Multifunctional well mouth sealing blowout-prevention box

A blowout preventer, multi-functional technology, used in sealing/packaging, wellbore/well components, earth-moving drilling, etc., can solve the problems of short service life, short service life of polished rod, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

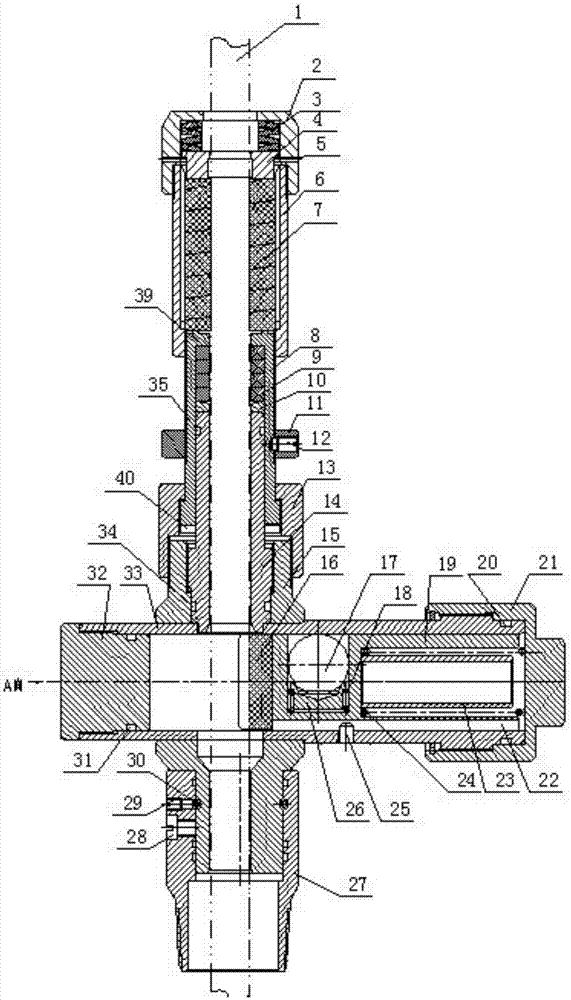

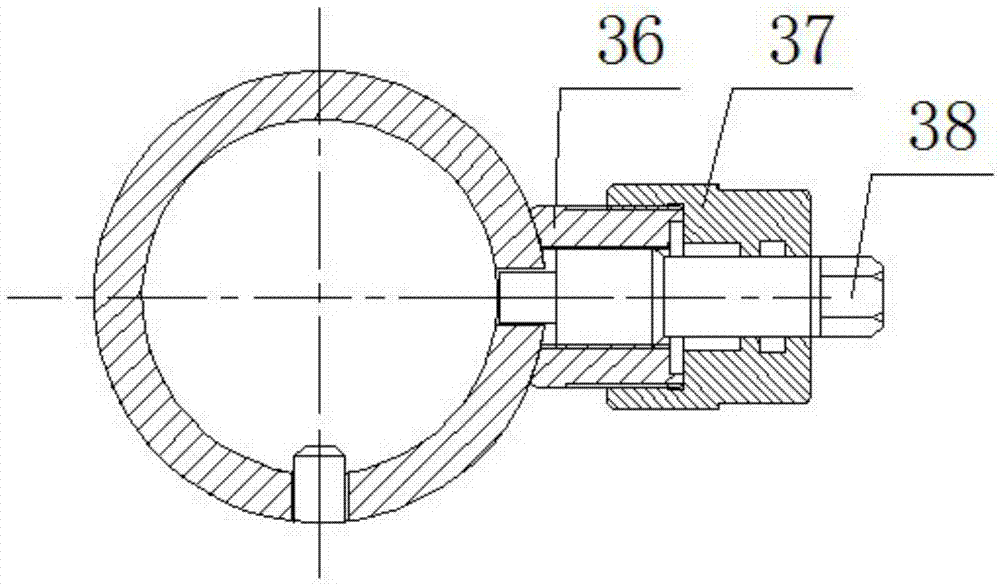

[0026] A multi-functional wellhead sealing blowout prevention box, which includes an upper stuffing box 6, a lower stuffing box 8, a main body string 15 and a lower connecting body 27, which are sequentially connected from top to bottom and can be inserted into a polished rod 1 of a pumping unit. The upper packing 7 is installed in the upper stuffing box and the packing gland 4 is installed, the lower packing 9 is set in the lower stuffing box, and the valve ball seat body 14 is coaxially fixed and installed in the main pipe string, and the lower end of the lower packing is connected with the valve A backing ring 10 is arranged between the upper ends of the ball seat body. An O-ring 34 is arranged between the main pipe column and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com