Milling mechanism and cutter thereof

A mechanical and milling technology, which is applied in roads, constructions, road repairs, etc., can solve the problems of low cost of use, achieve the effects of prolonging the service life, increasing the rotation performance, and solving the problem of eccentric wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The core of the present invention is to provide a milling machine tool, which can effectively solve the problem of eccentric wear of the tool in the working process, thereby prolonging the service life of the tool.

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

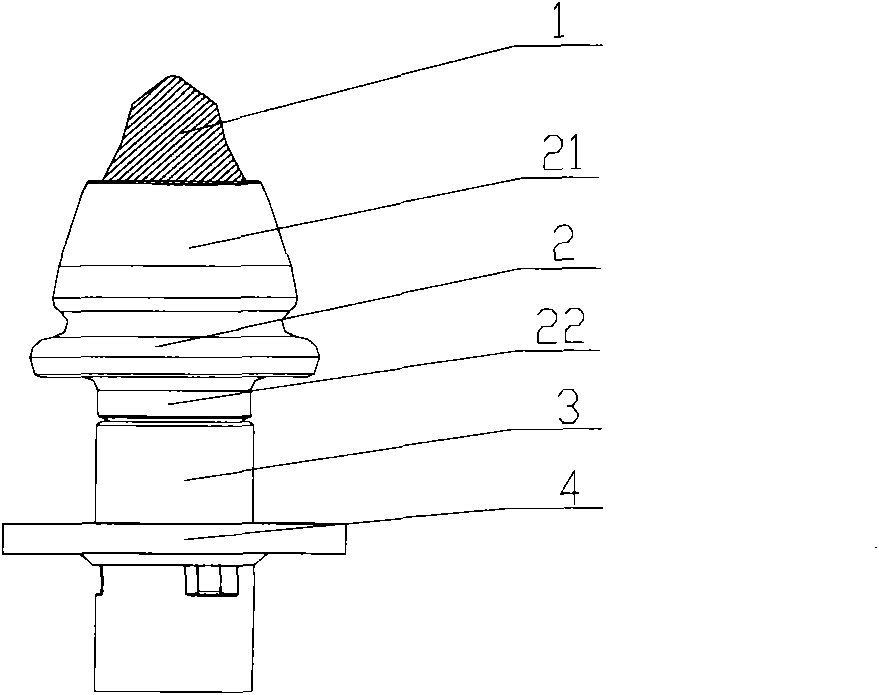

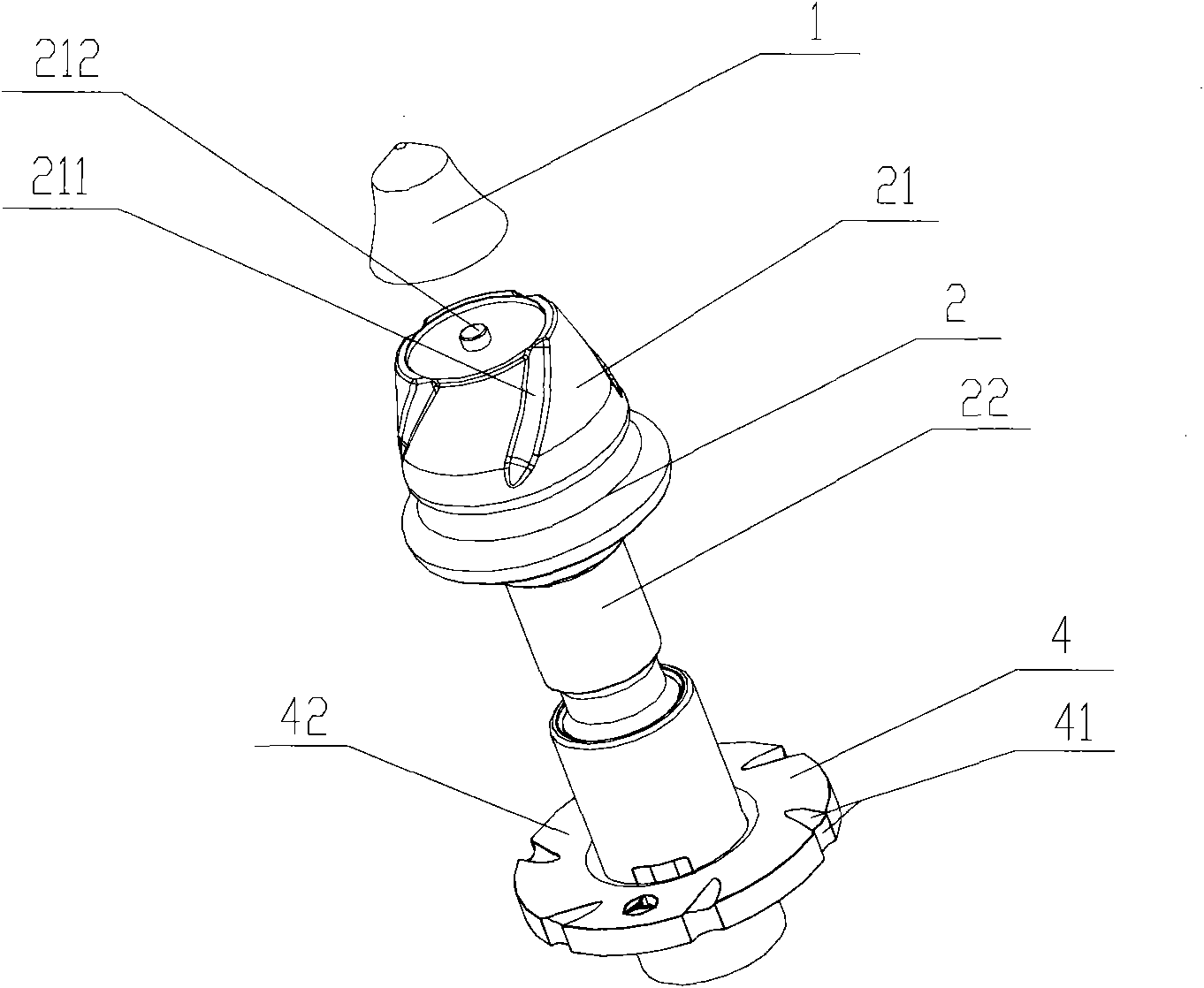

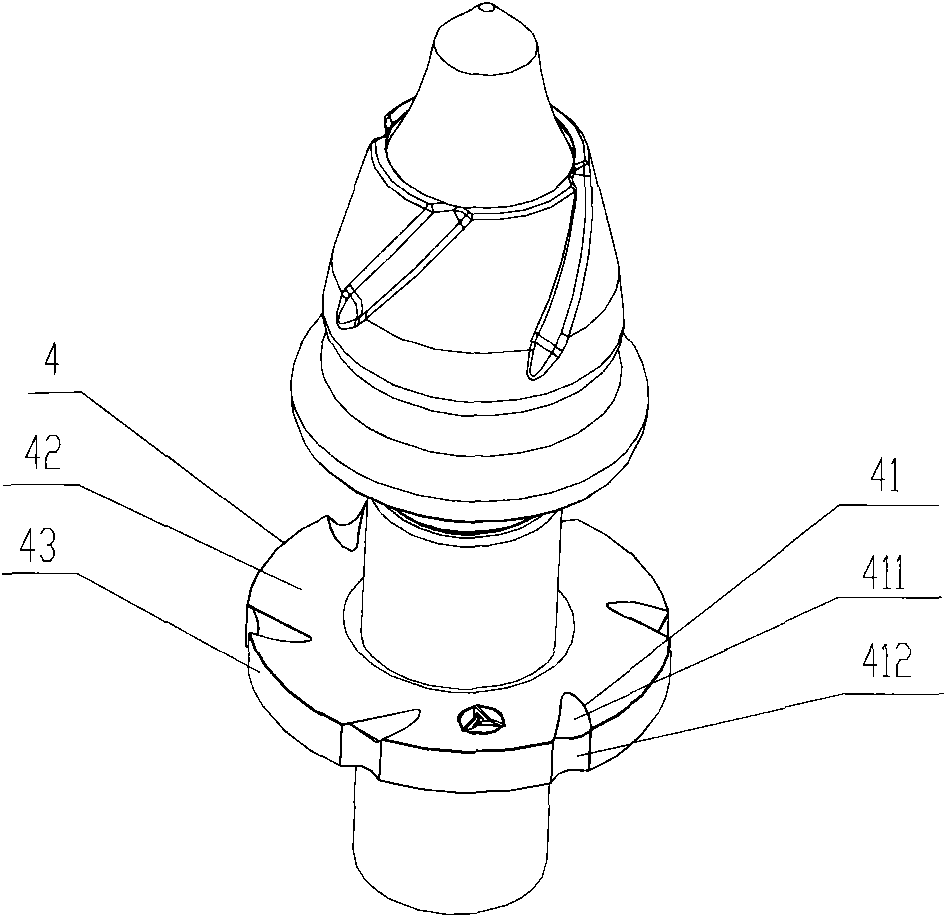

[0031] Please refer to figure 2 , figure 2 It is an isometric view of the separation of the cutter head and the cutter body of the cutter of the milling machine in a specific embodiment of the present invention.

[0032] In the first embodiment, if figure 2 As shown, the present invention provides a milling machine tool, including a cutter head 1, a cutter body 2, and an annular spacer 4; the cutter body 2 includes a frustum-shaped head 21 and a cylindrical body 22, and the cutter head 1 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com