Outfit for detecting plugging and choking of sewage pipelines and inspection wells by full air bag method

A technology for inspection wells and plugging devices, which is applied in the direction of liquid tightness measurement using liquid/vacuum degree, etc., can solve the problems of high mechanical cost, long cycle, large water consumption, etc., and achieve good sealing performance of equipment and fast test speed , the effect of short test period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

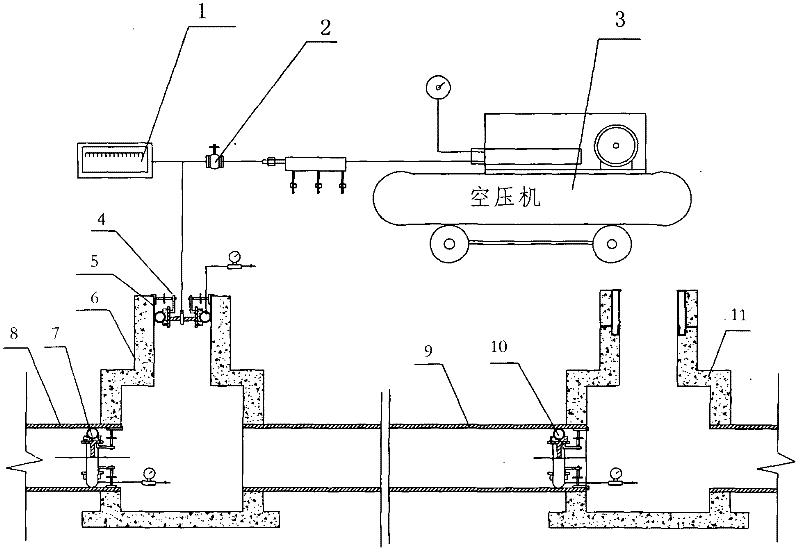

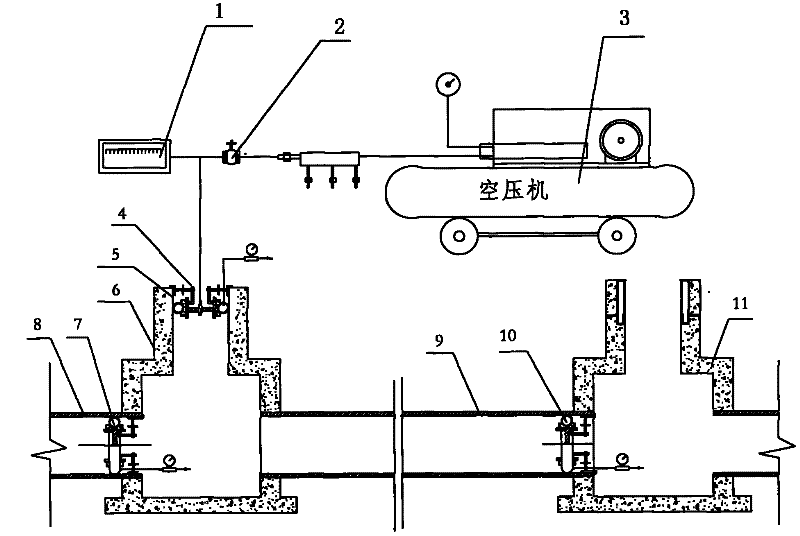

[0025] Apply sealing medium to the inspection well → install air-tight equipment → add high-pressure air to conduct air-tight test → deflate and remove the equipment for air-tight main equipment and preparations:

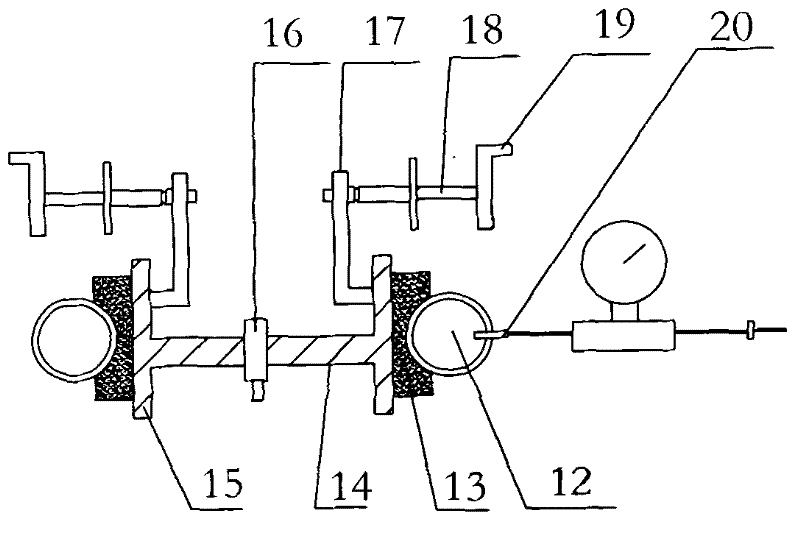

[0026] 1. The sealing air bag adopts the annular air bag, and the inflatable valve core and pressure gauge are installed on the middle plate of the air bag at the shaft.

[0027] 2. Inflatable and air pressure control equipment is mainly an air compressor.

[0028] The specific construction steps are as follows:

[0029] 1. After the installation of one section (or multiple sections) of the sewage pipeline is completed and the masonry of the inspection well is completed, the airtightness test shall be carried out according to the quality inspection requirements. First check the places where air leakage is likely to occur, such as the connection between the inspection well and the pipeline, and the installation of the cover plate, and there is no suspicious point of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com