Method for improving flowability of milltailings and application of method

A fluidity and tailings technology, which can be used in earth-moving drilling, filling, safety devices, etc., can solve problems such as the cumbersome preparation method of enhanced tailings mortar, improve enterprise and social economic benefits, improve strength, and improve slurry concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

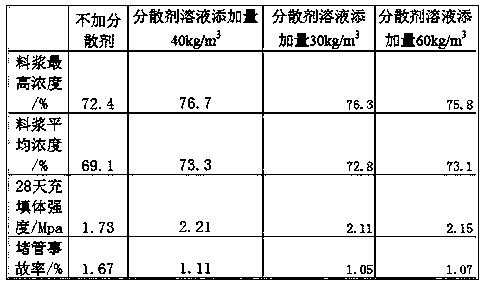

Embodiment 1

[0012] Embodiment 1: A method for enhancing the fluidity of tailings, which includes the following steps: (1), configuring a sodium carboxymethyl cellulose solution with a mass fraction of 0.1%; (2), preparing a carboxymethyl cellulose solution with a mass fraction of 0.1% The sodium methyl cellulose solution is added to the sand silo and fully mixed with the sand liquid. The addition amount of the sodium carboxymethyl cellulose solution is 30kg / m 3 .

Embodiment 2

[0013] Embodiment 2: A method for enhancing the fluidity of tailings, which includes the following steps: (1), configuring a sodium carboxymethyl cellulose solution with a mass fraction of 0.1%; (2), preparing a carboxymethyl cellulose solution with a mass fraction of 0.1% The sodium methyl cellulose solution is added to the sand silo and fully mixed with the sand liquid. The addition amount of the sodium carboxymethyl cellulose solution is 40kg / m 3 .

Embodiment 3

[0014] Embodiment 3: A method for enhancing the fluidity of tailings, which includes the following steps: (1), preparing a sodium carboxymethyl cellulose solution with a mass fraction of 0.1%; (2), preparing a carboxymethyl cellulose solution with a mass fraction of 0.1% The sodium methyl cellulose solution is added into the sand silo and fully mixed with the sand liquid. The addition amount of the sodium carboxymethyl cellulose solution is 60kg / m 3 .

[0015] Sodium carboxymethyl cellulose is generally used as a suspending agent in mud retaining wall drilling, but the drilling slag will be suspended. The applicant took advantage of this characteristic of sodium carboxymethyl cellulose and applied it as an additive for tailings mortar. After many tests on site, it was believed that a dispersant solution of 0.1% mass concentration was ideal, mainly because it was easy to distribute evenly, Thereby, the dispersant solution is fully mixed with the sand liquid in the sand bin.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com