Waterproofing and drainage system for tunnel-type anchorage of suspension bridge, and construction method

A construction method and technology for tunnel anchors, which are used in drainage, bridge construction, bridges, etc., can solve the problems of large concrete volume of tunnel anchor anchor plugs, high pumping and drainage costs, and weak layered interfaces, and improve physical and mechanical properties. , low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

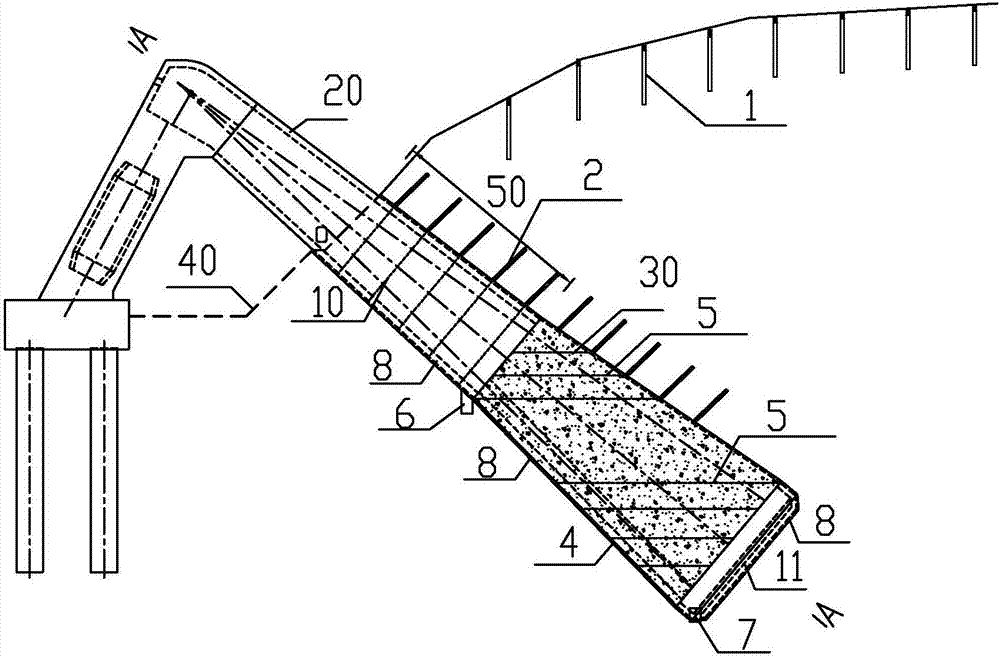

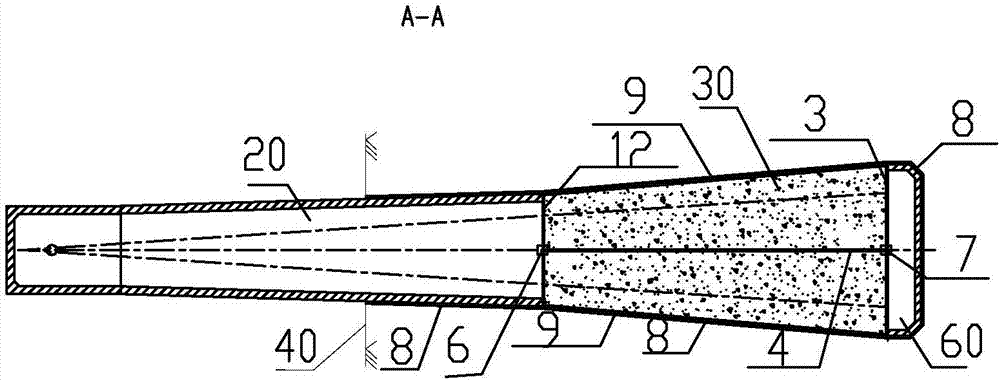

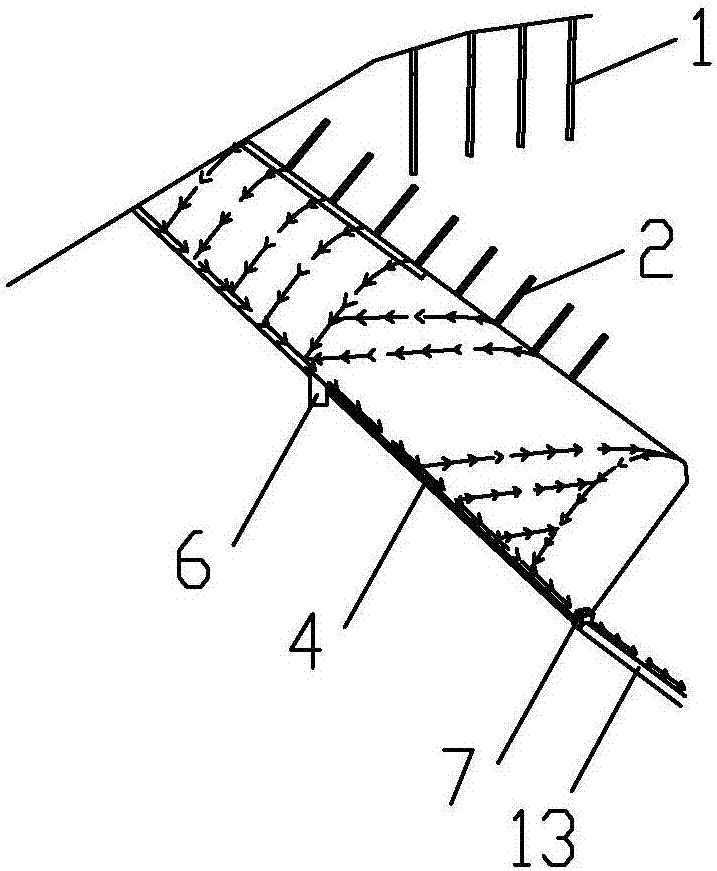

[0042] A set of suspension bridge tunnel anchor waterproof and drainage system, its structure is as follows Figure 1 to Figure 6 shown. Firstly, the top grouting 1 outside the tunnel anchor hole is carried out, and the surrounding rock grouting 2 inside the tunnel anchor hole is carried out immediately after the initial support. The waterproof and drainage system in the tunnel anchor hole is constructed. In the water collection well 6, the water bodies in the rear anchor chamber and the lower anchor plug body are collected in the lower water collection well 7, and the upper water collection well 6 and the lower water collection well 7 are connected by an inclined drainage pipe 4, and the accumulated water in the lower water collection well 7 is connected Into the tunnel anchor lateral drainage channel 13 and out of the tunnel anchor.

[0043] Grouting 1 on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com