Conjugate cam type high-speed pot seedling transplanting mechanism

A conjugated cam and cam-type technology, which is applied in the field of agricultural machinery, can solve the problems of high quality requirements, complex mechanism, and low efficiency of pot seedlings, and achieve outstanding dynamic performance, improved transplanting efficiency, and good transplanting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

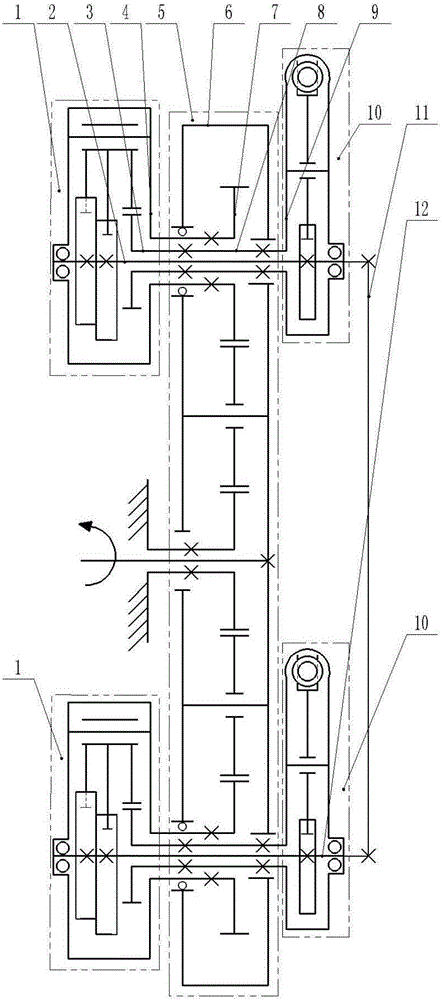

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A conjugate cam type high-speed pot seedling transplanting mechanism includes a planetary gear mechanism 5, a conjugate cam swing mechanism 1 and a transplanting arm assembly 10, on the planetary gear mechanism 5, the positions differ by 180° along the circumferential direction The first planetary shaft 2 and the second planetary shaft 12 are respectively inserted and fitted symmetrically and rotatably, on the first planetary shaft 2 and the second planetary shaft 12, the planet carrier housing 6 of the planetary gear train mechanism 5 is located At the inner part, through the installation and cooperation with the cam box 4 of the conjugate cam swing mechanism 1, the conjugate cam swing mechanism 1 is rotatably fitted on the first and second planet shafts 2, 12 respectively, and the first planet On the shaft 2 and the second planetary shaft 12, at the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com