Shaft-end deslagging spiral conveyer

A technology of screw conveyor and shaft end, applied in the field of screw slag discharge device, can solve the problems of difficult control of soil bin pressure, unfavorable belt conveyor transportation, tunnel construction progress and safety impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

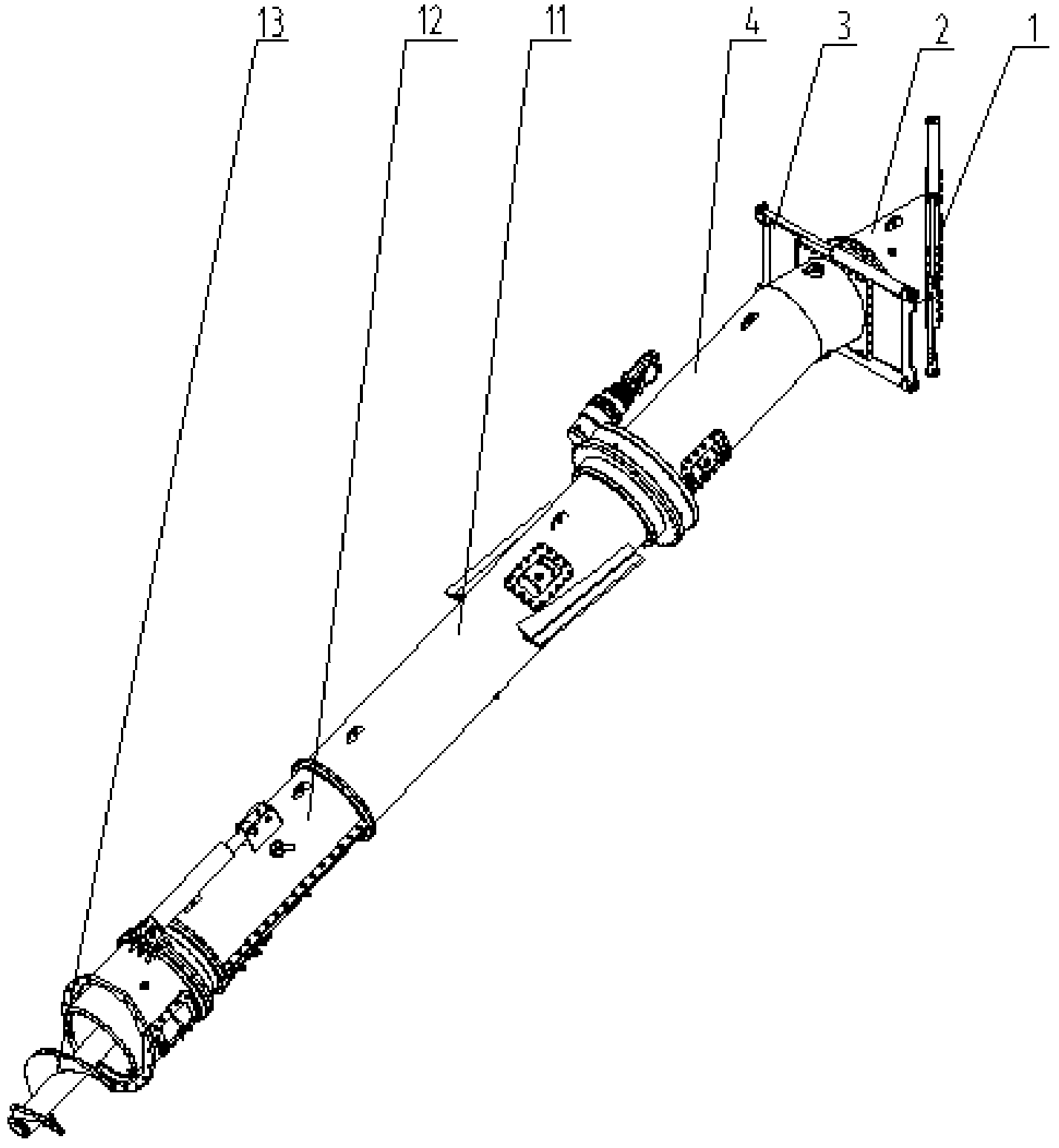

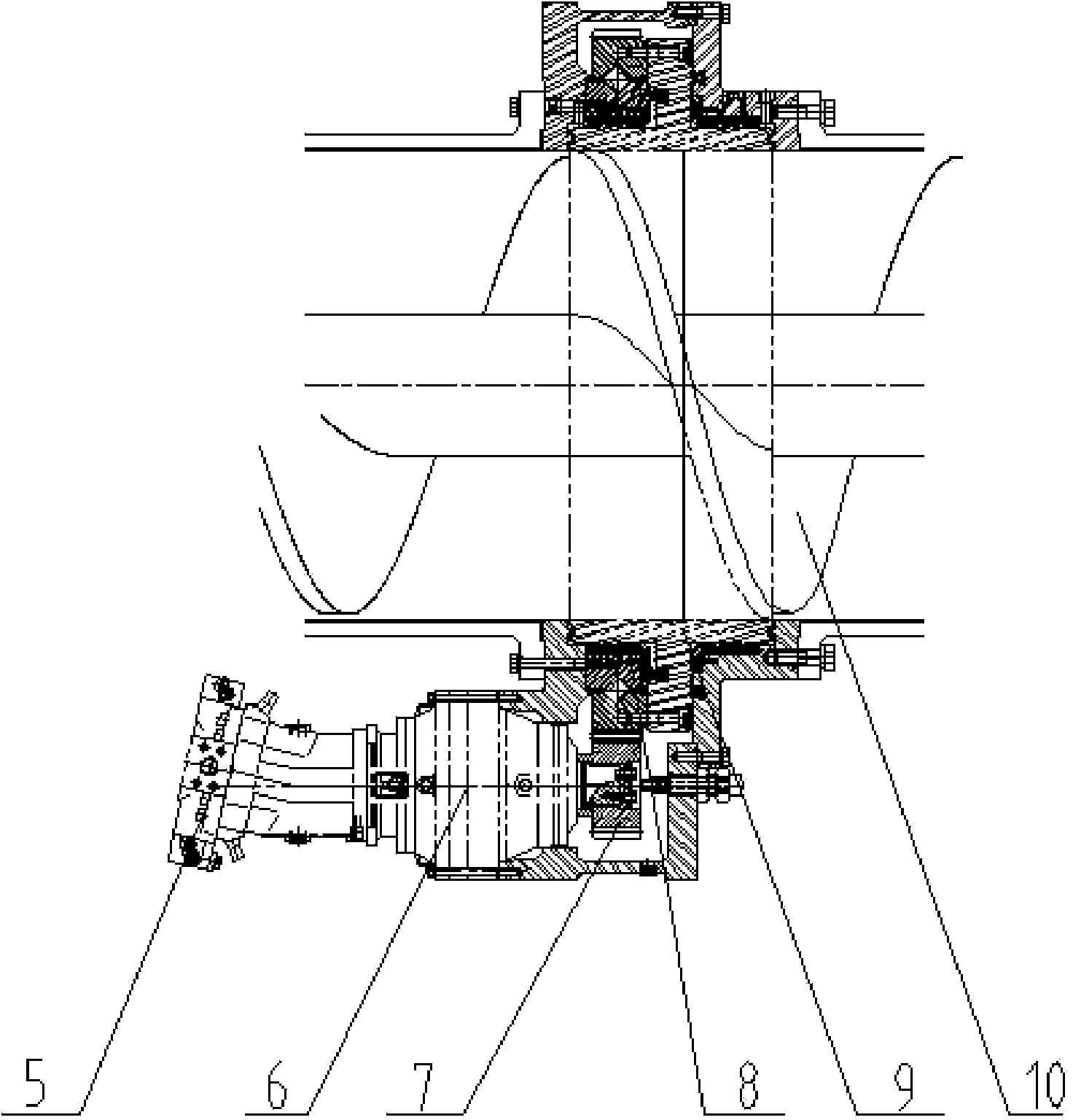

[0010] Referring to the accompanying drawings, the whole device consists of a secondary gate 1, a muck storage pipe 2, a primary gate 3, a conveying cylinder 4, a driving device 5, a reducer 6, a driving gear 7, a sealing device 8, a driven device 9, The driven blade 10, the second-stage conveying cylinder 11, the three-stage conveying cylinder 12, the screw conveying device 13 and the like are composed. The muck storage pipe 2 is installed between the secondary gate 1 and the primary gate 3, and a driving device 5, a reducer 6, a driving gear 7, and a sealing device 8 are installed between the first-stage conveying cylinder 4 and the second-stage conveying cylinder 11 , the driven device 9 , the driven blade 10 , and the screw conveying device 13 run through the one-stage conveying cylinder 4 , the second-stage conveying cylinder 11 and the three-stage conveying cylinder 12 .

[0011] A slag storage pipe 2 is installed between the secondary gate 1 and the primary gate 3 for s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com