Deep well single-action hydraulic piston pump

A hydraulic piston, single-acting technology, applied to piston pumps, pumps with flexible working elements, pumps, etc., can solve problems such as impact damage, no flow channel, slide valve fluid erosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

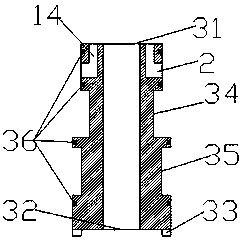

[0018] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in detail:

[0019] first look figure 1 and image 3 , after being pressurized by the surface pump, the power fluid flows through the fishing assembly 1, enters the first flow channel 3 through the right communication hole 2 of the slide valve, and enters the lower cavity 19 of the upper cylinder and the lower cavity 10 of the lower cylinder through the first flow channel 3. At the same time, the high-pressure power fluid flows through the second channel 4 and enters the chamber formed by the slide valve 15 and the upper baffle 6 , and the high-pressure power fluid acts on the lower end surface 32 of the slide valve. The high-pressure power fluid acts on the upper end surface 31 of the spool valve and the lower end surface 32 of the spool valve respectively, but because the area of the lower end surface 32 of the spool valve is larger than the area of the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com