Heavy-duty crushing machine

A crusher, heavy-duty technology, applied in the field of mechanical equipment, can solve the problems of affecting the combustion effect of the boiler, the particle size of the output can not be guaranteed, and reduce the combustion efficiency of the boiler, etc., and achieve the effect of low noise, small vibration and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be further described below through the accompanying drawings and embodiments.

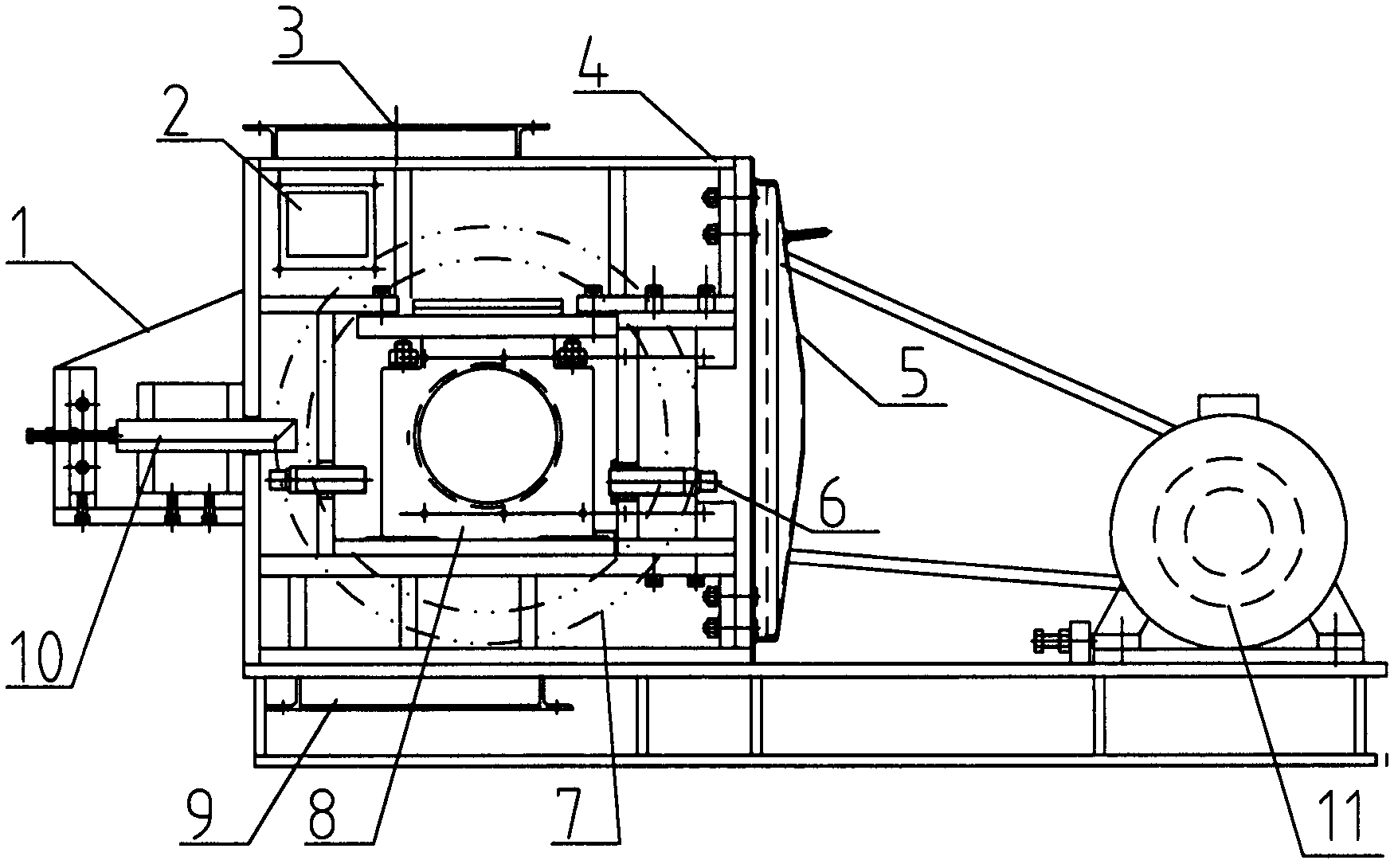

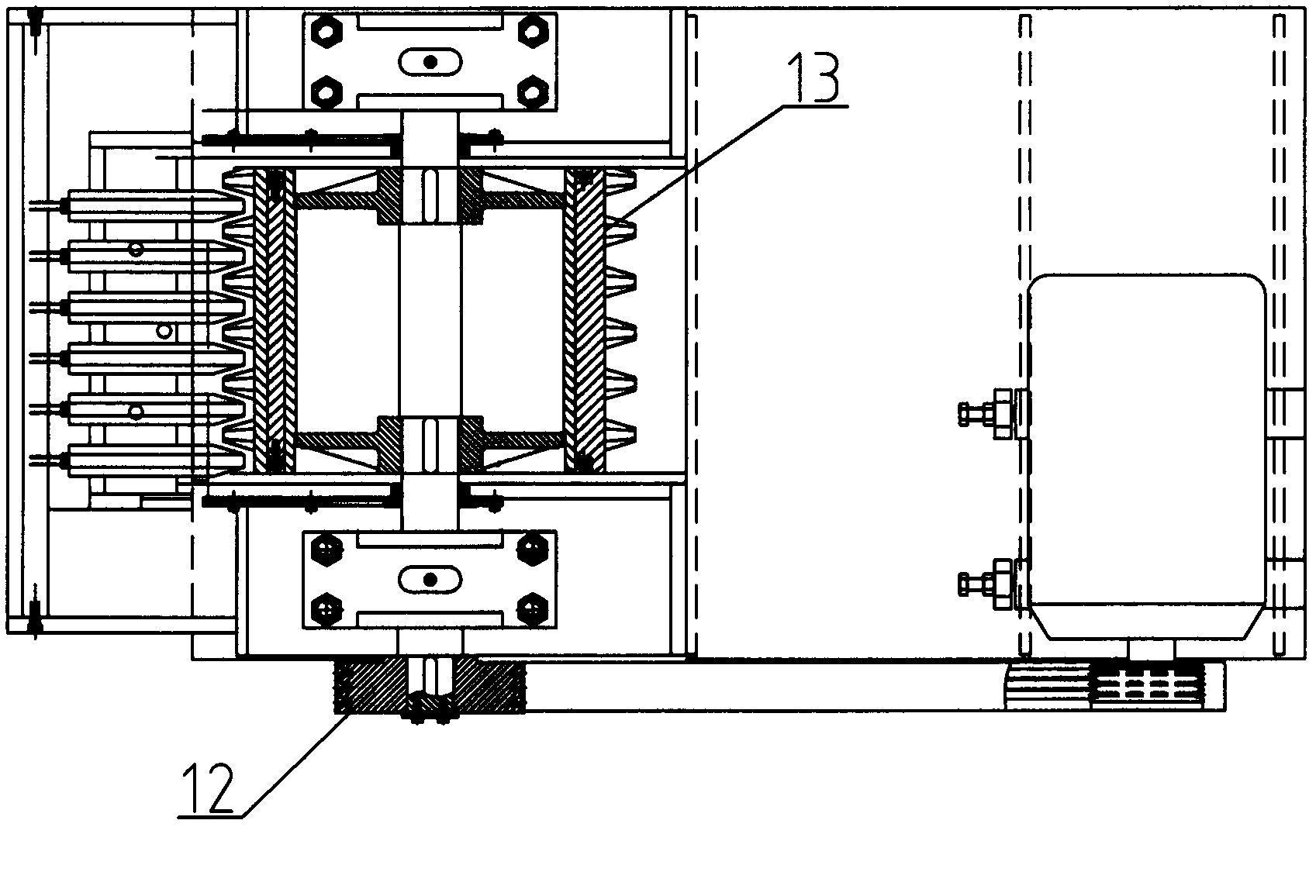

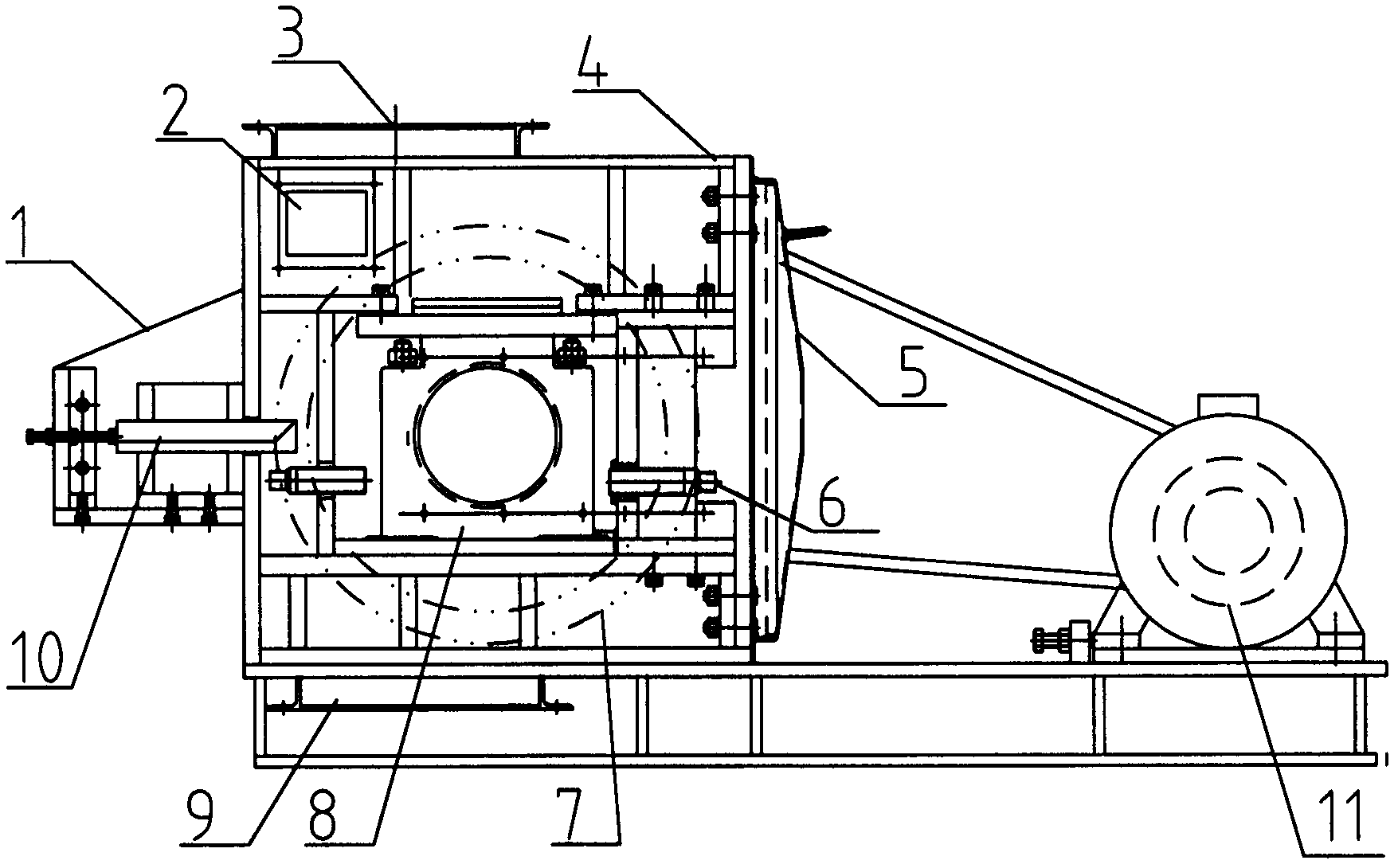

[0017] Such as figure 1 As shown, the heavy-duty crusher of the present invention consists of a rack box 1, an observation port 2, a material inlet 3, a frame 4, an inspection door 5, an adjusting bolt 6, a rotor 7, a bearing seat 8, a discharge port 9, The rack 10, the motor 11, the pulley 12 and the tooth plate 13 are assembled. The specific structure and connection method are:

[0018] The motor 11 is connected with the rotor 7 through the pulley 12, the pulley 12 and the tooth plate 13 are installed on the rotor 7, the feed inlet 3 is installed on the top of the heavy crusher and connected with the frame 4, and the discharge outlet 9 is located at Below the heavy crusher, the rotor 7 is installed on the bearing housing 8 and fixed on the frame 9 . Rack 10 is installed in rack box 1 li and is fixed on the frame 9, and observation po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com