Piston assembly and application thereof

A piston assembly and piston technology, applied in the field of compressors, can solve the problems of diaphragm rupture, eccentric wear of the piston assembly, and seal failure, and achieve the effect of solving the eccentric wear of the piston.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Hereinafter, specific embodiments of the present application will be described in detail with reference to the accompanying drawings. According to these detailed descriptions, those skilled in the art can clearly understand the present application and can implement the present application. Without departing from the principle of the present application, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

[0035] The crosshead 1 is a part connecting the piston rod and the piston, which converts the rotary motion of the crankshaft into the reciprocating motion of the piston, and has a guiding effect.

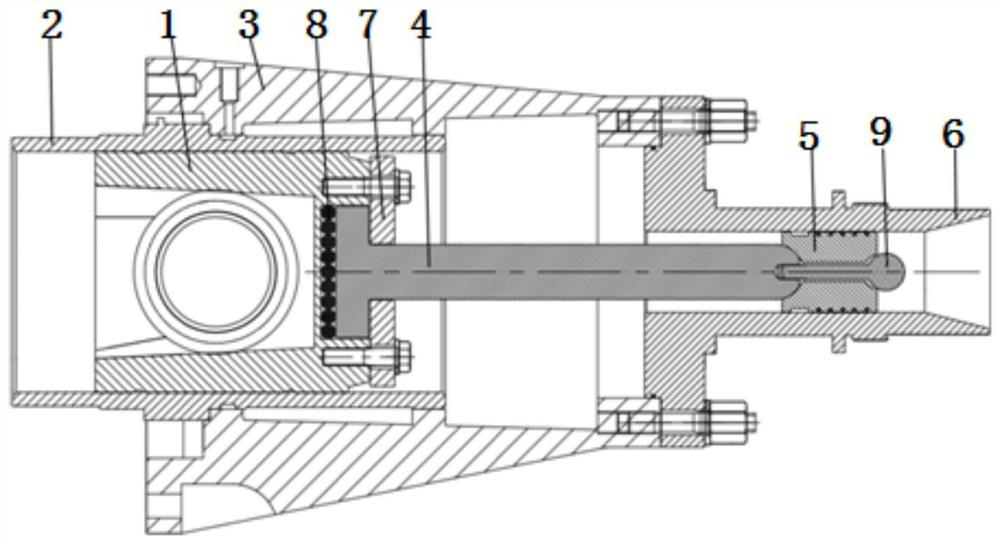

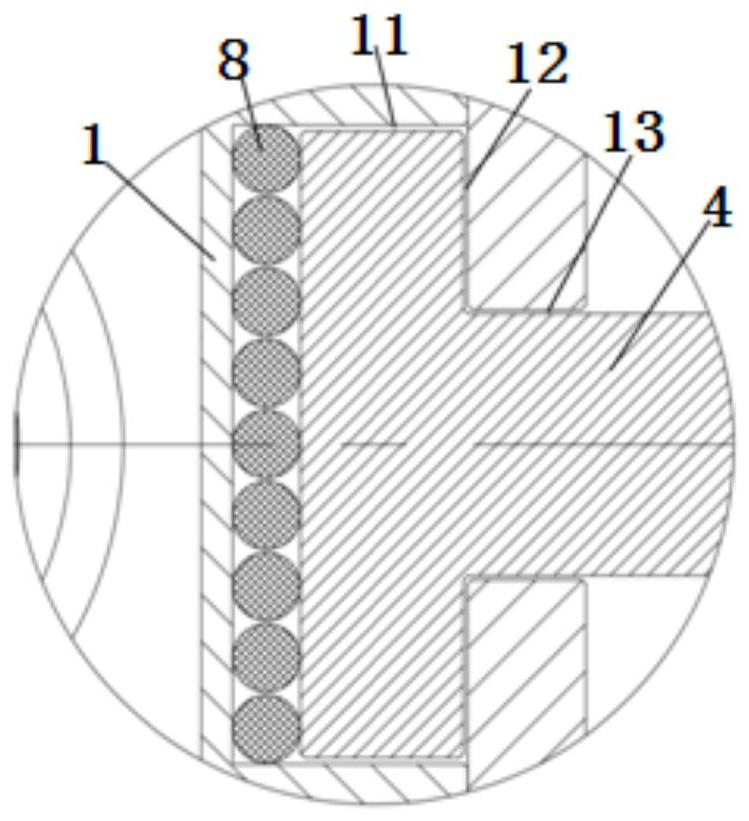

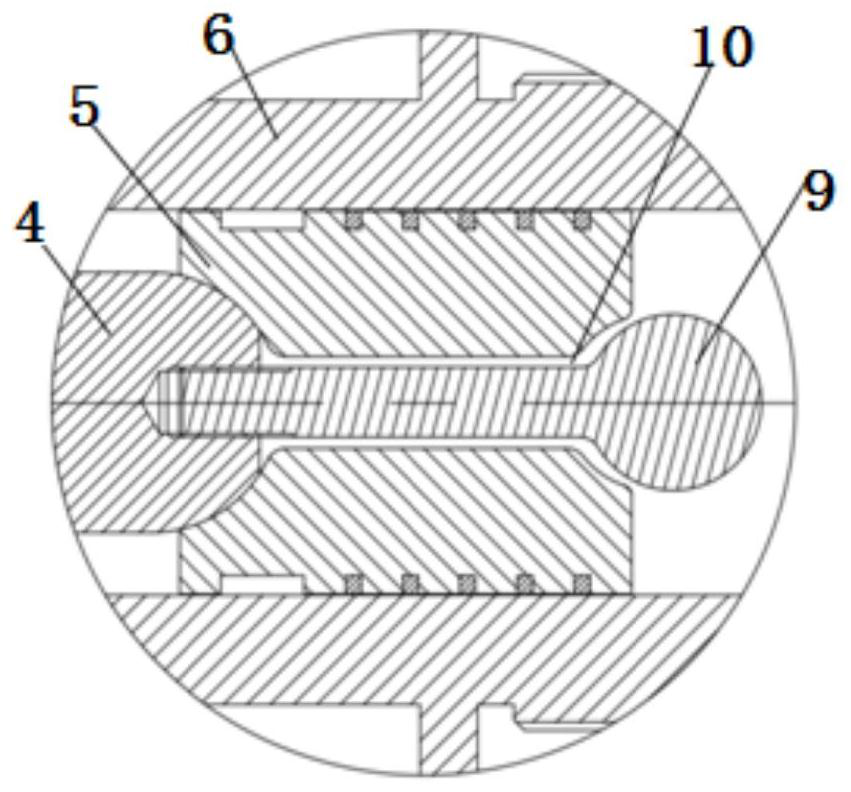

[0036] see Figure 1~4 , the application provides a piston assembly, including a crosshead member, a piston member and a middle body member 3, the crosshead member is connected with the piston member, the crosshead member is connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com