Split precipitation type hanging scaffold water tank for automatic pollution discharge of vertical shaft

An automatic sewage and sedimentation technology, which is applied in drainage, safety devices, mining equipment, etc., can solve the problems of increasing the cycle time of construction and production planning, insufficient sewage sedimentation, and affecting normal drainage, so as to reduce labor consumption and sediment The effect of reducing and reducing the wear rate of the water pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

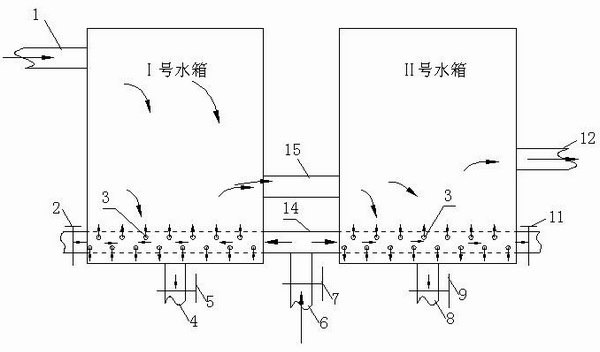

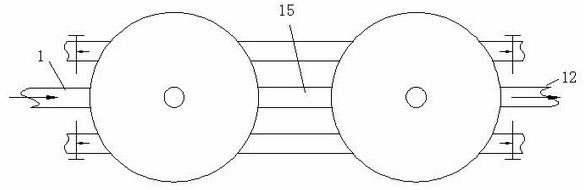

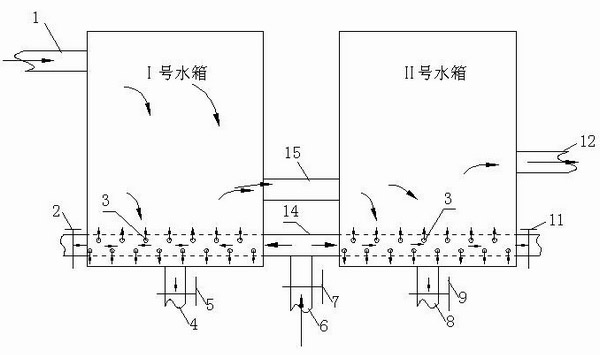

[0016] The vertical well automatic sewage discharge split sedimentation type hanging pan water tank is composed of No. I water tank and No. II water tank. The No. I water tank and No. II water tank are arranged side by side on the hanging pan. Pipe 15 is lower in the middle of No. I water tank and No. II water tank. Water inlet pipe 1 is arranged on the left side wall of No. I water tank. Water inlet pipe 1 is close to the upper mouth of No. I water tank. Water outlet pipe 12 is provided, and water outlet pipe 12 is in the middle part of No. II water tank. There are several through pipes 14 running through No. I water tank and No. II water tank near the bottom of No. I water tank and No. II water tank. The casing inner section of No. II water tank all has the through hole 3 that is covered with the whole body of pipe body, and the end that stretches out No. I water tank in through pipe 14 is provided with No. I through pipe sewage cut-off door 2, stretches out No. II in through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com