Patents

Literature

106results about How to "Solve partial wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

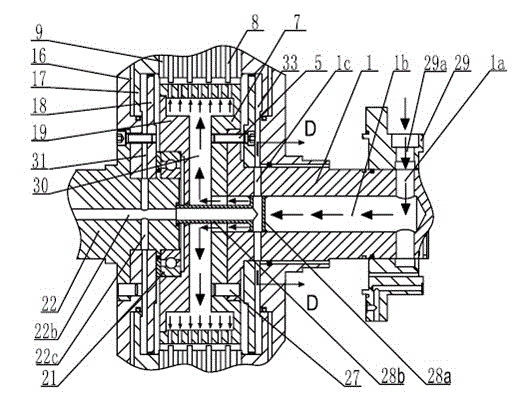

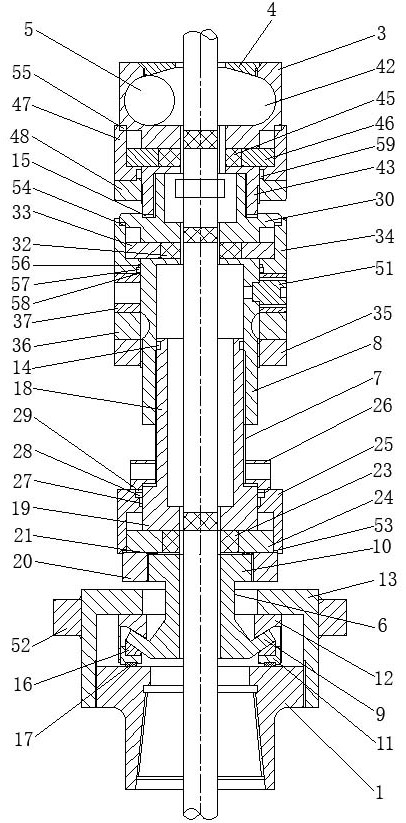

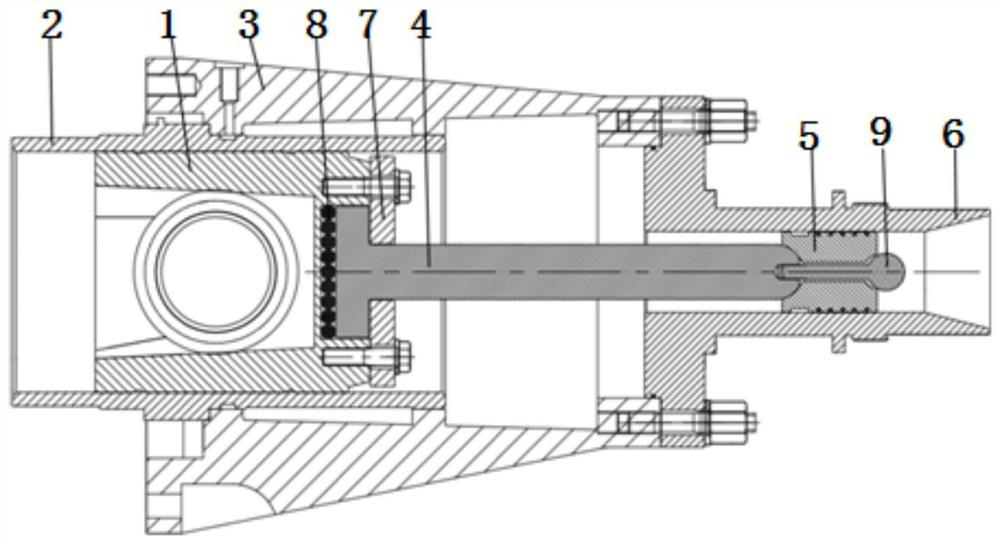

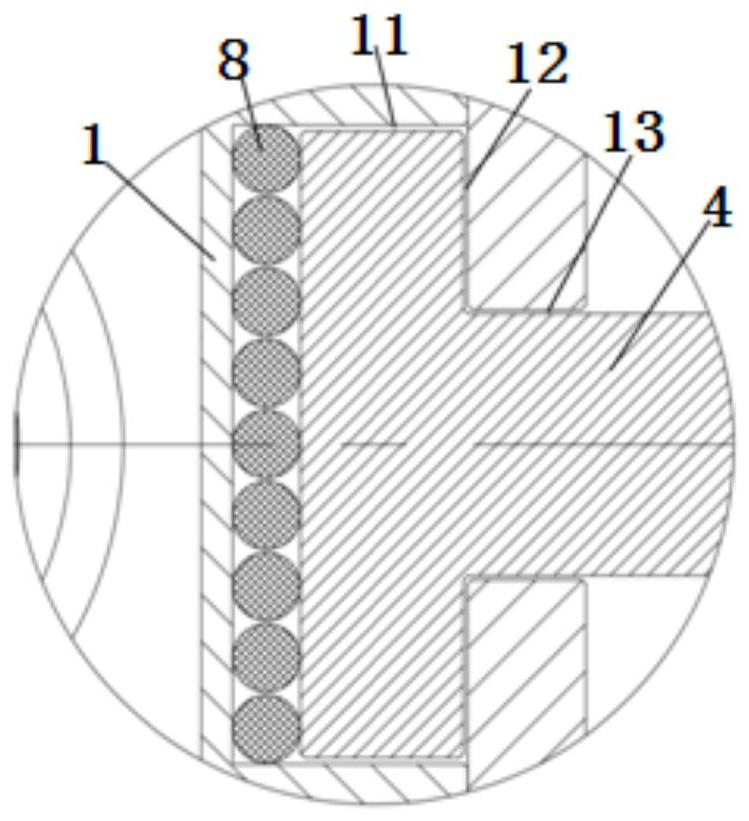

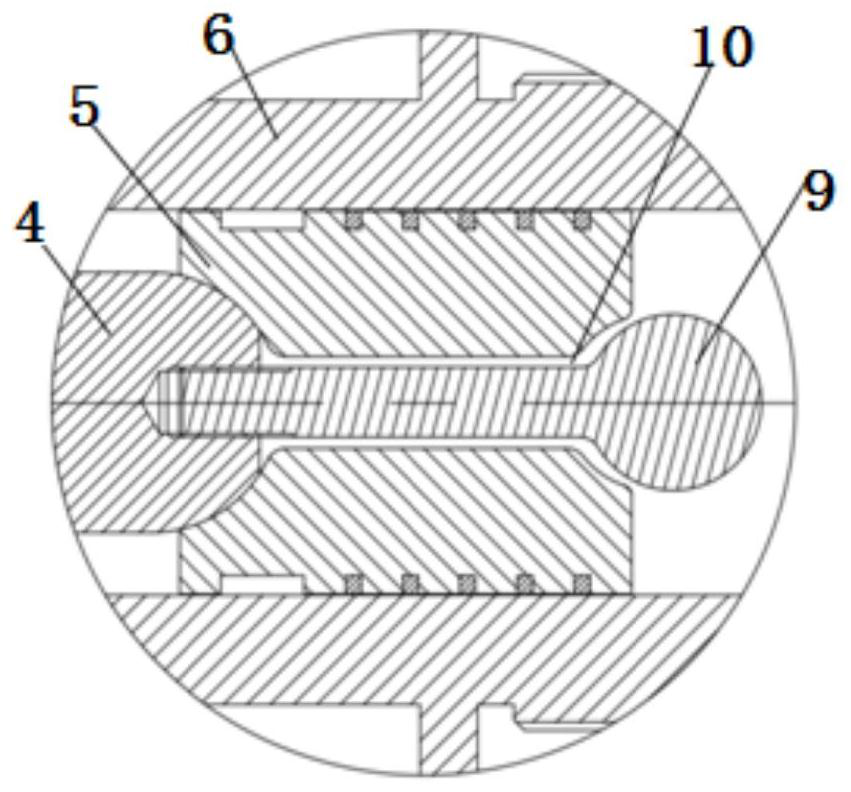

Hydro-viscous speed regulation device

The invention discloses a hydro-viscous speed regulation device which comprises a transmission mechanism, a control mechanism, a drive shaft transparent cover and a driven shaft transparent cover, and the hydro-viscous speed regulation device further comprises a gear sleeve and a support base, wherein the gear sleeve is fixedly connected with a drive shaft and is located at the end part of a power output end of the drive shaft, and an initiative friction plate is arranged on the gear sleeve; the support base is connected with a driven shaft and can rotate opposite to the driven shaft; the support base is located at the end part of a power input end of the driven shaft, the support base is connected with the gear sleeve, the support base and the gear sleeve enclose to form a lubricating oil cavity together, an axial oil duct of the drive shaft is communicated with the lubricating oil cavity, an axial oil duct of the driven shaft is not communicated with the lubricating oil cavity, and the lubricating oil can go between the initiative friction plate and a passive friction plate; and a working oil cavity of a piston cylinder is communicated with a second radial oil duct. According to the invention, the drive shaft is changed into a split type from an integral type to further improve a lubricating oil duct, so that the problem of eccentric wear of friction plates in the prior art is solved fundamentally.

Owner:ZHEJIANG UNIV

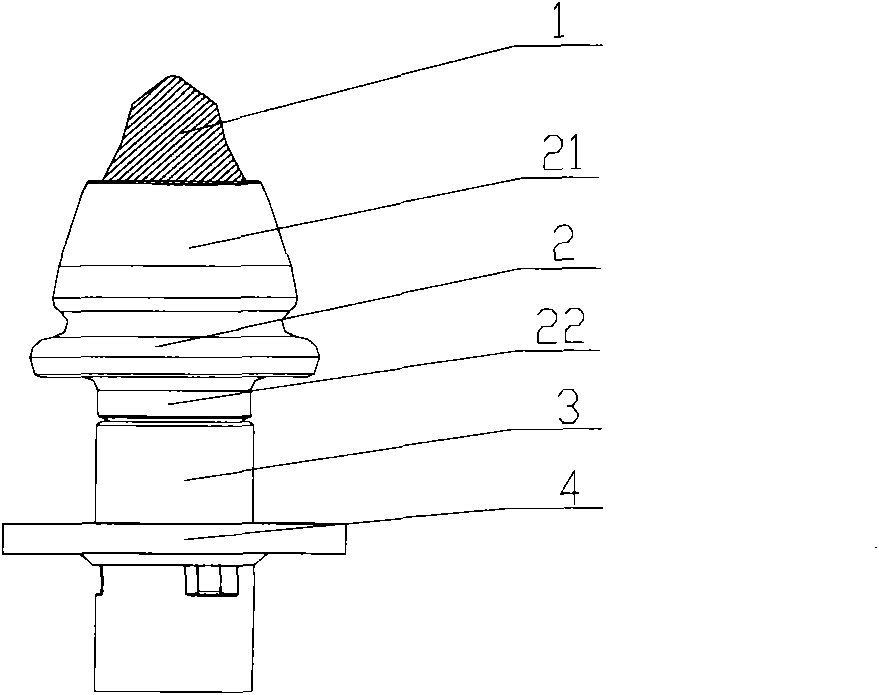

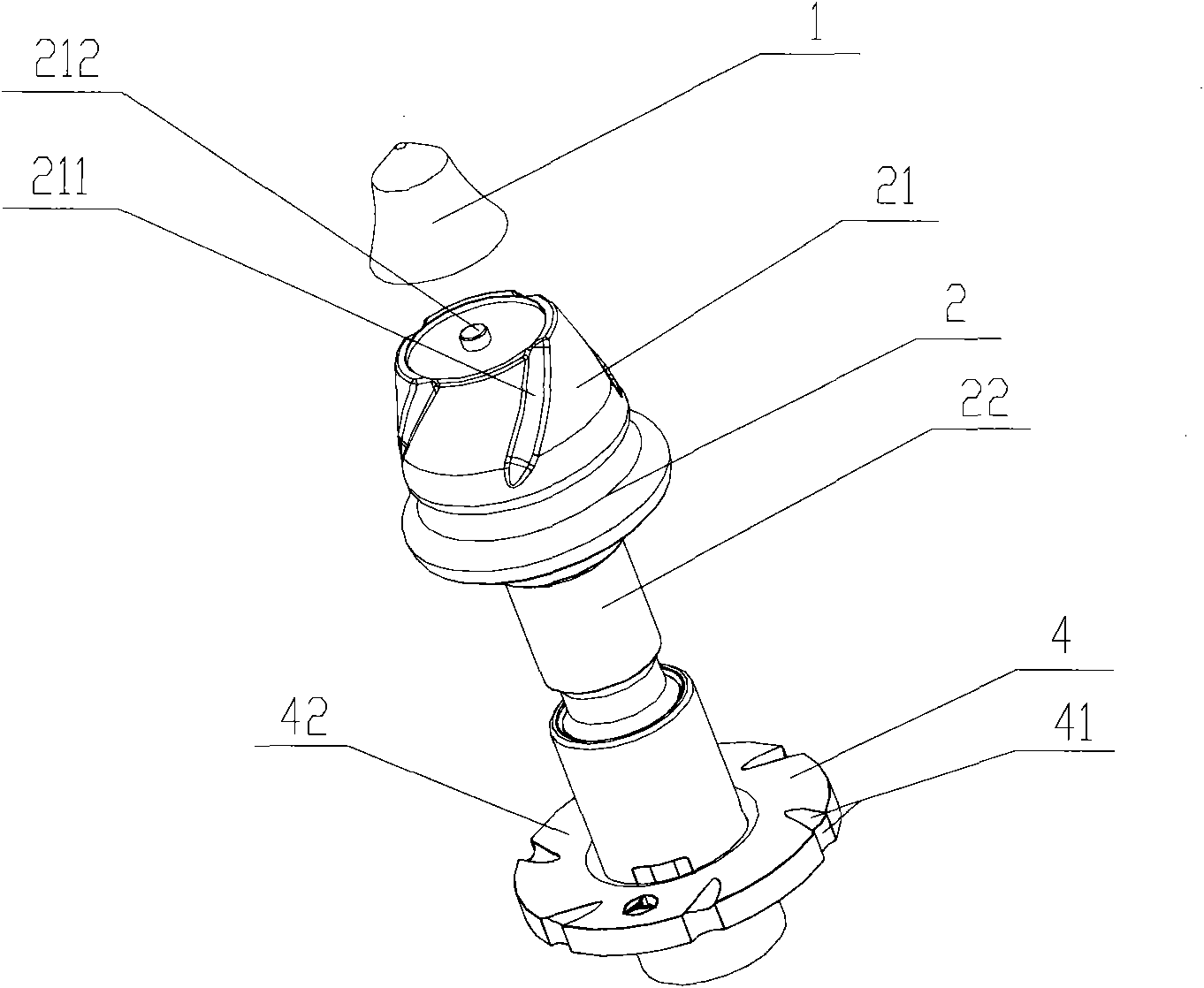

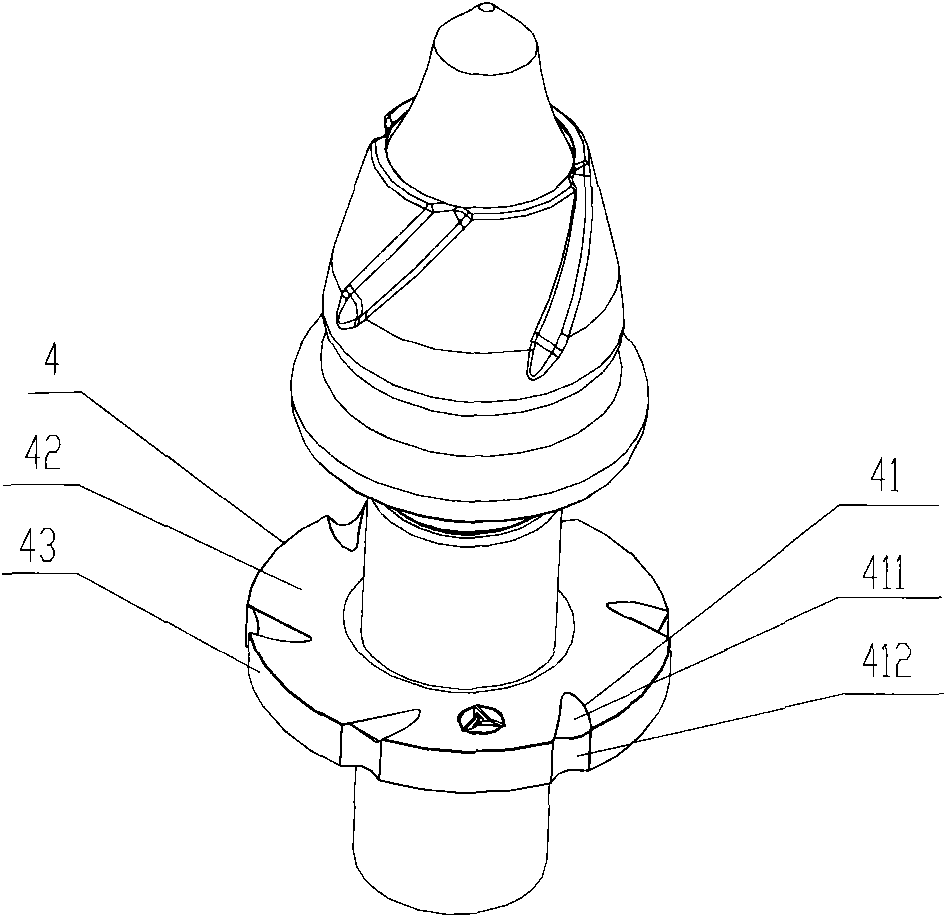

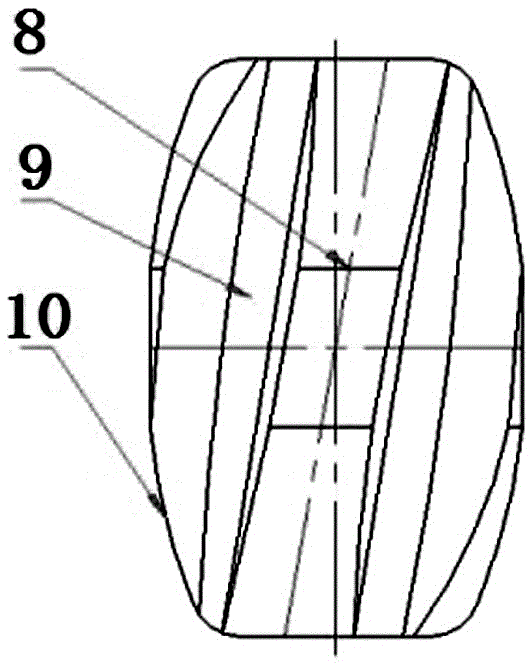

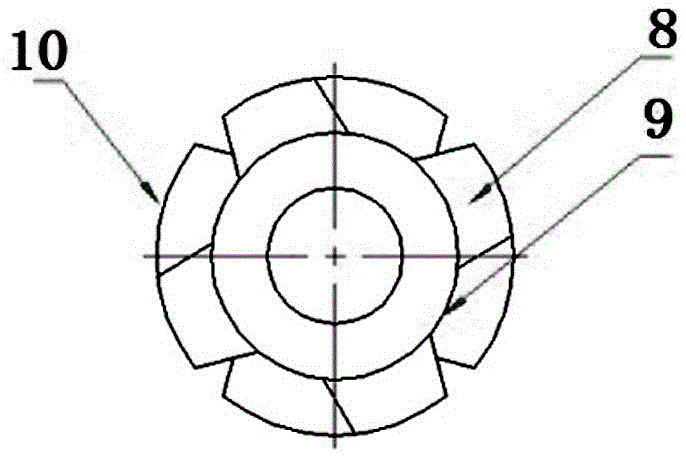

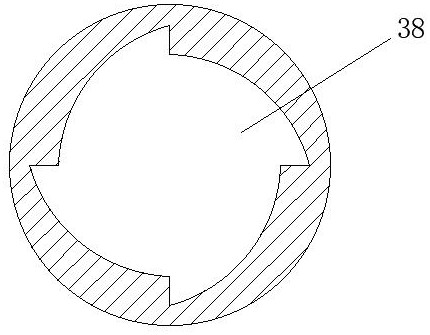

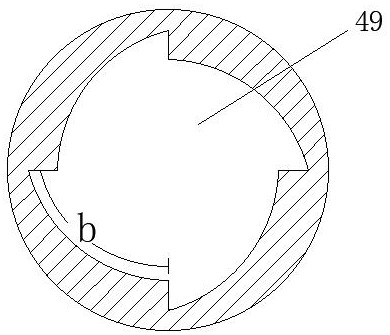

Milling mechanism and cutter thereof

InactiveCN101597883ASmooth rotationFacilitate the rotational forceRoads maintainenceEngineeringGasket

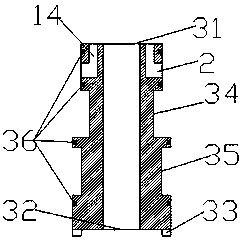

The invention discloses a cutter of a milling mechanism, which comprises a cutter head, a cutter body and an annular gasket, wherein the cutter body comprises a round platform shaped head and a cylindrical body, the cutter head is connected with the round platform shaped head, and the annular gasket is sleeved on the cylindrical body; and the lateral wall of the round platform shaped head is provided with a first groove which intersects with the generating line of a rotating surface and forms proper included angle, the annular gasket is provided with a channel generally extending along the circumferential direction, and the channel is communicated with the upper surface and the lower surface of the annular gasket. By adopting the cutter of the milling mechanism, the problem of eccentric wear of the cutter is effectively solved so that the service life of the cutter is prolonged.

Owner:SANY HEAVY IND CO LTD (CN)

Shaft-end deslagging spiral conveyer

The invention discloses a shaft-end deslagging spiral conveyer. The shaft-end deslagging spiral conveyer comprises conveying drums, a conveying threaded rod arranged in the conveying drums, and a driving mechanism for driving the conveying threaded rod. The shaft-end deslagging spiral conveyer is characterized in that the conveying drums at least include the first-section conveying drum and the second-section conveying drum, and the driving mechanism is arranged between the first-section conveying drum and the second-section conveying drum; the driving mechanism comprises an annular shell which is connected between the first-section conveying drum and the second-section conveying drum, and a driven ring is arranged and positioned in the annular shell through a bearing encircling the conveying threaded rod; the driven ring encircles the conveying threaded rod and is fixedly connected with the conveying threaded rod and is driven by a power unit. Through the shaft-end deslagging spiral conveyer, the deslagging function can be achieved without changing the flow direction of slag, intermediate driving is achieved, and the problem of eccentric wear of the threaded rod and the drums is effectively solved; a slag buffering and deslagging region is arranged, so blowout risks are effectively reduced, the tunnel construction progress and the safety performance are greatly improved, and the shaft-end deslagging spiral conveyer can be widely applied to the tunnel engineering construction machinery industry.

Owner:辽宁三三工业有限公司

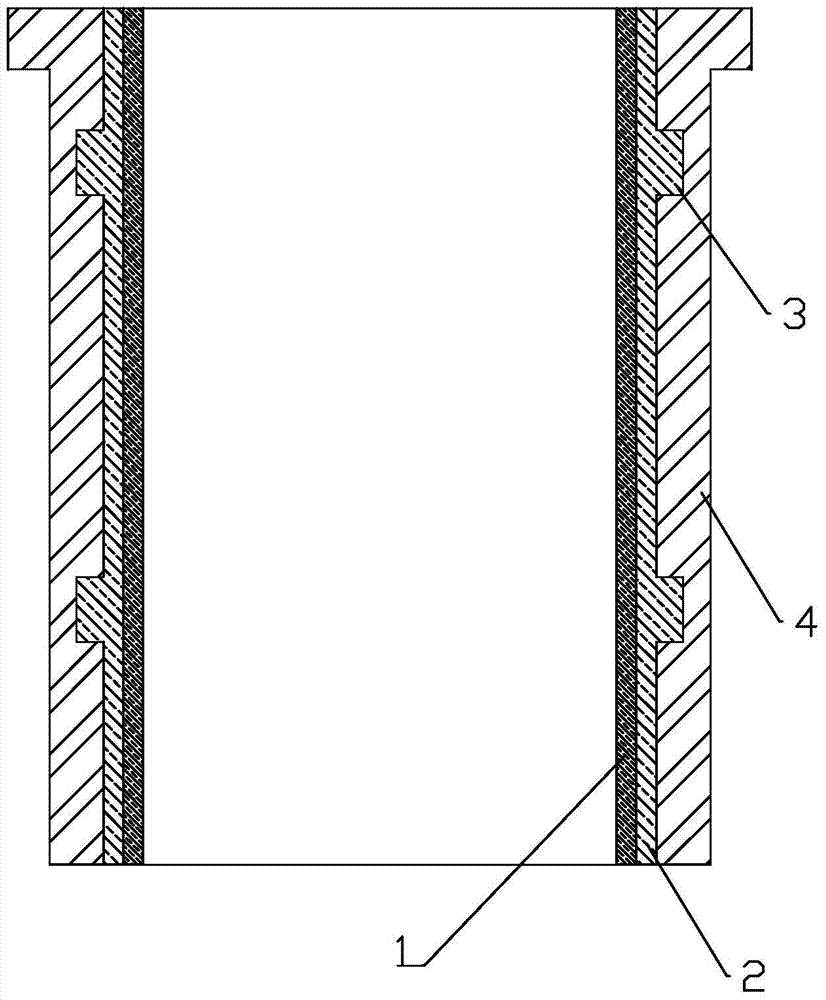

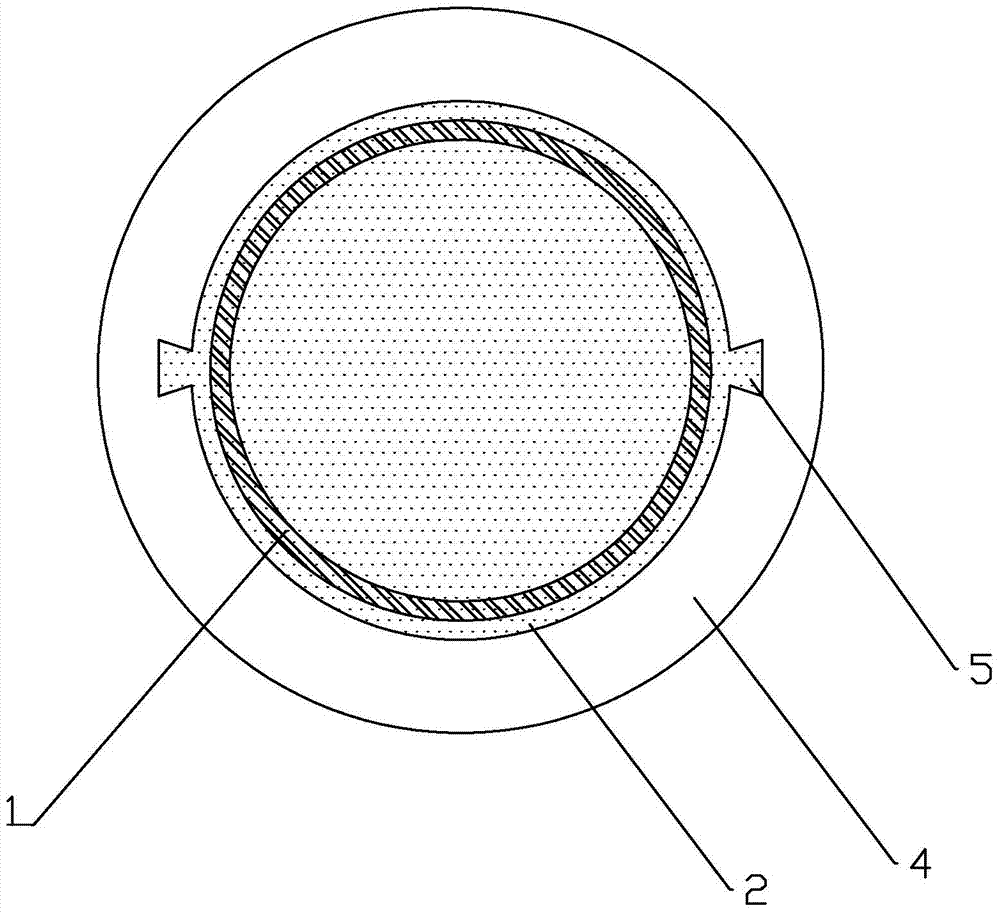

Multi-layer laminated elastic-plastic alloy automatic fluid lubricating bearing and manufacturing method thereof

ActiveCN104728260AExcellent dynamic performanceIncrease dynamicsLamination ancillary operationsLaminationAdhesiveManufacturing engineering

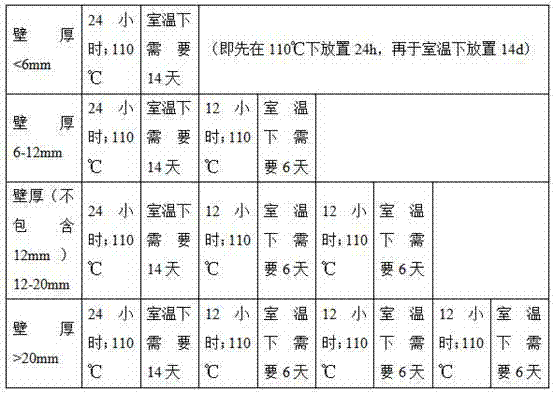

The invention discloses a multi-layer laminated elastic-plastic alloy automatic fluid lubricating bearing and a manufacturing method thereof. The bearing comprises a bearing body, an elastic damping layer and a bearing bush layer, wherein the elastic damping layer and the bearing bush layer are sequentially arranged on the inner surface of the bearing body. The manufacturing method of the bearing comprises the following steps: (1) processing an axial limiting ring groove and a radial limiting dovetail groove in the inner surface of the bearing body; (2) sanding the inner surface of the bearing block and removing greasy dirt; (3) coating the inner surface of the bearing body with a prime coat adhesive, drying, and coating a topcoat adhesive, drying at a room temperature, and rebaking to form an adhesive layer; (4) coating the adhesive layer with the elastic damping layer, when the adhesive is nearly completely solidified, i.e., the damping layer is in a wire-drawing state, coating the bearing bush layer, and solidifying; and (5) annealing. A German NDI engineering elastomer material is introduced between a bearing bush and the bearing body as the elastic damping layer, so that the fluid lubricating bearing has damping cushioning property and axis adaptability; and the problems of dry start-up and eccentric abrasion of upper and middle guide bearings of a water pump are effectively solved.

Owner:广东研理复合材料科技股份有限公司

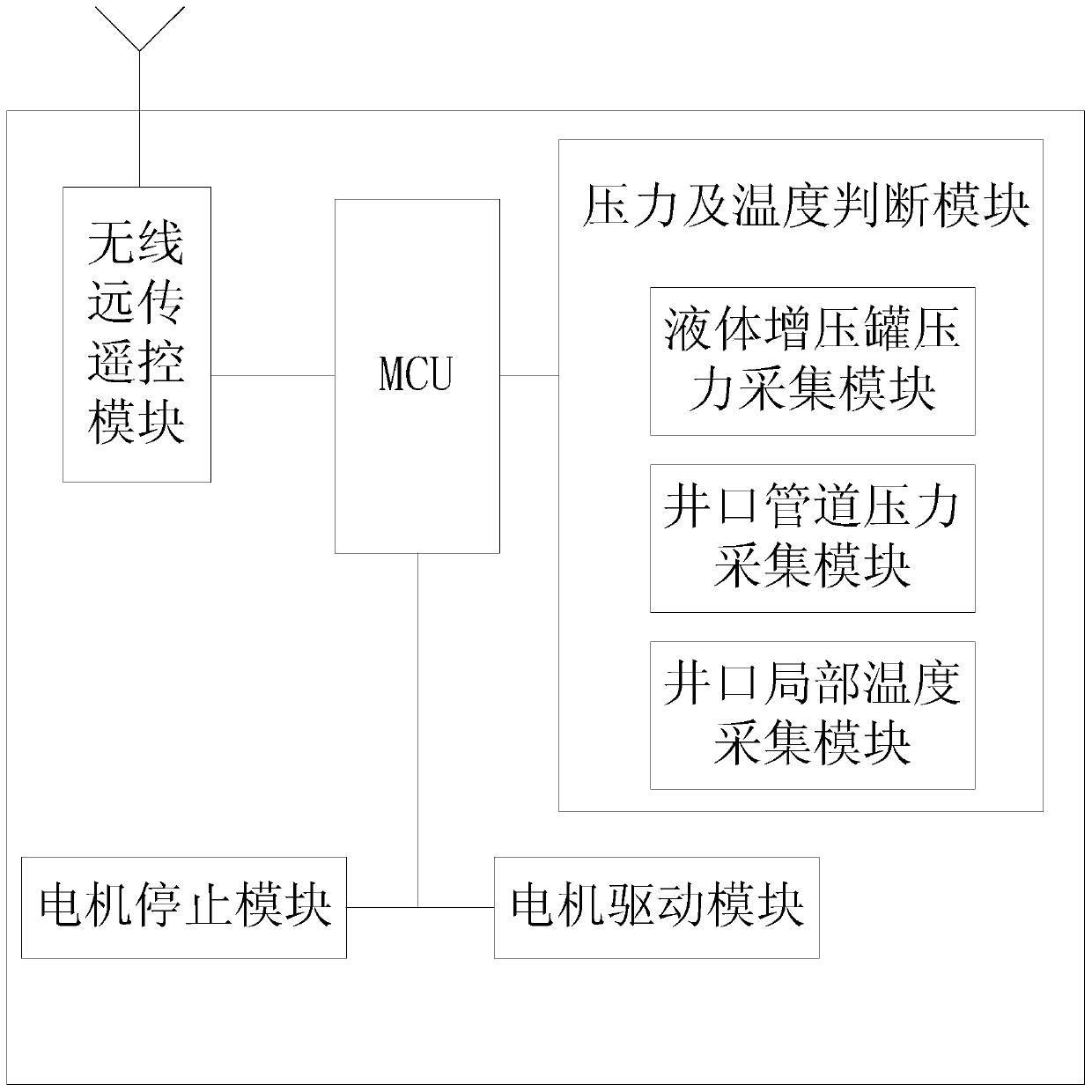

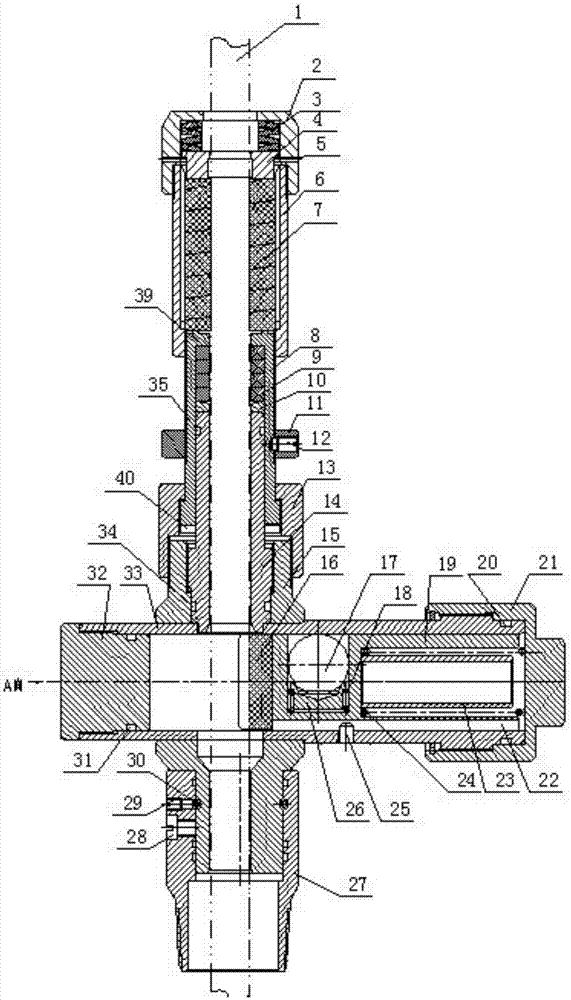

Intelligent wellhead sealing device

PendingCN109736739ASolve the sealing problemEnsure safe productionSurveyConstructionsEngineeringHigh pressure

The invention discloses an intelligent wellhead sealing device. The device comprises a floating double-sealing device and a set of hydraulic energy storage and reinforcement system capable of compensating pressure; the floating double-sealing device comprises a shell and an annular sealing sleeve; a 360-degree sliding groove is formed in the top end of the shell; an annular sealing sleeve is fixedly installed in an inner cavity of the shell through a first supporting ring and a second supporting ring; the annular sealing sleeve is composed of a straight cylinder connecting sleeve and at leastone annular high-pressure sealing cavity; a floating packing box capable of horizontally floating in a sliding groove in the top end of the shell is installed at the upper end of the straight cylinderconnecting sleeve on the upper portion of the annular sealing sleeve; packing is installed in the floating packing box; an elastic pressing plate and a packing locking cap are installed on the packing; a polished rod of an oil pumping unit is installed in the annular sealing sleeve; the upper end of the polished rod of the oil pumping unit sequentially penetrates through the floating packing box,the packing, the elastic pressing plate and the packing locking cap; and the lower portion of the shell is connected with the hydraulic energy storage reinforcement system communicating with the high-pressure sealing cavity. An eccentric wear problem generated in 90% or more of oil wells is solved, and the service life of the oil pumping unit is prolonged.

Owner:刘胜益

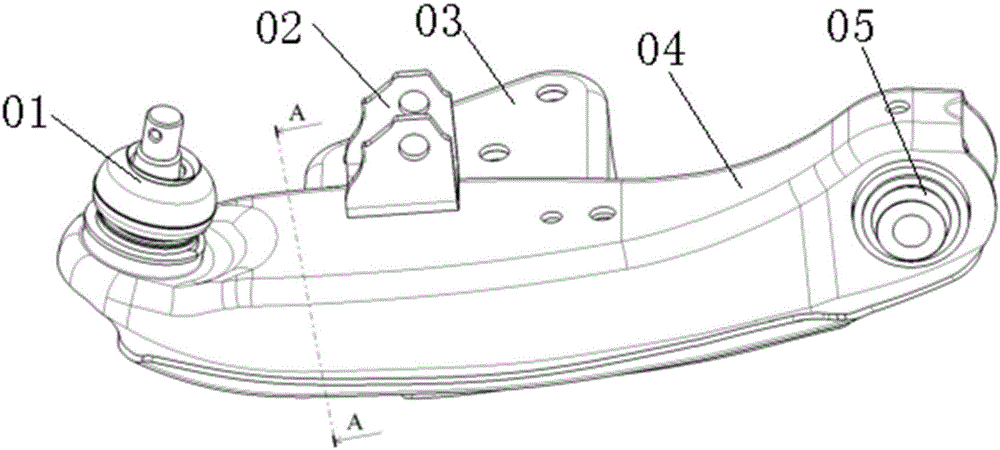

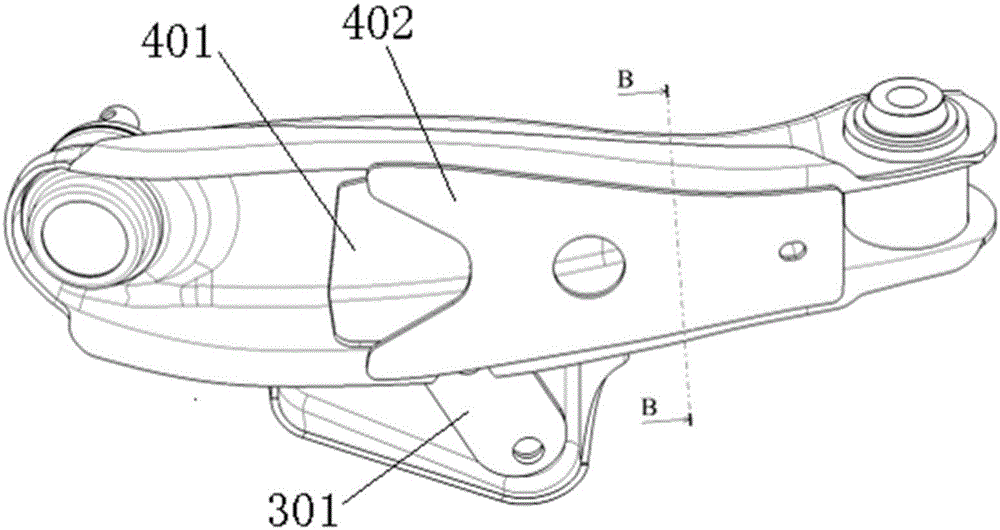

Lower swinging arm

The invention relates to a lower swinging arm. The lower swinging arm comprises a fork-arm lower swinging arm body, a ball pin is arranged on one side of the lower swinging arm body, a damper installing base is arranged on the lower swinging arm body, a first lining is arranged at the front end of the other side of the lower swinging arm body, and a second lining is arranged at the back end of the other side of the lower swinging arm body; the installing direction of the first lining and the installing direction of the second lining are different on the lower swinging arm body. According to the lower swinging arm, the installing position of the first lining and the installing position of the second lining on the lower swinging arm body are set; in other words, the positions of first discharging grooves in the first lining are same as the positions of second limiting blocks of the second lining, and the positions of first limiting blocks of the first lining are same as the positions of second discharging grooves of the second lining; according to the structure, the rigidity of the first lining is large in the left and right direction of a vehicle, and is small in the forward and backward direction and the torsion direction of the vehicle, and stable steering and comfortable driving can be achieved accordingly.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

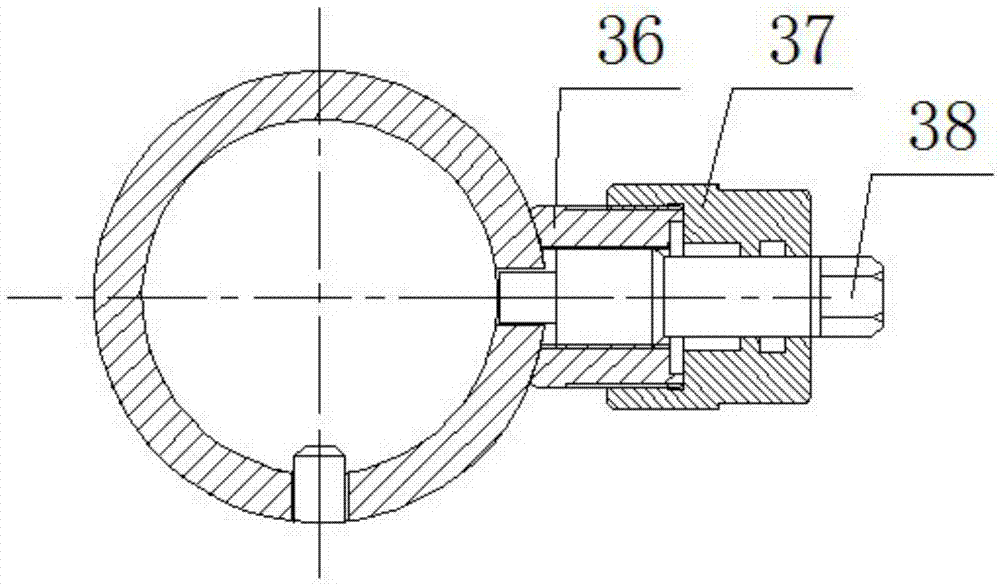

Multifunctional well mouth sealing blowout-prevention box

InactiveCN105443069ARealize blowout preventionAvoid misalignment of the ball seat bodySealing/packingEngineeringOil well

The invention relates to a multifunctional well mouth sealing blowout-prevention box. The multifunctional well mouth sealing blowout-prevention box comprises an upper stuffing box, a lower stuffing box, a body tube column and a lower connecting body which are sequentially connected from top to bottom and can be used for the polish rod of an oil pumping unit to be inserted, wherein upper packing is arranged in the upper stuffing box and the upper stuffing box is provided with a packing gland, lower packing is arranged in the lower stuffing box, a valve ball seat body is coaxially and fixedly installed in the body tube column, and a valve ball mechanism is arranged at the middle of the body tube column under the valve ball seat body in a criss-cross mode and comprises a shaft barrel, a sliding plunger piston, a polish rod seat and a shaft barrel end cover. The sliding plunger piston is installed in the shaft barrel, a horizontal plunger piston spring is arranged at one end of the sliding plunger piston and the shaft barrel, a valve ball is arranged in the valve ball seat at the end of the sliding plunger piston, a longitudinal valve ball spring is arranged between the bottom of the valve ball and the valve ball seat, and the polish rod seat is fixedly arranged at the outer end of the sliding plunger piston. The problems of polish rod breakage and fall, eccentric abrasion of an oil well, horse head and well mouth misalignment, short service life of the corresponding polish rod and the like are effectively solved.

Owner:TIANJIN LONGXIN PETROLEUM MACHINERY MFG CO LTD

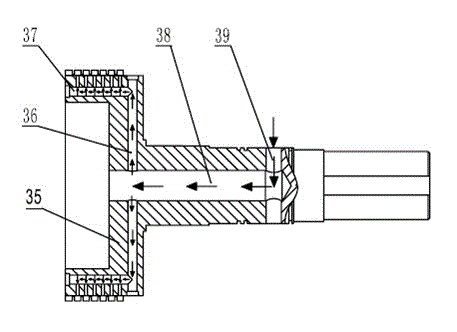

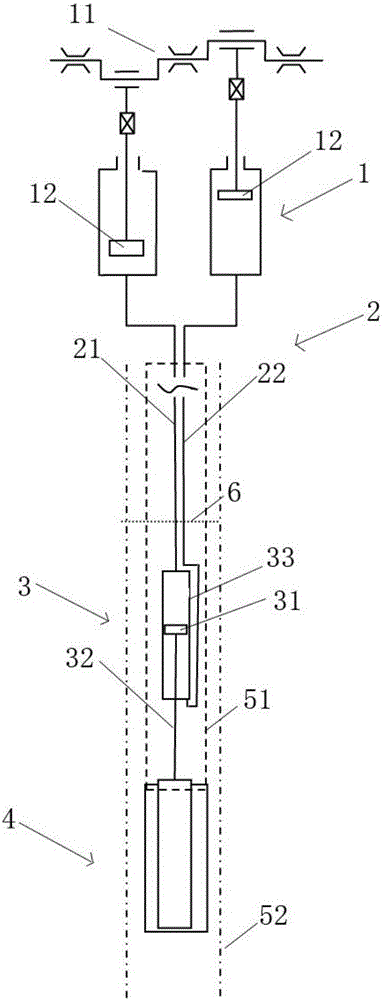

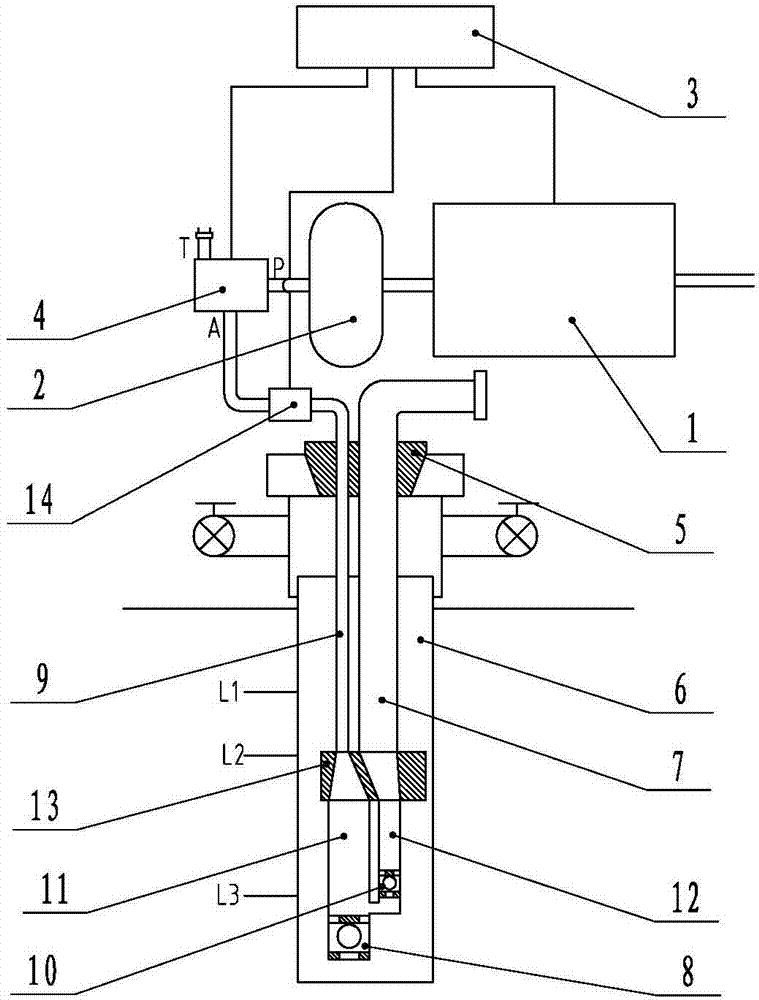

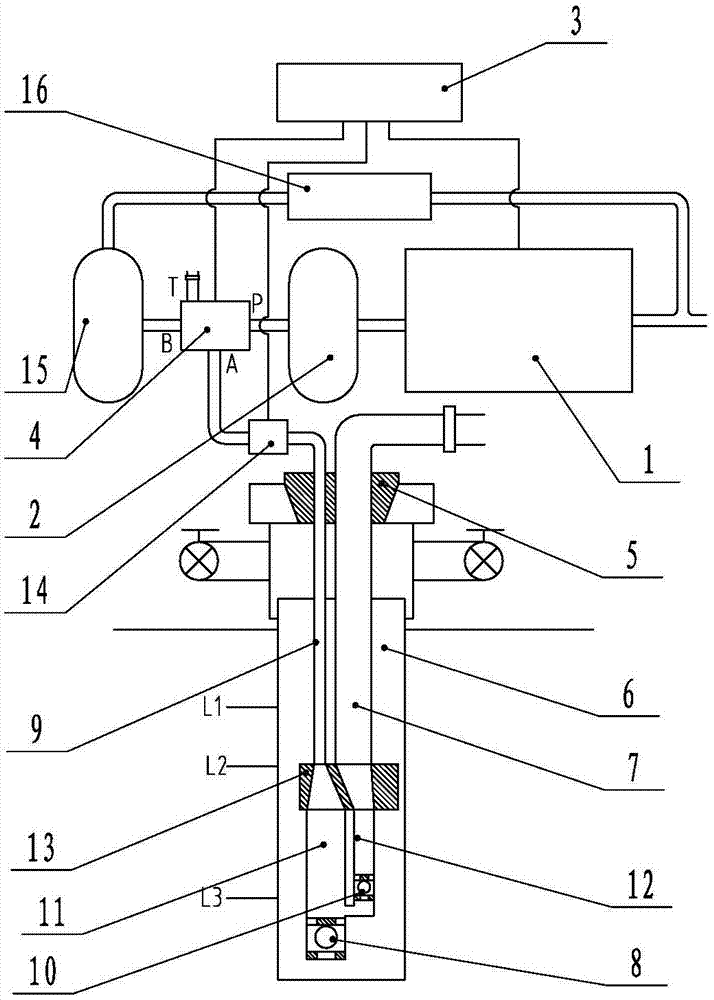

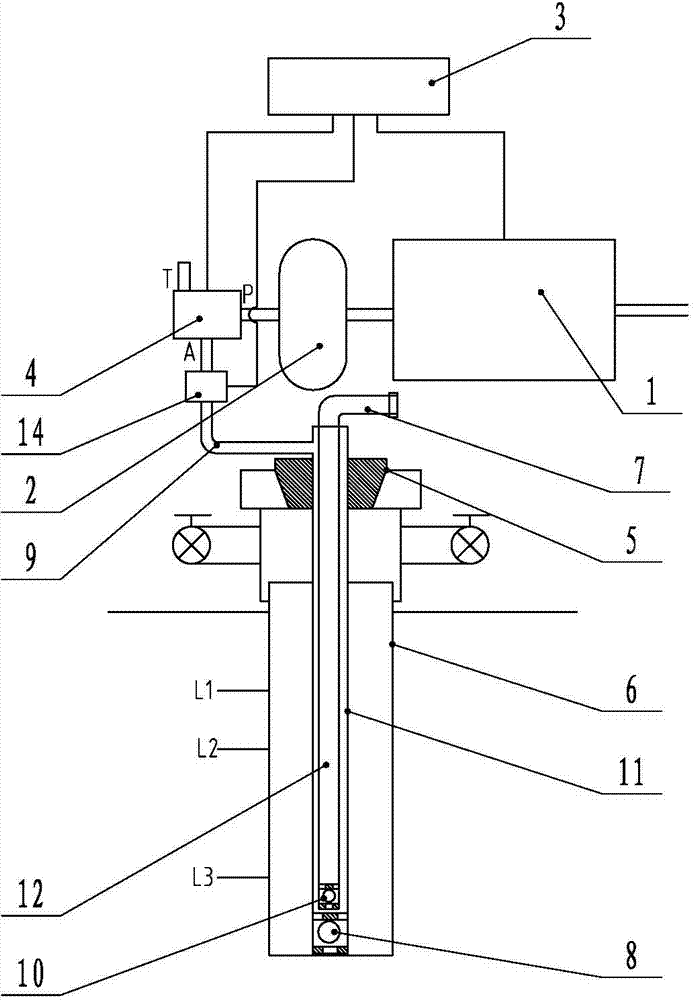

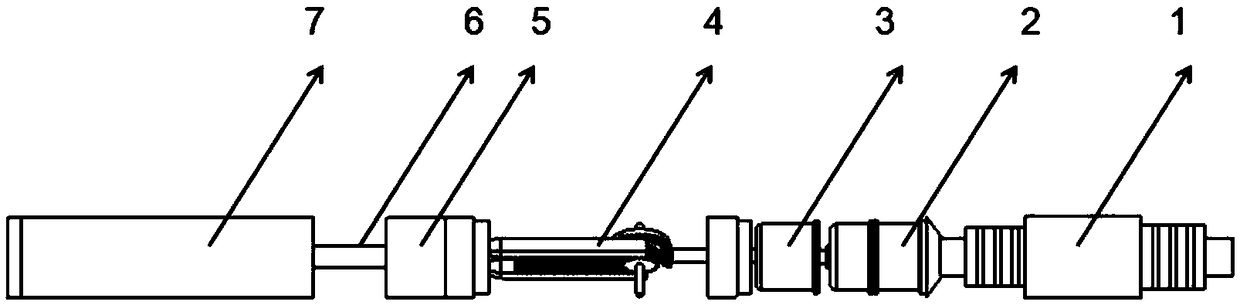

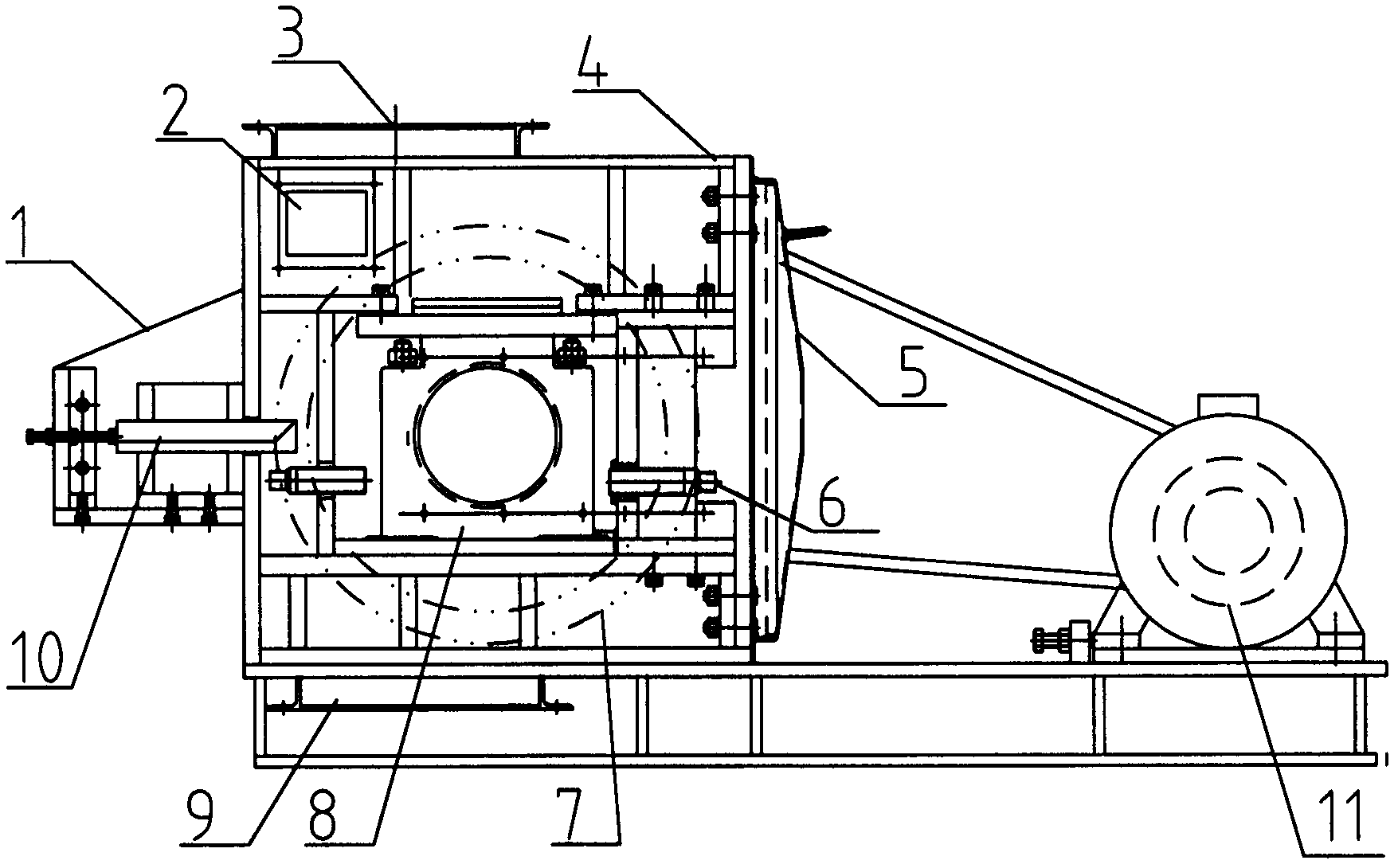

Water-based double-hydraulic drive discharge and mining system

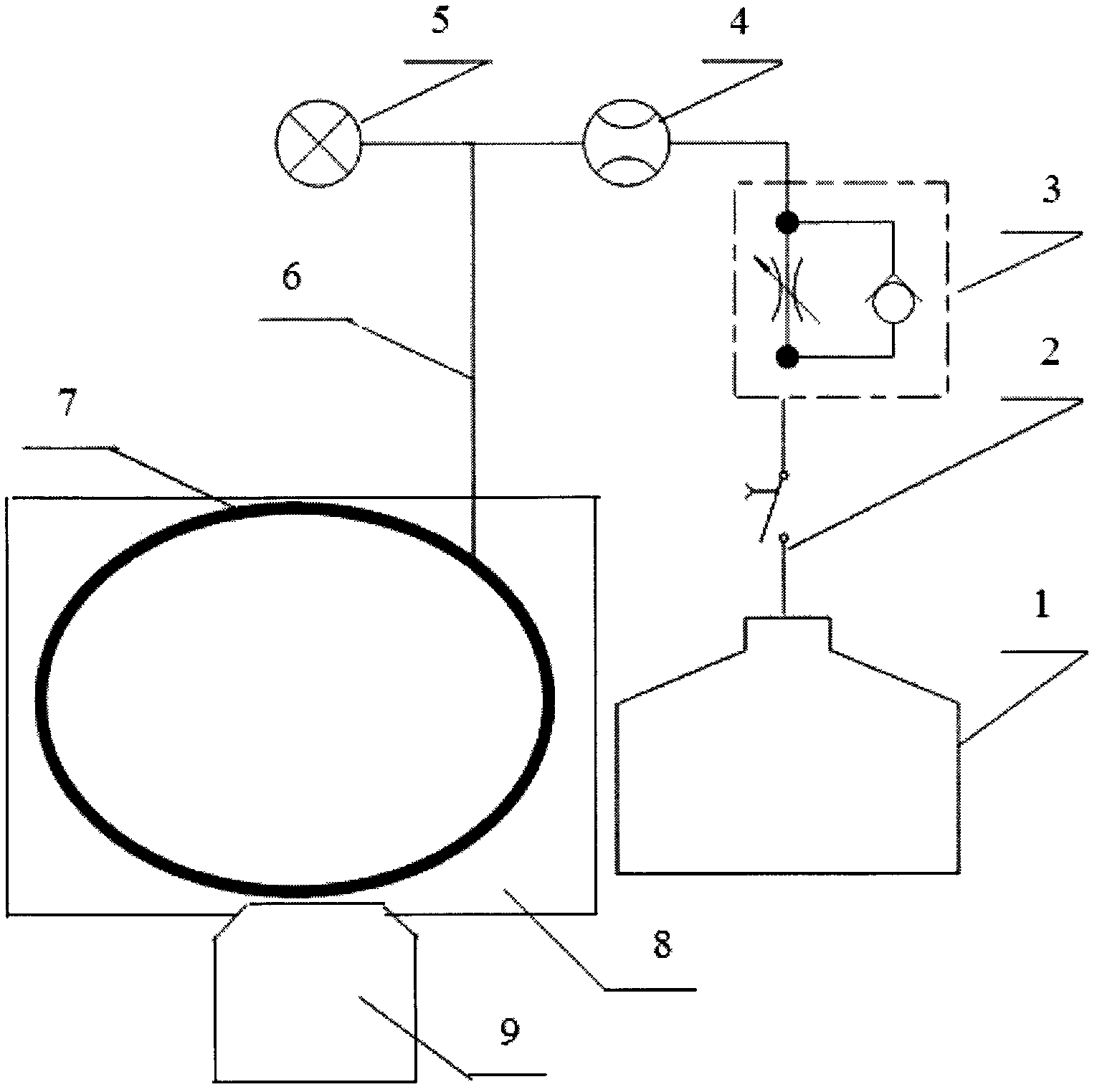

InactiveCN105673465ASolve partial wearOvercome the disadvantage of not being able to downloadFlexible member pumpsFluid removalWater basedDouble tube

The invention discloses a water-based double-hydraulic drive discharge and mining system, which comprises a reverse double-piston ground drive pump unit, a flexible tube and hard tube double-tube water-based power transmission unit, a two-sided piston power applying unit and a rod pump unit used for oil pumping and discharge and mining; the flexible tube and hard tube double-tube water-based power transmission unit comprises a flexible tube and a hard tube; the flexible tube is attached to the hard tube and goes deep into an oil tube and a casing under the shaft; the reverse double-piston ground drive pump unit is equipped so as to apply suction to the hard tube while applying pressure to the flexible tube or apply pressure to the hard tube while applying suction to the flexible tube; the upper side of the two-sided piston power applying unit is connected with the flexible tube, and the lower side of the two-sided piston power applying unit is connected with the hard tube; and the rod pump unit used for oil pumping and discharge and mining is in linkage with the two-sided piston power applying unit.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

Oil well anti-eccentric wearing, corrosion-inhibiting and scale-removing agent with reversed phase accumulation

ActiveCN101948682ASolve partial wearSolve corrosiveDrilling compositionBorehole/well accessoriesBacillus licheniformisBeta-Carotene

The invention relates to an oil well anti-eccentric wearing, corrosion-inhibiting and scale-removing agent with reversed phase accumulation, which is applied in corrosion inhibition and scale removal of an oil well. The agent comprises the following components by weight percent: 6.75-8.25% of iturin A, 8.15-11.15% of bacillus licheniformis, 6.25-7.75% of fengycin, 0.01-0.03% of beta-carotene, 0.01-0.03% of vitamin C, 0.5-0.75% of sodium nitrite and the balance of water. The agent has the effects that the prepared scale-removing agent can be applied in the oil well, solve the problems of eccentric wear, corrosion and scale formation of the oil well which contains more than 45% of the water, and prolong the pump detection cycle by 2.15 times on average under the situation of leading the adding amount of the oil well to be 150mg / l.

Owner:PETROCHINA CO LTD

Method and equipment for forcibly lifting water or oil by air energy

ActiveCN104500007ASolve partial wearThere is no disadvantage of self-respect and workFluid removalHigh pressureControl valves

The invention discloses a method and equipment for forcibly lifting water or oil by air energy. The method is completed by the following steps that firstly, an oil storage pipe and an oil discharge pipe are firstly arranged in a well casing pipe, each of the lower end of the oil storage pipe and the lower end of the oil discharge pipe is provided with an one-way valve, an inlet of the one-way valve arranged at the lower end of the oil discharge pipe is communicated with the bottom of an inner cavity of the oil storage pipe, a compressor provides high-pressure air energy for a high-pressure air storage tank and stores the high-pressure air energy, the high-pressure air storage tank is communicated with an air inlet of a control valve, an air outlet of the control valve is communicated with the oil storage pipe, when the air inlet and the air outlet are communicated, the high-pressure air can enter the oil storage pipe for pressing the liquid into the oil discharge pipe, finally, and the liquid is lifted onto the ground, so that the air outlet of the control valve is communicated with an exhaust opening, in addition, liquid in the well casing pipe enters an oil storage pipe cavity, and the circulation is repeatedly carried out in such a way. The method and the equipment have the advantages that no moving component is adopted under the ground, the fault rate is low, and the maintenance operation cost is greatly reduced.

Owner:SHANDONG WEIMA PUMPS MFG

Automatic deflection adjusting sealing device for thick oil thermal production well mouth polish rod

This invention discloses a polish rod automatic regulation sealing device of heavy crude thermal production well, which belongs to pump well port sealing technique field. The device comprises six parts, from top to end: polish rod protective part, disc root sealing part, polish rod erection part, automatic regulation part, anti-theft part and disc root chip filtering part; wherein the automatic regulation part comprises bulb, bulb seat and bulb cap, set outside the polish rod regulation cover and the disc root chip filtering shield; the disc root sealing part comprises helical disk root which adhere to the pump polish rod, a disc root box outside the disc root and the disc root cap and mat in the top; every part are connected with each other through flight. Said invention can regulate the pump polish rod, preventing the disc root deflection; the axial pressure can be adjusted at any time with good sealing effect; besides, it can add new disc root continuously. The invention is fit for heavy crude thermal production and kinds of pump well.

Owner:中国石化胜利油田有限公司胜利采油厂

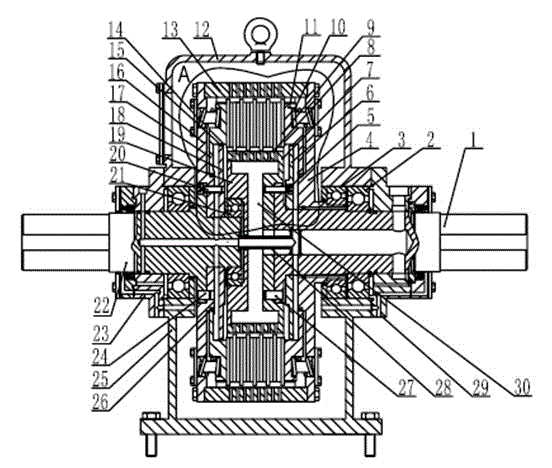

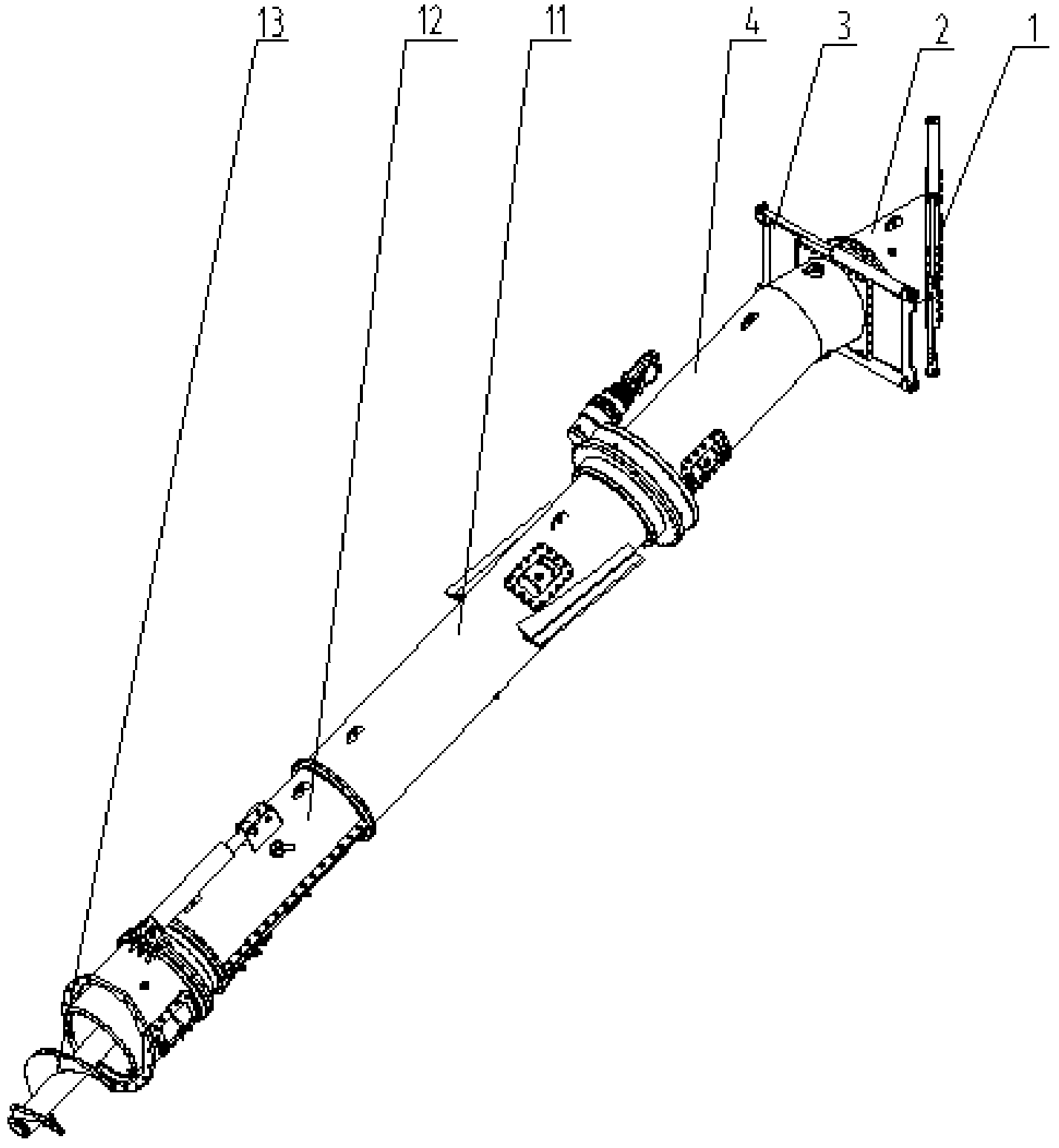

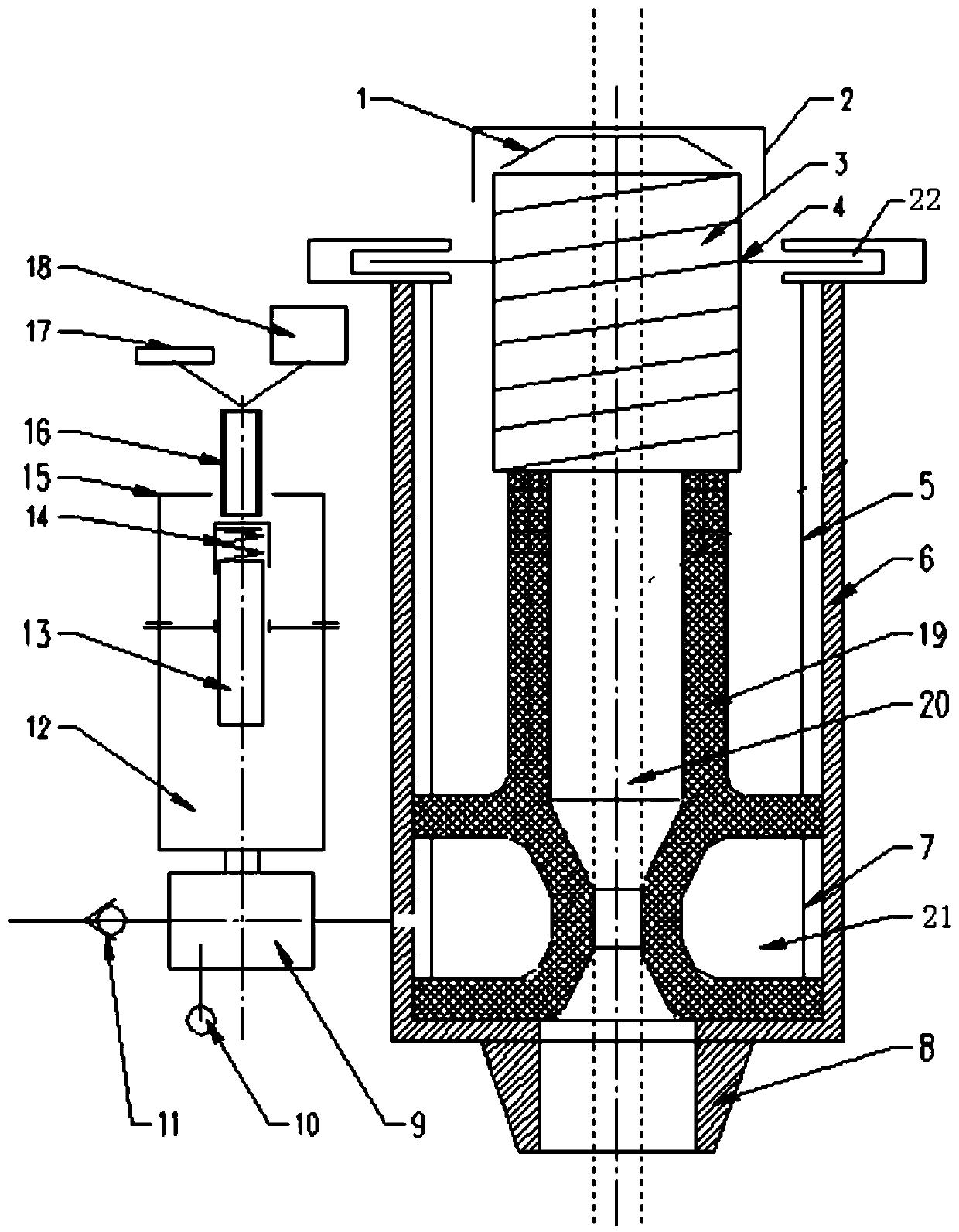

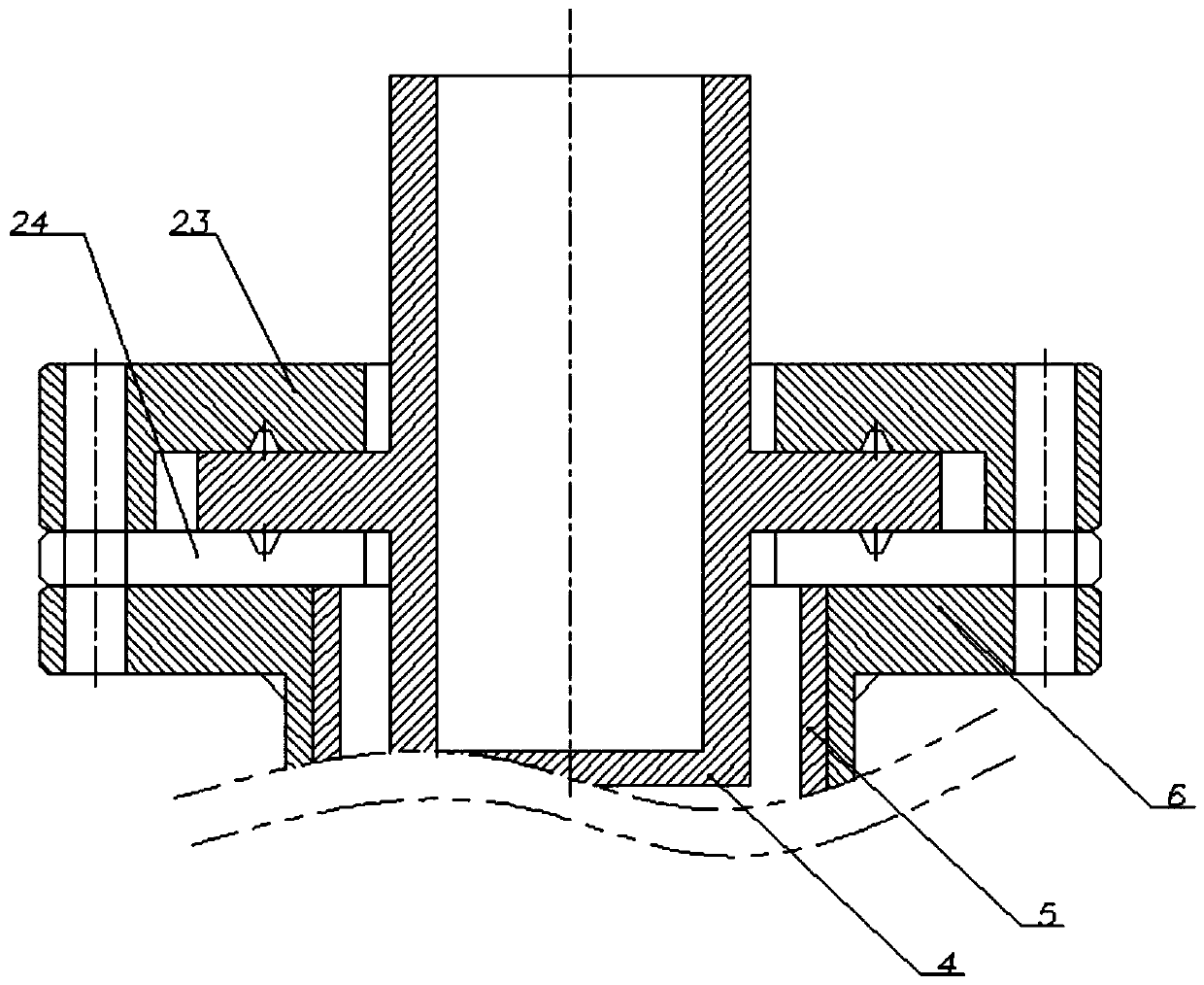

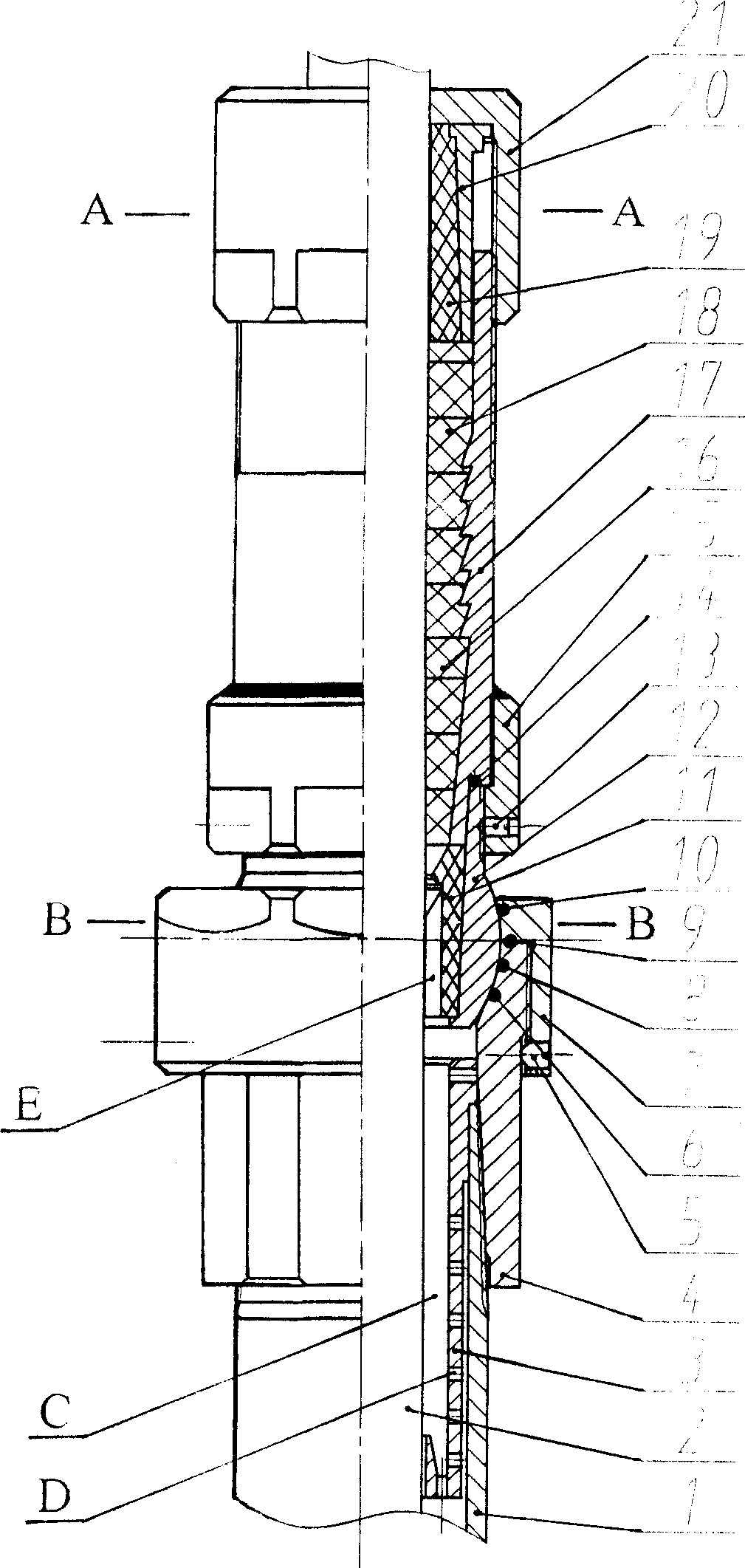

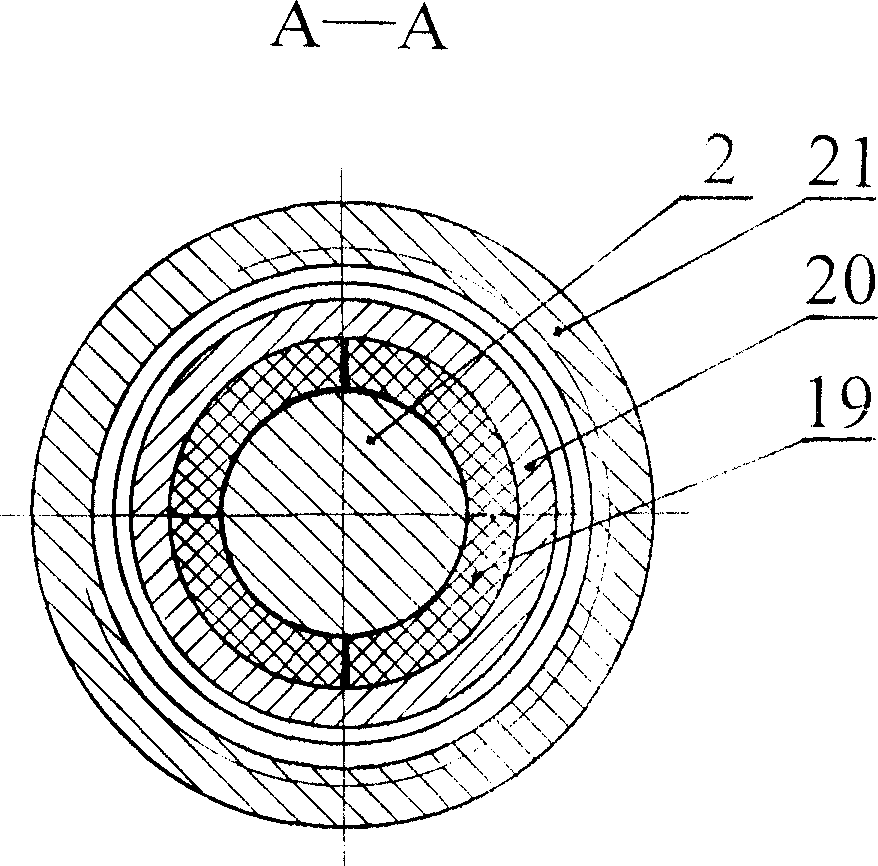

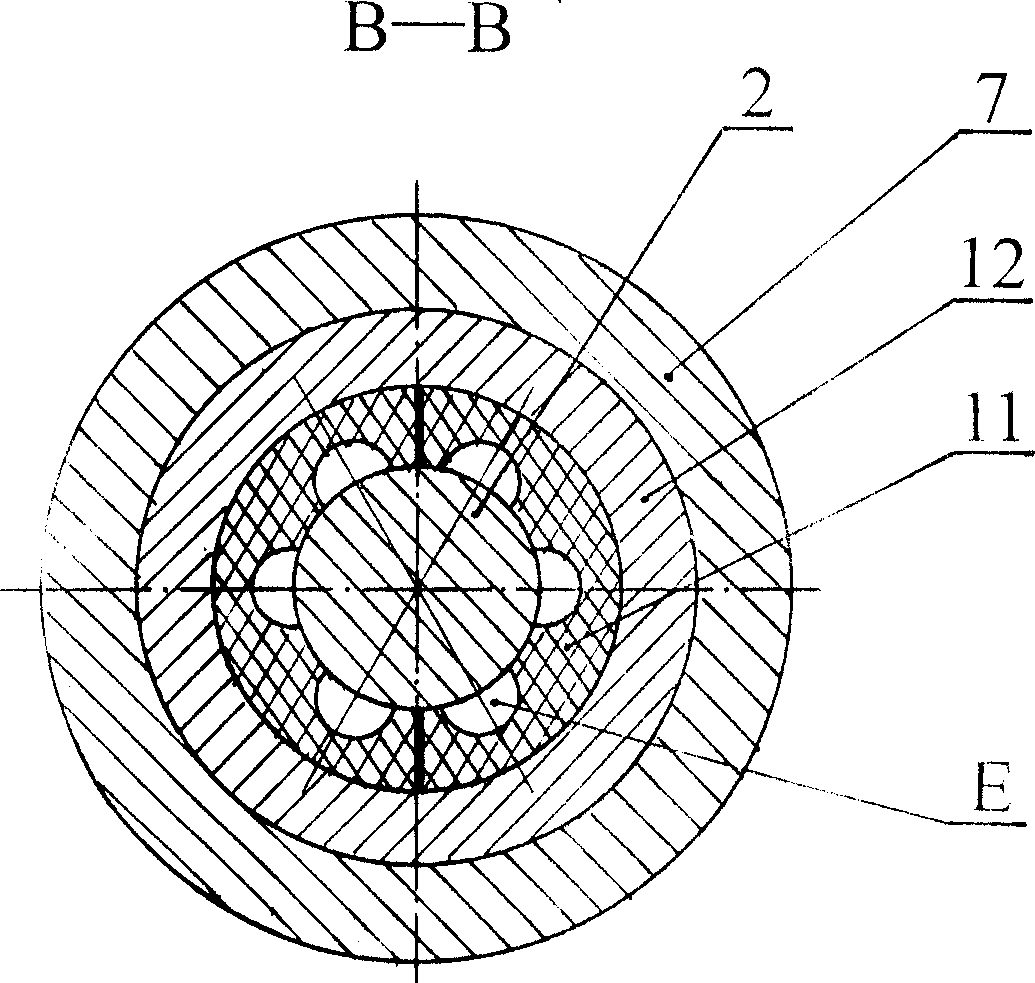

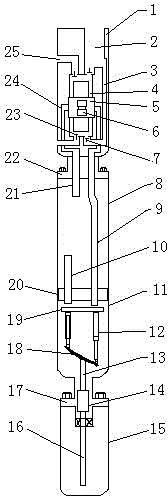

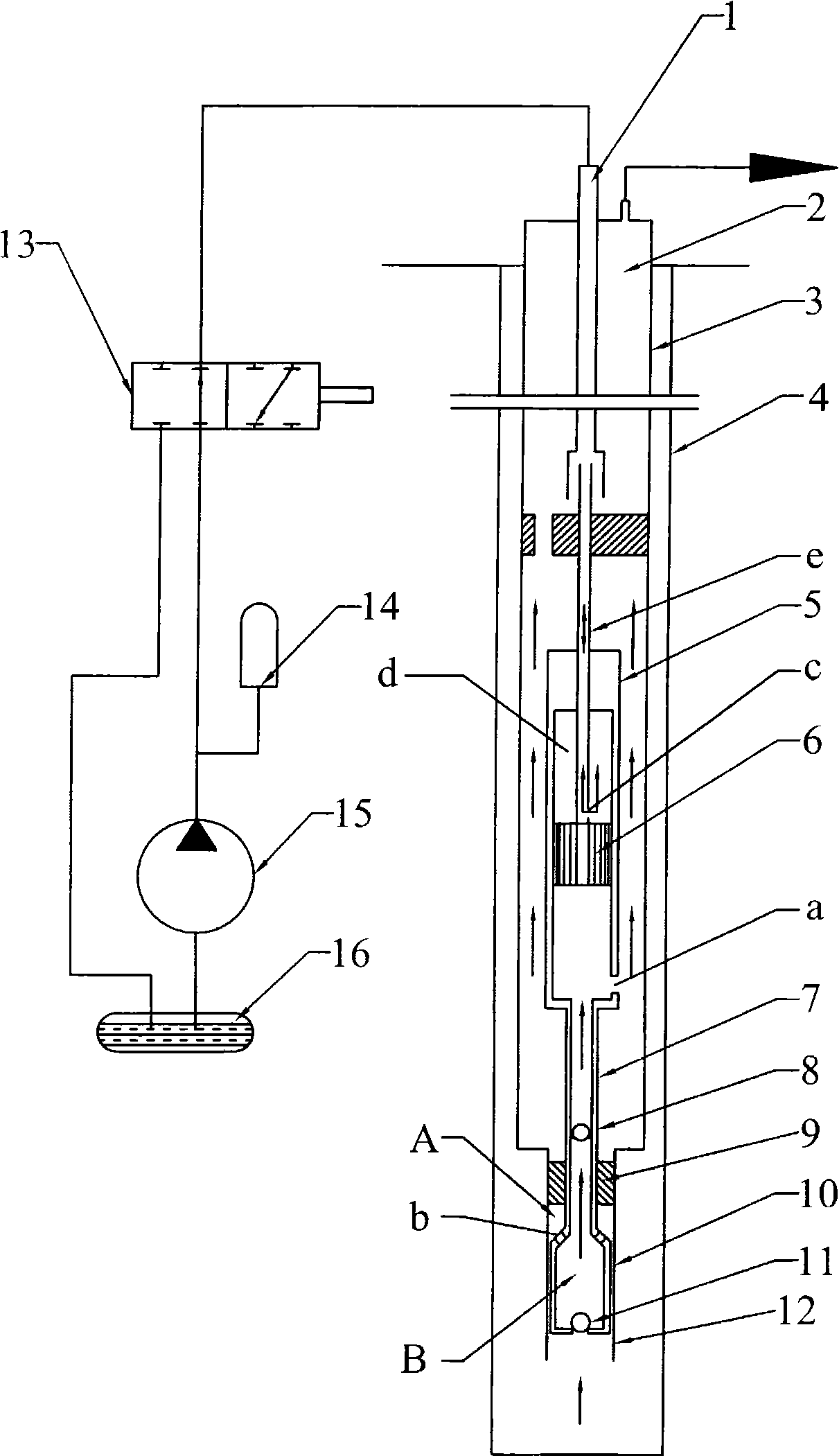

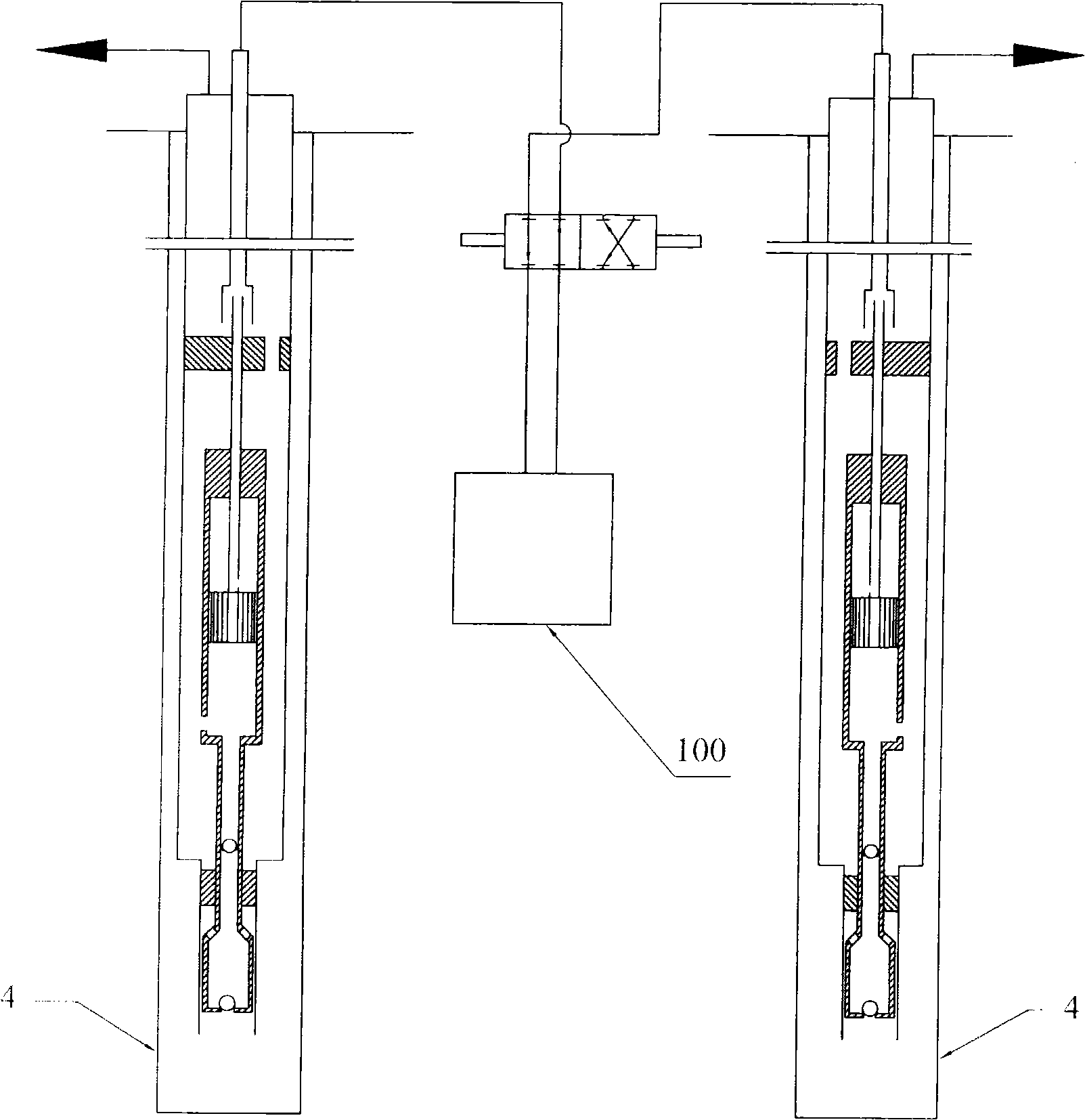

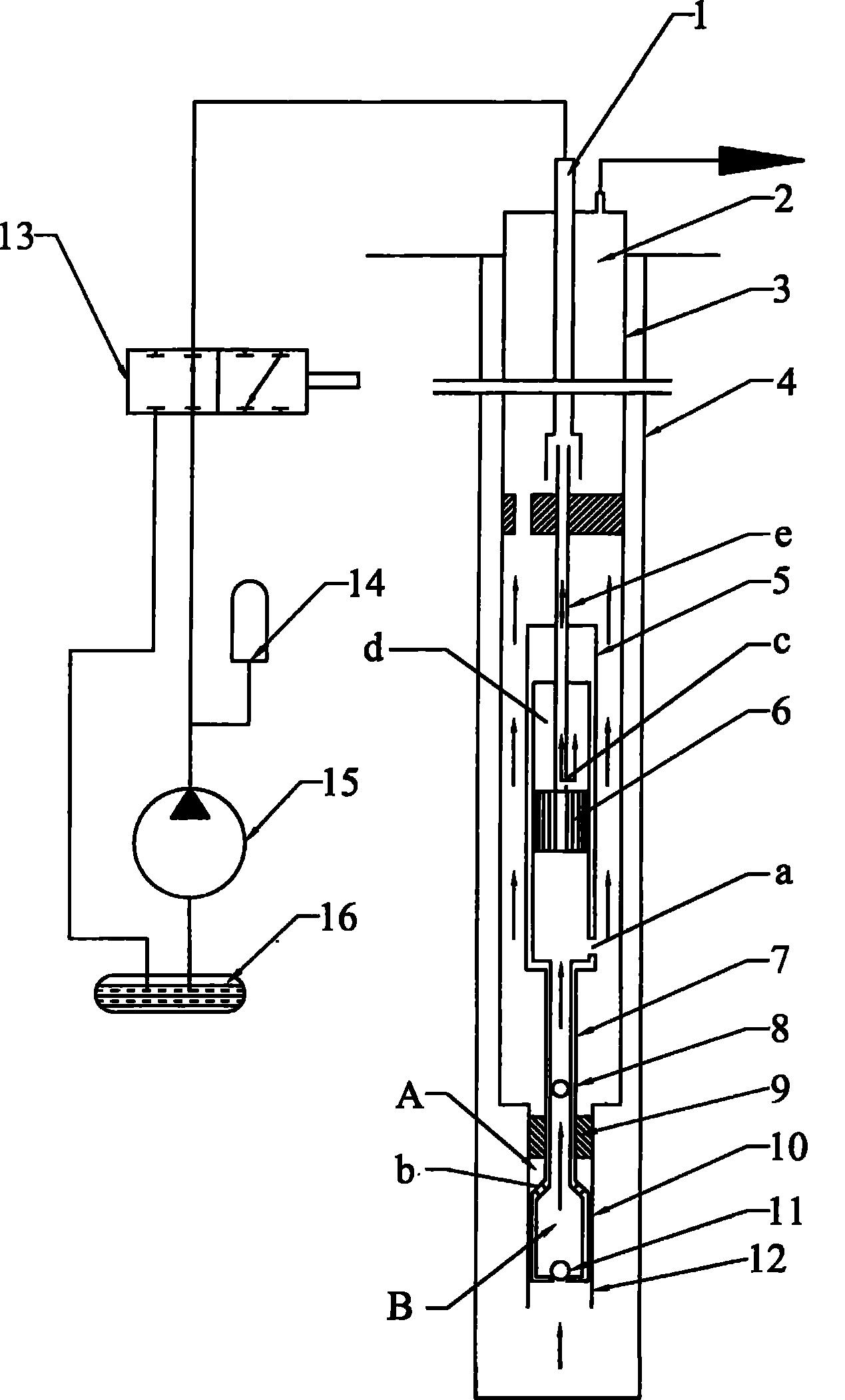

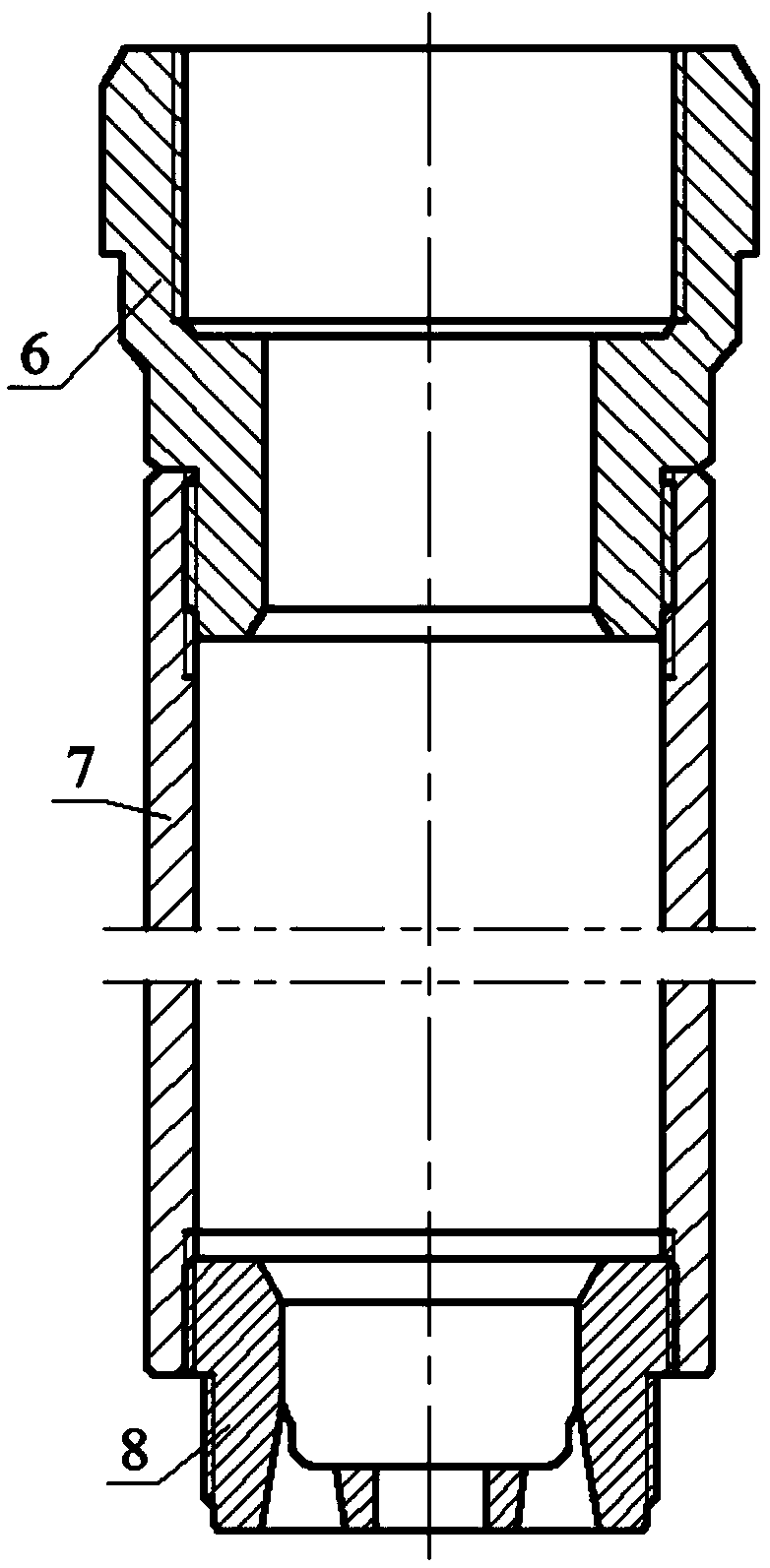

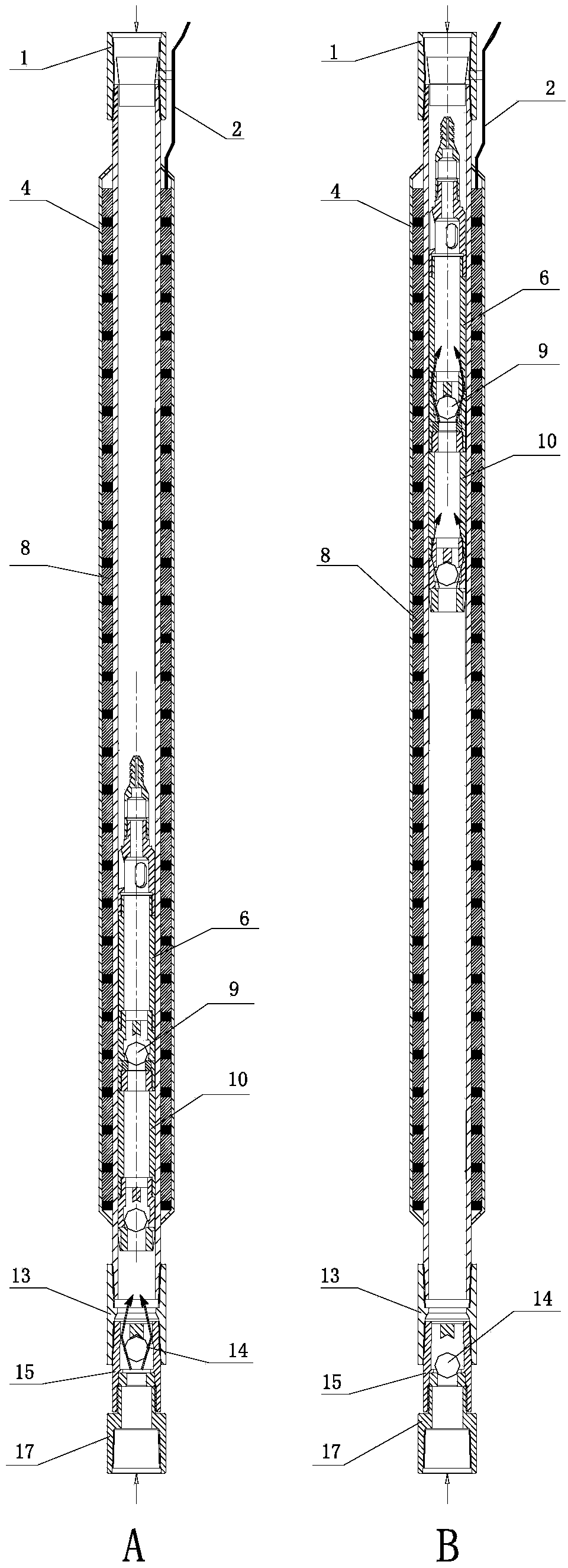

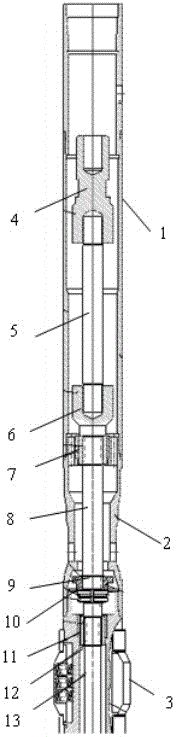

Well electric hydraulic conversion high-lift plunger pump

InactiveCN105332901ASolve partial wearExtend your lifeFlexible member pumpsFluid removalInlet valveHigh lift

The invention provides a well electric hydraulic conversion high-lift plunger pump. According to the technical scheme, the well hydraulic conversion high-lift plunger pump is mainly composed of a cylindrical pump A (1), an A pump liquid outlet (2), an A pump liquid flow pipeline (3), an A pump work cavity (4), an A pump plunger (5), an A pump reversing valve (6), an A pump drain valve (7), a cylindrical power liquid tank (8), a power liquid pipe (9), a first power liquid pipe opening (10), a cylindrical pump B (11), a B pump plunger (12), a B pump shaft (13), a coupling device (14), a cylindrical motor (15), a motor shaft (16), a first connecting mechanism (17), a B pump plunger drive plate (18), a B pump oil distributing disc (19), a second connecting mechanism (20), a second power liquid pipe opening (21), a third connecting mechanism (22), an A pump liquid inlet valve (23), an A pump power liquid pipeline (24) and an A pump work liquid inlet (25). The well electric hydraulic conversion high-lift plunger pump is reasonable and practical in design, the problem of eccentric wear of a rod pipe is basically solved, the service life of an oil pipe is effectively prolonged, high efficiency and low consumption are achieved, and energy is saved.

Owner:满灵子

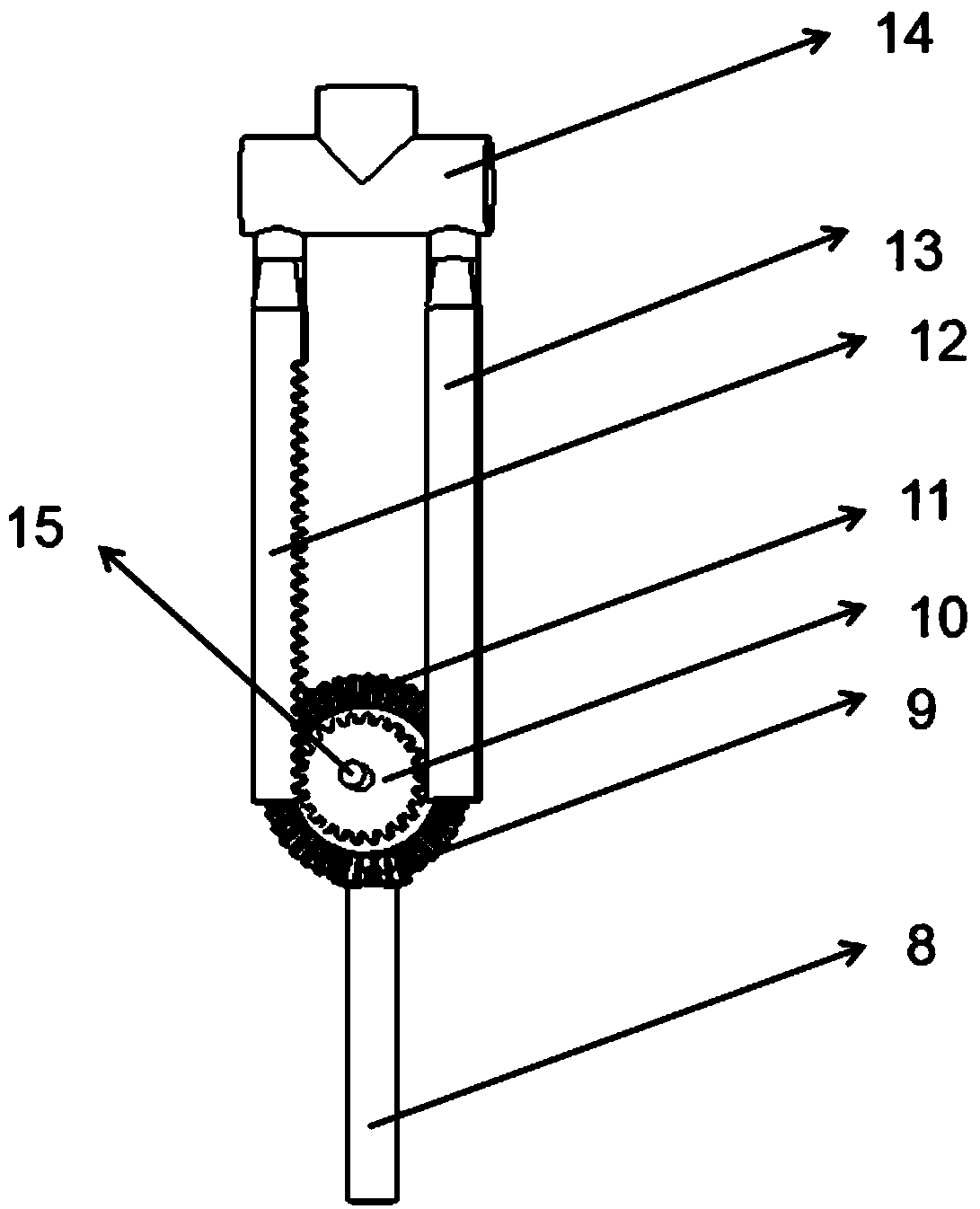

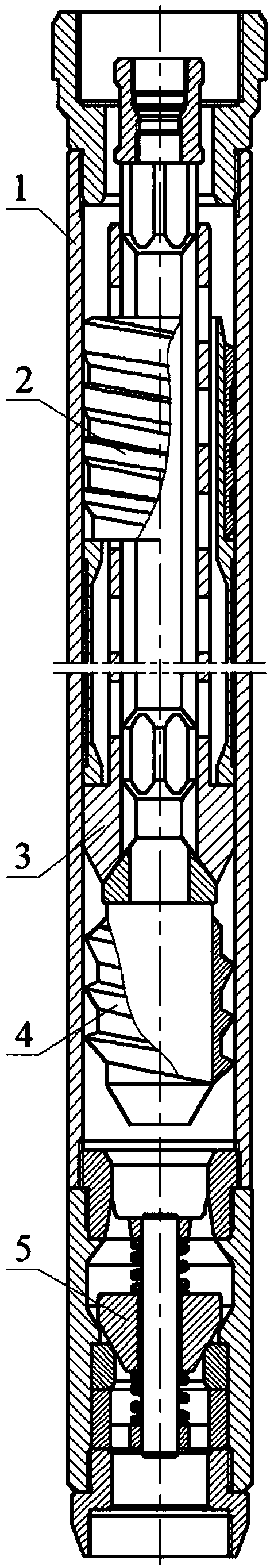

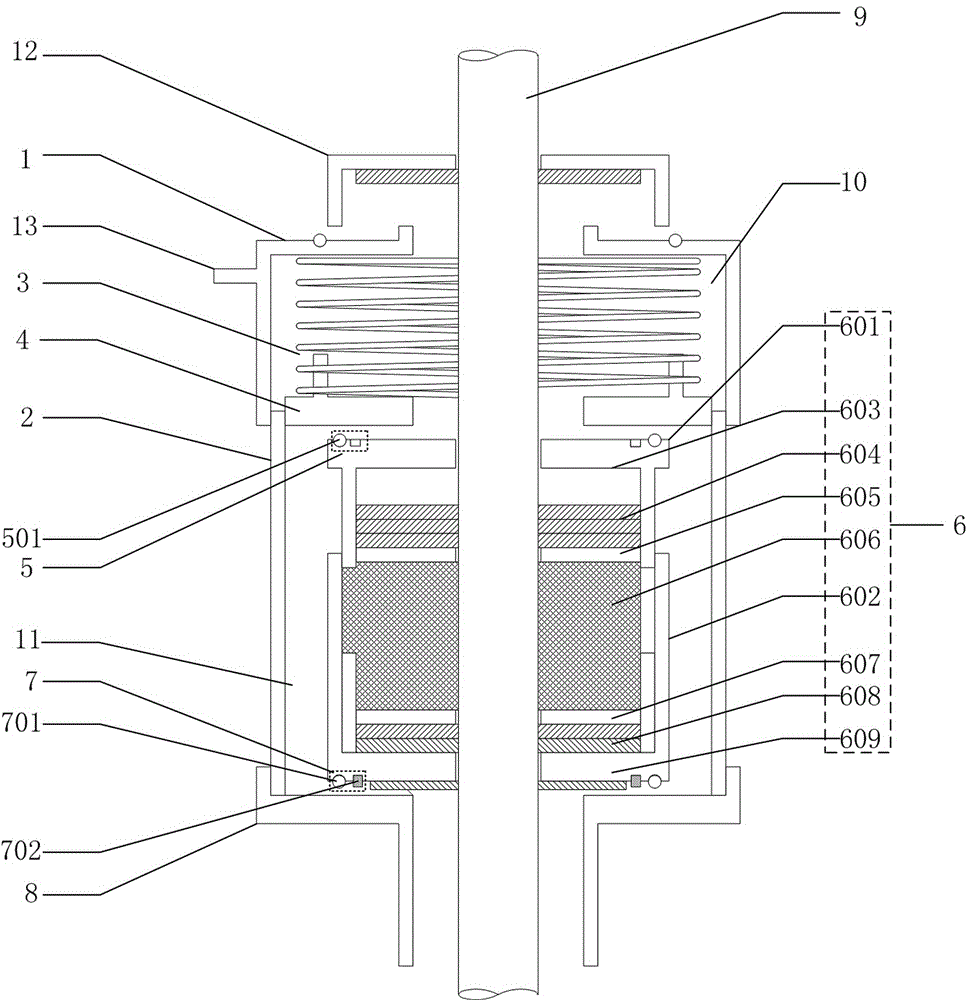

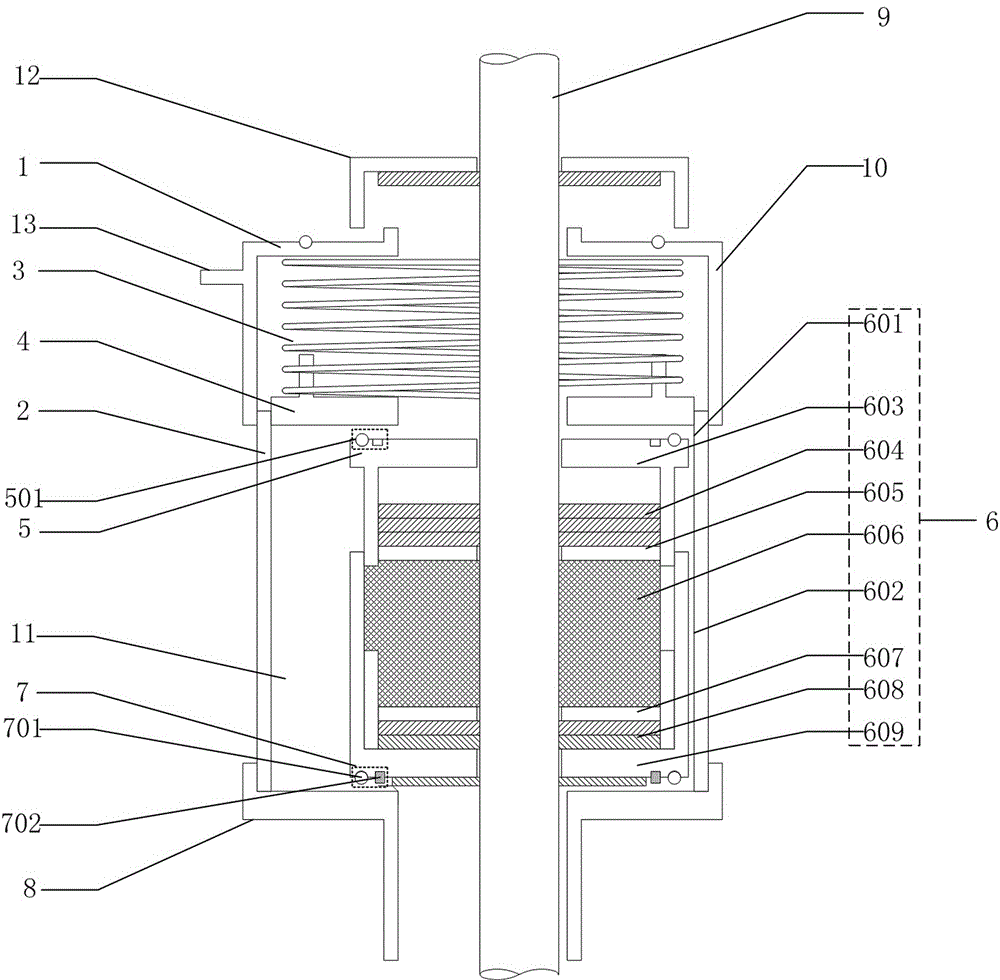

Downhole driven reciprocating pump oil recovery device

InactiveCN109113674AEliminate transmission lossesSolve partial wearFlexible member pumpsFluid removalLow speedHorizontal wells

Disclosed is a downhole driven reciprocating pump oil recovery device. A rotating motor is connected with a planetary reducer. The planetary reducer is connected with an incomplete gear reversing mechanism. The incomplete gear reversing mechanism is connected with an intermediate transmission mechanism. The intermediate gear transmission mechanism is connected with a piston rod of a plunger pump.When the whole oil recovery device works, the rotating motor transmits power to the planetary gear reducer for speed reduction, then the power is transmitted to the incomplete gear reversing mechanism, thus low-speed forward and reverse rotation can be achieved, and finally, up-down reciprocating motion is achieved through the intermediate gear transmission mechanism; the problem of eccentric wearof a rod pipe is completely solved, meanwhile, the transmission loss of a sucker rod is eliminated, the efficiency is improved, the downhole driven reciprocating pump oil recovery device is more suitable for highly-deviated wells and horizontal wells, and is low in energy consumption, convenient to maintain, high in operating reliability, low in weight and low in cost.

Owner:XI'AN PETROLEUM UNIVERSITY

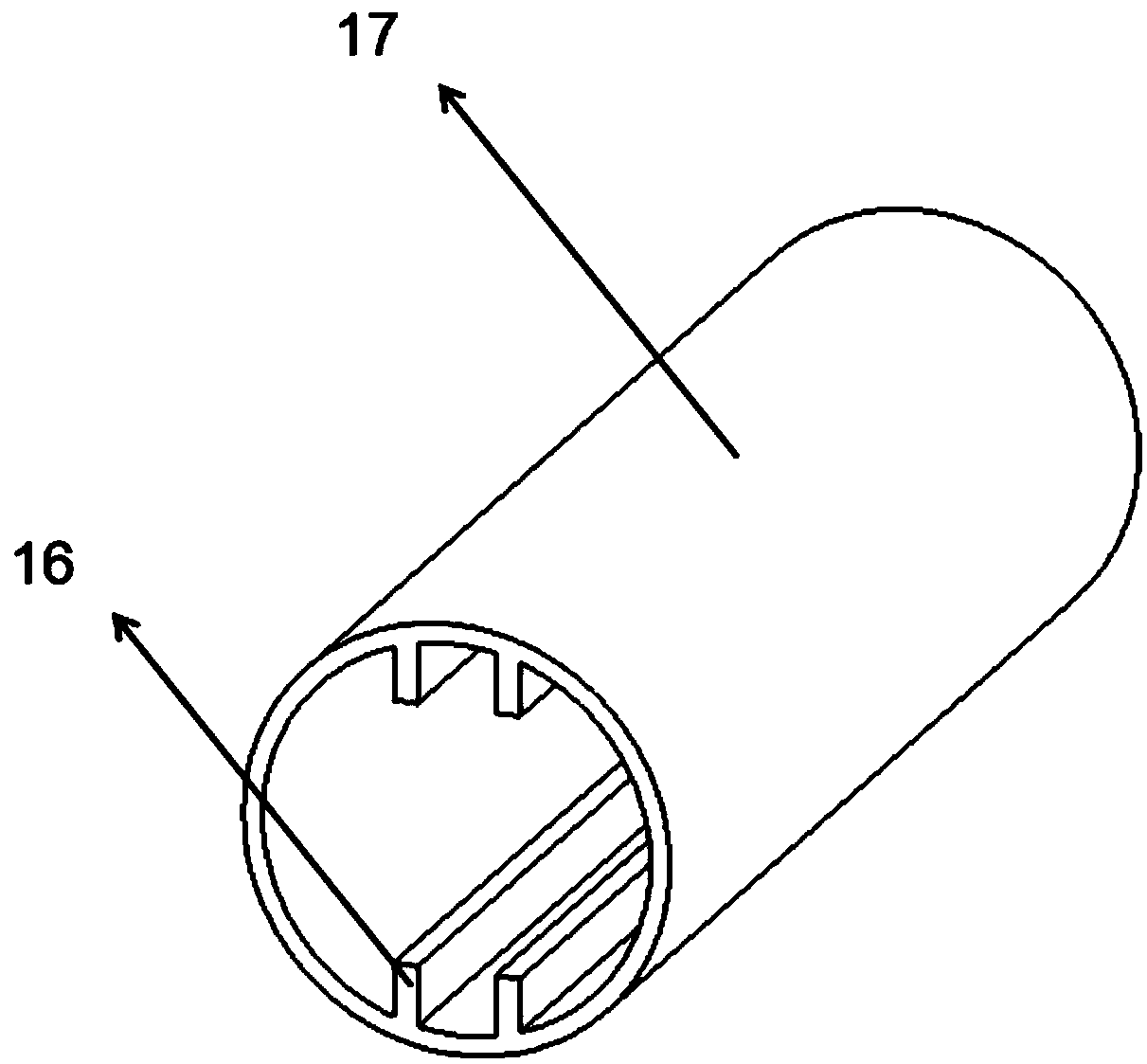

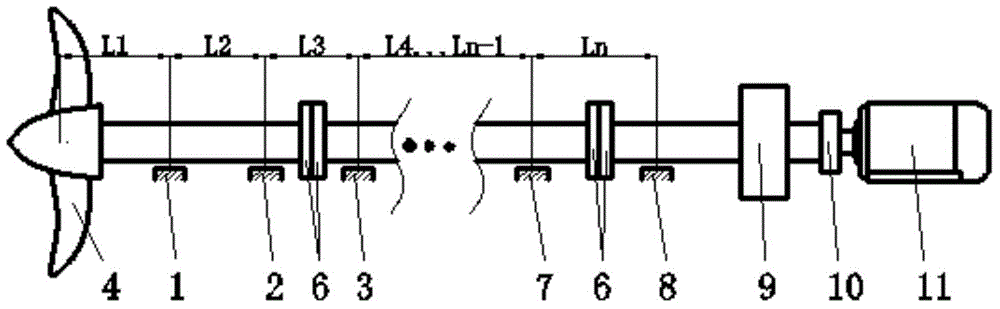

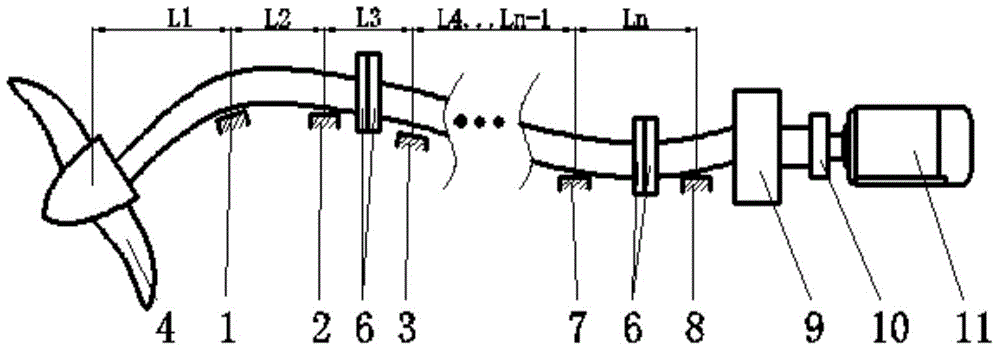

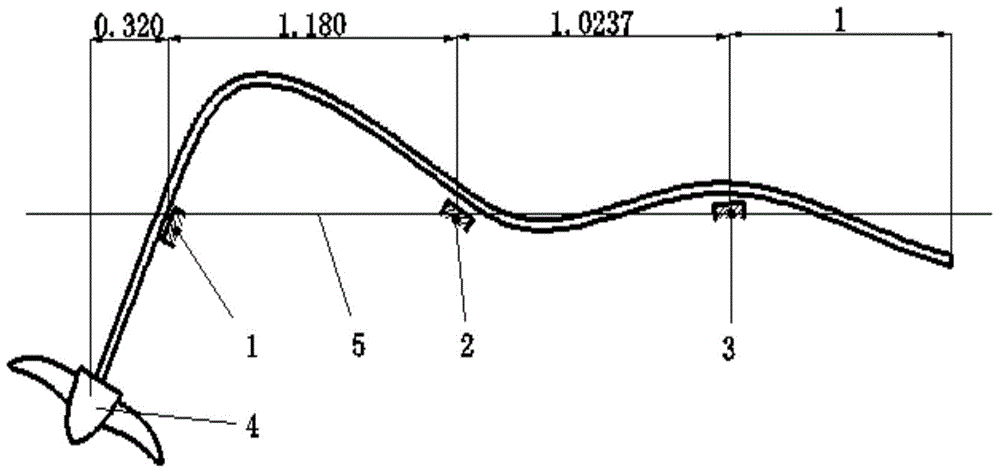

Arrangement method of bearing hole system of rotary shaft system conforming to deflection curve

ActiveCN104976325AEven contactSolve partial wearVessel designingGearing detailsEngineeringDeflection angle

The invention discloses an arrangement method of a bearing hole system of a rotary shaft system. The arrangement method is characterized in that through the arrangement on positions and deflection angles of axes of bearing holes supporting various bearings of the rotary shaft system, stresses or pressures borne by the single bearing along the same circumferential position and different axial positions are basically consistent, and supporting to the rotary shaft system is realized, and eccentric wear of the bearings of the shaft system is eliminated; and the various bearings are mounted and arranged according to a deflection curve of the shaft system conforming to bearing hole mandrils of the bearings. The method is specific to the rotary shaft system which is provided with three or more bearing holes and has the working conditions that a deflection value and a corner value of the deflection curve of the shaft system at the bearing hole mandril exceed a manufacturing tolerance and a rotary in-service tolerance; and on the steady load condition, the method is applicable to the working condition that the end of the axis of the shaft system bears the load, and also applicable to the working condition that the borne load is in the other axial position in the axis of the shaft system.

Owner:HUAZHONG UNIV OF SCI & TECH

Hydraulic oil pump

ActiveCN101782060AReduce wear and tearReduce wearFlexible member pumpsPositive-displacement liquid enginesReciprocating motionHydraulic pump

The invention relates to a hydraulic oil pump, which comprises an oil pipe 3, a small pump tube 9, a large pump tube 12, an up pump tube 5, a small plunger piston 7 and a large plunger piston 10, wherein the oil pipe 3, the small pump tube 9 and the large pump tube 12 are sequentially connected in series, the up pump tube 5, the small plunger piston 7 and the large plunger piston 10 are sequentially connected, the up pump tube 5 is arranged in the oil pipe 3, the side wall is provided with a first oil opening a, an inner cavity is provided with a fixed plunger piston 6, the up pump tube 5 makes up-down reciprocating movement outside the fixed plunger piston 6 through power liquid, the small plunger piston 7 makes up-down reciprocating movement inside the small pump tube 9, a second oil opening b is arranged at the joint of the small plunger piston 7 and the large plunger piston 10, the large plunger piston 10 makes up-down reciprocating movement inside the large pump tube 12, the bottom of the large plunger piston 10 is provided with a lower oil outlet valve 11, and the oil extraction is realized through the reciprocating movement of the up pump tube 5, the small plunger piston 7 and the large plunger piston 10 in the oil pipe 3, the small pump tube 9 and the large pump tube 12. The hydraulic oil pump of the invention has the advantages of large range of lower side depth, wide use range, safety, reliability, long service life, low use cost and the like.

Owner:克拉玛依九工环保技术有限公司

Horizontal well self-centering moving piston type cone valve pump

ActiveCN109162908AScrape off in timeSmooth dischargePositive displacement pump componentsFlexible member pumpsReciprocating motionEngineering

The invention provides a horizontal well self-centering moving piston type cone valve pump. The horizontal well self-centering moving piston type cone valve pump is used in horizontal well and inclined well pumping conditions. The horizontal well self-centering moving piston type cone valve pump is composed of a pump cylinder body, a sand scraping type plunger piston, a stirring centralizer, a walking cone valve and a fixed cone valve. The problems of sand abrasion and eccentric wear between a long pump cylinder and a moving plunger piston, horizontal well valve leakage as well as valve ball difficult opening and loose closing can be effectively solved. The sand scraping type plunger piston adopts a moving piston type spiral sand scraping plunger piston and combine with a compensation ringto prevent sand falling into an annular gap between the long pump cylinder and the moving plunger piston, a spiral sand scraping column timely scraping and discharging out of sand adsorbed to the cylinder wall of the long pump cylinder, and the stirring centralizer adopts a double centralizing spiral tooth stirring rod body to realize self-centering of the sand scraping type plunger piston and the walking cone valve. The walking cone valve adopts a structure of a fixed cone valve and a moving cone valve seat and automatically opens and closes with the reciprocating movement of the stirring centralizer, the fixed cone valve adopts a structure of a moving cone valve and a fixed cone valve seat, and a fixed cone valve body is opened and closed smoothly through assisting of double springs anda guide rod.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Magnetic suspension machine-pump integrated underground oil extraction device

InactiveCN103510923ARealize stepless adjustmentSolve partial wearFluid removalThermodynamicsDirectional well

The invention relates to a magnetic suspension machine-pump integrated underground oil extraction device used during oil extraction in the field of oil fields. The magnetic suspension machine-pump integrated underground oil extraction device comprises an oil well pump cylinder and an internally-arranged throwing-salvage pup joint. The throwing-salvage pup joint is connected with a magnetic suspension motor runner through an adapting connector, the lower end of the magnetic suspension motor runner is connected with an oil well pump movable valve combination, the outer wall of the oil well pump cylinder is sleeved with a magnetic suspension motor stator, and the magnetic suspension motor stator is placed inside a shell. The magnetic suspension machine-pump integrated underground oil extraction device has the sand prevention function, the wax prevention function and the stepless adjustment function, is compact in structure, efficient, free of maintenance, long in service life, capable of greatly reducing the production cost and particularly suitable for land oil wells and offshore oil wells such as deep wells, directional wells, wax precipitation wells, thickened oil wells and evacuation oil wells, and saves energy.

Owner:大庆九方石油仪器设备有限公司

Follow-up type automatic compensation polished rod sealing device

InactiveCN105971544AUniform and stable penetrationAvoid corrosionSealing/packingOil fieldEngineering

The invention provides a follow-up type automatic compensation polished rod sealing device and belongs to the technical field of oil field machinery. The follow-up type automatic compensation polished rod sealing device comprises a sealing cover, a sealing shell, a pressure adjusting spring, a translation pressing plate, an upper follow-up platform, a follow-up packing box, a lower follow-up platform and a sealing foundation support; the follow-up packing box is in close contact with a polished rod, parallel movement in any direction in the horizontal plane is conducted by means of the upper follow-up platform and the lower follow-up platform, and the problem of eccentric wear is effectively solved; the follow-up packing box is provided with compensation packing and centralization packing, close contact with the polished rod can be achieved under continuous pressure, the sealing effect is improved, and packing wear can be compensated continuously; an annular cavity formed by a sealing cover retaining ring and the sealing shell is filled with lubricating oil and can provide continuous lubrication and oil seal for the upper follow-up platform, the lower follow-up platform, the polished rod and even the packing, radial and axial friction is reduced, meanwhile multiple purposes of saving energy, sealing, prolonging the service life and the like are achieved, and the follow-up type automatic compensation polished rod sealing device can be widely applied to wellhead sealers of oil field pumping units with rods.

Owner:HARBIN UNIV OF SCI & TECH +1

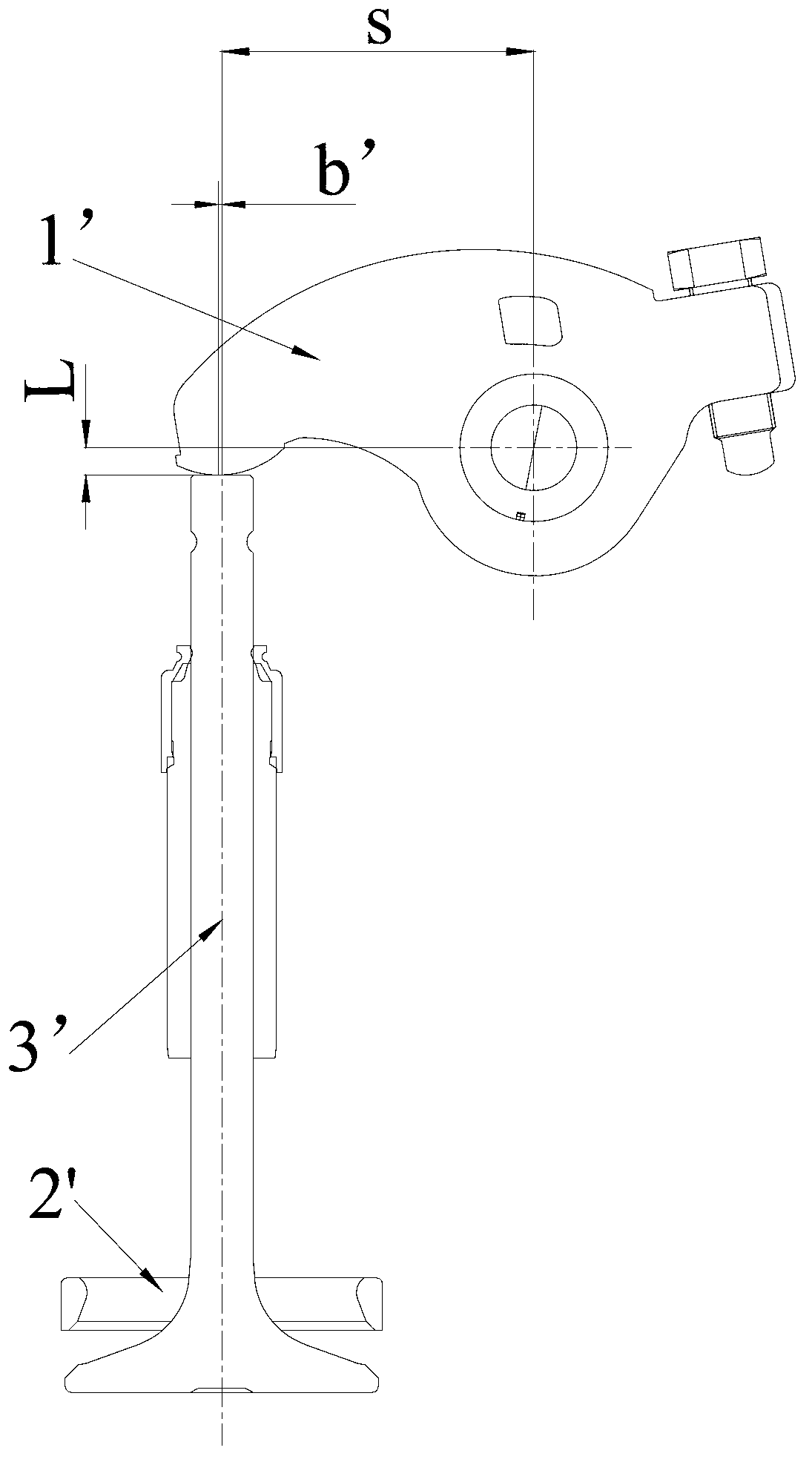

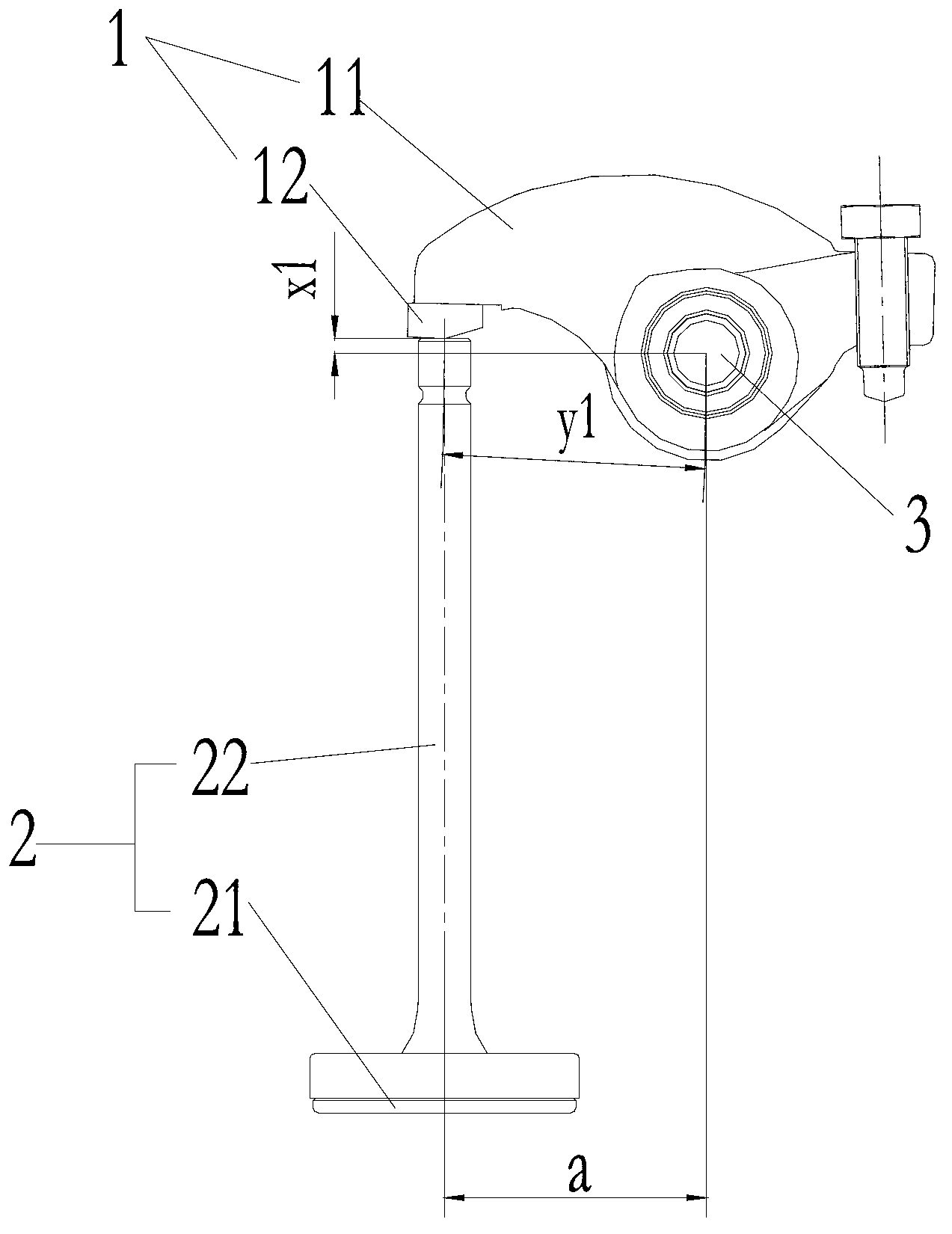

Rocker arm, rocker arm assembly, engine and engineering machinery

ActiveCN102797526ASolve the problem of eccentric wearAvoid valve leaksValve arrangementsMachines/enginesRocker armEngineering

The invention provides a rocker arm, which is matched with the valve of an engine. The rocker arm comprises a rocker arm body and a head part, wherein the head part is arranged at one end of the rocker arm body, which is matched with the valve; and the head part is a double curved surface. The invention further provides a rocker arm assembly, the engine and engineering machinery. When the rocker arm with the structure is matched with the valve, a contact line of the head part and the valve is always on the center line of the valve, so that the problem of eccentric abrasion of a duct and a housing washer of the valve is solved, and the problems of valve leakage, steam blowby increase of a crankcase and engine oil blowby existing in relevant technologies are avoided. Therefore, the stability and the safety of the engine are improved.

Owner:昆山三一动力有限公司

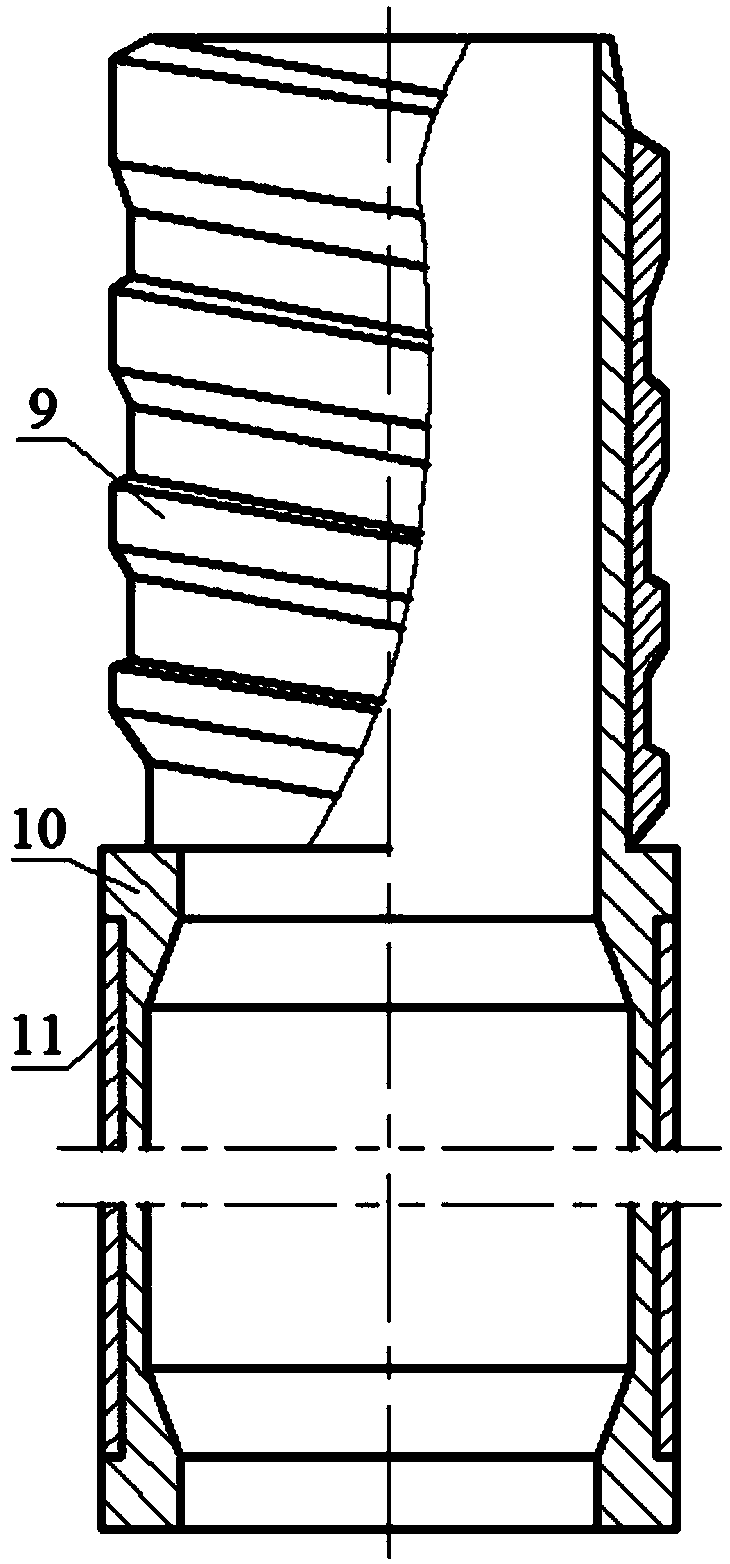

Deep well single-action hydraulic piston pump

PendingCN108457831ASolve partial wearAvoid breakingPositive displacement pump componentsFlexible member pumpsBottom hole pressureReciprocating motion

The invention relates to a deep well single-action hydraulic piston pump. The deep well single-action hydraulic piston pump implements automatic reversing underground through power fluid provided by asurface pump. The deep well single-action hydraulic piston pump is characterized in that the upper end of a piston rod is grooved. During an up stroke, a sliding valve is located in an upper extremeposition under the action of upward acting force, and the piston rod moves upwards under the action of the upward acting force. When moving upwards, the piston rod can gradually cut off the power fluid to act on a flow channel at the lower end of the sliding valve, and the sliding valve starts to bear the downward acting force to move downwards to arrive at a lower extreme position. The force direction and the moving direction of the piston rod can be changed by changing the upper and lower extreme positions of the sliding valve, and then the piston pump can do up-down reciprocating motion tosuck and discharge crude oil. When sucking fluid during the up stroke, the hydraulic piston pump serves as a double-fluid motor driven single pump, can overcome huge bottom hole pressure and can be truly applied to deep well and ultra-deep well oil production. Through the ingenious design, the sealing surface of the sliding valve is free of fluid erosion, and the sliding valve is high in operatingreliability.

Owner:SOUTHWEST PETROLEUM UNIV

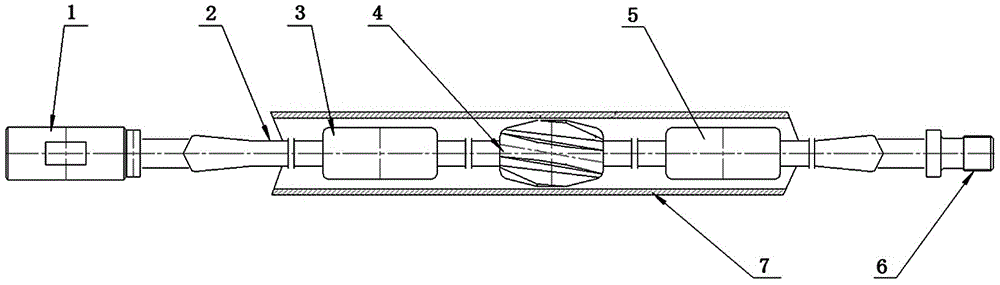

Lubrication simulation device for piston ring and cylinder sleeve of engine

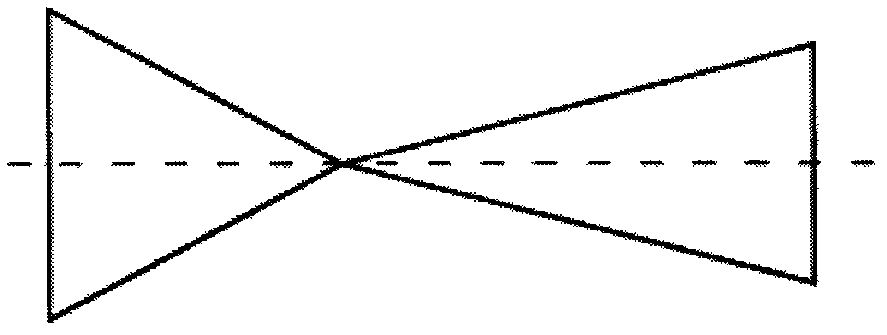

InactiveCN102323061ASolve partial wearImprove controllabilityMachine part testingEngine testingPiston ringEngineering

The invention relates to a lubrication simulation device for a piston ring and a cylinder sleeve of an engine. A lubricating oil tank (1) is connected with an oil spray copper pipe (7) through a plastic hose (6); the plastic hose (6) is connected with a timing controller (2), an electronic pump (3), a flow pump (4) and a pressure gauge (5); more than two double-trumpet-shaped spray holes are uniformly formed on the oil spray copper pipe (7); the hole distance between two adjacent double-trumpet-shaped spray holes is 10 millimeters; the included angle between the axis and the normal line of each double-trumpet-shaped spray hole is 30 degrees; the oil spray copper pipe (7) is arranged in an annular groove of an annular fixture (8); the annular fixture (8) is connected with an upper piston (9); and the cross section of a connecting surface between the annular fixture (8) and the upper piston (9) is conical. The device is used for simulating the splash lubrication state of a piston ring-cylinder sleeve friction pair in the engine, runs stably and reliably, and has a good lubrication simulation effect. By adopting the lubrication simulation device, the problem of camber wear of a cylinder sleeve-piston ring is solved.

Owner:CHINA NORTH IND GRP NO 70 RES INST

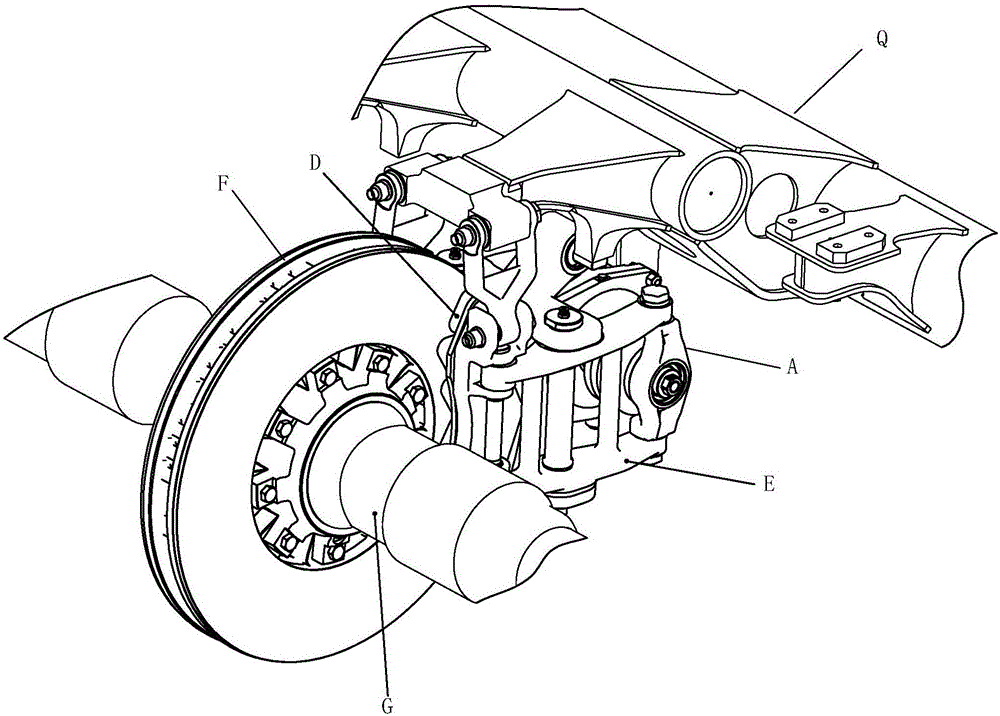

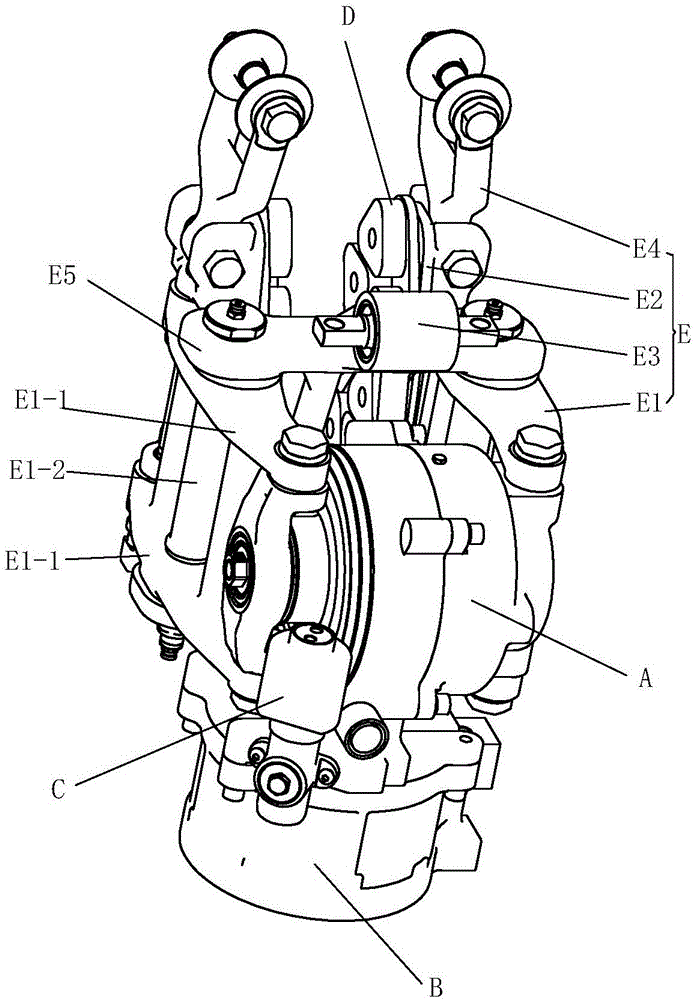

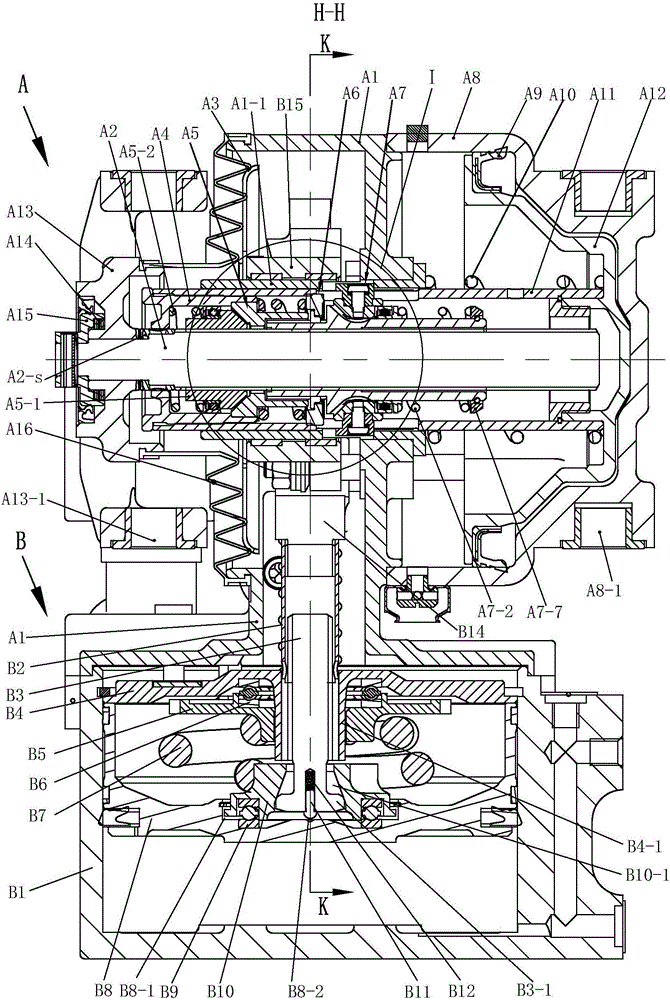

Parking foundation brake device for vehicle

ActiveCN106763309ASimple compositionSave spaceAxially engaging brakesBraking discsParking brakeBrake pad

The invention relates to a parking foundation brake device for a vehicle. The device comprises a braking clamp, a parking unit brake cylinder, a brake pad and a brake disc. The parking unit brake cylinder is composed of a unit brake cylinder and a parking cylinder; the unit brake cylinder comprises a brake cylinder, a middle body, a brake piston assembly, a brake adjusting mechanism and a yoke; the brake adjusting mechanism comprises an adjusting shaft, a guiding nut assembly, a resistant adjusting assembly and an adjusting nut assembly; the parking cylinder comprises a parking cylinder body, a parking piston assembly and a parking control mechanism; the parking control mechanism comprises a wedged body and a thrust sleeve. According to the device provided by the invention, a gap, between the brake pad and the brake disc, which is enlarged due to abrasion, can be automatically adjusted in the brake process, and the resistance adjusting assembly immediately acts when the brake force reaches a certain limit to resist the brake adjusting mechanism to adjust, so that the gap between the brake pad and the brake disc is still maintained in a normal range. The parking brake force provided by the invention is transferred through a bevel of the wedged body, so that the parking brake force is improved.

Owner:CRRC CHANGZHOU TECH MARK IND CO LTD +1

Flexible shaft transmission device of submersible direct-drive screw pump

The invention provides a flexible shaft transmission device of a submersible direct-drive screw pump. The transmission device comprises a long connection pipe, a stator connection pipe and a straightening device which are sequentially connected from top to bottom; an upper screw connector, a flexible shaft and a lower screw connector are sequentially connected in the long connection pipe from top to bottom; and a connection shaft is arranged in the stator connection pipe; and a lower connection pipe is arranged in the straightening device. The flexible shaft transmission device is simple in structure, only a control cabinet is arranged on the ground part of the system, the occupied area of a well mouth is small, the ubiquitous problem that eccentric abrasion happens to a rod and a pipe of a directional well is fundamentally solved, and later-period running and maintaining cost and labor intensity are reduced.

Owner:PETROCHINA CO LTD

Curved limited movement type anti-wear sucker rod and manufacturing method thereof

The invention discloses an arc-shaped surface limited movement type anti-wear sucker rod and a manufacturing method thereof. The limited movement type anti-wear sucker rod is formed by additionally arranging a plurality of limiters and strengthening bodies on a sucker rod body. The limiters are firmly connected onto the sucker rod body through casting and a strengthening body is arranged between every two adjacent limiters; a plurality of spiral lug bosses and spiral grooves are arranged on the circumferential side of each strengthening body; the spiral groove between every two spiral lug bosses is used as an oil flowing channel; and the outer circle of the strengthening body is of an arc-shaped surface shape. Compared with the prior art, the arc-shaped surface limited movement type anti-wear sucker rod can prevent a connecting hoop of the sucker rod from eccentric wear and a rod body of the sucker rod from the eccentric wear, and can also prevent the sucker rod from being broken and falling off, so that the strengthening bodies can move when necessary; and meanwhile, the served limited movement type anti-wear sucker rod can also be used for scraping wax and the sucker rod can be prevented from releasing.

Owner:程佑富

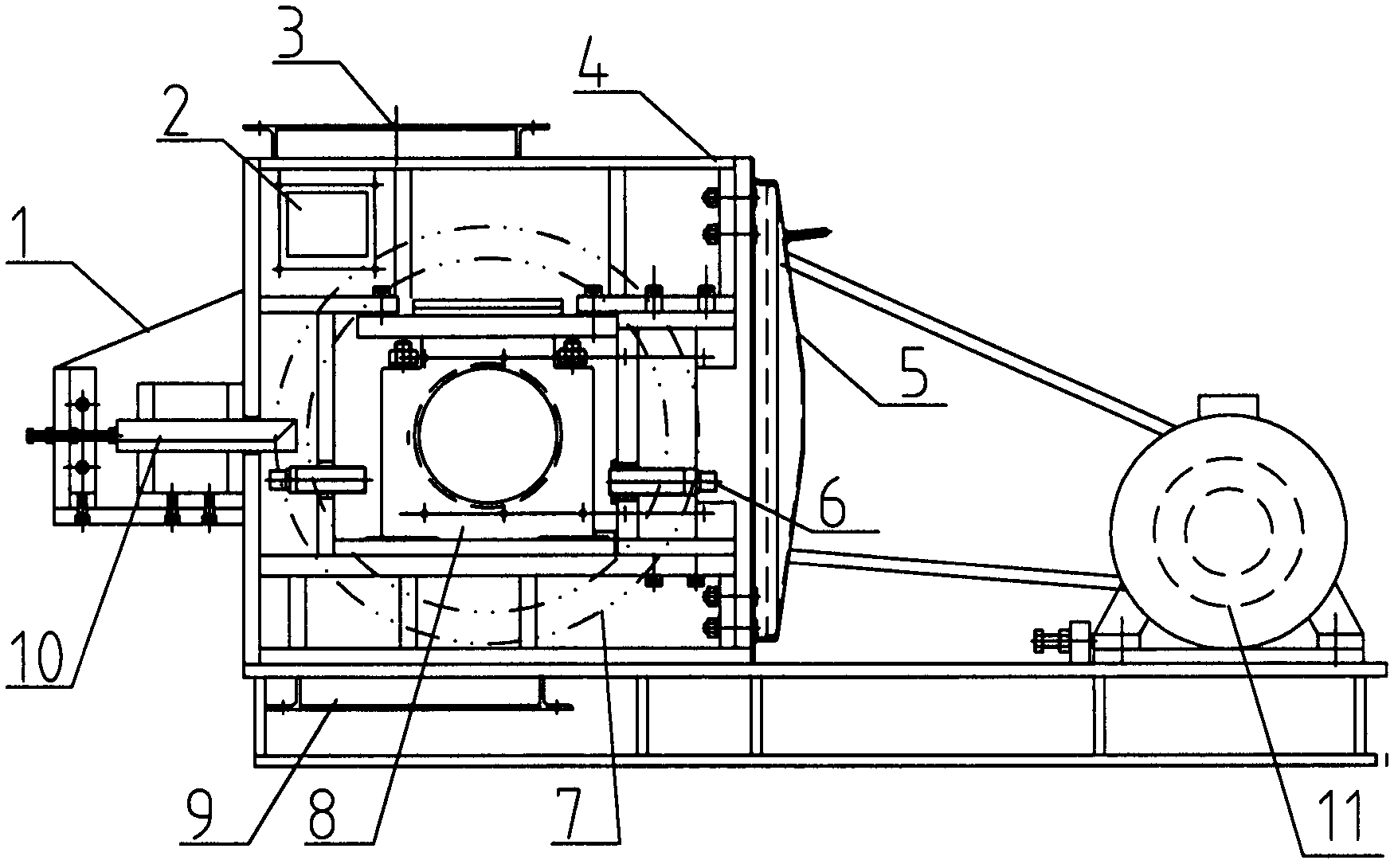

Heavy-duty crushing machine

The invention relates to a heavy-duty crushing machine. According to the invention, a motor and a rotor of the crushing machine are connected by using a belt; a feeding port is arranged on the top of the heavy-duty crushing machine, and is connected to a frame; a discharging port is arranged below the heavy-duty crushing machine; and the rotor is arranged on a bearing pedestal, and is fixed on the frame. With the crushing machine, during a material crushing procedure, adhesion or blocking does not occur, an over crushing rate is low, the noise is low, the vibration is low, a dust amount is low, the energy consumption is low, and the land occupation is low. There is no requirement on the water content of the material requiring crushing.

Owner:广西南宁东创通用机械设备工程有限公司

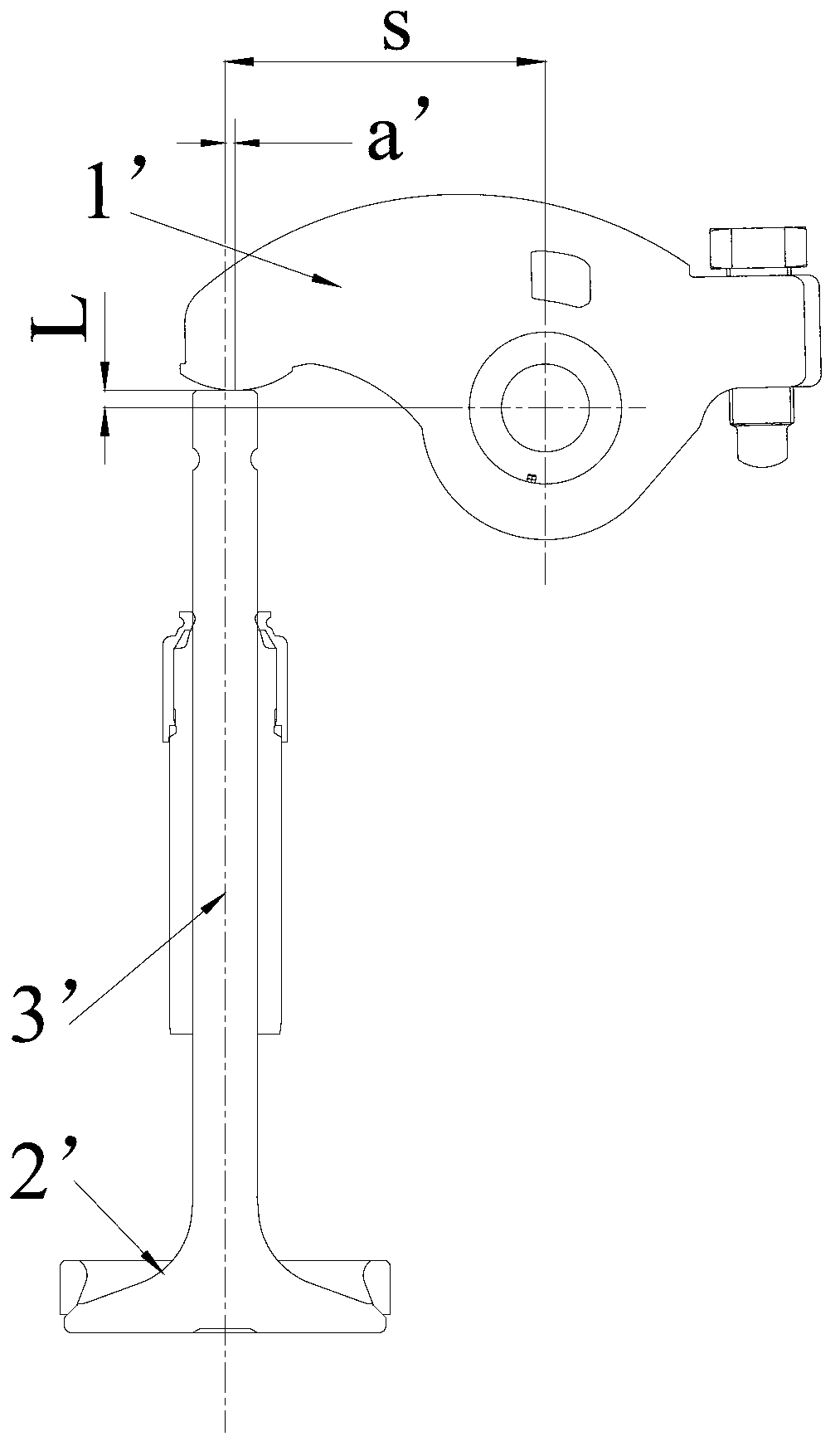

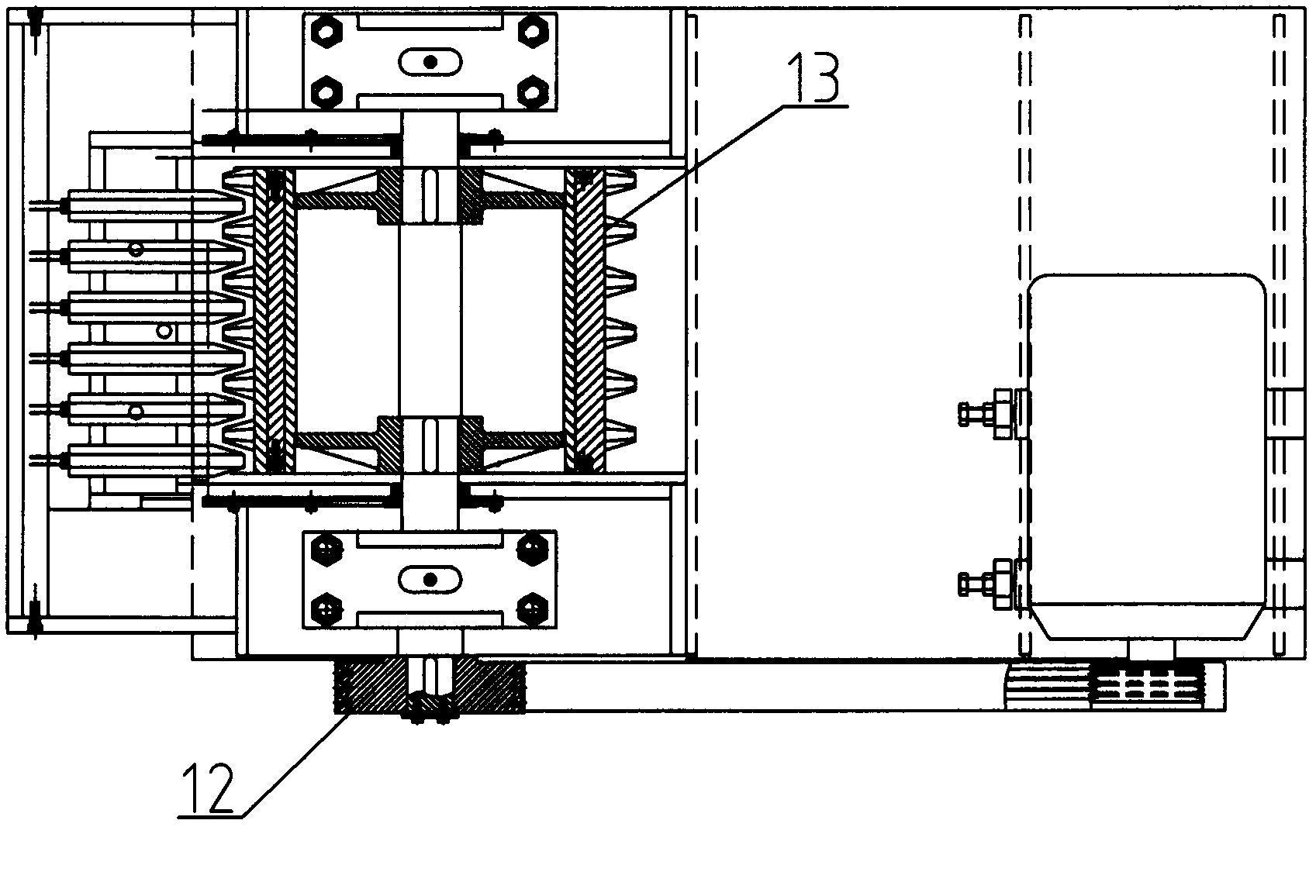

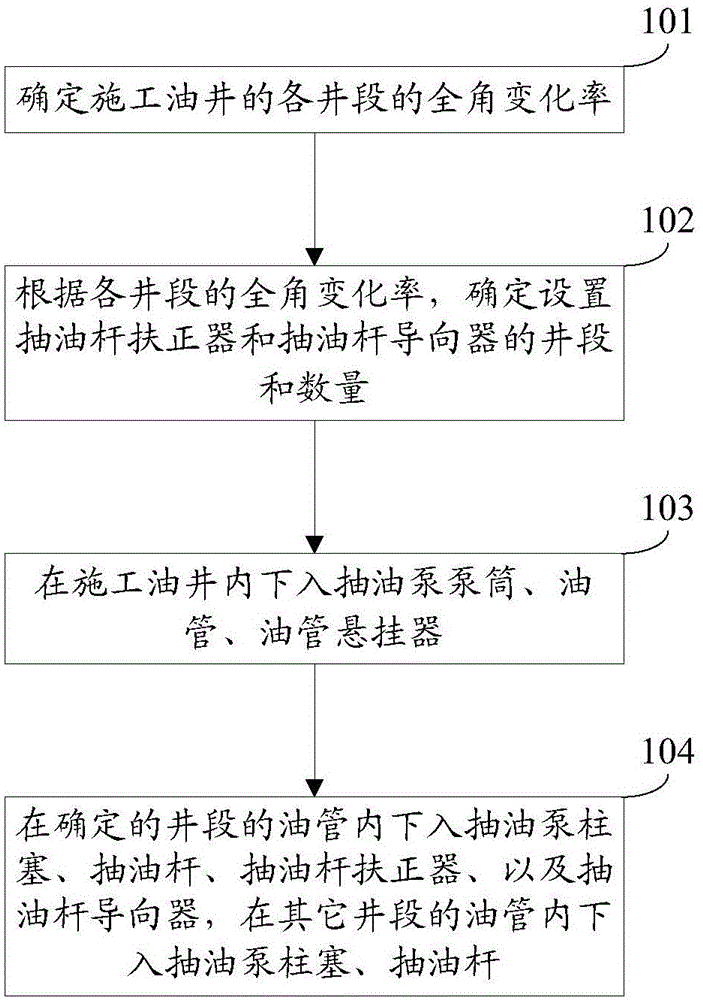

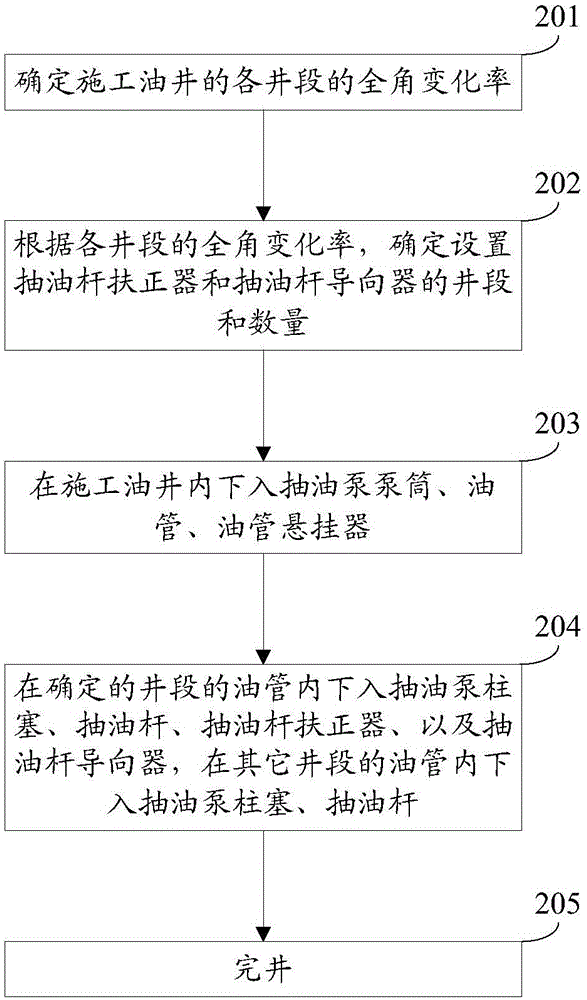

Method for preventing eccentric wearing of sucker rod and tube

ActiveCN105064929ASolve partial wearThe average pump inspection cycle is extendedDrilling rodsDrilling casingsTubing hangerOil production

The invention discloses a method for preventing eccentric wearing of a sucker rod and tube, and belongs to the field of oil industry oil production engineering. The method comprises the following steps of: determining the overall angle change rate of each well section of a construction oil well; determining the well sections provided with sucker rod centralizers and sucker rod guide devices and the number of the sucker rod centralizers and the sucker rod guide devices according to the overall angle change rate of each well section; feeding a pump tube of an oil sucking pump, an oil tube and a sucker tube suspender into the construction oil well; feeding an oil sucking pump plunger piston, the sucker rod, the sucker rod centralizers and the sucker rod guide devices into an sucker tube of the determined well section; and feeding the oil sucking pump plunger piston and the sucker rod into the sucker tube of other well sections, wherein the other well sections refer to well sections beyond the determined well section in each well section of the construction oil well. The method has the advantage that after the application to sites of more than 30 oil wells, the single-well average pump checking period of the oil well is prolonged by 307 days.

Owner:PETROCHINA CO LTD

Automatic centering and deviation-adjusting sealing device for wellhead of oil well

PendingCN114856475AReasonable structural designIncrease productionSealing/packingScrew threadMechanics

The invention relates to an automatic centering and deviation-adjusting sealing device for an oil well mouth, which belongs to oil well mouth equipment and is formed by sequentially connecting an internal thread connector, a centering and deviation-adjusting device and a blowout prevention box, and the centering and deviation-adjusting device is formed by sequentially connecting a universal connector, a main packing cylinder and an auxiliary packing cylinder from bottom to top. The universal connector is in threaded connection with a lower opening of the main packing cylinder, an upper opening of the main packing cylinder is in threaded connection with a lower opening of the auxiliary packing cylinder, and an upper opening of the auxiliary packing cylinder is in threaded connection with a lower opening of the blowout prevention box. Horizontal sealing holes are formed in the main packing cylinder and the packing cylinder, sealing blocks and sliding blocks are sequentially inserted into the sealing holes from inside to outside, and the thrust rotating disc is clamped outside the sliding blocks and matched with the sliding blocks in a rotating mode. According to the device, the automatic centering and deviation adjusting function can be achieved, automatic translation centering of 14 mm and automatic deviation adjusting of 2 degrees can be achieved, sealing blocks in the main packing cylinder and the auxiliary packing cylinder forcibly center a polish rod in the packing cylinders, the problem of eccentric wear of packing and a packing box is solved, meanwhile deviation adjusting and center fixing are combined, and the deviation adjusting angle is increased.

Owner:王亚祥

Piston assembly and application thereof

ActiveCN111911397ASolve the problem of piston eccentric wearTroubleshoot the problemPositive displacement pump componentsFlexible member pumpsReciprocating motionIntake pressure

The invention belongs to the technical field of compressors, and particularly relates to a piston assembly and application thereof. In an actual production process, the phenomena of poor final centering between a piston and a piston cylinder, eccentric wear of the piston and sealing failure due to insufficient machining precision easily occur. The piston assembly provided by the invention comprises a crosshead component, a piston component and a middle body component, wherein the piston component comprises a piston rod; one end of the piston rod is connected to a crosshead and a displacement component is arranged at a joint of the two, so that the piston rod has a certain radial displacement; and the other end of the piston rod is connected to the piston in a joint mode, so that the pistonrod has a certain deflection, and good centering between the piston and the piston cylinder is guaranteed. A piston pull-back rod is arranged at the end, connected to the piston, of the piston rod, and when the intake pressure is too small to push the piston to move downwards or the piston is blocked, the piston pull-back rod can pull the piston to continue to do regular reciprocating motion.

Owner:XI AN JIAOTONG UNIV +1

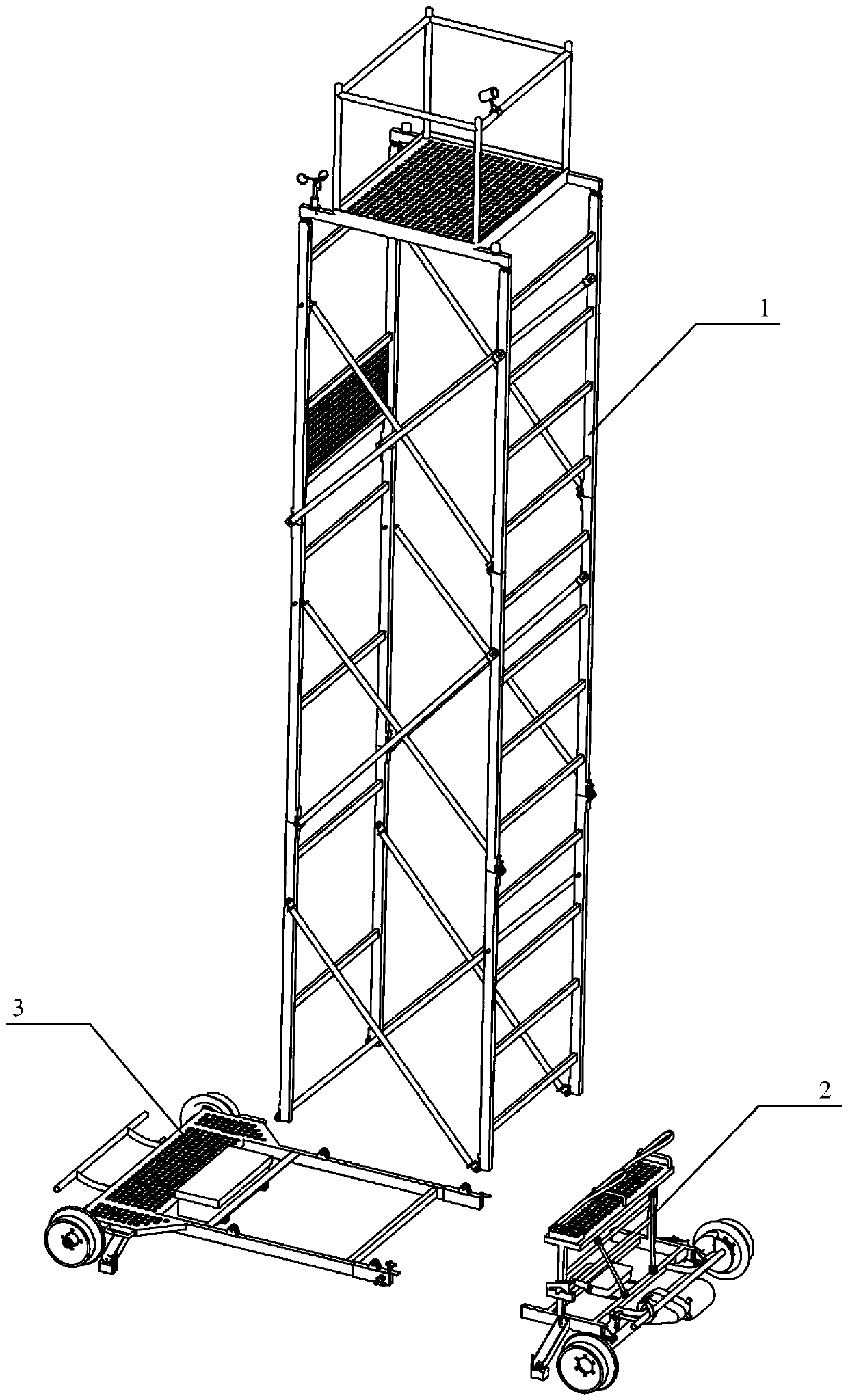

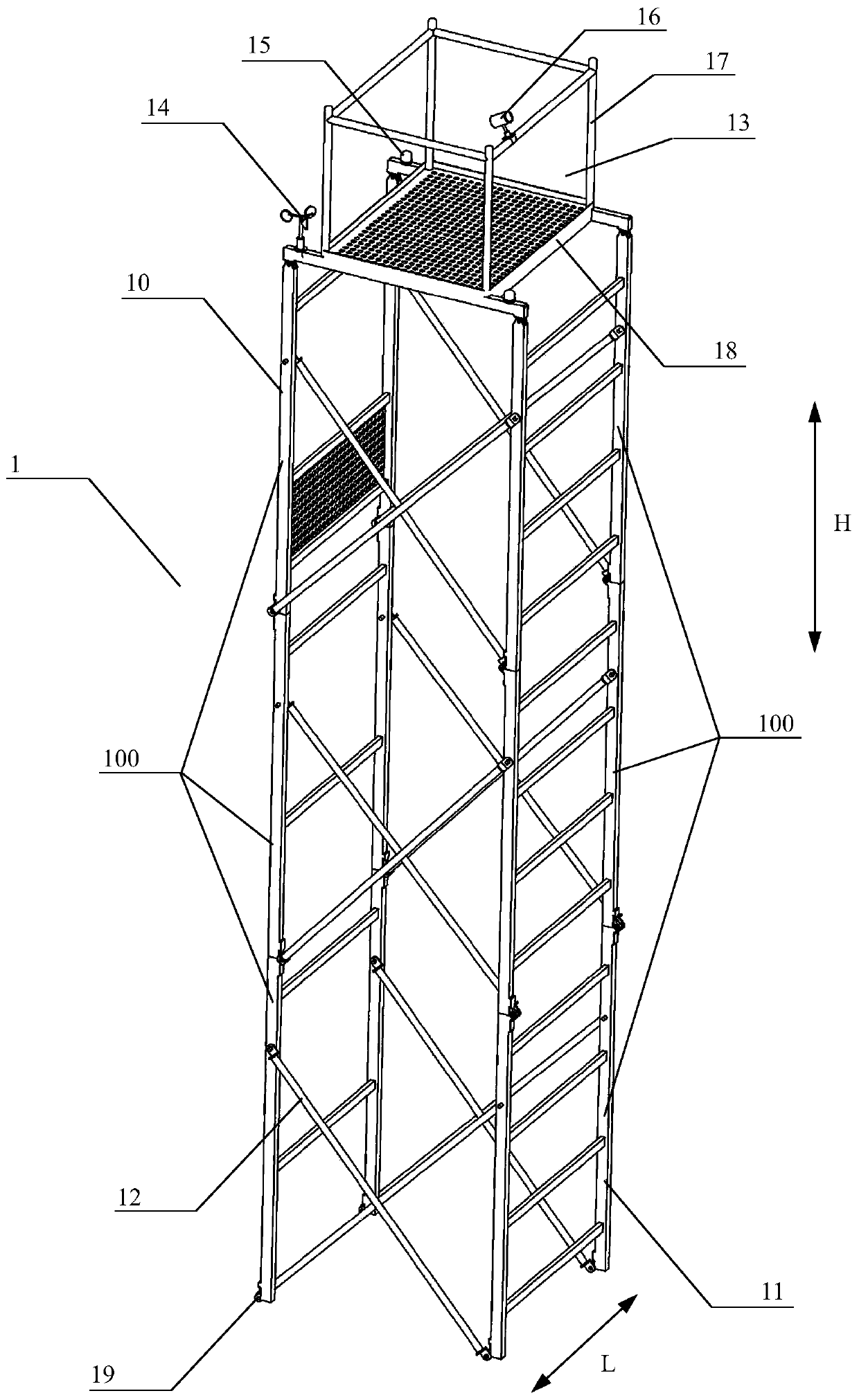

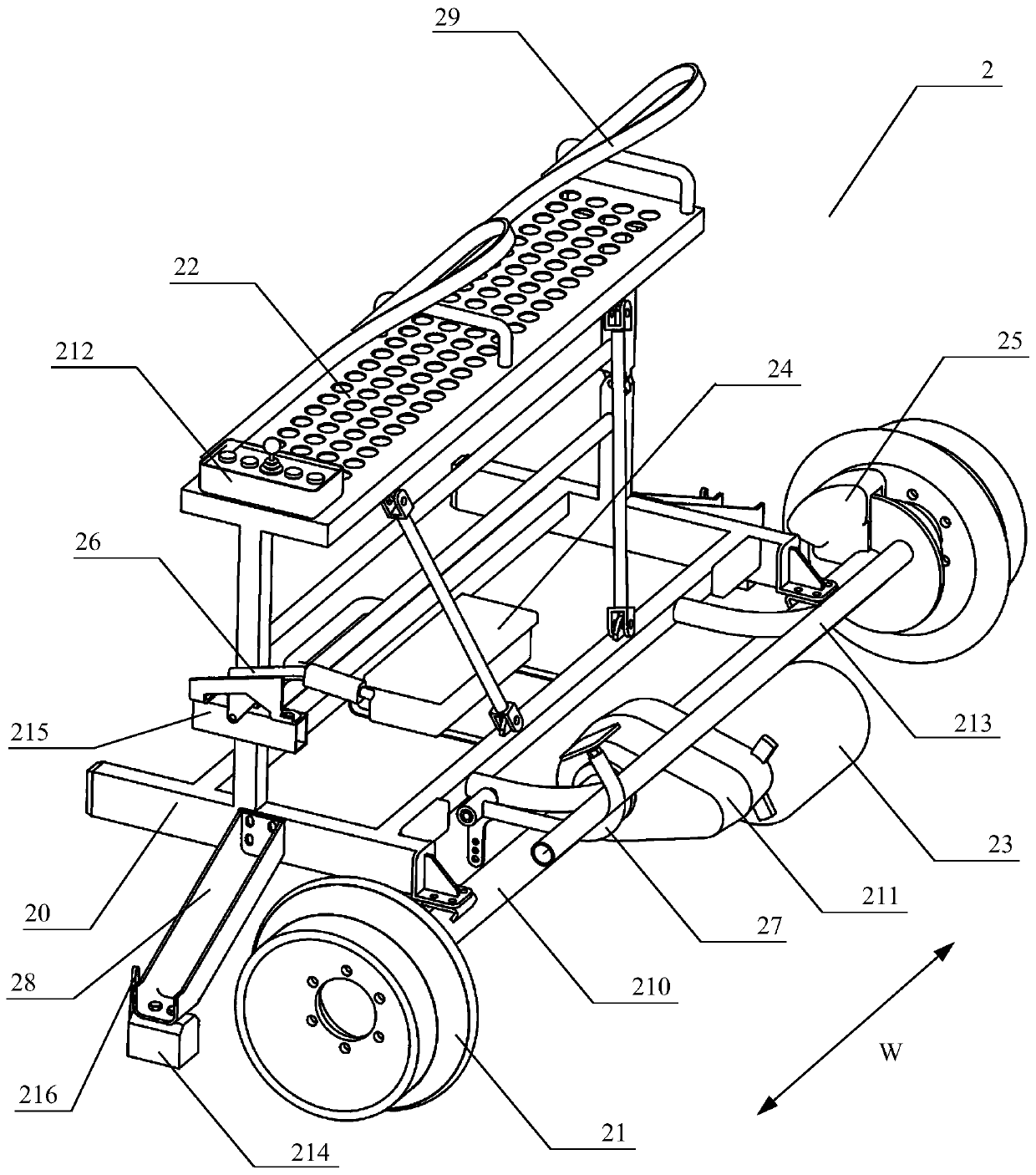

A railway maintenance work platform

ActiveCN109017876BSimple structureSimple partsVehicle servicing/repairingRailway auxillary equipmentControl theoryAutomotive engineering

The invention discloses a railway maintenance operation platform, which comprises a ladder frame module, a chassis frame 1 and a chassis frame 2. The chassis one and the chassis two are connected to form a movable platform which is self-driven and can travel along the rail. The chassis one and the chassis two are connected to form a movable platform. The ladder module is fixed on the mobile platform, and a work platform is arranged on the top of the ladder module. The chassis 1 and the chassis 2 are connected by a quick pin shaft. A support is arranged on that chassis 2, and the bottom of theladder module is fix on the support by a snap device. The invention can solve the technical problems existing in the existing railway maintenance operation platform, such as complex structure, numerous components, more operators, time-consuming assembly and low modularization degree.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

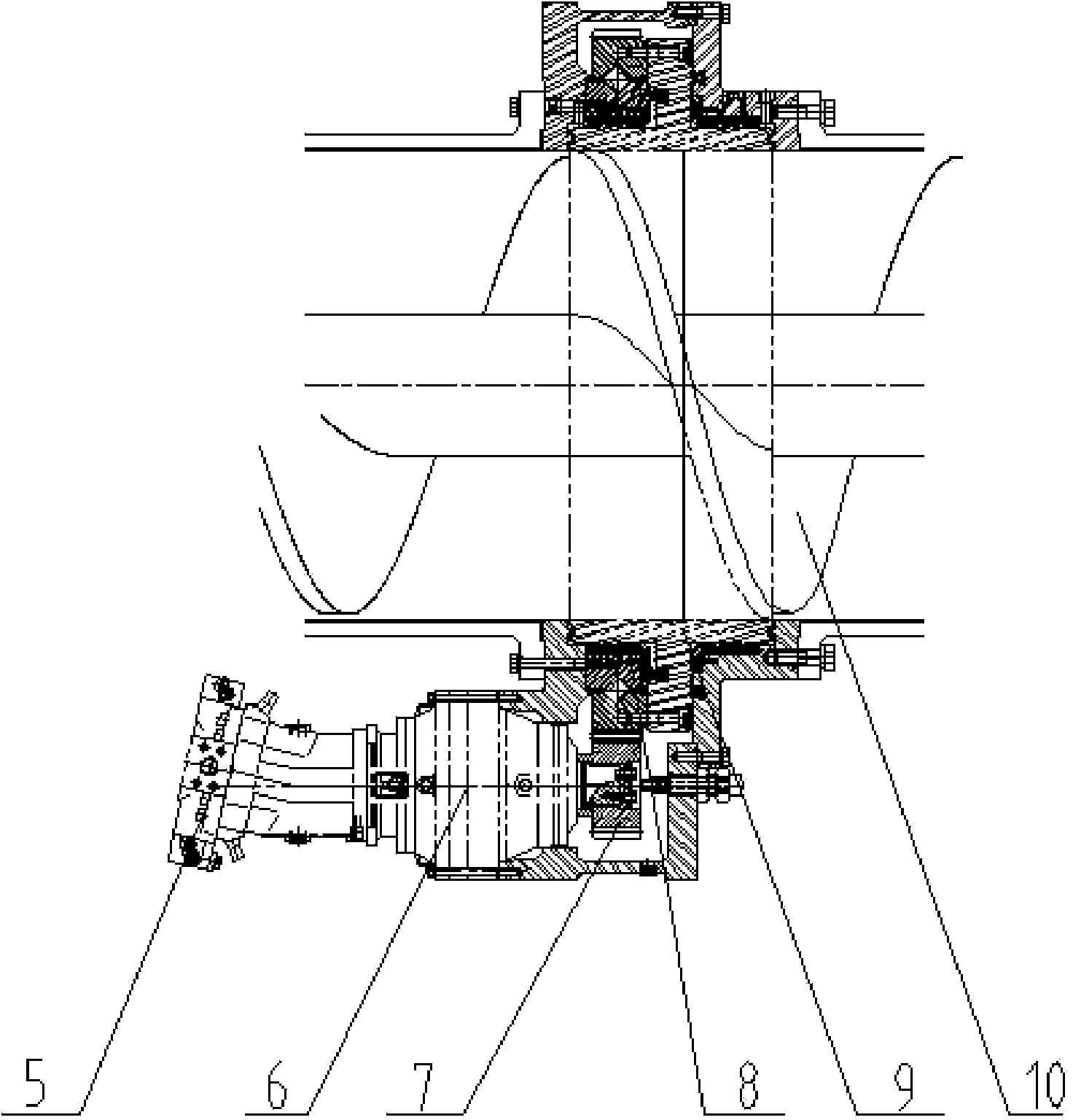

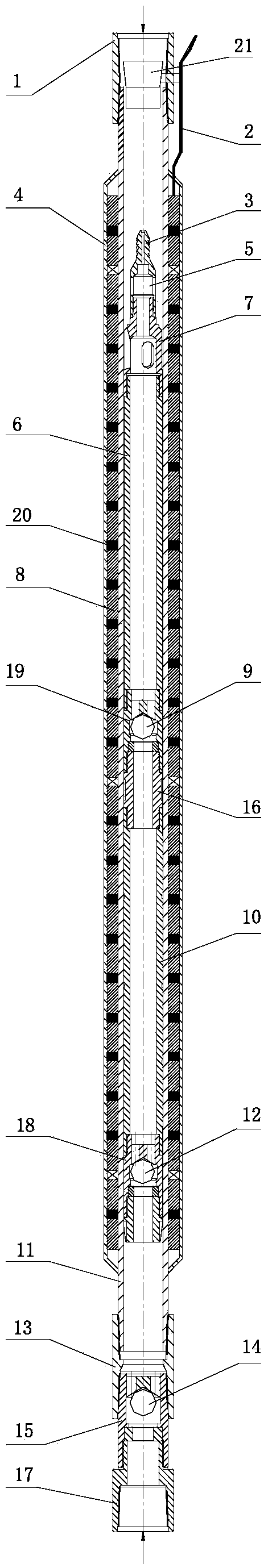

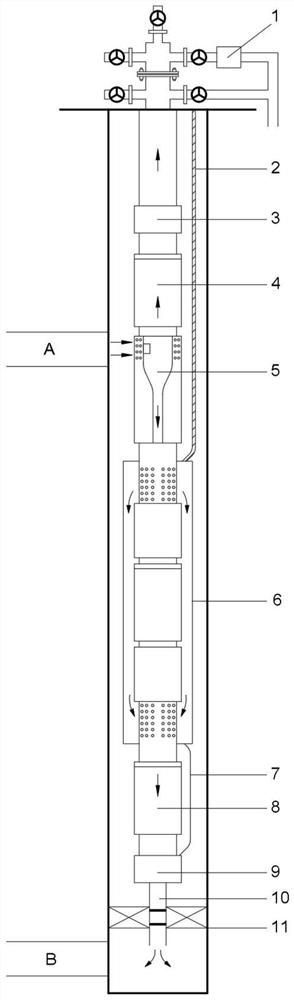

Downhole oil-water separation and same well injection-production device and method capable of utilizing single motor to drive two pumps

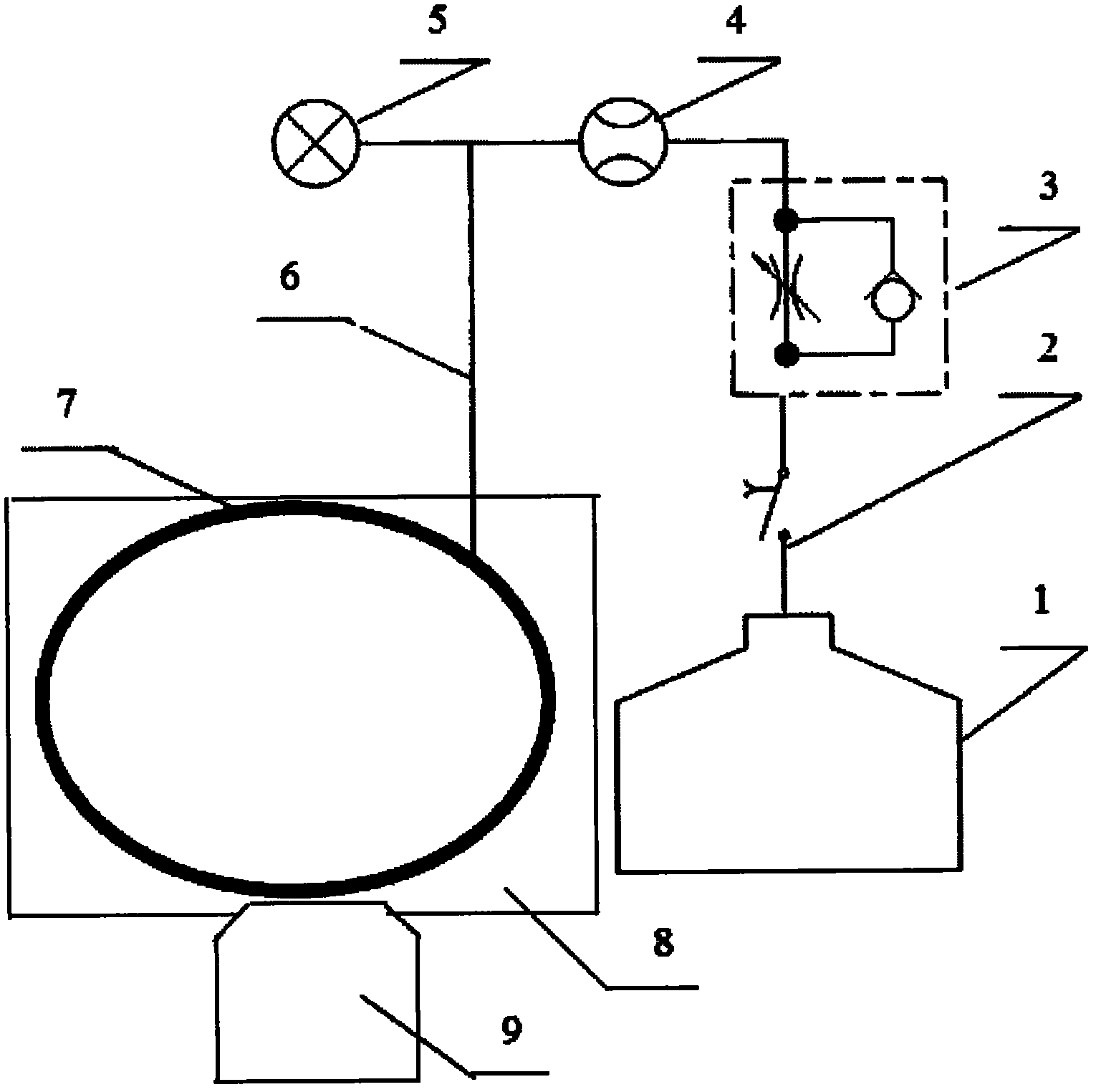

ActiveCN111608638AImprove separation efficiencyAchieve regulationFluid removalPower cableElectric machine

The invention relates to the technical field of oil production technology, discloses a downhole oil-water separation and same well injection-production device and method capable of utilizing a singlemotor to drive two pumps, and aims to solve the problems that according to the screw pump extraction-electric pump injection scheme of the original same well injection-production technology, the eccentric wear of a rod and tube is serious, the pump inspection period is short, and the one-time invested cost is high. The downhole oil-water separation and same well injection-production device is composed of a pressure adjusting valve (1), a power cable (2), a check valve (3), an extraction pump (4), a hydrocyclone (5), a submersible motor (6), a signal cable (7), an injection pump (8), a downholemulti-parameter sensor (9), a sealing section (10) and a packer (11). The device can use one submersible motor to simultaneously drive two electric submersible pumps, controls the injected liquid quantity and the extracted liquid quantity through a ground control cabinet and the pressure adjusting valve separately, and has the advantages of being adjustable independently, high in oil-water separating efficiency and low in one-time invested cost of an injection-production system.

Owner:PETROCHINA CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com