Multi-layer laminated elastic-plastic alloy automatic fluid lubricating bearing and manufacturing method thereof

A technology for lubricating bearings and manufacturing methods, which is applied in the direction of sliding contact bearings, bearings, flexible bearings, etc., can solve the problems of low load-carrying capacity, not supporting dry start, etc., and achieve the effect of superior dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for manufacturing a multilayer laminated elastic-plastic alloy self-lubricating bearing, comprising the following steps:

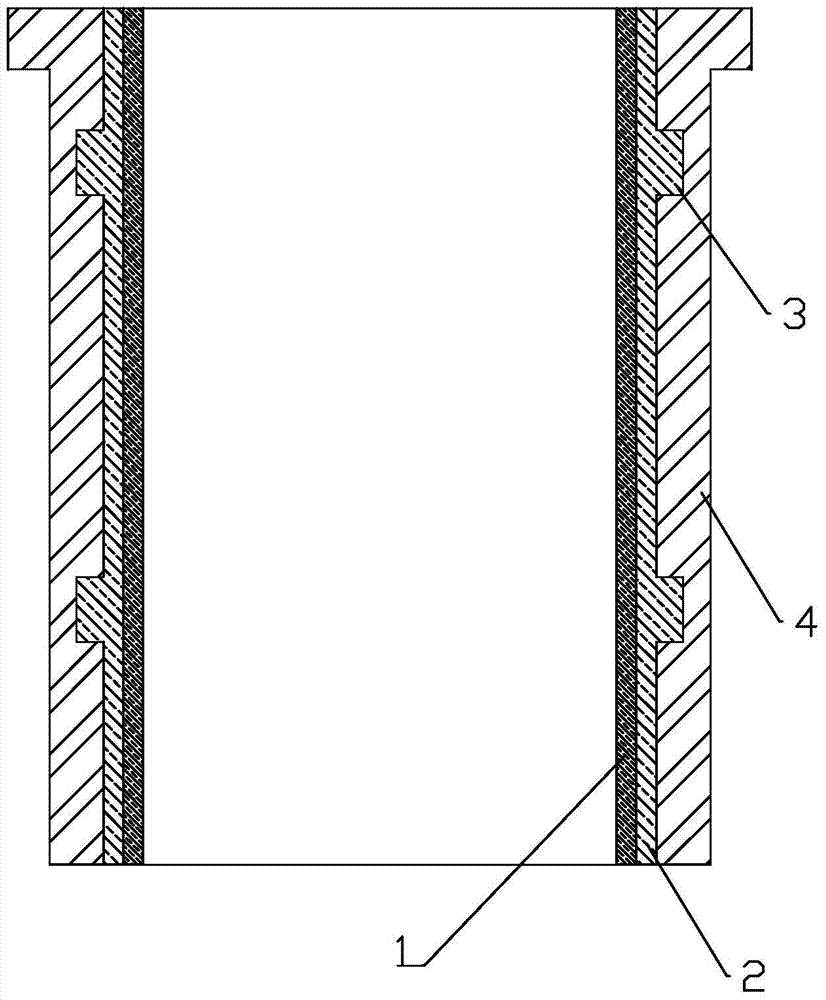

[0046] 1) Several axial limit ring grooves and radial limit dovetail grooves are processed on the inner surface of the bearing;

[0047] 2) Sand the inner surface of the bearing to remove oil stains;

[0048] 3) Apply the adhesive CH219 on the inner surface of the bearing with a thickness of 20 μm and dry it at room temperature, then apply the adhesive CH213 with a thickness of 20 μm and dry it at room temperature, then put the workpiece coated with the adhesive into the oven Pre-bake at 125°C for 2.5 hours to form an adhesive layer;

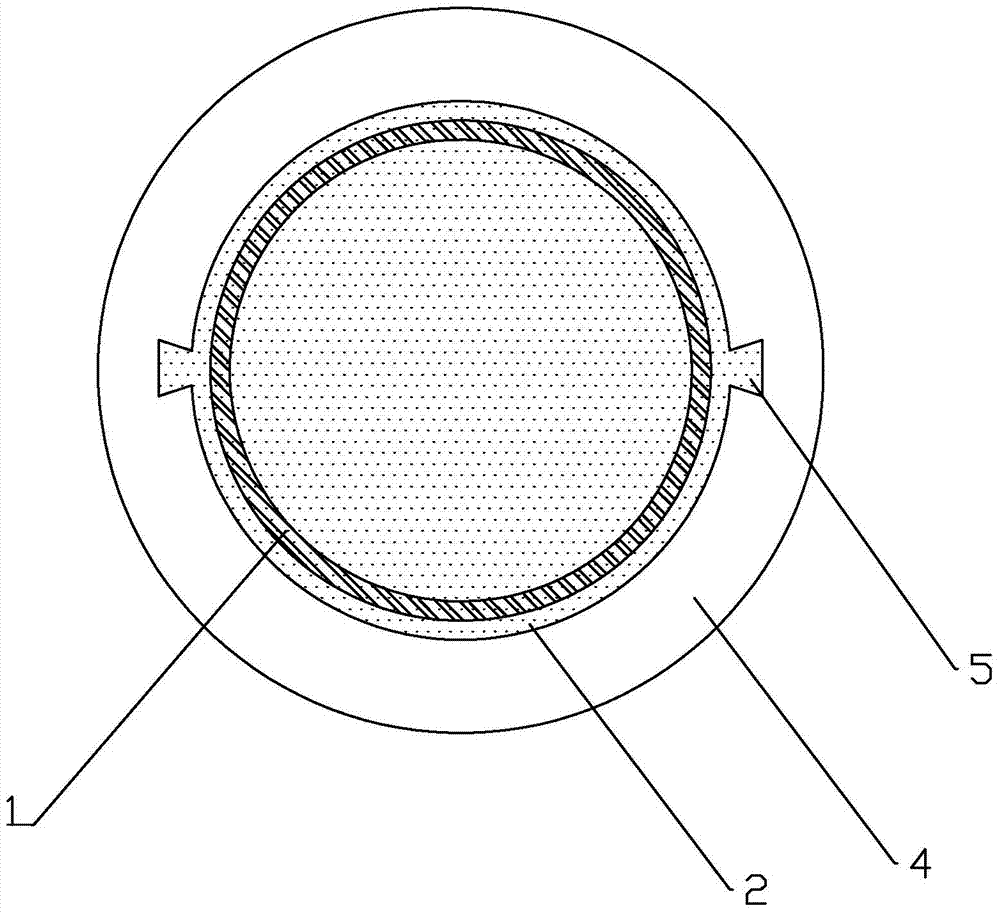

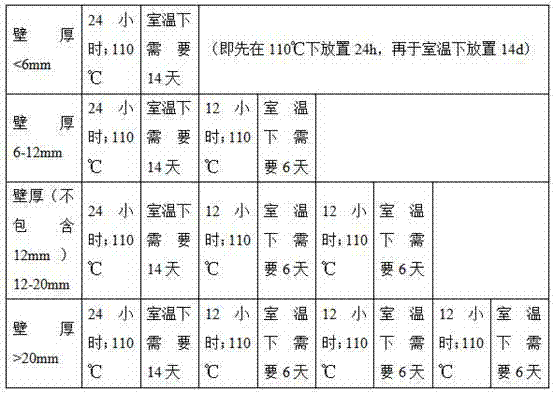

[0049] 4) Centrifugally coat the elastic cushioning layer (Vulkollan type polyurethane elastomer) on the adhesive layer. When the cushioning layer is nearly completely cured, that is, the cushioning layer is in a drawing state, then centrifugally coat the bearing layer and cure; after curing, The thickness ...

Embodiment 2

[0053] A method for manufacturing a multilayer laminated elastic-plastic alloy self-lubricating bearing, comprising the following steps:

[0054] 1) Two axial limit ring grooves and three radial limit dovetail grooves are processed on the inner surface of the bearing;

[0055] 2) Sand the inner surface of the bearing to remove oil stains;

[0056] 3) Apply the adhesive CH219 on the inner surface of the bearing with a thickness of 20 μm and dry it at room temperature, then apply the adhesive CH213 with a thickness of 20 μm and dry it at room temperature, then put the workpiece coated with the adhesive into the oven Pre-bake at 125°C for 2.5 hours to form an adhesive layer;

[0057] 4) Centrifugally coat the elastic cushioning layer (CHEMTURA L 100 polyurethane elastomer) on the adhesive layer. When the cushioning layer is nearly completely cured, that is, the cushioning layer is in a drawing state, then centrifugally coat the bearing layer and cure; after curing , the thickne...

Embodiment 3

[0061] A method for manufacturing a multilayer laminated elastic-plastic alloy self-lubricating bearing, comprising the following steps:

[0062] 1) Several axial limit ring grooves and radial limit dovetail grooves are processed on the inner surface of the bearing;

[0063] 2) Sand the inner surface of the bearing to remove oil stains;

[0064] 3) Coat the adhesive CH219 on the inner surface of the bearing with a thickness of 20 μm and dry it at room temperature, then apply the adhesive CH213 with a thickness of 20 μm and dry it at room temperature, then put the workpiece coated with the adhesive into the oven Pre-bake at 125°C for 2.5 hours to form an adhesive layer;

[0065]4) Centrifugally coat the elastic cushioning layer (CHEMTURA L 167 polyurethane elastomer) on the adhesive layer. When the cushioning layer is nearly completely cured, that is, the cushioning layer is in a drawing state, then centrifugally coat the bearing layer and cure; after curing , the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com