Horizontal well self-centering moving piston type cone valve pump

A self-centering, horizontal well technology, applied to variable displacement pump components, pumps, pump components, etc., to achieve the effect of solving the problem of eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

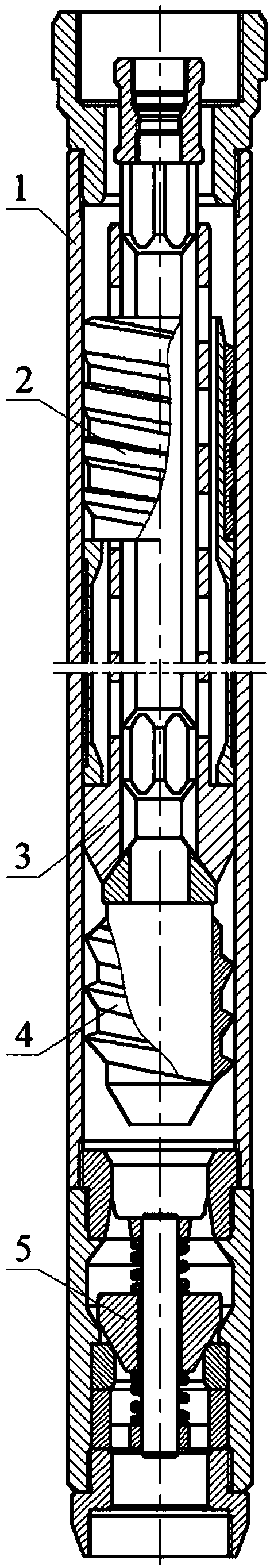

[0041] exist figure 1 Among them, the horizontal well self-centering moving plug cone valve pump is mainly composed of pump barrel 1, sand-scraping plunger 2, floating cone valve 3, stirring centering device 4 and fixed cone valve 5, which can realize liquid production Timely discharge of sand particles, self-centering of the sand-scraping plunger 2 and the floating cone valve 3, and smooth opening and closing of the floating cone valve 3 and the fixed cone valve 5, to solve the sand wear between the pump cylinder 1 and the sand-scraping plunger 2 and eccentric wear, horizontal well valve leakage, and difficulty in opening and closing of the valve ball. The upper part of the movable plug type cone valve pump is fixed to the bottom end of the tubing string through the pump barrel collar of the pump barrel 1, and the lower part is connected with the gas anchor and tailpipe by the gas anchor collar fixing the cone valve 5, and scraping at the same time The sand type plunger 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com