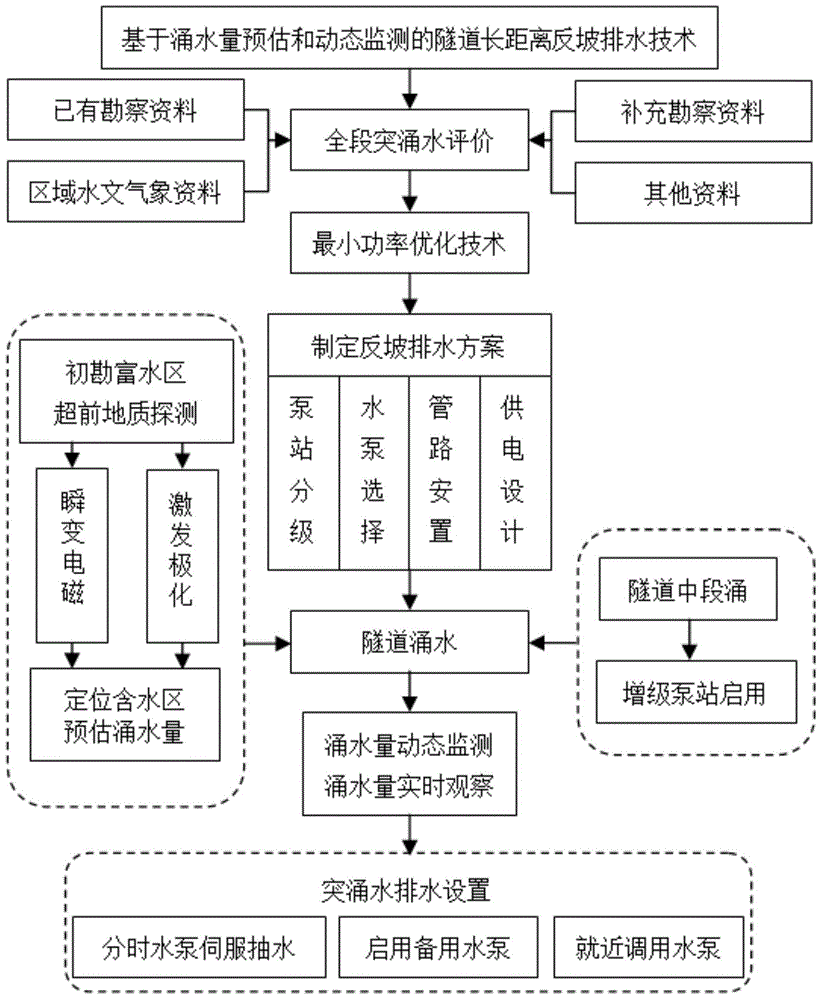

Tunnel counter-slope drainage design method based on water inflow estimation and dynamic monitoring

A technology of dynamic monitoring and design method, applied in drainage, mining equipment, earth-moving drilling, etc., can solve problems such as excess drainage capacity, water gushing disaster, waste of resource allocation, etc., to avoid the increase of drainage potential energy, ensure normal progress, reduce The effect of drainage costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

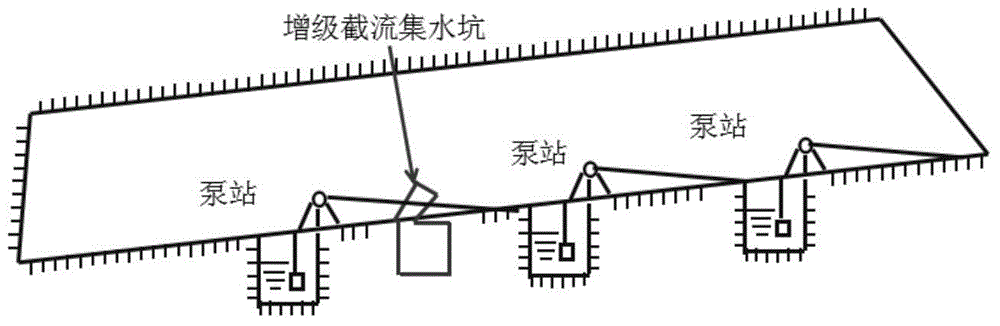

Method used

Image

Examples

Embodiment 1

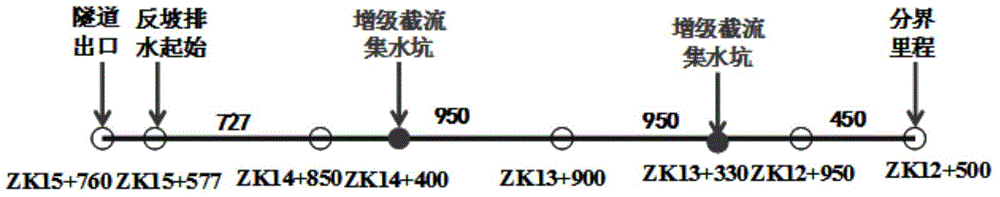

[0048] The implementation steps of its drainage technology take the application of Dongmao Expressway Liupanshan Tunnel as an example, as follows:

[0049] Step 1. Geological Survey

[0050] By collecting and analyzing geological data, detailed surface investigation and other methods, understand the geological conditions of the tunnel site, use geological theory, compare, demonstrate, infer and predict the engineering geology and hydrogeology before the tunnel construction; Paragraphs of water inrush risk assessment. According to the calculation and analysis of preliminary survey data, it is predicted that the general water inflow in the section where the tunnel passes is Q=17427.6m 3 / d, the maximum water inflow is 37999.4m 3 / d. According to the engineering geology and hydrogeological conditions of the tunnel site area, the water inrush section of the tunnel is predicted. The sections with a high possibility of water inrush are mainly: the tunnel crosses the Daxia River Val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com