Coal mine underground abrasive continuous supply system

A technology for supplying system and abrasives, applied in abrasives, abrasive feeding devices, metal processing equipment, etc., can solve the problems of water jet operation failure, affecting material conveying function, large pipe wear, etc., to simplify the system structure And the effect of system installation process, improving stability and security, and saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

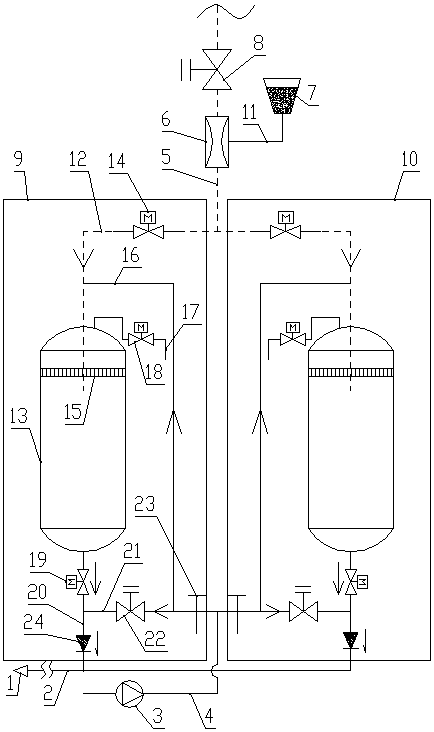

[0022] In the present invention, the fluid flow direction is taken as the downstream direction. Such as figure 1 As shown, the coal mine underground abrasive continuous supply system of the present invention includes a first feeding mechanism 9 and a second feeding mechanism 10 arranged in parallel, a jet adding mechanism for adding abrasives to the first charging mechanism 9 and the second charging mechanism 10, The high-pressure water mechanism that is used to provide high-pressure water for the first feeding mechanism 9 and the second charging mechanism 10 and the water spraying mechanism that is used to spray high-pressure water to carry out water jet operation; Mechanisms 10 are connected; the first feeding mechanism 9 and the second feeding mechanism 10 are both feeding mechanisms.

[0023] The water spray mechanism includes a spray head 1 and a high-pressure water spray pipeline 2 connected with the spray head 1 .

[0024] The high-pressure water mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com