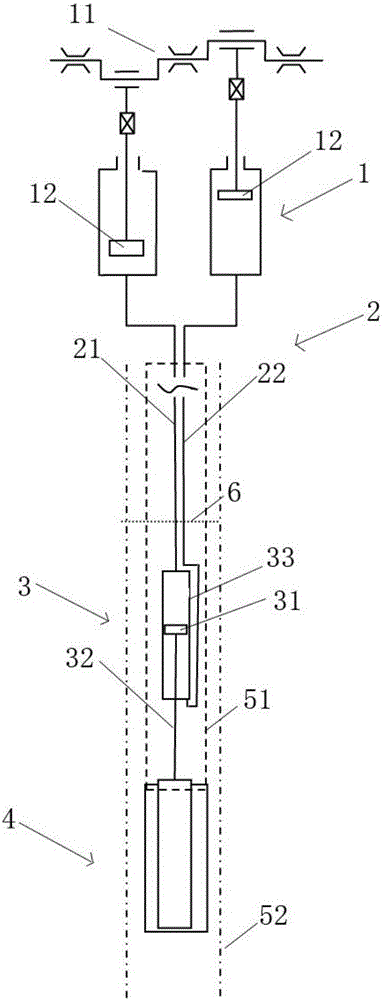

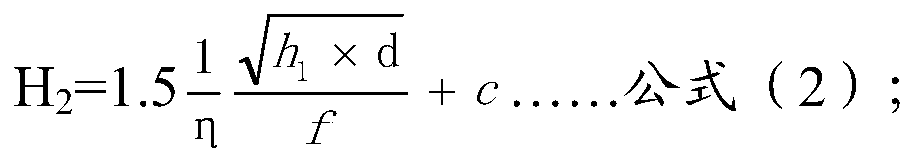

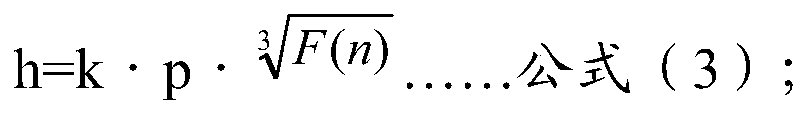

Tunnel counter-slope drainage design method based on water inflow estimation and dynamic monitoring

ActiveCN104948226AAccurate estimateReduce construction costsDrainageGeological surveyDynamic monitoring

The invention discloses a tunnel counter-slope drainage design method based on water inflow estimation and dynamic monitoring. The method comprises the following steps that on-site geological survey is carried out, geological conditions of sections where a tunnel is located are learned, and water burst risk assessment is carried out on all the sections through first investigation data; based on power minimization optimization, water inflow of all the sections of the tunnel is estimated, a power minimization optimization method is adopted for carrying out grading calculation on pump stations, and optimal water pump power is selected; the power of the pump stations is set according to the optimal water pump power, it is ensured that the power of all the pump stations is set to correspond to the actual water outlet amount of the tunnel, and a counter-slope drainage scheme is set; a TEM transient electromagnetic method and an induced polarization method are adopted for accurately locating water containing areas of the water containing sections of the tunnel, the water content is estimated, the water inflow of the tunnel face can be dynamically monitored in real time, and the set of the counter-slope drainage arrangement is adjusted according to the water inflow, the water inflow change rate and the estimated water content. The water containing areas before the excavated tunnel face can be located accurately, and the water inflow can be estimated accurately.

Owner:THE FIFTH PROJECT OF CHINA RAILWAY BUREAU 14 GROUP +1

Low-level prepressing drainage dynamic consolidating soft soil foundation processing method

InactiveCN101021068ALarge processing depthShort construction periodSoil preservationDynamic compactionCrushed stone

The present invention discloses a soft soil foundation treatment construction method by adopting low-position precompressed dewatered dynamic compaction process. It is characterized by that said method includes the following steps: firstly, building horizontal dewatering network on the foundation surface; then placing vertical dewatering body in the soft soil layer, inserting said vertical dewatering body into the bottom portion of soft soil layer; setting water-collecting wells around the periphery of said soft soil foundation, and making them be communicated with water-collecting channel of precompressed zone edge; back-filling broken stone soil and rolling by layers.

Owner:包国建

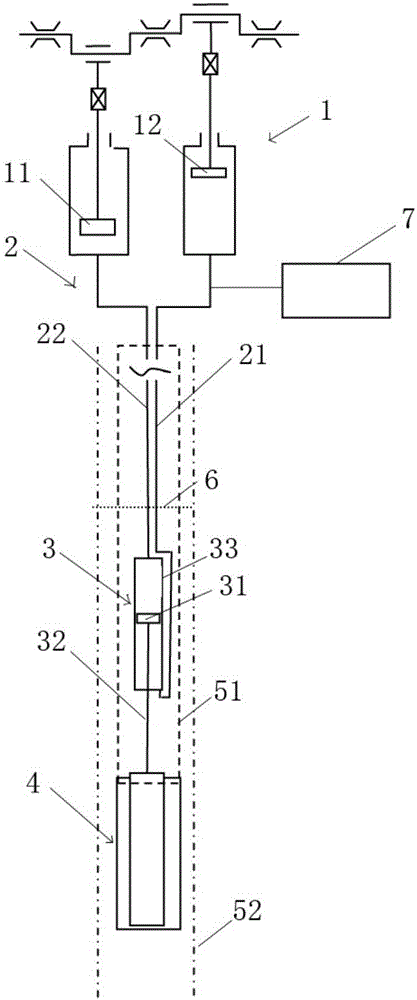

Water-based double-hydraulic drive discharge and mining system

InactiveCN105673465ASolve partial wearOvercome the disadvantage of not being able to downloadFlexible member pumpsFluid removalWater basedDouble tube

The invention discloses a water-based double-hydraulic drive discharge and mining system, which comprises a reverse double-piston ground drive pump unit, a flexible tube and hard tube double-tube water-based power transmission unit, a two-sided piston power applying unit and a rod pump unit used for oil pumping and discharge and mining; the flexible tube and hard tube double-tube water-based power transmission unit comprises a flexible tube and a hard tube; the flexible tube is attached to the hard tube and goes deep into an oil tube and a casing under the shaft; the reverse double-piston ground drive pump unit is equipped so as to apply suction to the hard tube while applying pressure to the flexible tube or apply pressure to the hard tube while applying suction to the flexible tube; the upper side of the two-sided piston power applying unit is connected with the flexible tube, and the lower side of the two-sided piston power applying unit is connected with the hard tube; and the rod pump unit used for oil pumping and discharge and mining is in linkage with the two-sided piston power applying unit.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

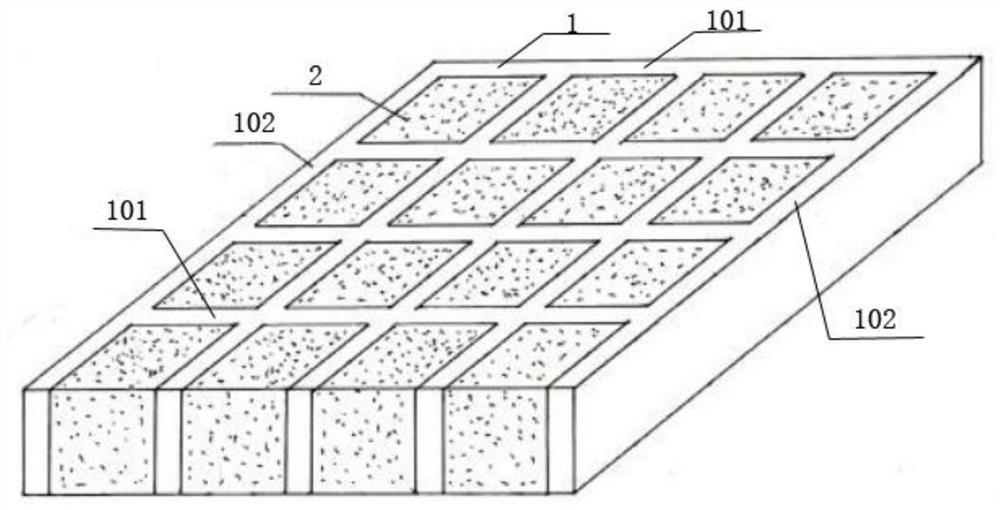

Goaf coal gangue supporting solid filling method

PendingCN112049682AReduce governance costsSave land acquisition costsMaterial fill-upUnderground transportCoal spontaneous combustionMining engineering

The invention discloses a goaf coal gangue compaction, roof contact, gridding and supporting solid filling method. Specifically, a high-strength coal gangue concrete filling material and a pure ganguenon-strength filling material are blended through a control system, and a net-shaped structure state combining a high-strength latticed supporting system and non-strength latticed inner filling is formed in a goaf by adopting a cross spraying operation mode of the two materials. The method has the beneficial effects that a gangue dump can be canceled; damage to a top plate and a bottom plate is reduced or eliminated, and water gushing of the top plate and the bottom plate is reduced; gas emission is reduced; the roadway retaining effect of two roadways is guaranteed, roadway retaining cost isreduced, coal pillar-free mining is achieved, the coal resource recovery rate is increased, the roadway tunneling amount is reduced, and mining continuing tension is relieved; the top and bottom plate approaching amount of the goaf is greatly reduced or eliminated, the top and bottom plate pressure is reduced, and good conditions are created for lower-layer mining; air circulation in the goaf iseffectively prevented, and coal gangue spontaneous combustion and residual coal spontaneous combustion are avoided; and great economic benefits are brought to enterprises.

Owner:孙嘉岐

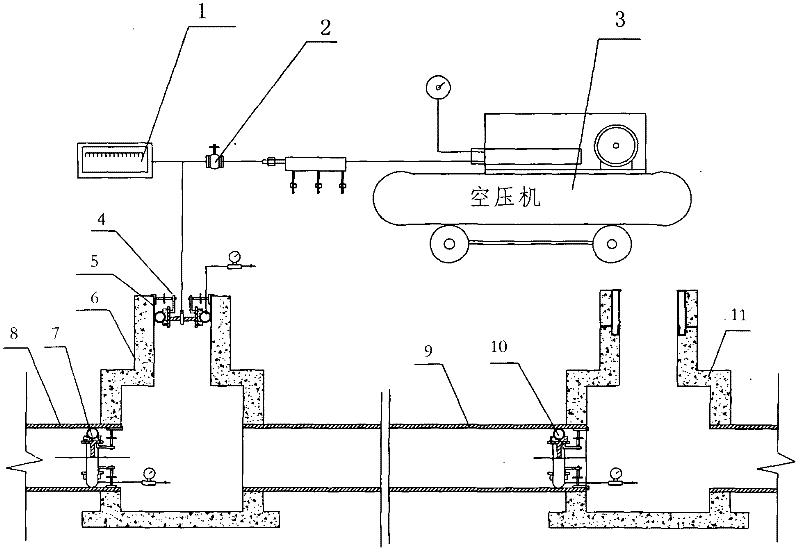

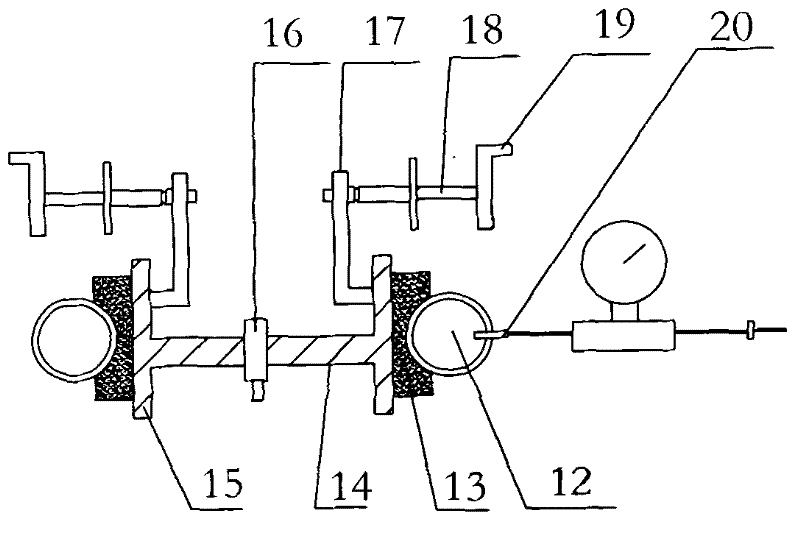

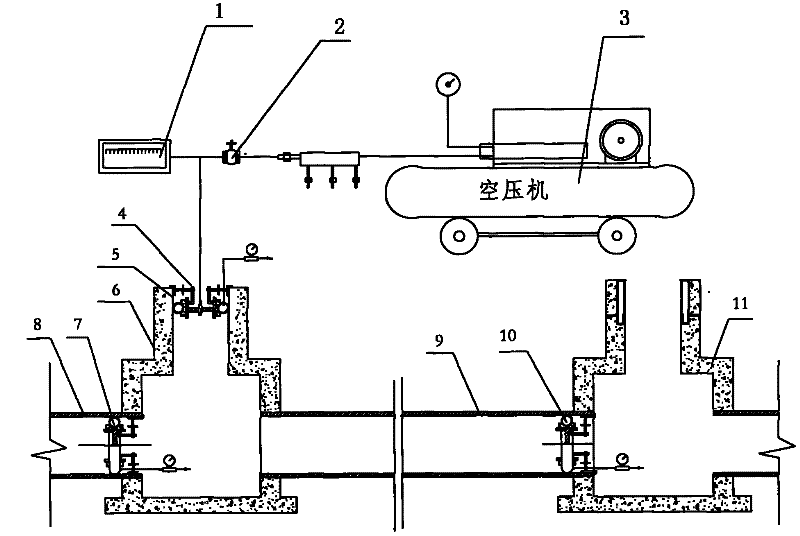

Outfit for detecting plugging and choking of sewage pipelines and inspection wells by full air bag method

InactiveCN102313629AReduce wasteHarm reductionFluid-tightness measurement using fluid/vacuumSewageEngineering

The invention provides an outfit for detecting plugging and choking of sewage pipelines and inspection wells by a full air bag method, which structurally comprises a detected sewage inspection well, a sewage inspection well to be detected, a detected sewage pipeline, a sewage pipeline to be detected and an air compressor. The detected sewage pipeline is connected between the detected sewage inspection well and the sewage inspection well to be detected. The inner wall of a wellhead of the detected sewage inspection well is coated with a sealing medium. A wellhead air bag plugging device is arranged at the position coated with the sealing medium. An air bag plugging device for the pipeline to be detected is arranged at the end port of the sewage pipeline to be detected at the bottom of the detected sewage inspection well. An air bag plugging device for the detected pipeline is arranged at one end of the detected sewage pipeline at the bottom of the sewage inspection well to be detected.The plugging and choking detection outfit has the beneficial effects that 1, the plugging and choking detection outfit accords with the scientific ideal of low carbon and environment protection, water is not used, and the waste on the water and the hazard of emission on the environment can be reduced; 2, the test period is short, the effect of completing test work of more than one well section inhalf of a working day can be achieved, test data can be shown immediately so that the leakproofness is verified; and 3, the outfit is simple to operate, the test speed is high, and equipment has highsealing performance.

Owner:JINAN URBAN CONSTR GRP

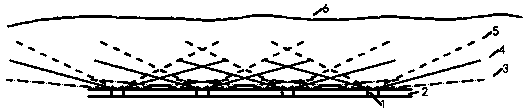

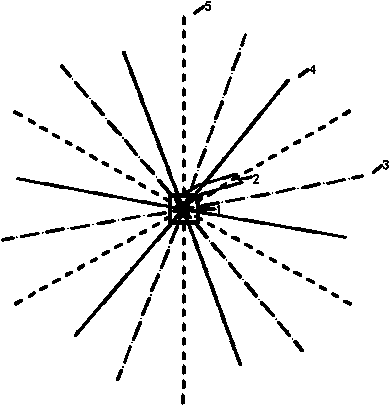

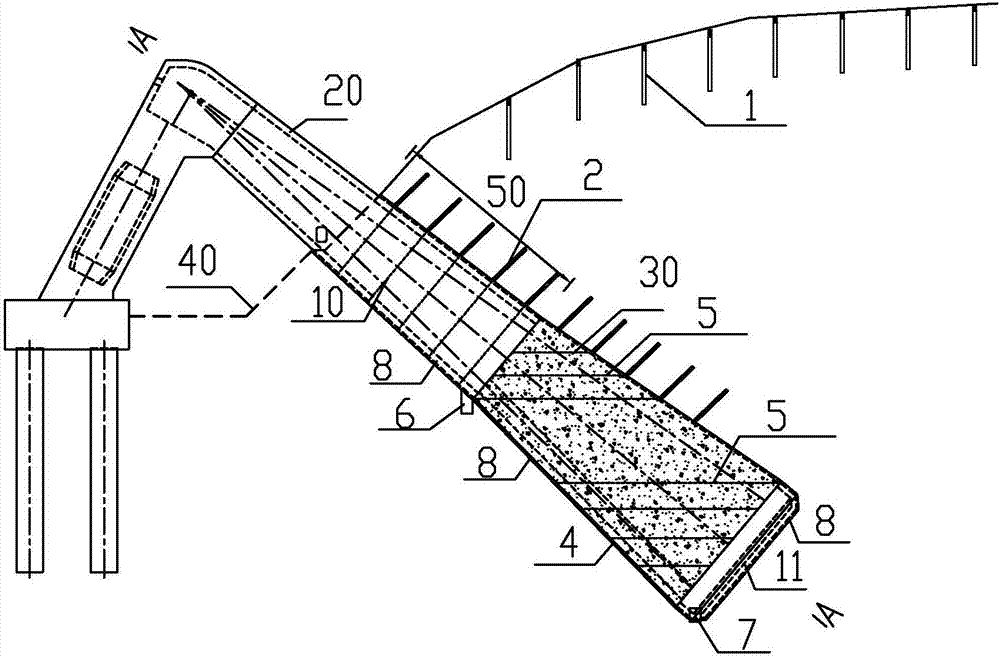

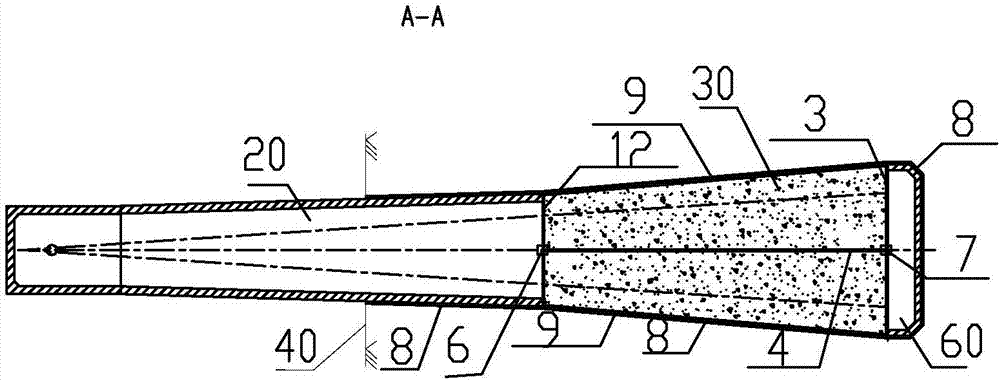

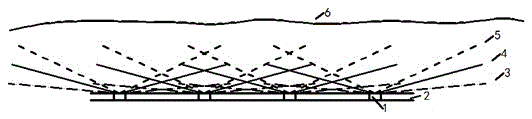

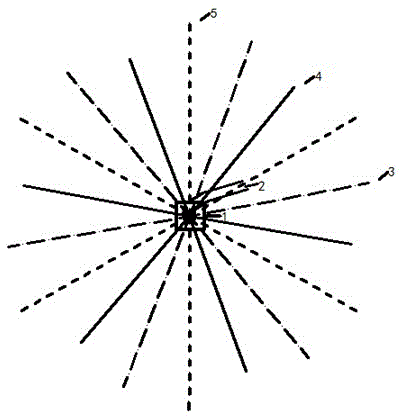

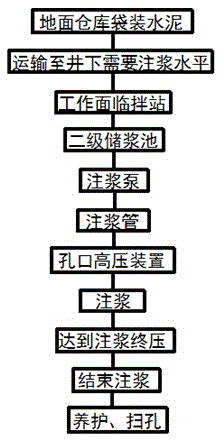

Curtain grouting technology for ore body roof karst fracture development and strong water-rich ore deposit

ActiveCN103967506AGuarantee safe miningReduce drainage costsUnderground chambersTunnel liningElevation angleGeomorphology

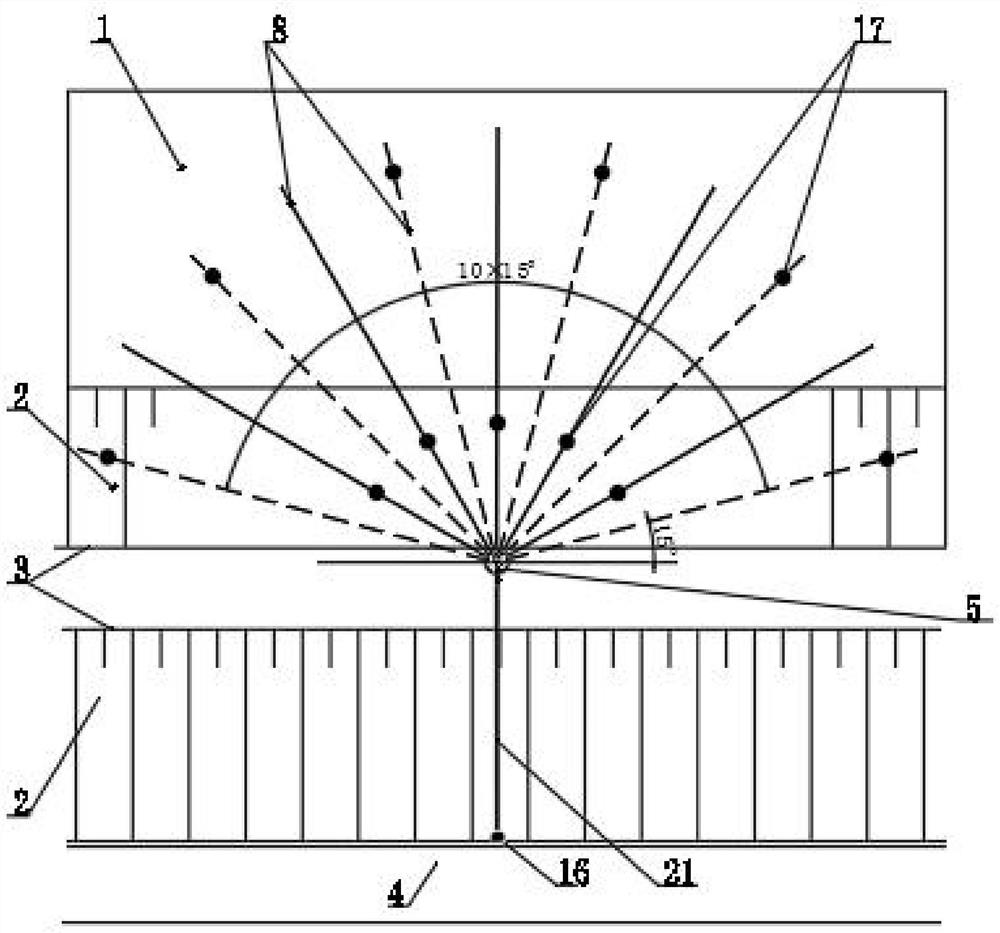

The invention discloses a curtain grouting technology for an ore body roof karst fracture development and strong water-rich ore deposit. According to the technical scheme, firstly, upward exploration and injection holes are distributed, six upward exploration and injection holes with an elevation angle of five degrees, six upward exploration and injection holes with an elevation angle of 15 degrees and six upward exploration and injection holes with an elevation angle of 25 degrees are distributed in each chamber, the exploration and injection holes are designed with the chambers as base points, all the exploration and injection holes of all the lengths are evenly distributed in the plane with a stagger angle of 60 degrees, the hole depth is 50 m, and the exploration and injection holes with the elevation angle of five degrees, the exploration and injection holes with the elevation angle of 15 degrees and the exploration and injection holes with the elevation angle of 25 degrees are evenly distributed in the plane with a stagger angle of 20 degrees; secondly, downward exploration and injection holes are distributed, the outward and downward exploration and injection holes with the angles of -5 degrees,-30 degrees and -60 degrees are distributed in end chambers, the hole depth is 50 m, all the downward exploration and injection holes are evenly distributed symmetrically in the plane, and the included angle is 10 degrees; thirdly, according to the requirement of accurate mining engineering, grouting is carried out, and a grouting curtain is formed. The grouting curtain with the high water plugging rate is built under a mine according to roof karst fractures, the functions of water separation and reinforcement can be achieved, ore bodies are released safely and efficiently under the protection of the grouting curtain, and technical guarantees are provided for safe and efficient mining of the mine.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

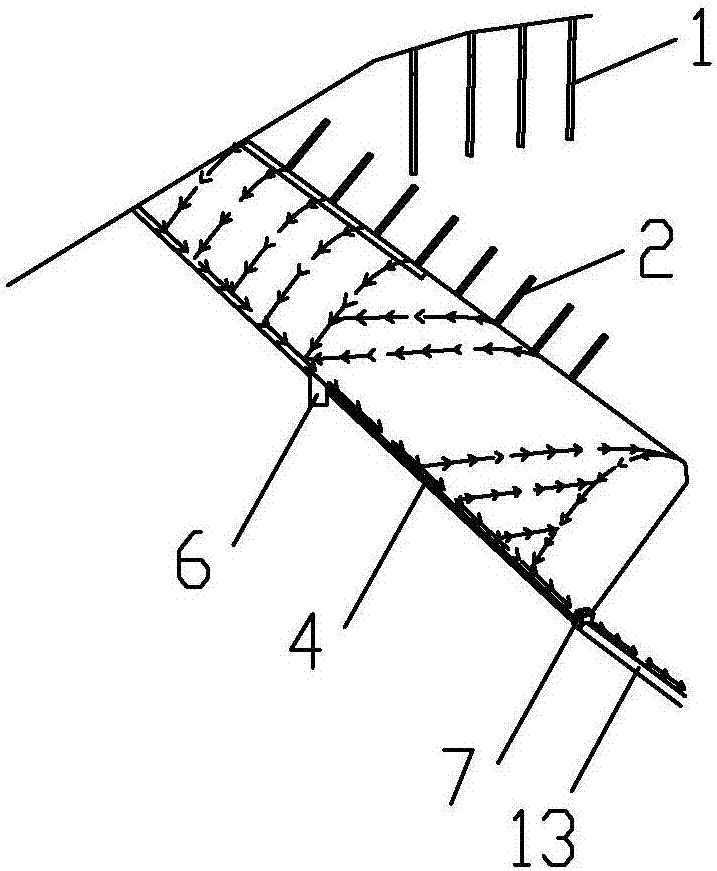

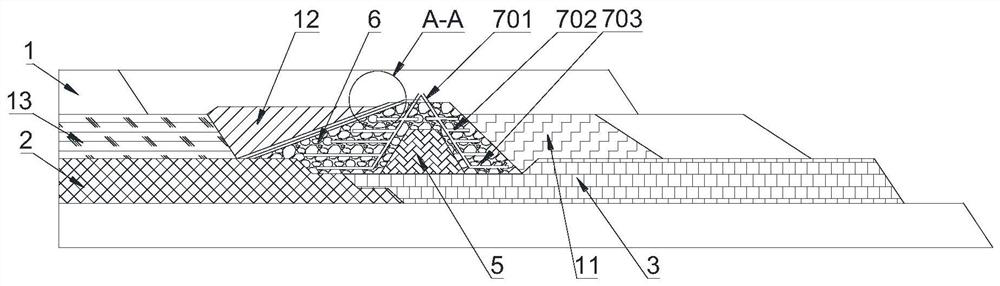

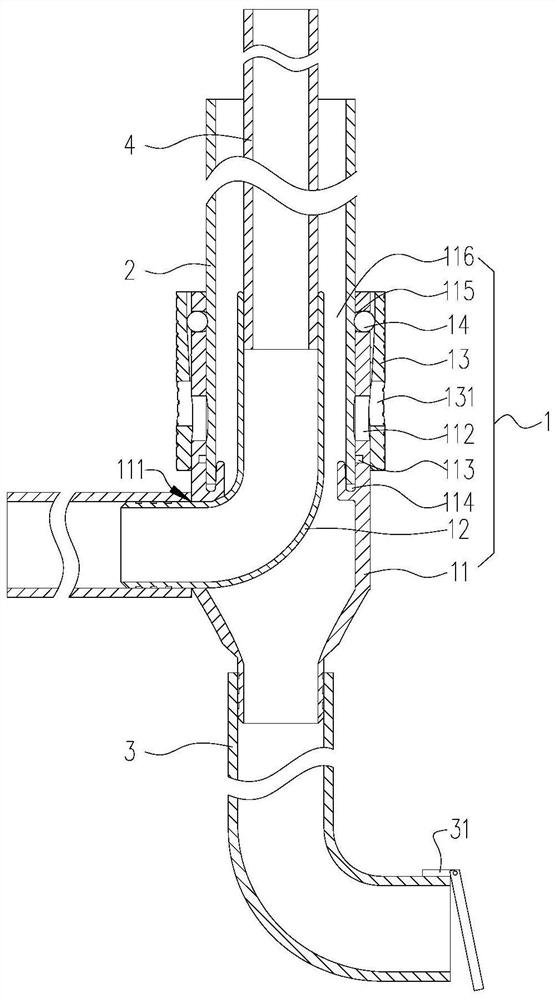

Construction method for intercepting curtain prevent and cure water by building L-shaped grouting

The invention relates to the technical field of prevent and cure water of mines, in particular to a construction method for intercepting curtain prevent and cure water by building L-shaped grouting. The method comprises the following steps: firstly, arranging an L-shaped curtain around a mining excavating face; then drilling a injected hole in the curtain; grouting the injected hole after hole flushing and a pump-in test; during grouting, first, putting a bushing in the injected hole, then carrying out grouting by way of sectional grouting from top to bottom, carrying out continuous grouting for 20-30 min if the acceptance of grout of the injected hole at a regulated pressure is smaller than 10 L / min to finish the grouting work; then injecting concentrated cement tailing slurry into the hole bottom of the injected hole; carrying out lifting while grouting to fulfill and seal the injected hole; and in 14 days after grouting, carrying out quality inspection to finish construction. The construction method can exert an obvious intercepting role to weaken the dissolution action of underground water, so that large surface subsidence is hard to form and the geological environment in the mine areas such as roads, rivers and villages is protected, thereby laying a solid foundation for future safe production in the mining area.

Owner:江西省宜丰万国矿业有限公司

Waterproofing and drainage system for tunnel-type anchorage of suspension bridge, and construction method

ActiveCN107012791AMaintaining Stressed StructuresImprove physical and mechanical propertiesBridge structural detailsDrainageEngineeringDrilling machines

The invention discloses a waterproofing and drainage system for a tunnel-type anchorage of a suspension bridge, and a construction method, belonging to the technical field of building construction. The construction method comprises grouting surrounding rocks to seal water, arranging annular, longitudinal and transverse water-percolating blind pipes on the periphery of the tunnel to divert water, hanging waterproof plates on the periphery of the tunnel to proof water, arranging water-collecting wells at the bottoms of a front anchorage chamber and a rear anchorage chamber to collect water, and arranging a transverse drainage channel at the bottom of the tunnel to discharge water. According to the waterproofing and drainage system for the tunnel-type anchorage of the suspension bridge, and the construction method, on the one hand, the stability of surrounding rocks around the tunnel-type anchorage is protected, and the project quality of the main body is protected, so that the bridge safety is enhanced; on the other hand, the drainage work of a water pump in the operation period is cancelled, the drainage cost of the tunnel-type anchorage in the operation period of the bridge is greatly reduced; and the transverse drainage channel of the tunnel-type anchorage is formed by horizontal drilling of a drilling machine, the method is simple, the use is flexible, the construction period is short, and the cost is low.

Owner:CCCC FIRST HIGHWAY XIAMEN ENG

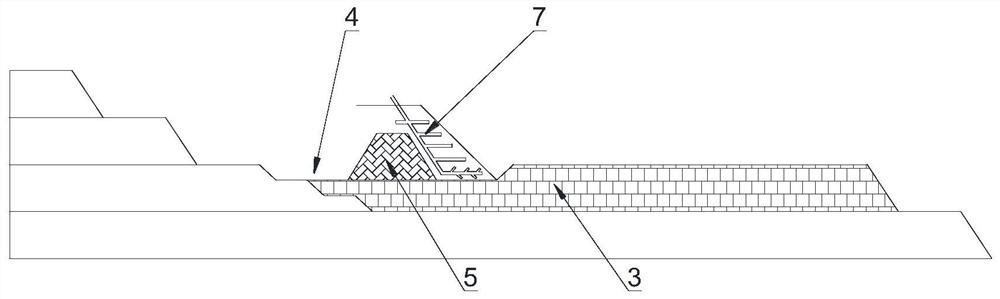

Method for constructing internal dam body of internally-discharged strip mine dump

ActiveCN113106988ABlock as soon as possibleReduce leakageBarrages/weirsProtective foundationStructural engineeringAquifer

The invention discloses a method for constructing an internal dam body of an internally-discharged strip mine dump. The method comprises the following steps that an upper surface connecting line of an original water-resisting layer is taken as an artificial water-resisting layer to fill a reference datum upper boundary; a dam body foundation pit is arranged, and a trapezoidal base platform is arranged on the center line of the dam body foundation pit; a halfpace-shaped water retaining dam core wall is built on the artificial water-resisting layer, and a reinforcing mesh and a grouting pipeline are arranged in the water retaining dam core wall; a foundation anti-seepage layer, waterproof geotechnical cloth and a clay anti-seepage layer are sequentially laid on the side, close to an original aquifer, of the water retaining dam core wall; advancing of a dumping working face is enhanced on the side, away from the original aquifer, of the water retaining dam core wall, and strip mine stripping objects are discharged to form a supporting body; a space between the clay anti-seepage layer and the original aquifer is filled to form a plugging body; and the construction is carried out according to the steps, the dump continues dumping, the facility formed in the steps is buried inside the dump, and a continuous water retaining dam is formed. The dam body is coordinated with strip mine stripping, mining and discharging operation, the water blocking effect is good, the dam body reliability is high, the influence on production is small, and the cost is low.

Owner:CHINA UNIV OF MINING & TECH

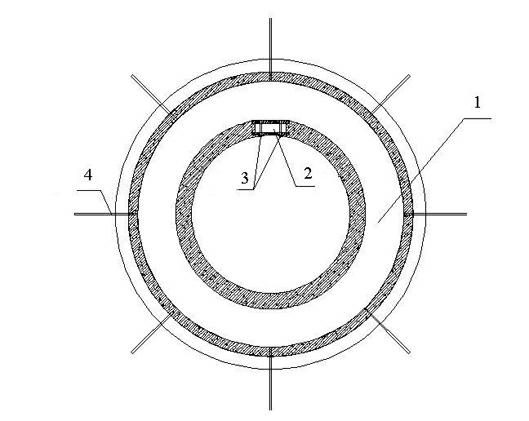

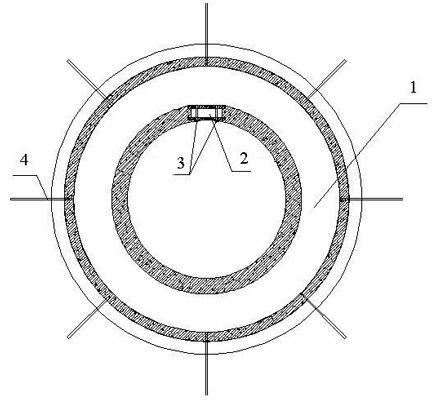

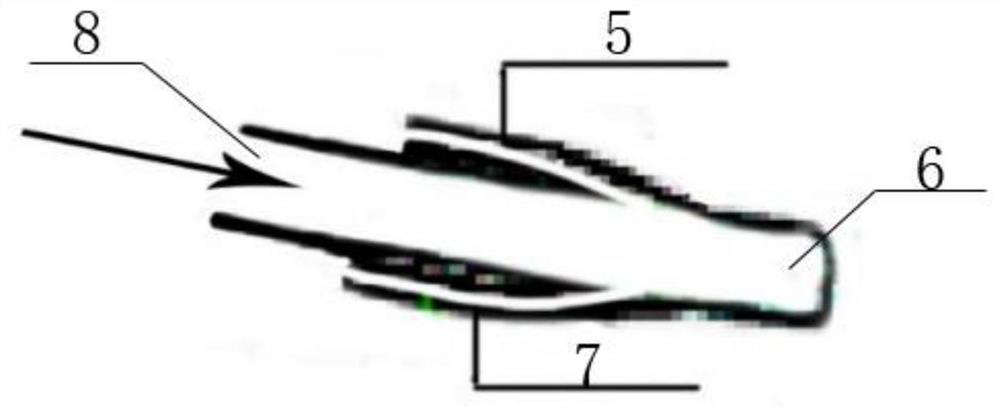

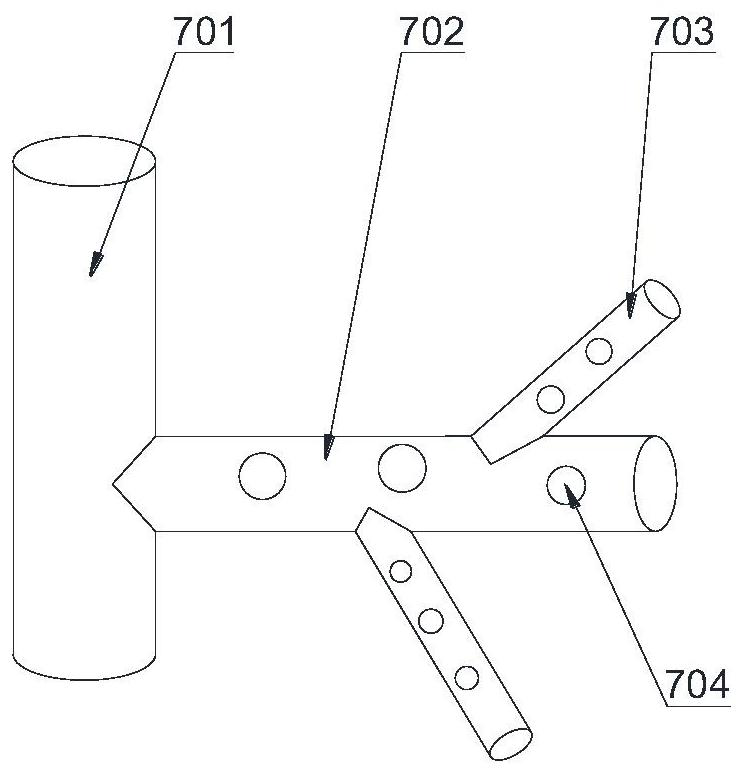

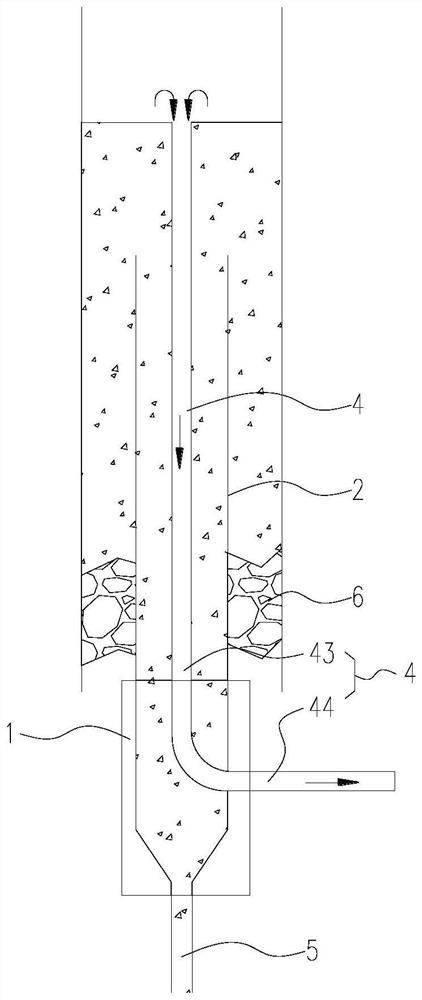

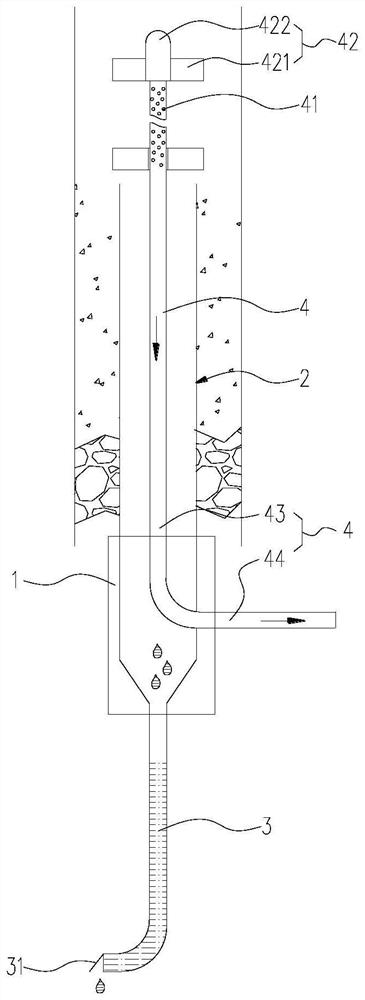

Gas extraction hole drainage method

ActiveCN111608723AThe drainage process is simple and easy to controlReduce drainage costsFluid removalDrainageCoal mine methaneCoal

The invention provides a gas extraction hole drainage method and belongs to the field of coal mine gas extraction. The gas extraction hole drainage method aims to achieve that drainage and exhaust ofan upward hole are synchronously conducted, so that gas extraction is conducted in time. The gas extraction hole drainage method comprises the following steps that firstly, a hole sealing embedded pipe is buried in the upward extraction hole; secondly, a connection device arranged at the bottom end of the hole sealing embedded pipe is utilized to assemble a drainage pipe and an exhaust pipe; thirdly, an extraction system is started, gas in the extraction hole is extracted out through an exhaust passage, and water in the extraction hole is discharged through a drainage passage under the actionof weight. According to the gas extraction hole drainage method, by means of the connecting device, the drainage pipe and the hole sealing embedded pipe are made to communicate to form the drainage passage; by means of the connecting device, the exhaust pipe is inserted into the hole sealing embedded pipe to form the exhaust passage; by means of design of an inner pipe and an outer pipe of the connecting device, the drainage passage and the exhaust passage are mutually independent and do not interfere each other, gas-water separation is achieved, so that gas extraction and drainage of an extraction hole can be simultaneously conducted, and the purpose of conducting gas extraction in time is achieved; and gravity drainage is conducted, so that control is easy, and cost is low.

Owner:四川川煤华荣能源有限责任公司

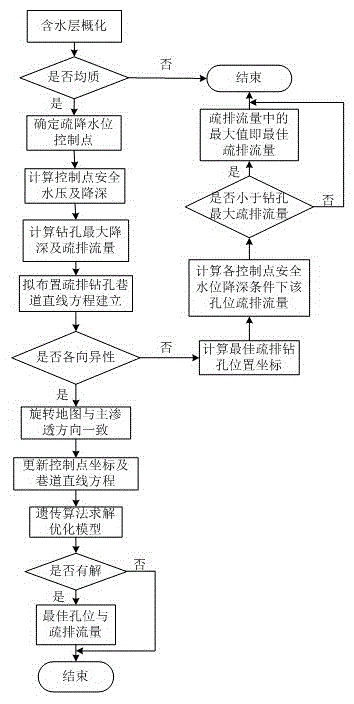

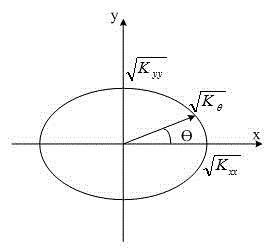

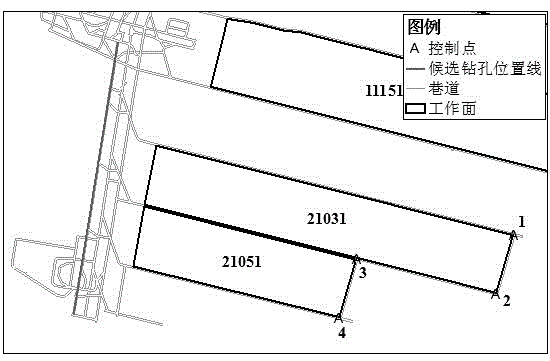

Optimization method for underground single-hole drainage of high-pressure coal seam floor water

InactiveCN105046060AHigh precisionReduce processing costsSpecial data processing applicationsPeak valueHigh pressure

An optimization method for underground single-hole drainage of high-pressure coal seam floor water is provided, and is suitable for drainage of water in a high-pressure coal seam floor water-containing layer by a single borehole in mining. The method comprises: conceptually converting a tunnel in which a candidate drainage borehole position is located into a straight line segment, wherein an optimum drainage borehole position is a point that is within the straight line segment and that satisfies that a peak value of a drainage flow required by all control points during falling to a safe water level is minimum; when a to-be-drained water-containing layer is a homogenizing isotropic water-containing layer, the point is a point that a farthest distance away from each control point in a roadway straight line segment is minimum; when the to-be-drained water-containing layer is a homogenizing anisotropic water-containing layer, the point is a point that a peak value of the drainage flow required by each control point in the roadway straight line segment is minimum; and by using a genetic algorithm, solving and obtaining a coordinate of the optimum drainage borehole position and the optimum drainage flow. The method optimizes a high-pressure coal seam floor water single-hole drainage project, with mining be safe, underground water resources are protected at maximum extent, realizing an optimum balance between safety, economy and environmental protection.

Owner:CHINA UNIV OF MINING & TECH

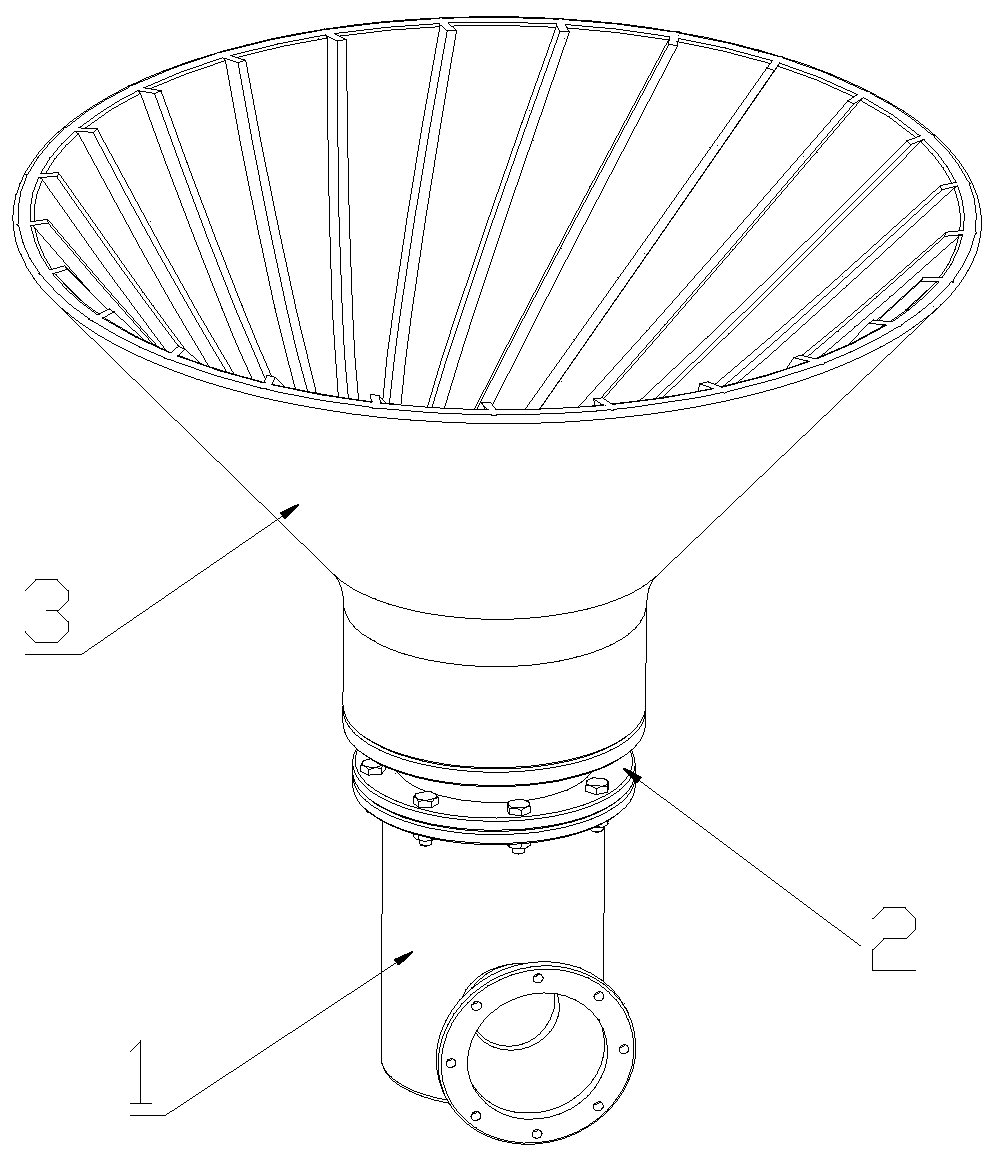

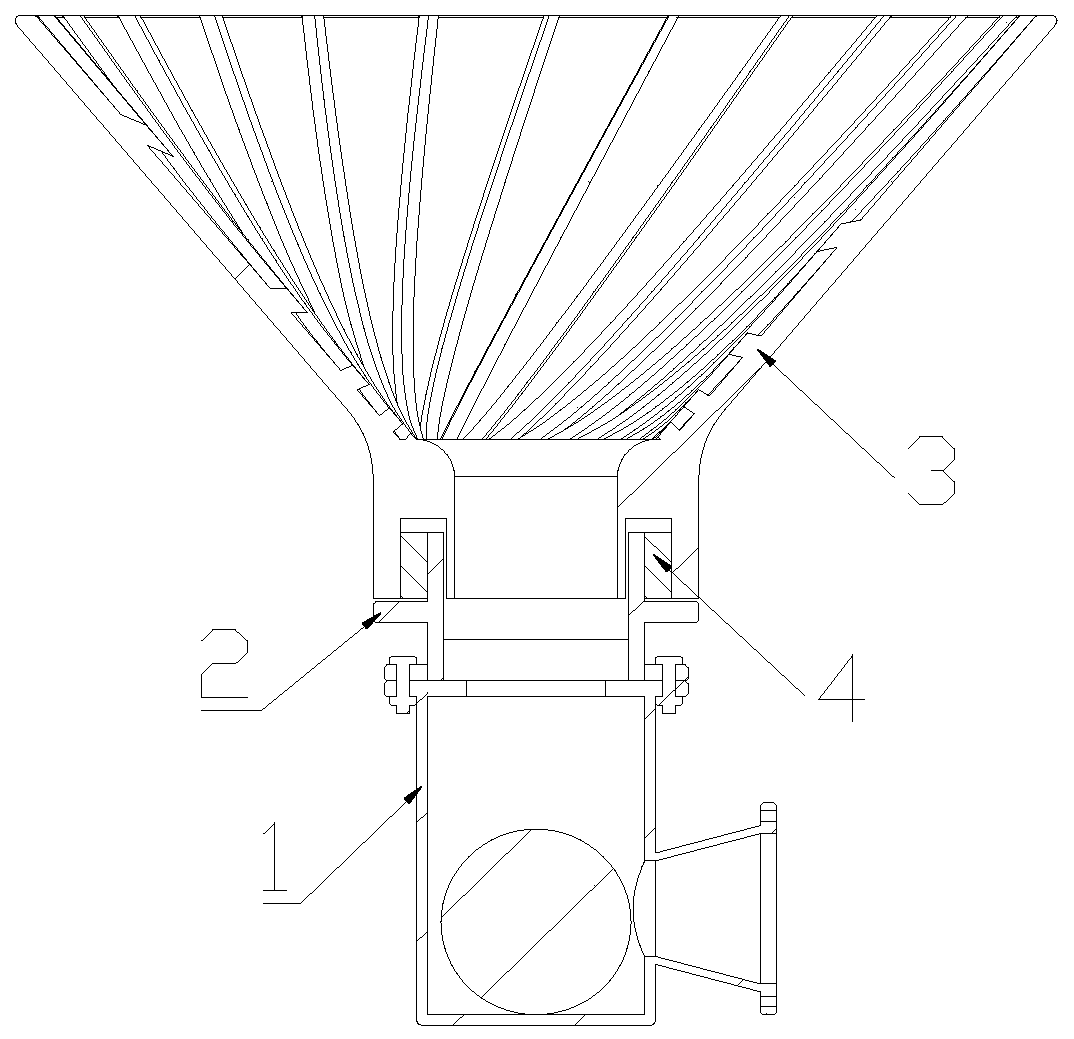

Vortex type floating ball check valve

InactiveCN110878854AAvoid gatheringImprove drainage efficiencyOperating means/releasing devices for valvesCheck valvesPartial gravityEngineering

The invention discloses a vortex type floating ball check valve. The check valve includes a check valve body, the check valve body is provided with a connecting member, the connecting member is rotationally connected with a rotating member, the rotating member includes a horn-shaped rotating body, and the inner wall of the horn-shaped rotating body is provided with blades distributed in an array.According to the check valve, rainwater falls into the horn-shaped rotating body and impacts the blades, at the time, part of gravity potential energy and kinetic energy of the rainwater is convertedinto kinetic energy of the rotating member, so that the rotating member rotates on the connecting member, and the rainwater rotates together with the rotating member; under the action of gravity, therainwater passes through the connecting member to flow out through the check valve body, in the flowing-out process, the rainwater obtains power potential energy in the rotating member, and the rainwater has the rotating speed to flow out, so that the drainage efficiency is improved, and accumulation of excessive rainwater is avoided; and when the precipitation amount is equivalent to the drainagetime, the diameter of a drainage pipe required by the vortex type floating ball check valve is small, and the drainage cost is reduced.

Owner:安庆泰悦机械科技有限公司

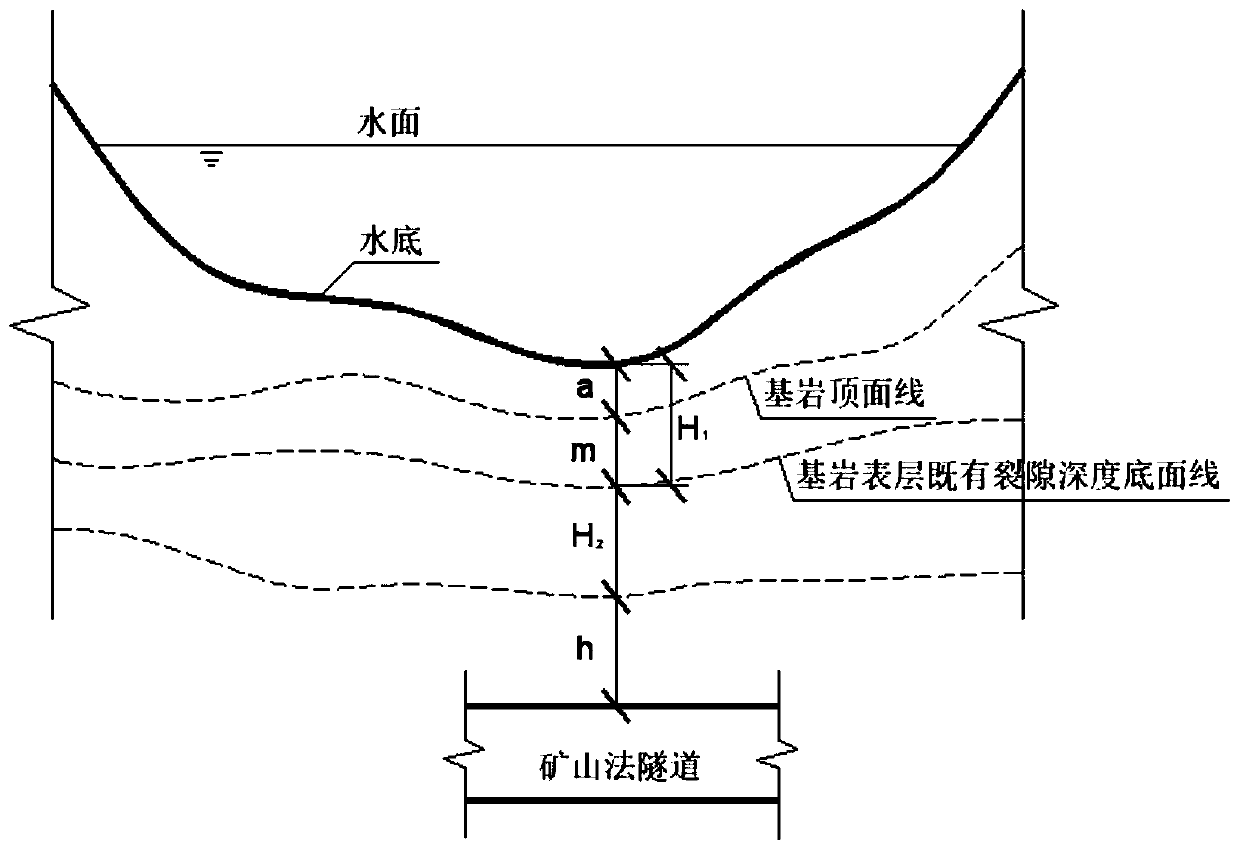

Underwater mining method tunnel reasonable burial depth calculation method

InactiveCN111441822AAvoid burying the shortcomings that are greatly affected by subjectivityAvoid the disadvantages that are greatly affected by subjectivityMining devicesData processing applicationsBedrockSoil science

The invention discloses an underwater mining method tunnel reasonable burial depth calculation method. The underwater mining method tunnel reasonable burial depth calculation method comprises the following steps of obtaining the thickness of a sludge layer or a soft soil layer and the existing crack depth of a bed rock surface layer through geological drilling exploration, and calculating the existing crack depth of a soft soil covering layer at the top of a tunnel structure and the existing crack depth of the bed rock surface; measuring the height of a water head and the maximum width of an arch waist of a tunnel, and calculating the thickness of a safety protection layer considering the water insulation and permeation effects of a rock stratum according to coefficients of the water insulation and permeation effects of the rock stratum, the firmness coefficient of the rock and the safety margin; according to the foundation coefficient and the minimum resistance line of a single most dangerous cartridge bag, calculating the length of a water guide crack of a surrounding rock loose circle due to drilling and blasting; and calculating the reasonable burial depth of the mining methodtunnel. On the premise of ensuring the safety of the covering layer at the top of the tunnel, each of water prevention and drainage is no longer one of main factors influencing the tunnel constructionprogress during mining tunnel construction, and the drainage cost during tunnel operation can be greatly reduced.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

A curtain grouting process suitable for water plugging in underground mining of water-rich mines

ActiveCN103967507BSafe and Efficient MiningReduce water gushingUnderground chambersTunnel liningKarstHigh pressure

Owner:SINOSTEEL MAANSHAN INST OF MINING RES CO LTD +1

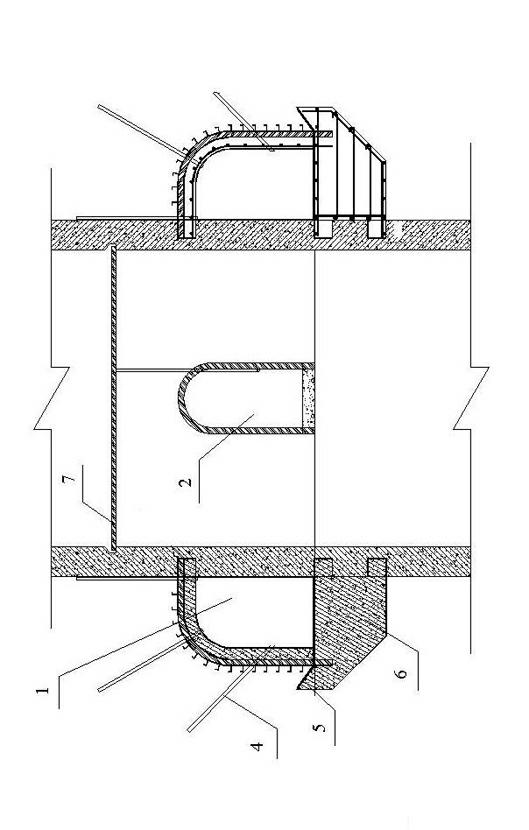

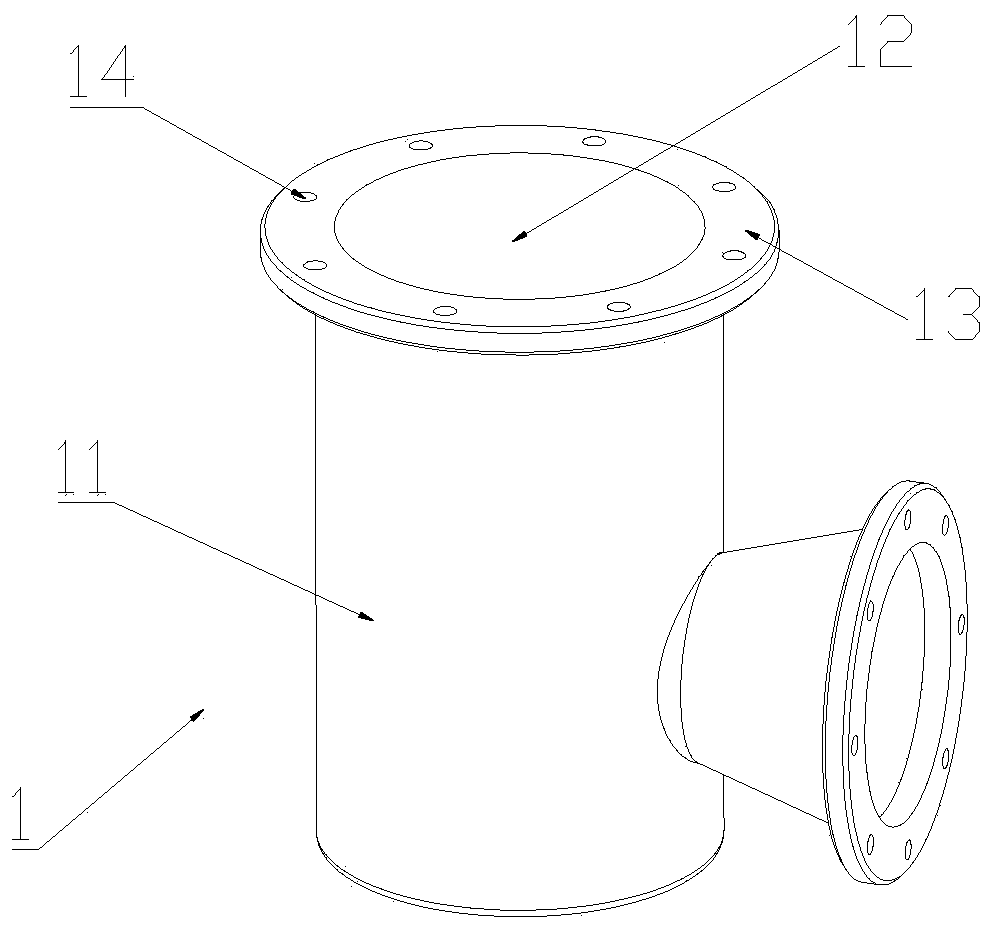

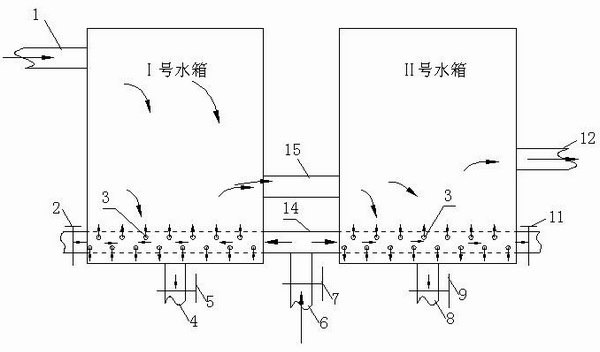

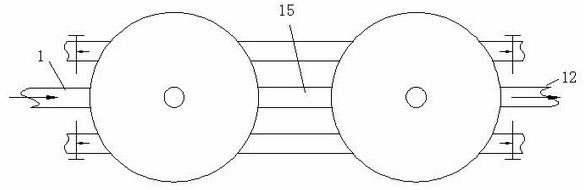

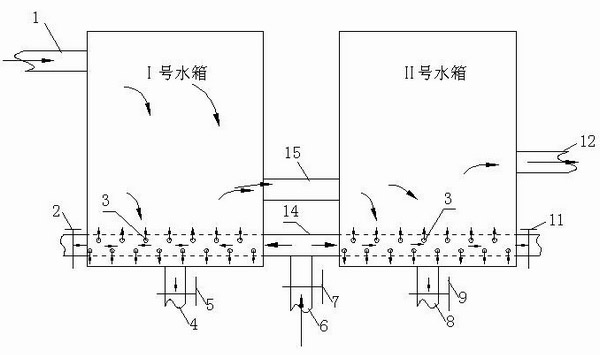

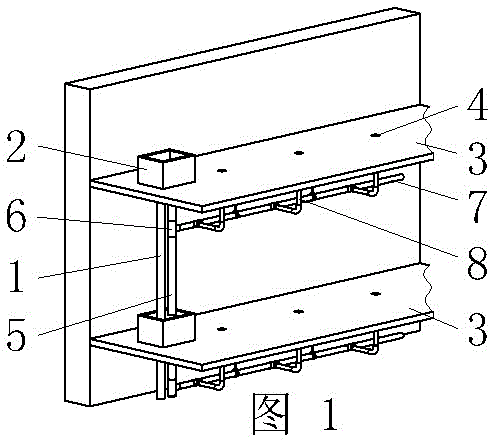

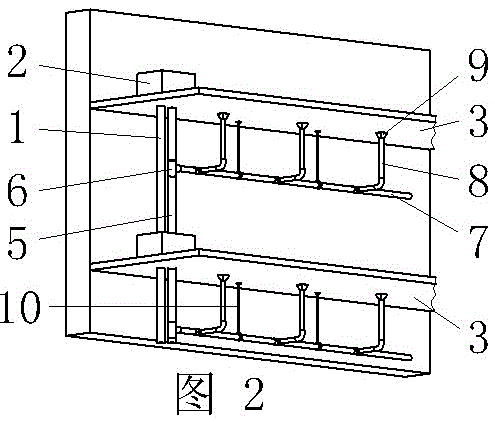

Split precipitation type hanging scaffold water tank for automatic pollution discharge of vertical shaft

The invention discloses a split precipitation type hanging scaffold water tank for automatic pollution discharge of a vertical shaft, consisting of an NO. I water tank and an NO. II water tank that are mutually communicated through communicating pipes, wherein the left wall of the NO. I water tank is provided with a water inlet pipe; the right wall of the NO. II water tank is provided with a water outlet pipe; a plurality of communicating pipes passing through the NO. I water tank and the NO. II water tank are arranged near the bottom of the NO. I water tank and the NO. II water tank; the communicating pipes are provided with through holes distributed all over the pipe bodies in the inner sections of the bodies of the NO. I water tank and the NO. II water tank; the communicating pipes areprovided with communicating pipe pollution discharge stop valves at the end extending out of the water tanks; the communicating pipe bodies are provided with high pressure air interface pipes; the lower part of the NO. I water tank is provided with an NO. I water tank pollution discharge pipe communicated with the NO. I water tank; the NO. I water tank pollution discharge pipe is provided with anNO. I water tank pollution discharge stop valve; the lower part of the NO. II water tank is provided with an NO. II water tank pollution discharge pipe communicated with the NO. II water tank; and the NO. II water tank pollution discharge pipe is provided with an NO. II water tank pollution discharge stop valve.

Owner:中煤邯郸第四十九矿山工程有限公司

Water and gas double-base driving discharge and mining system

InactiveCN106522888ASolve partial wearOvercome the difficulty of on-site installation and implementationFluid removalSuction forceEngineering

The invention discloses a water and gas double-base driving discharge and mining system. A first piston of a ground driving pump unit is connected with a hard water pipe to apply suction force or pressure to the hard water pipe. A second piston of the ground driving pump unit is connected with a capillary gas pipe which is connected with a gas pressure buffering tank. The upper side of a double-side piston power implementation unit communicates with the hard water pipe, and the lower side of the double-side piston power implementation unit communicates with the capillary gas pipe. An oil drawing and discharge and mining rod pump unit is in linkage with the double-side piston power implementation unit. When the ground driving pump unit is used for applying pressure to the hard water pipe, the double-side piston power implementation unit drives the oil drawing and discharge and mining rod pump unit to move downwards. When the ground driving pump unit is used for applying suction force to the hard water pipe, the gas pressure buffering tank is used for keeping relative constant pressure when the first piston moves upwards and a cylinder piston of the double-side piston power implementation unit is lifted upwards, so that the oil drawing and discharge and mining rod pump unit is driven to move upwards.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

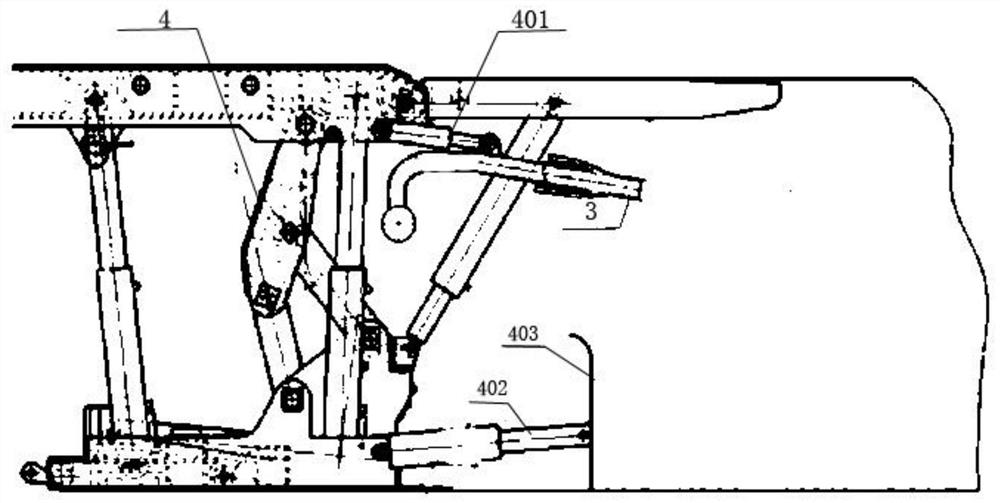

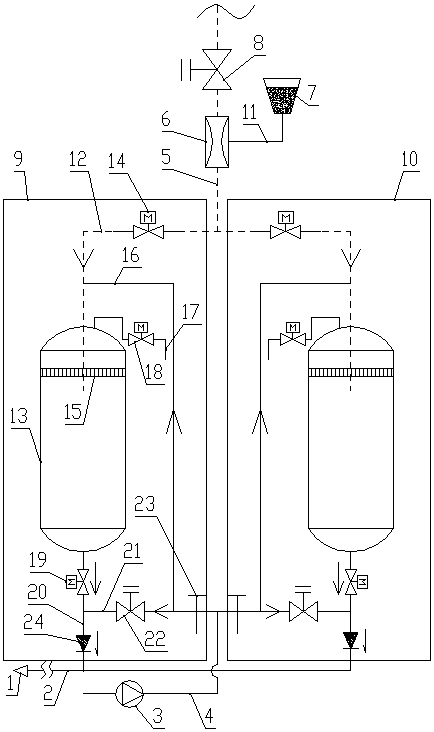

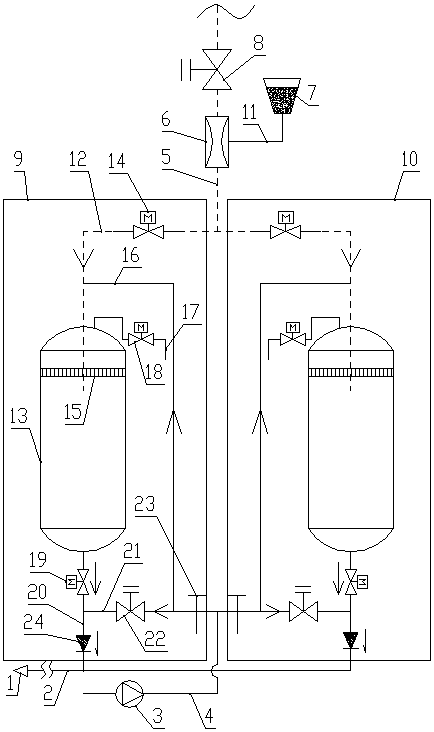

Grinding material continuous supply method

The invention discloses a grinding material continuous supply method. The grinding material continuous supply method comprises a single-tank operation mode and a double-tank continuous operation mode.One material feeding mechanism is applied in the single-tank mode, a material feeding tank is filled with grinding materials in a material supplement state, and then the mode is switched to a workingmode for water jet operation; a high-pressure water pump is stopped after the water jet operation is finished; in the double-tank operation mode, a first material feeding mechanism and a second material feeding mechanism operate alternately according to the working state, and one material feeding mechanism of which the working state is finished operates according to the material supplement state,and the material feeding mechanism waits for the next time to operate according to the working state after the material feeding tank is filled with the grinding materials and a pressure adjusting valve is closed; and the first material feeding mechanism and the second material feeding mechanism operate alternately according to the working state for ceaseless water jet operation. Operation is performed in the different modes according to the different conditions, and the flexibility and adaptability of a coal mine underground grinding material continuous supply system are improved. Through alternate operation of the different material feeding mechanisms, ceaseless supply of the grinding materials for the water jet operation can be achieved even though only one high-pressure water mechanism.

Owner:HENAN POLYTECHNIC UNIV

Coal mine underground abrasive continuous supply system

PendingCN108789173AImprove adaptabilityWater jet workcontinuousAbrasive feedersOperation modeHigh pressure water

The invention discloses a coal mine underground abrasive continuous supply system. The coal mine underground abrasive continuous supply system adopts the flow direction of fluid as a downstream direction, and comprises a first feeding mechanism, a second feeding mechanism, a jet flow adding mechanism for adding abrasives to the first feeding mechanism and the second feeding mechanism, a high-pressure water mechanism for supplying high-pressure water to the first feeding mechanism and the second feeding mechanism and a water spray mechanism for spraying the high-pressure water for water jet operation, wherein the first feeding mechanism and the second feeding mechanism are arranged in parallel. The water spray mechanism is connected with the first feeding mechanism and the second feeding mechanism. The first feeding mechanism and the second feeding mechanism are both feeding mechanisms. The coal mine underground abrasive continuous supply system provides a basis for a plurality of operation modes, greatly enhances the adaptability of the coal mine underground abrasive continuous supply system, enables continuous operation, and avoids the defects of water transportation.

Owner:HENAN POLYTECHNIC UNIV

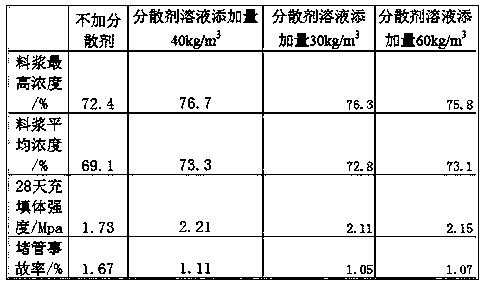

Method for improving flowability of milltailings and application of method

The invention discloses a method for improving flowability of milltailings and application of the method. The method comprises the following steps: (1) preparing a 0.1% sodium carboxy methyl cellulosesolution in mass fraction; and (2) putting the 0.1% sodium carboxy methyl cellulose solution into a sand cabin, and sufficiently mixing with a sand liquid, wherein the addition amount of the sodium carboxy methyl cellulose solution is 30-60kg / m<3>. The method has the beneficial effects that due to mixing of the 0.1% sodium carboxy methyl cellulose solution with the sand liquid, the flowability ofmaterial slurry is improved, then the concentration of the material slurry is increased, the water drainage expense is reduced, the filling strength is improved, and the method has great significances for both the company and social and economic benefits.

Owner:TONGLING NON FERROUS METAL GROUP CORP

Drainage method and device for floor water during construction of super high-rise buildings

ActiveCN103882918BConducive to civilized constructionReduce drainage costsDomestic plumbingFloor slabWater leak

The invention discloses a method and a device for draining water accumulated on a floor during construction of a super high-rise building. The method is to build a pool at the mouth of the construction water supply pipe on each floor, and a drainage riser leading to the pool on the lower floor is provided at the bottom of the pool, and the water leaked from the water supply pipe is discharged layer by layer to the bottom drainage through the drainage riser. A set of floor drains are arranged at intervals on the edge of each floor slab. The floor drains are connected to the horizontal drainage pipes under the floor slabs, and the horizontal drainage pipes are connected to the vertical drainage pipes. The accumulated water or rainwater during the construction process is drained layer by layer to the bottom floor through the floor drains. gutter. The main function of the invention is to timely and orderly discharge the accumulated water generated on the floors during super high-rise building construction or the accumulated water generated by rainfall from the construction site. It is no longer necessary to use artificial drainage to dump the accumulated water to the outside of the floor directly by using a bucket truck. It will not affect the construction workers below, passing pedestrians and vehicles. Conducive to the civilized construction on site. Can reduce drainage costs.

Owner:CCFED THE FIRST CONSTR & ENG

A high water rate fast-setting filling material and its preparation method and use method

The invention discloses a high-moisture-ratio quick-setting filling material which is prepared from the following raw materials in parts by weight: master batch including 90-94 parts of aluminate cement and 6-10 parts of an additive, and auxiliary materials including 65-85 parts of modified gypsum, 15-35 parts of quick lime and 2-4 parts of a coagulation accelerator. The filling material is high in water-solid ratio, good in hydrophilicity, short in gel time, quick in early strength enhancement, slow in later strength enhancement, good in flowability and pumpability, nontoxic and harmless, and can meet the requirements of mine filling.

Owner:河北充填采矿技术有限公司

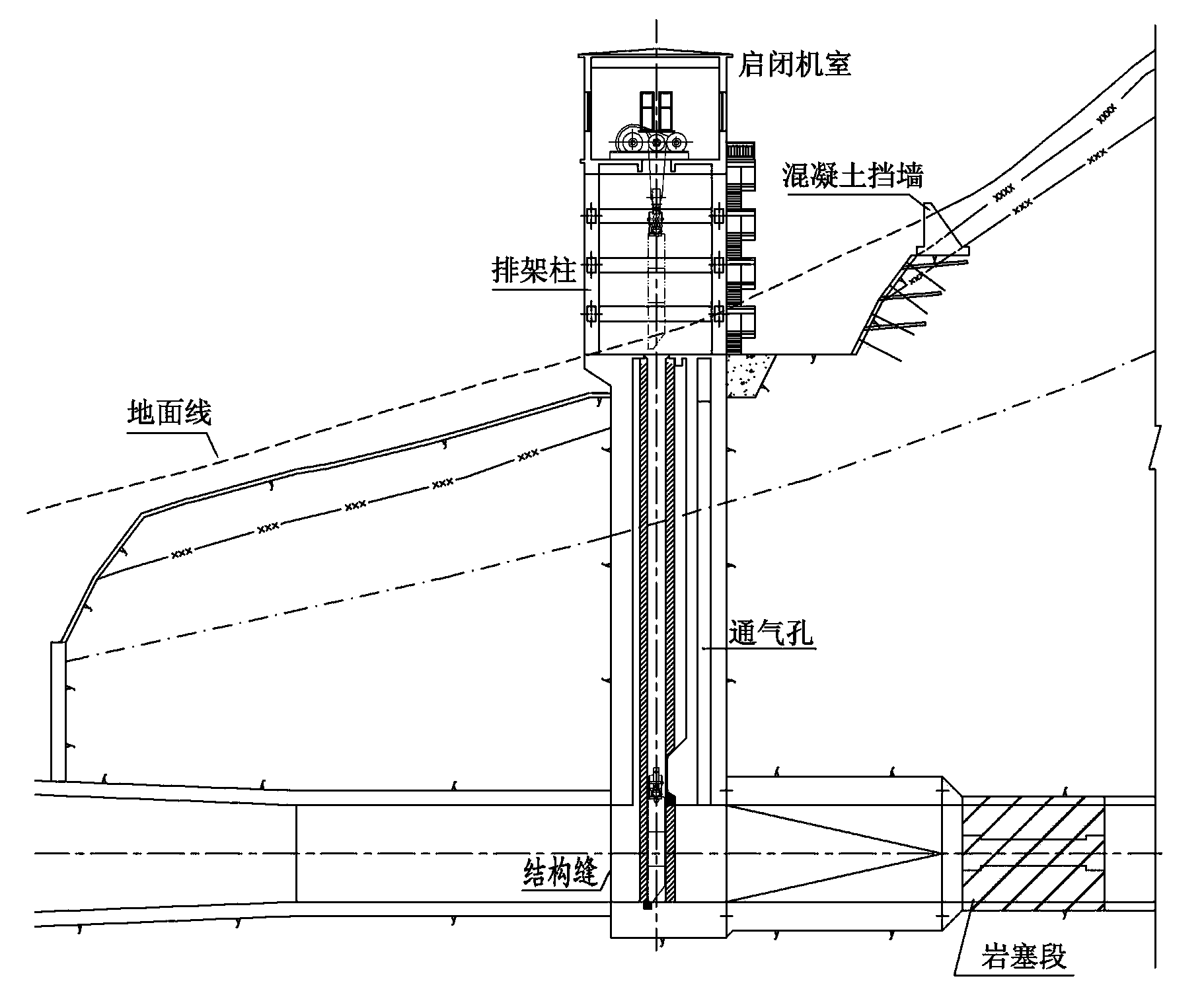

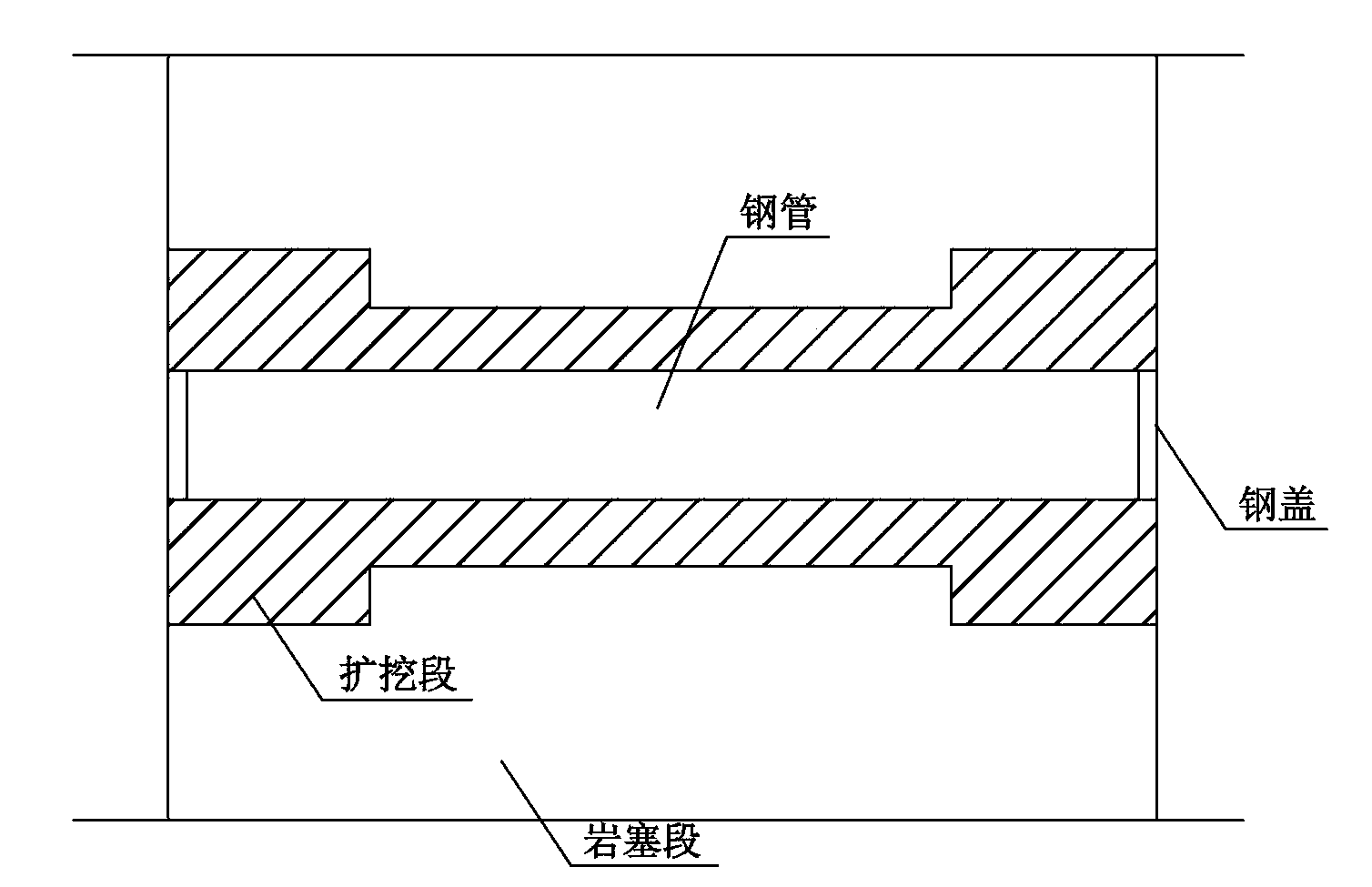

Construction technology for reserving novel rock plug

InactiveCN104234018AEasy constructionSimple and fast constructionWater-power plantsHydro energy generationUnderground cavernHydro power

The invention discloses a construction technology for reserving a novel rock plug and relates to the technical field of hydraulic and hydro-power engineering, in particular to the construction technology for entrance / exit engineering of an underground cavern with the higher flood prevention requirement. According to the construction technology disclosed by the invention, the rock plug is reserved between an entrance / exit and the underground cavern; the reserved rock plug is arranged in a tunnel which is 10-15m apart from a structural joint between structural concrete of the entrance / exit and lining concrete of the tunnel; a steel pipe channel is formed in the reserved rock plug; the tip of the steel pipe channel is provided with a steel valve; after construction on the concrete of the entrance / exit and a gate is switched out, the reserved rock plug is removed by explosion. The construction technology disclosed by the invention is simple in pattern, safe and reliable to run and convenient in construction, and has very good application prospect and promotion value on the entrance / exit engineering construction of the underground cavern with the higher flood prevention requirement.

Owner:STATE GRID CORP OF CHINA +3

Combined drainage and seepage system suitable for weak seepage soil layer slope drainage

PendingCN114575358ASolve drainage problemsAuto excludeSewerage structuresClimate change adaptationVacuum pumpingEnvironmental engineering

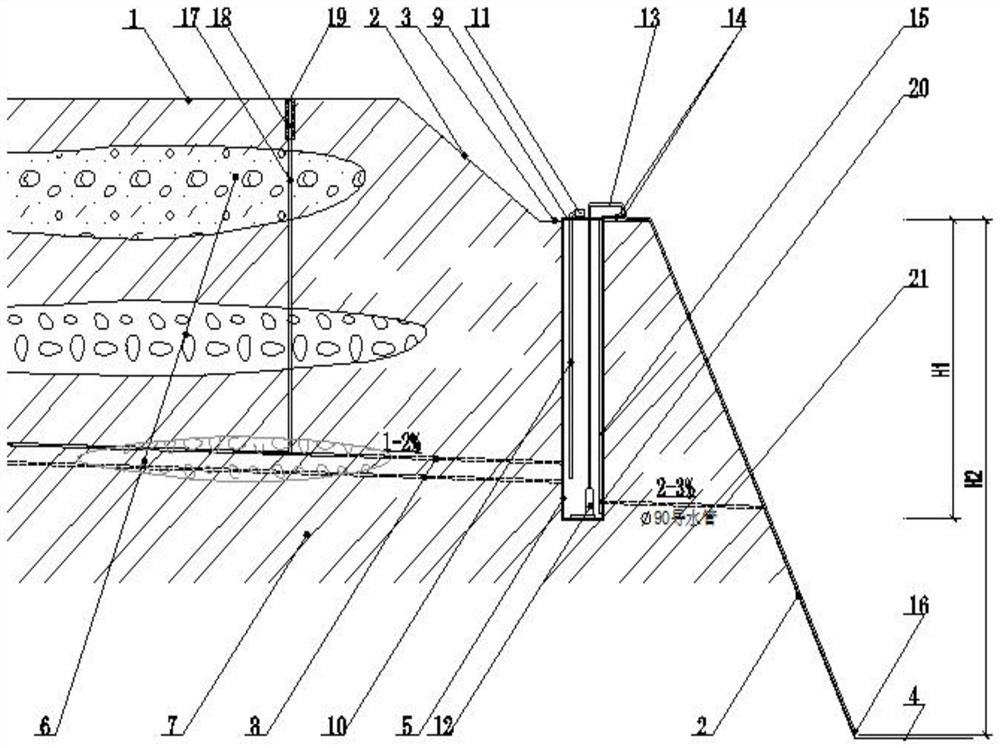

The invention discloses a combined drainage system suitable for drainage of a weakly permeable soil layer slope, which is formed by combining a three-dimensional drainage system, a vacuum drainage assisting system and a siphon / direct drainage system, the three-dimensional drainage system comprises a horizontal drainage floral tube (8), a vertical drainage floral tube (17) and a water collecting well (5), and the vacuum drainage assisting system comprises a vacuum pump (11) and a vacuum exhaust tube (10). The siphon / direct drainage system comprises a self-flow direct drainage mode and a siphon drainage mode, the direct drainage system comprises a water guide hole and a direct drainage pipe (21), the siphon drainage system comprises a deep-well pump (12), a siphon (15) and a siphon water supplementing pipe (13), the deep-well pump (12) is installed at the bottom of the water collecting well (5), and the water inlet end of the siphon (15) extends into the lower portion of the water collecting well (5) along the inner wall of the water collecting well (5). The method can effectively realize smooth and concentrated drainage of weak-permeability soil layer slope underground water, prevents slope surface soil layer saturation and erosion damage, and improves the lasting stability of the slope.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

Open channel section construction system and method adopting layer-by-layer drainage method

PendingCN114233384AImprove the construction environmentControl moisture contentDrainageArchitectural engineeringWater flow

The invention discloses an open channel section construction system and method adopting a layer-by-layer drainage method, and the system comprises construction platforms which are sequentially arranged in the excavation direction, the construction platforms are each of a trapezoidal structure with the wide top and the narrow bottom in the horizontal radial direction, and the arrangement heights of the construction platforms are gradually reduced to form a stepped hierarchical platform structure; a multi-pipe self-priming pump drainage system for drainage of the open channel section is arranged on each construction platform, an inclined face structure is formed from the excavation inlet to the target depth, the open channel section is formed, and the open channel section comprises a plurality of construction layers which are the same as the hierarchical platform structures in number and sequentially constructed in the vertical direction. According to the core thought of the degradation drainage construction system and method for open channel section construction, peripheral water flow of open channel excavation is blocked through special construction measures in the excavation process, and the construction measures comprise step-by-step drainage and step-by-step excavation till the designed excavation size is finally achieved; and finally, the water content of the sand layer in the open channel opening range is effectively controlled.

Owner:CHINA COAL NO 3 CONSTR GRP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com