Water and gas double-base driving discharge and mining system

A water-gas driving pump technology, which is applied in the field of oil exploitation, coalbed methane and shale gas exploitation, can solve problems such as eccentric wear of sucker rods and oil pipes, increase the number of workovers, and reduce service life, so as to increase service life, The effect of reducing drainage cost and reducing well workover times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

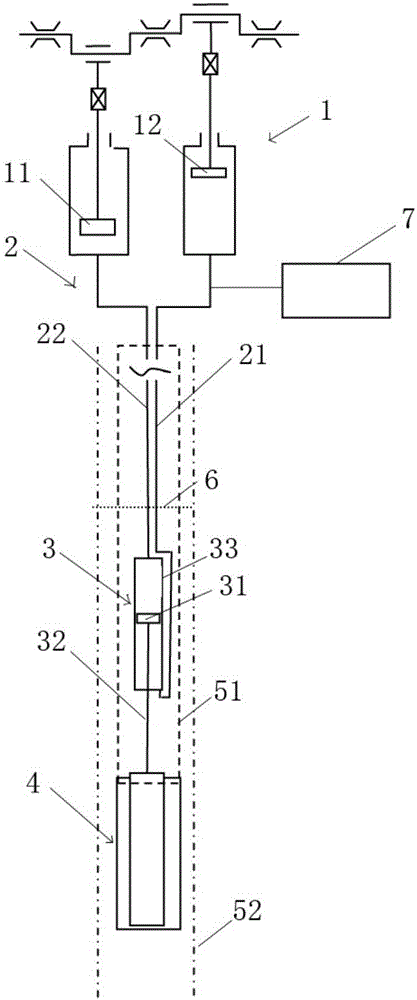

[0008] Such as figure 1 As shown, this water-air dual-base drive drainage system includes a ground-driven pump unit 1, a hard-pipe water-based power and capillary air pressure transmission unit 2, a double-sided piston power implementation unit 3, and a rod pump unit for oil pumping and drainage. 4. The ground drive pump unit is on the ground and includes a motor, a crank linkage mechanism, a first piston 11, and a second piston 12. The motor drives the crank linkage mechanism to make the two pistons move in reverse; the hard pipe water-based power and The capillary air pressure transmission unit, the double-side piston power implementation unit, the rod pump unit used for oil extraction and drainage are in the oil pipe 51 and casing 52 in the downhole; the hard pipe water-based power and capillary air pressure transmission unit includes a capillary air pipe 21 and a hard pipe water pipe 22 , the capillary air tube is attached to the hard water pipe and goes deep into the down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com