High pressure casing sensor and testing method thereof

A technology of high-voltage bushing and test method, applied in the field of sensors, can solve the problems of reducing the service life, increasing the cost, and the grounding metal flexible wire cannot be effectively and reliably grounded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

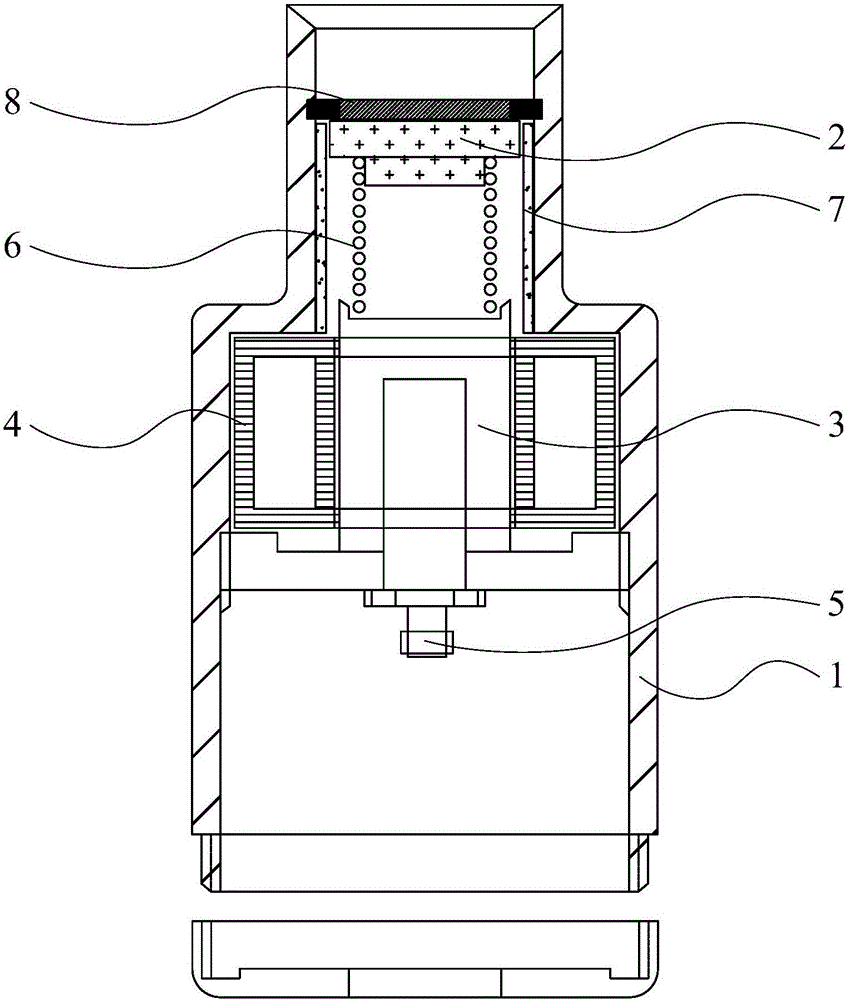

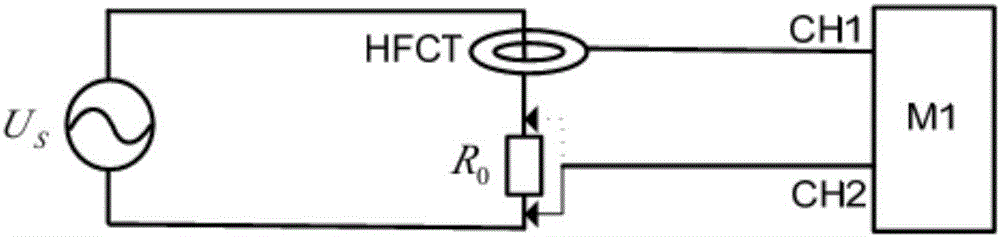

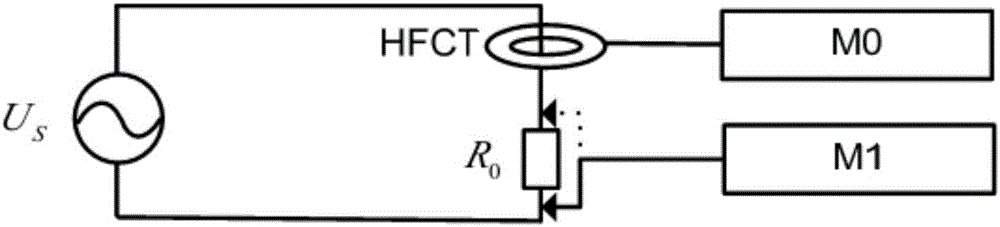

[0028] The present invention provides a high-voltage bushing sensor, which includes a casing 1 and a slider 2 arranged inside the casing 1, and also includes a grounding connection seat 3 arranged inside the casing 1, and the grounding connection seat 3 is surrounded by the casing 1. It forms a closed grounding circuit, and the grounding connection seat is made of brass with nickel-plated surface, which ensures the reliable grounding of the end of the bushing and solves the problem of failure caused by changing the grounding of the end screen of the bushing in the traditional method, and the shell is fully enclosed The metal shielding structure ensures that the internal induction circuit of the sensor is not affected by the external electromagnetic field. The signal acquisition device 4 is arranged outside the ground connection seat 3. The signal acquisition device 4 is a high-frequency mutual induction coil, so that the signal extraction is completely isolated from the lead wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com