Intelligent wellhead sealing device

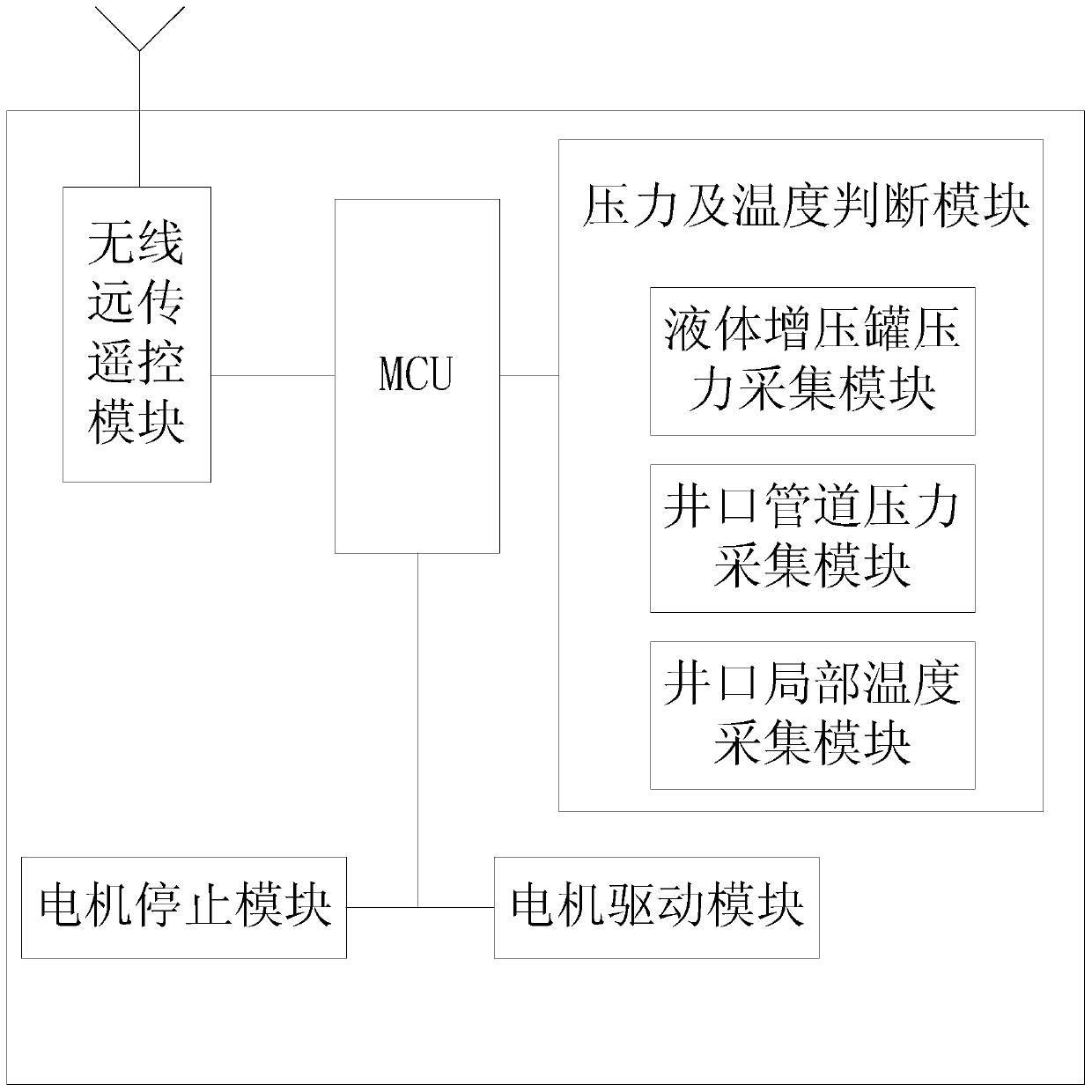

A sealing device and intelligent technology, applied in sealing/isolation, wellbore/well components, measurement, etc., can solve problems such as long downtime, impact on production, long pipeline response, etc., to reduce installation and maintenance costs and reduce labor. Strength, effectiveness in solving leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

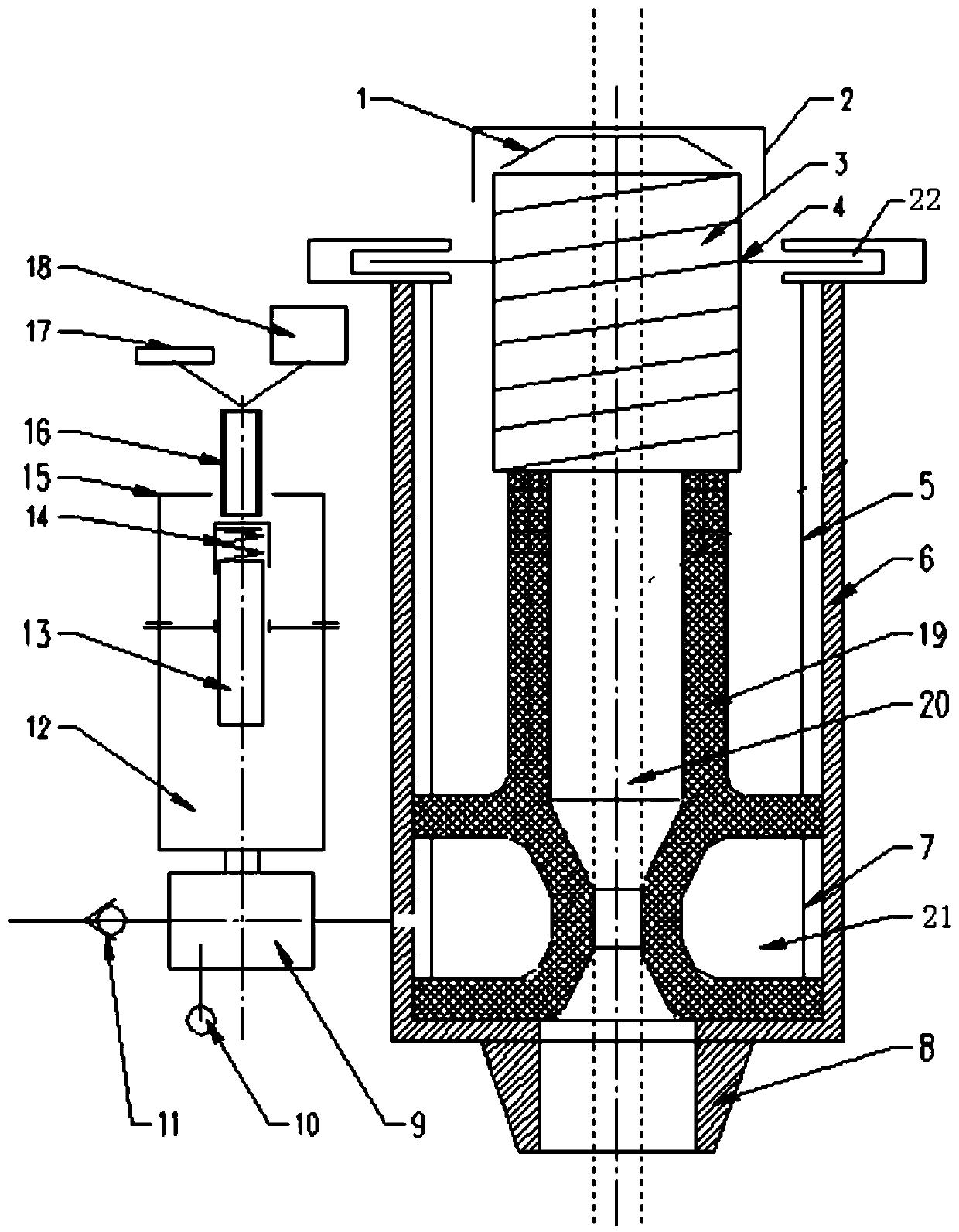

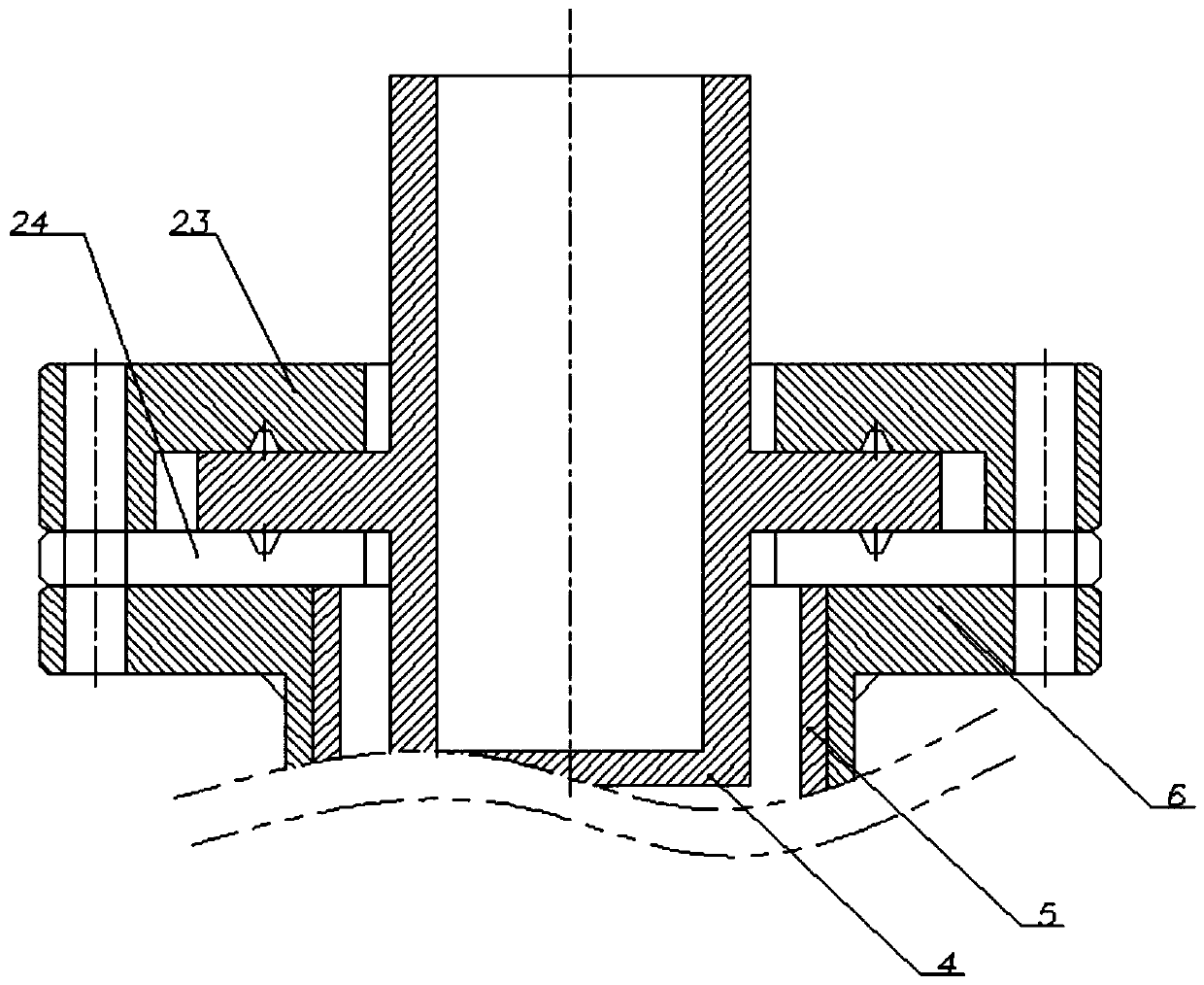

[0023] see Figure 1 to Figure 3 , an intelligent wellhead sealing device, including a floating double sealing device and a set of pressure-compensated hydraulic energy storage booster system; the floating double sealing device includes a casing 6 and an annular sealing sleeve 19; the top of the casing 6 has a 360-degree chute 22. An annular sealing sleeve 19 is fixedly installed in the inner cavity of the housing 6 through the first supporting ring 5 and the second supporting ring 7, and the annular sealing sleeve is composed of a straight cylinder connecting sleeve and at least one annular high-pressure sealing chamber 21 , the upper end of the straight connecting sleeve on the upper part of the annular sealing sleeve 19 is equipped with a floating packing box 4 that can float horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com