Flexible shaft transmission device of submersible direct-drive screw pump

A transmission device and flexible shaft technology, applied in the direction of pumps, pump components, machines/engines, etc., can solve the problems of large space occupation, rod and tube eccentric wear equipment efficiency, high cost, etc., achieve less floor space, solve rod and tube eccentricity Grinding problems and the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

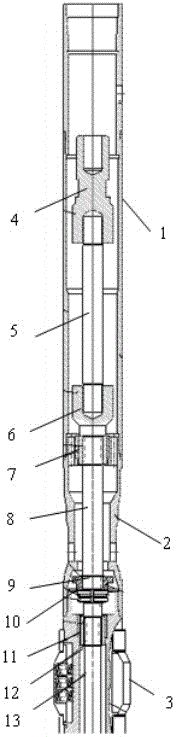

[0028] In order to overcome the common problems of eccentric wear of rods and pipes in directional wells, low equipment efficiency, large space occupation, and high cost, this embodiment provides a method such as figure 1 The flexible shaft transmission device of the submersible direct drive screw pump shown, the transmission device includes a long connecting pipe 1, a stator connecting pipe 2 and a centralizer 3 connected sequentially from top to bottom;

[0029] The inside of the long connecting pipe 1 is sequentially connected with an upper screw connector 4, a flexible shaft 5 and a lower screw connector 6 from top to bottom;

[0030] The stator connecting pipe 2 is provided with a connecting shaft 8 inside;

[0031] The centralizer 3 is provided with a lower connecting pipe 13 inside;

[0032] The long connecting pipe 1 top is provided with a suction port, the bottom of the lower screw connecting head 6 is connected with the upper part of the connecting shaft 8 through t...

Embodiment 2

[0038] In order to overcome the common problems of eccentric wear of rods and pipes in directional wells, low equipment efficiency, large space occupation, and high cost, this embodiment provides a method such as figure 1 The shown flexible shaft transmission device of the submersible direct drive screw pump includes a screw pump, a transmission device and a motor connected sequentially from top to bottom, and the transmission device includes a long connecting pipe 1 connected sequentially from top to bottom, a stator connecting pipe 2 and a centralizer 3; the inside of the long connecting pipe 1 is sequentially connected with an upper screw connecting head 4, a flexible shaft 5 and a lower screw connecting head 6; the inside of the stator connecting pipe 2 is provided with a connecting shaft 8; The centralizer 3 is provided with a lower connecting pipe 13 inside; the upper part of the long connecting pipe 1 is provided with a suction port, the lower part of the lower screw con...

Embodiment 3

[0041] In order to overcome the common problems of eccentric wear of rods and pipes in directional wells, low equipment efficiency, large space occupation, and high cost, this embodiment provides a method such as figure 1 The shown flexible shaft transmission device of the submersible direct drive screw pump includes a screw pump, a transmission device and a motor connected sequentially from top to bottom, and the transmission device includes a long connecting pipe 1 connected sequentially from top to bottom, a stator connecting pipe 2 and a centralizer 3; the inside of the long connecting pipe 1 is sequentially connected with an upper screw connecting head 4, a flexible shaft 5 and a lower screw connecting head 6; the inside of the stator connecting pipe 2 is provided with a connecting shaft 8; The centralizer 3 is provided with a lower connecting pipe 13 inside; the upper part of the long connecting pipe 1 is provided with a suction port, the lower part of the lower screw con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com