Downhole oil-water separation and same well injection-production device and method capable of utilizing single motor to drive two pumps

A single-motor-driven, oil-water separation technology, applied in wellbore/well components, production fluid, earthwork drilling and production, etc., can solve the problems of rod and pipe eccentric wear, short pump inspection period, high investment cost, etc., to solve the problem of rod and pipe deviation Grinding, reducing input costs, and prolonging the effect of pump inspection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

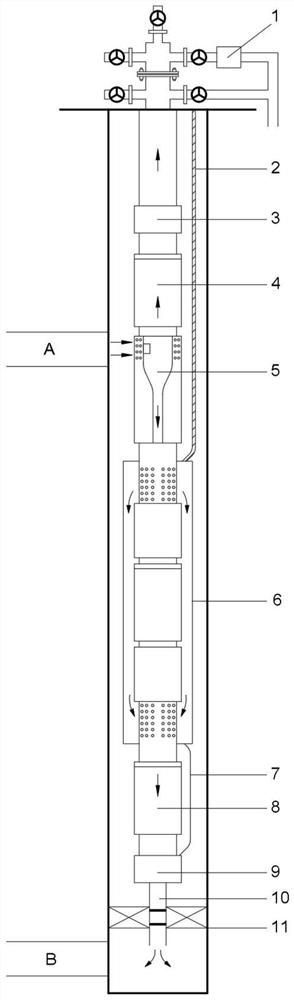

[0023] Specific embodiments: The present invention will be further described below in conjunction with the accompanying drawings: a single-motor-driven double-pump downhole oil-water separation and injection-production device in the same well consists of a pressure regulating valve 1, a power cable 2, a check valve 3, a production pump 4, It consists of hydrocyclone 5, submersible motor 6, signal cable 7, injection pump 8, downhole multi-parameter sensor 9, sealing section 10, and packer 11; the pressure regulating valve 1 is connected to the wellhead Christmas tree, and the power cable 2 is connected to the Submersible motor 6 is connected, check valve 9, production pump 4, hydrocyclone 5, submersible motor 6, injection pump 7, downhole multi-parameter sensor 9, sealing section 10 are connected in sequence, submersible motor 6 and downhole multiple The parameter sensor 9 is connected through the signal cable 7, and the sealing section 10 is inserted into the inner cavity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com