Patents

Literature

57results about How to "Conducive to civilized construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method of prefabricated wallboard

InactiveCN108118900AImprove construction qualitySpeed up the progress of the projectBuilding material handlingTower craneWall plate

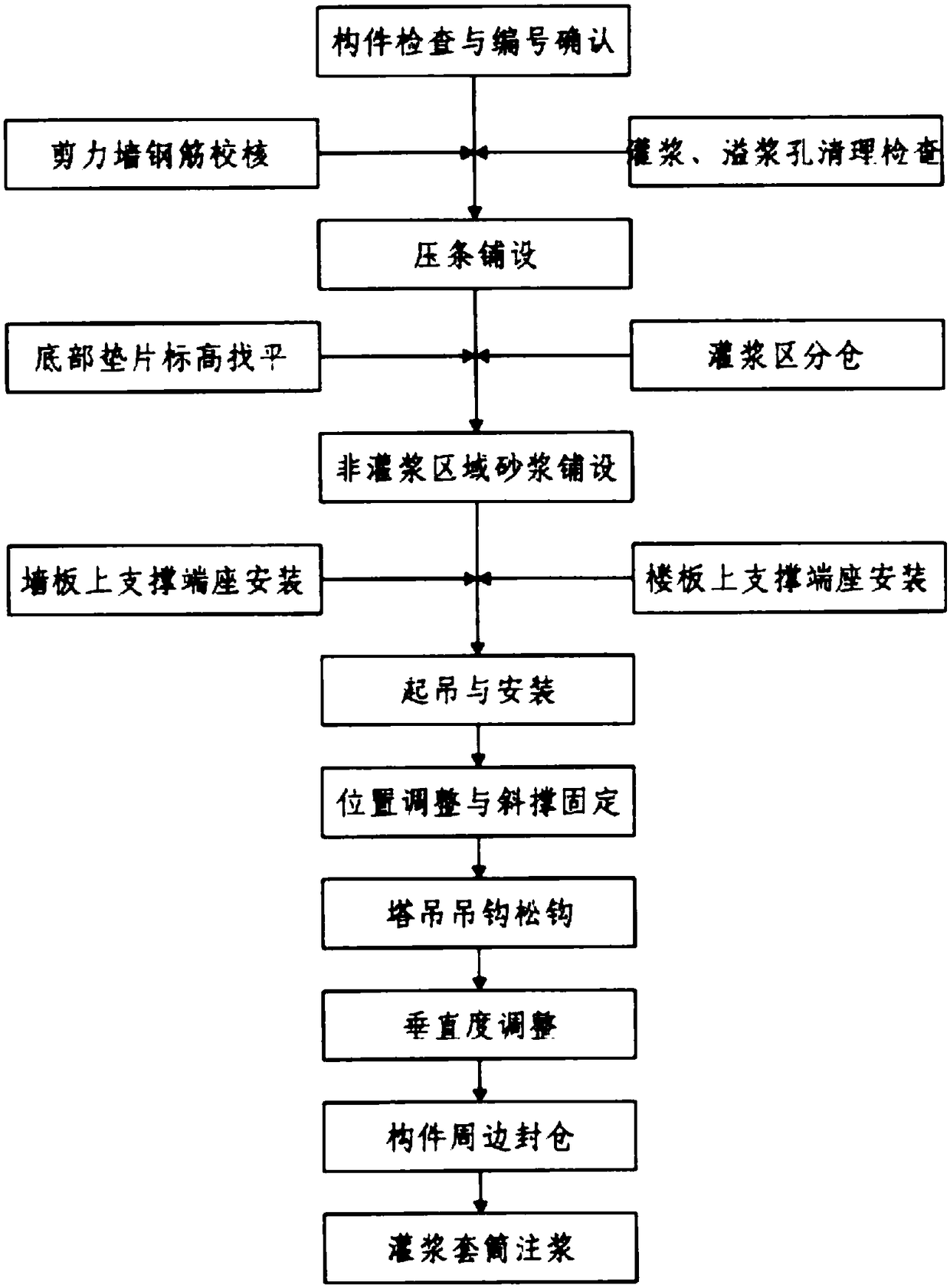

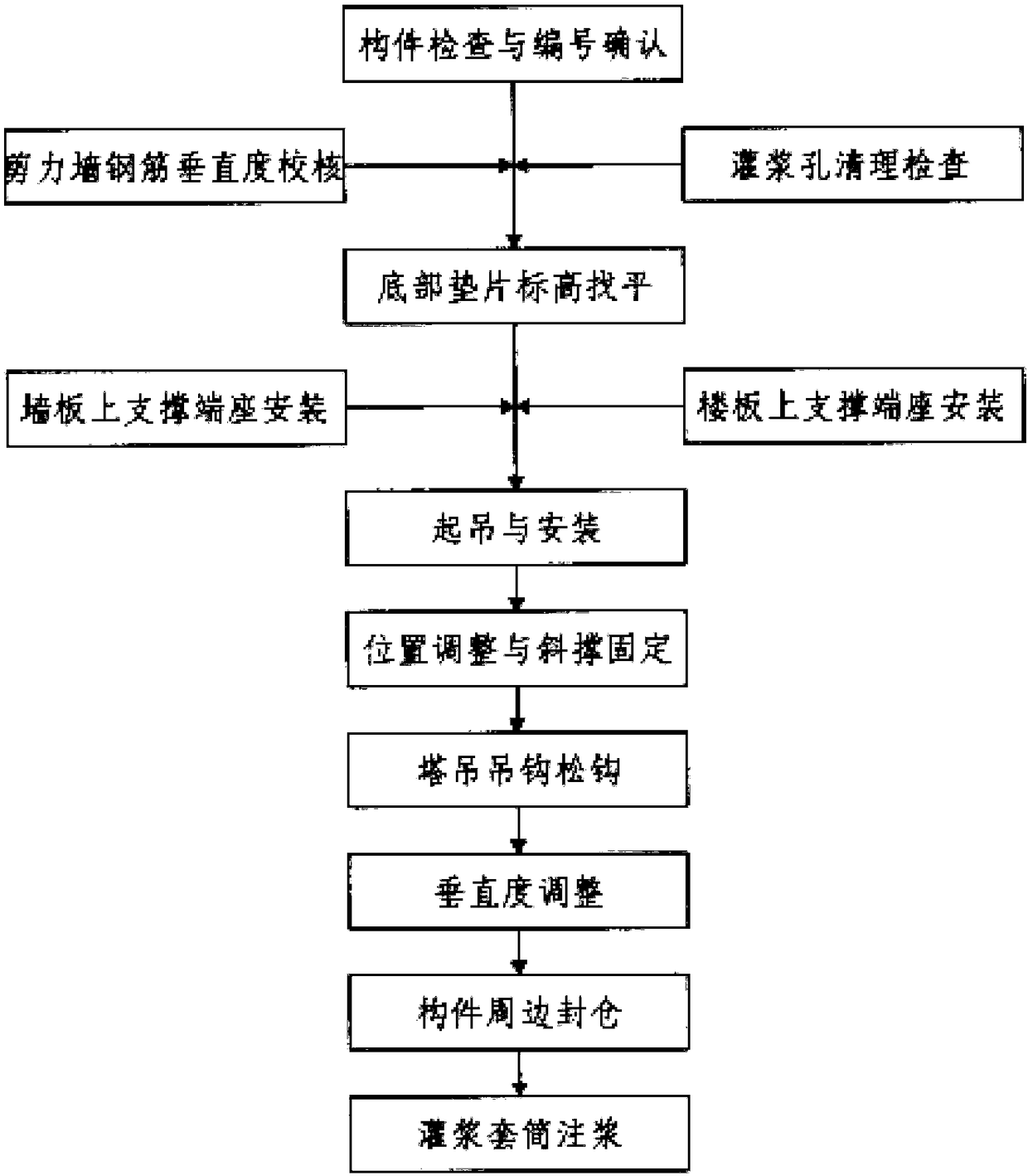

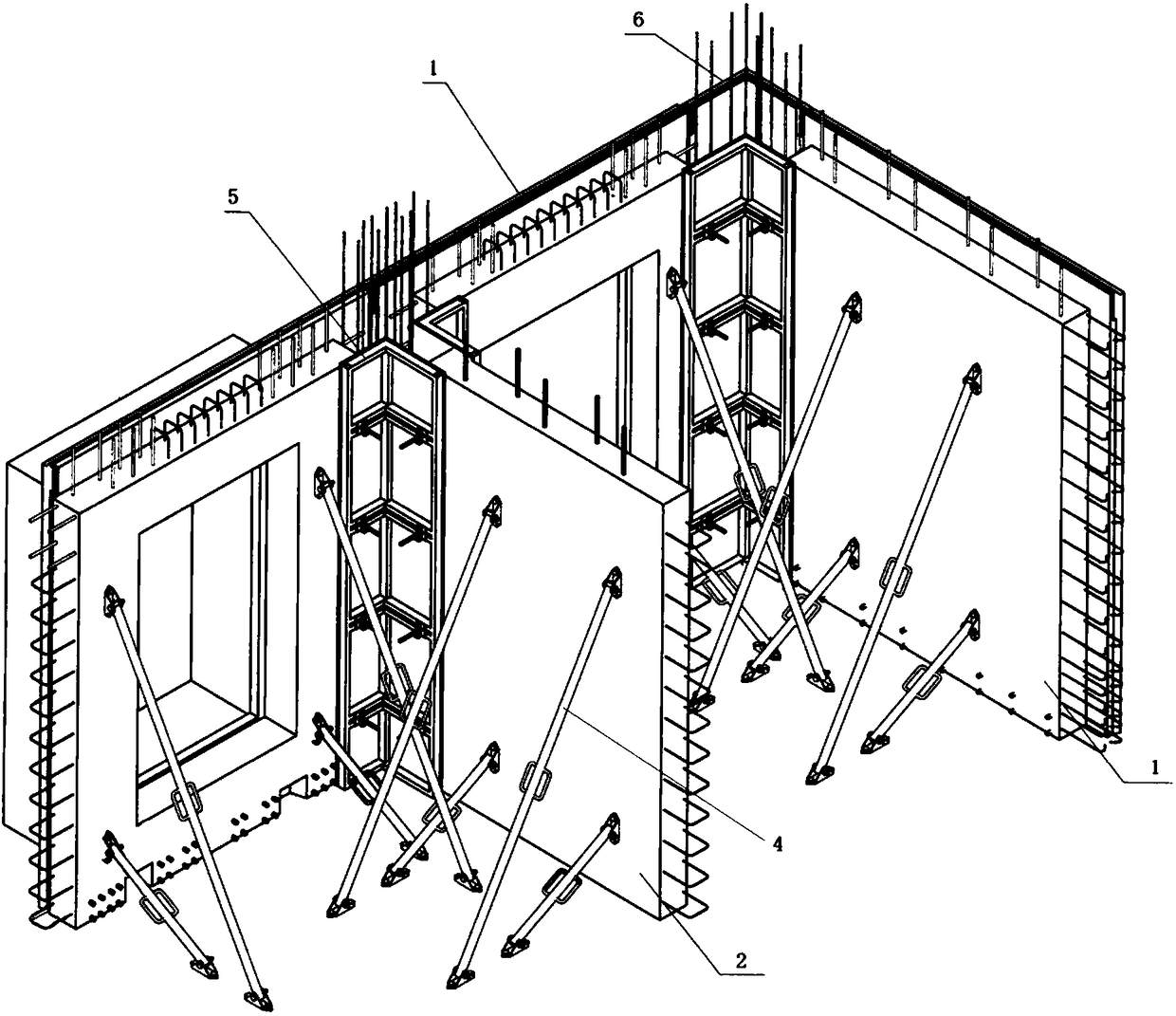

The invention discloses a construction method of a prefabricated wallboard. The construction method of the prefabricated wallboard comprises the following steps of 1, numbering the prefabricated wallboard after the wallboard is prefabricated in a factory, and transporting the prefabricated wallboard to a site; 2, checking components and confirming the number; 3, before hoisting, constructing the bottom laying position of the prefabricated wallboard; 4, hoisting and installing the prefabricated wallboard, wherein before the prefabricated wallboard is hoisted, upper and lower supporting end bases of an inclined strut are firstly installed, after the prefabricated wallboard is hoisted, the prefabricated wallboard is adjusted in position and is connected with the inclined strut to be fixed, then a tower crane hook is unhooked, the perpendicularity of the prefabricated wallboard is adjusted, finally, the periphery of the prefabricated wallboard is sealed, and a grouting sleeve is utilized to conduct mortar injecting. By means of the construction method of the prefabricated wallboard, a component assembly mode is adopted, a structural wallboard is divided into multiple blocks, after being prefabricated in the factory, the prefabricated wallboard is hoisted and installed on spot, and certain construction treatment is conducted, which helps to improve the construction quality, accelerate the engineering progress, and improve the building quality.

Owner:BEIJING URBAN CONSTR NORTH CONSTR

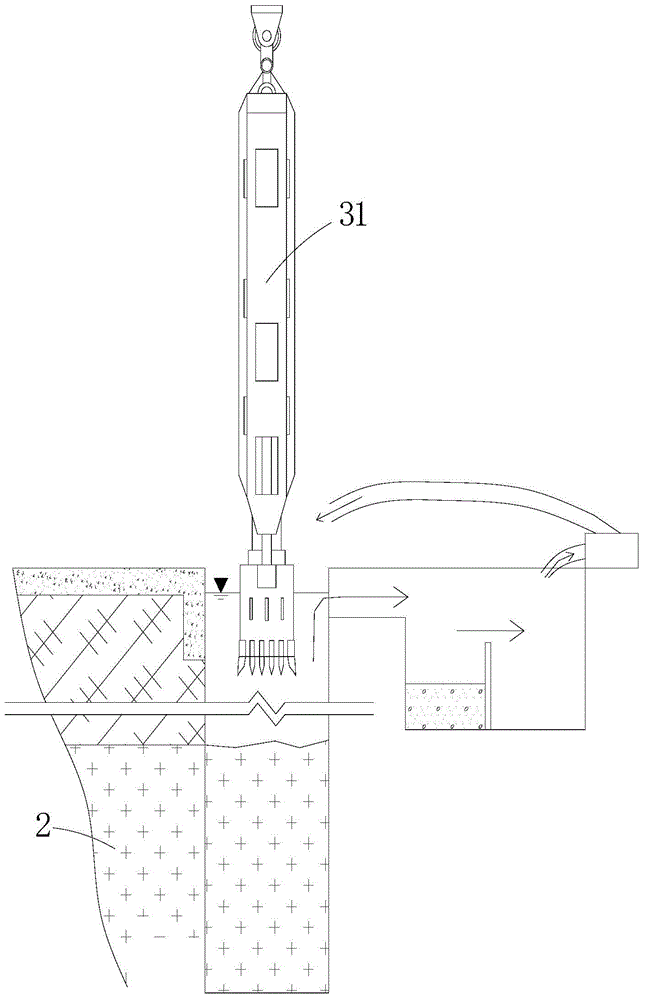

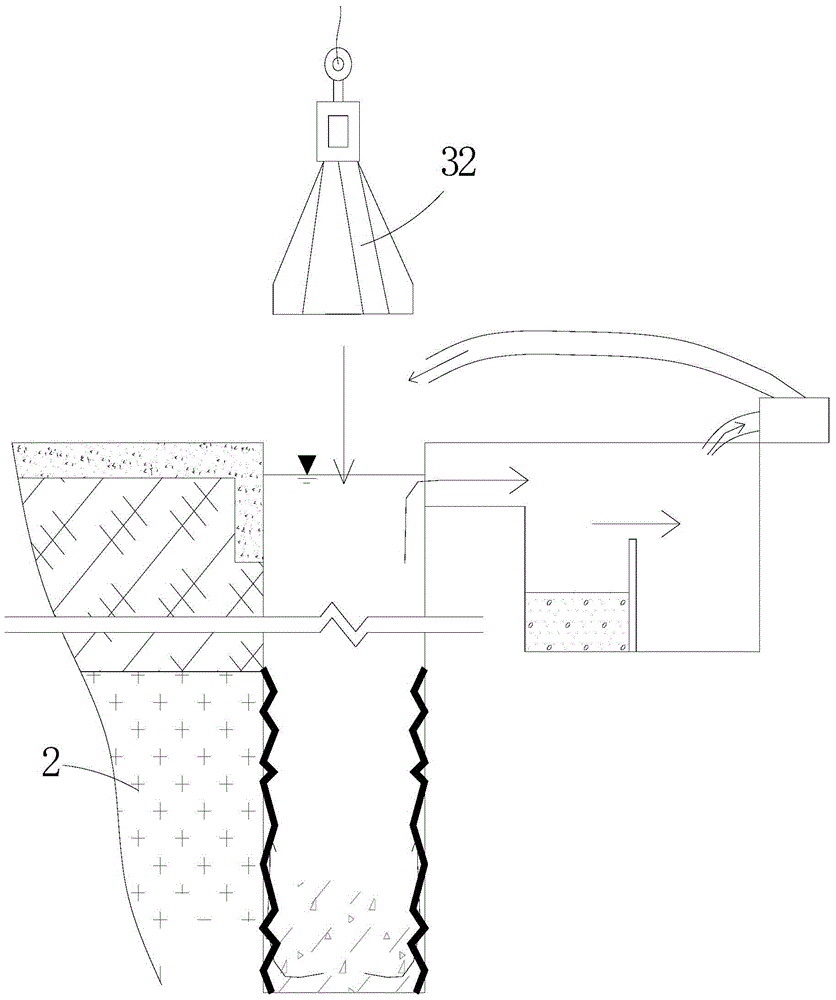

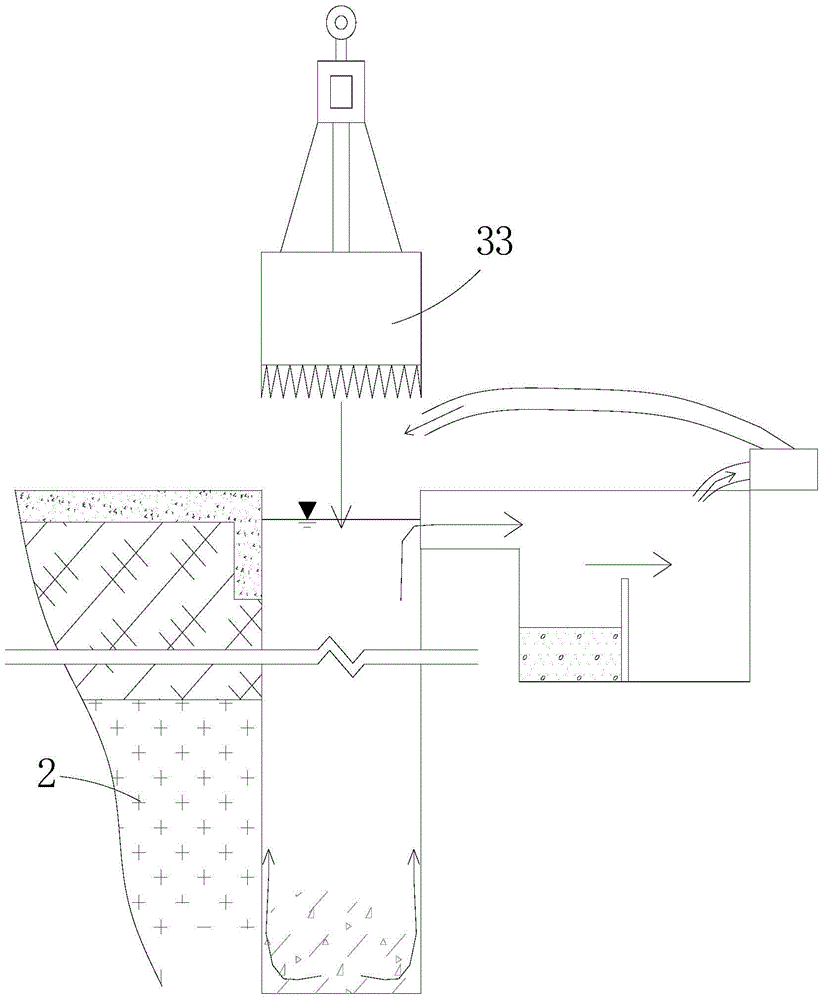

Grooving construction method for embedding underground continuous wall into rock

The invention relates to the technical field of embedding underground continuous walls into rock and grooving of the underground continuous walls and discloses a grooving construction method for embedding an underground continuous wall into rock. The method includes the steps that firstly, a grab bucket is used for excavating soil so that a groove can be formed, and a residual soil layer is reserved between the groove bottom and a rock face; secondly, a rotary excavating drilling tube is used for drilling holes in the residual soil layer and a seriously-weathered layer, a cutting-tooth drilling tube is used for drilling medium-weathered rock and micro-weathered rock, and rock entering holes in bed rock are formed; thirdly, the second step is repeated, and a plurality of rock entering holes are formed in the length extension direction of a groove segment; fourthly, a plane set-hammer is used for clearing away hard rock tooth edges. According to the construction method, the grooving speed is high, and on-site general layout and civilized construction are facilitated; meanwhile, the cutting-tooth drilling tube is used for performing rotary excavation and entering the rock to take a core, and impacting vibration is avoided; due to the fact that the grooving construction period is short, the exposing time of the groove wall is relatively short, the risk that groove wall soil collapses is reduced, the groove wall is stable, and construction cost is indirectly reduced; the residual soil layer is reserved on the rock face of the bed rock, the rotary excavating drilling tube plays a guiding role in the hole forming process, and the situation that because the inner rock face of the groove segment is inclined, hole drilling deflects is prevented.

Owner:SHENZHEN SUNHUI MECHANICAL CO LTD

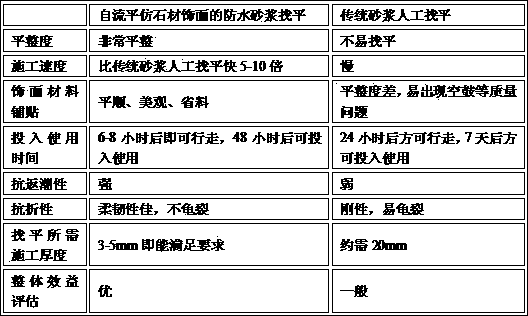

Self-leveling waterproof mortar of imitated stone facing and construction process of waterproof mortar

InactiveCN103936370AFast constructionRapid deployment for high construction speedFlooringCelluloseFiber

The invention discloses a self-leveling waterproof mortar of an imitated stone facing and a construction process of the waterproof mortar. The self-leveling cement mortar is composed of the following components in parts by weight: 250-300 parts of cement, 50-80 parts of ground calcium carbonate, 900-1000 parts of natural color sand, 2-8 parts of cellulose ether, 3-8 parts of wood fibers, 1-3 parts of PP (Poly Propene) fibers, 18-25 parts of latex powder and 2-8 parts of special natural rock slices for really stone paint; a water-to-material ratio is 4.2L-4.5l / 25kg. The construction process of the waterproof mortar comprises the steps of base surface treatment, interface treatment, material stirring and material construction. The self-leveling waterproof mortar is a dry-blending type powdery material composed of a plurality of active ingredients, and can be mixed with water in field to be use. The self-leveling waterproof mortar is slightly spread by using a scraper knife and then a high-level base surface can be obtained. The self-leveling waterproof mortar is hardened quickly, and after 4-8 hours, people can walk on the hardened mortar or subsequent work can be carried out on the hardened mortar; the self-leveling waterproof mortar is quick, simple and convenient in construction and can be applied to industrial factory buildings, workshops, commercial stores and the like.

Owner:南通苏宝建筑节能科技有限公司

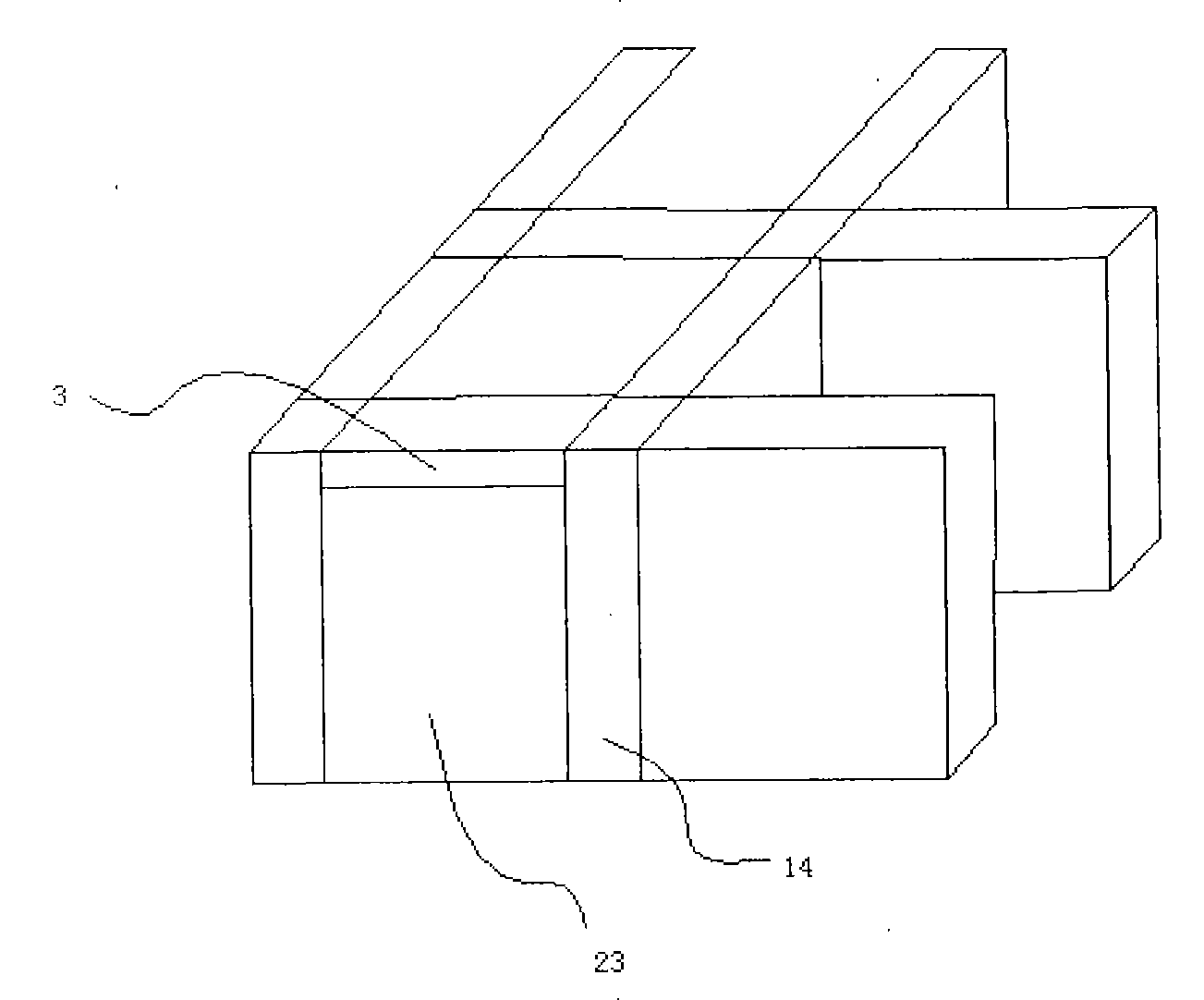

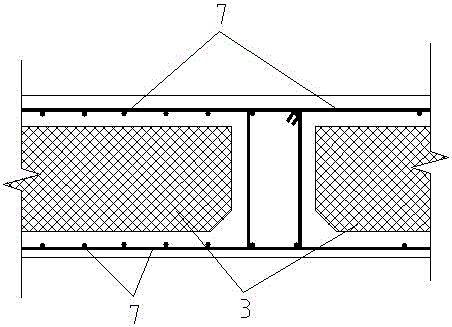

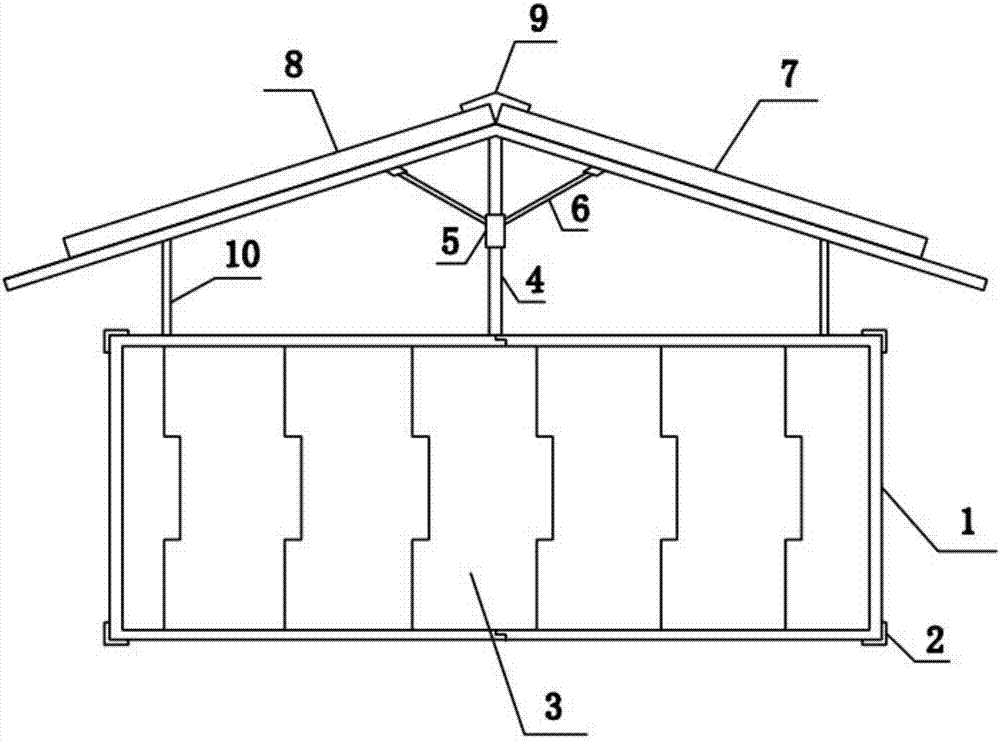

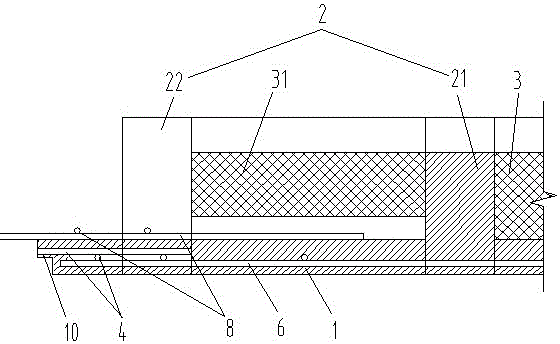

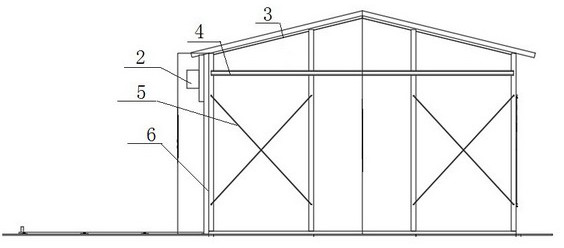

Fully-fabricated building system with grid steel structure

InactiveCN102174858AMeet different energy saving requirementsMeet energy saving requirementsWallsFloorsSteel frameWall plate

The invention discloses a fully-fabricated building system with a grid steel structure. The system comprises wall plates, a floor plate and load bearing combination columns, wherein each wall plate comprises a grid steel frame and gelatine powder granular layers pressed on the two side faces of the grid steel frame in a casting way; both ends of the wall plate are provided with a bulged clamping head; a door opening is formed on the wall plate on one side; each load bearing combination column comprises a connecting column and a gelatine powder granular layer; the gelatine powder granular layer is arranged adjacent to the outer side at the periphery of the connecting column through press casting to make the cross section of the load bearing combination column rectangular; slots matched with clamping heads at the two ends of the wall plate are formed on two, three or four side faces of the load bearing combination column; the wall plates are clamped together through the load bearing combination columns to form a building; and the floor plate is arranged on the top surfaces of the wall plates. The fully-fabricated building system with the grid steel structure has an environment-friendly building structure which has light weight and is heat-preserving, sound-proof, fire-resistant, rust-proof, load-bearing and quake-proof, has high construction efficiency, saves labor hours, has small construction floor area, does not have dust in a site environment and contributes to civilized construction.

Owner:黄志元

Construction method of red sandstone roadbed

ActiveCN101831851AHigh linearity standardLarge amount of filling and cuttingRoadwaysArchitectural engineeringRed sandstone

The invention relates to a construction method of a red sandstone roadbed, which adopts special mechanical assembly. Aiming at the mechanics of the I type red sandstone roadbed and the II type red sandstone roadbed and the analysis of the road performance, a large-tonnage special compacting machine is used for rolling, wherein the rolling comprises the rolling, the crushing and the compactly extruding through a YZTY-22T pulling type cavel with the vibrating force of 45t, the rolling through a YZ32 ultra-large vibrating force vibrating road rolling machine, and the shocking and the reinforcing through a QCY360 (25KJ trilateral double wheels) shocking road rolling machine. The linear standard of the super highway is high and the work amount of filling and cutting is large, so that the design of wiring can not avoid a wider red sandstone zone and a mass of red sandstones have to be dug up during constructing. If the roadbed can not be filled with the red sandstones but the far-distant other materials, not only the construction period is delayed, but also the construction cost is high. Meanwhile, areas for borrowing and abandoning the soil are difficult to find, so that the existing construction mode can pollute the environment and bring much future troubles. The construction method well makes use of the spot red sandstones, reduces the construction cost, saves the resources, and is good for the civilized construction and the environment protection.

Owner:ANHUI ROAD & BRIDGE GRP +1

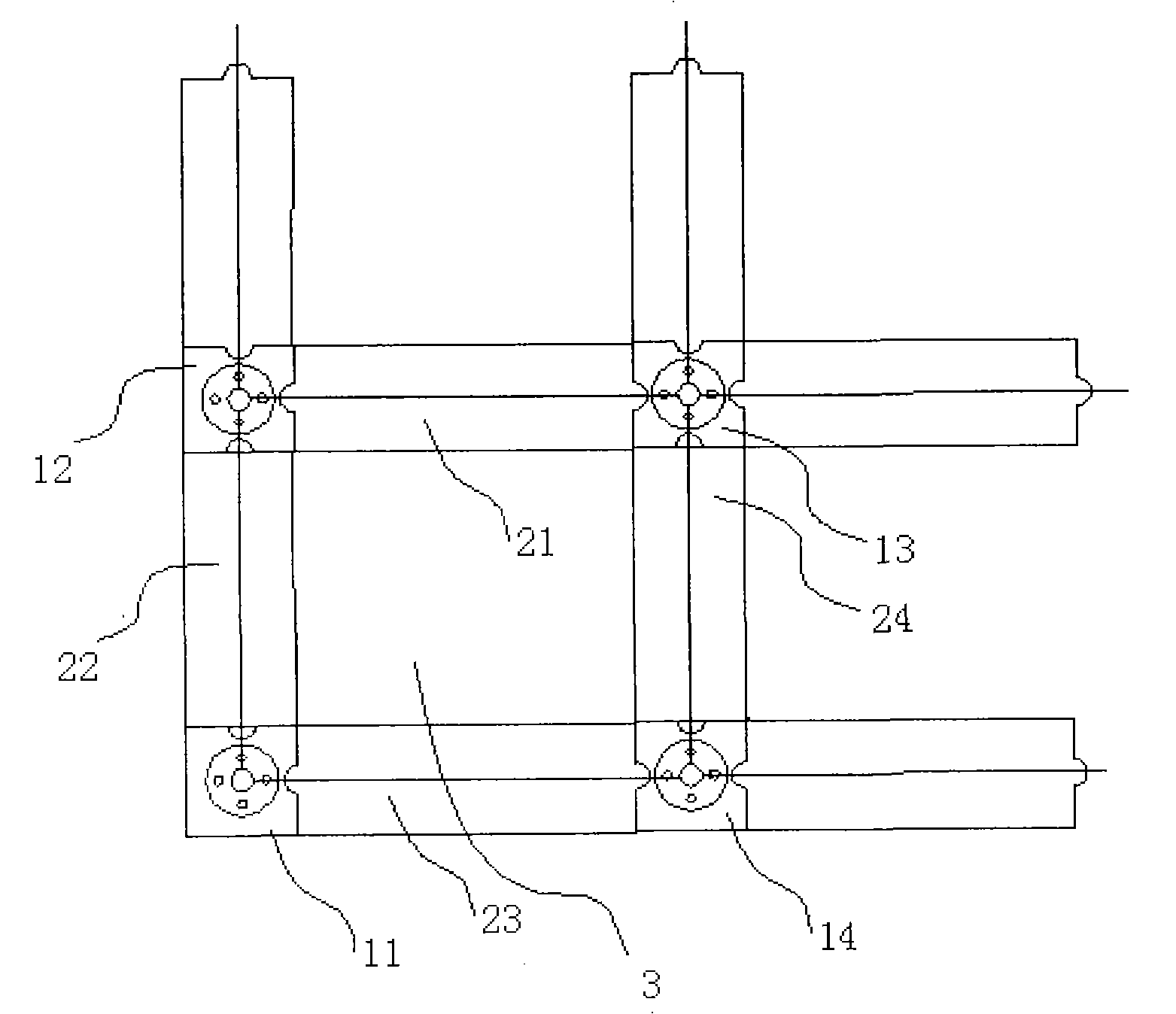

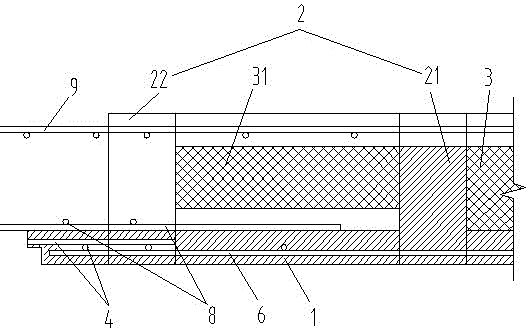

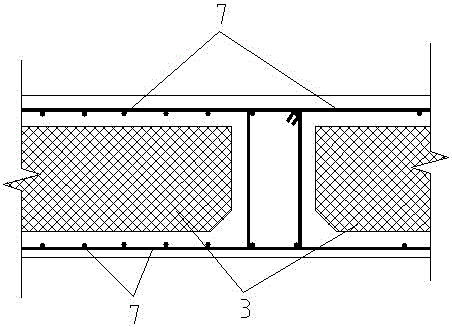

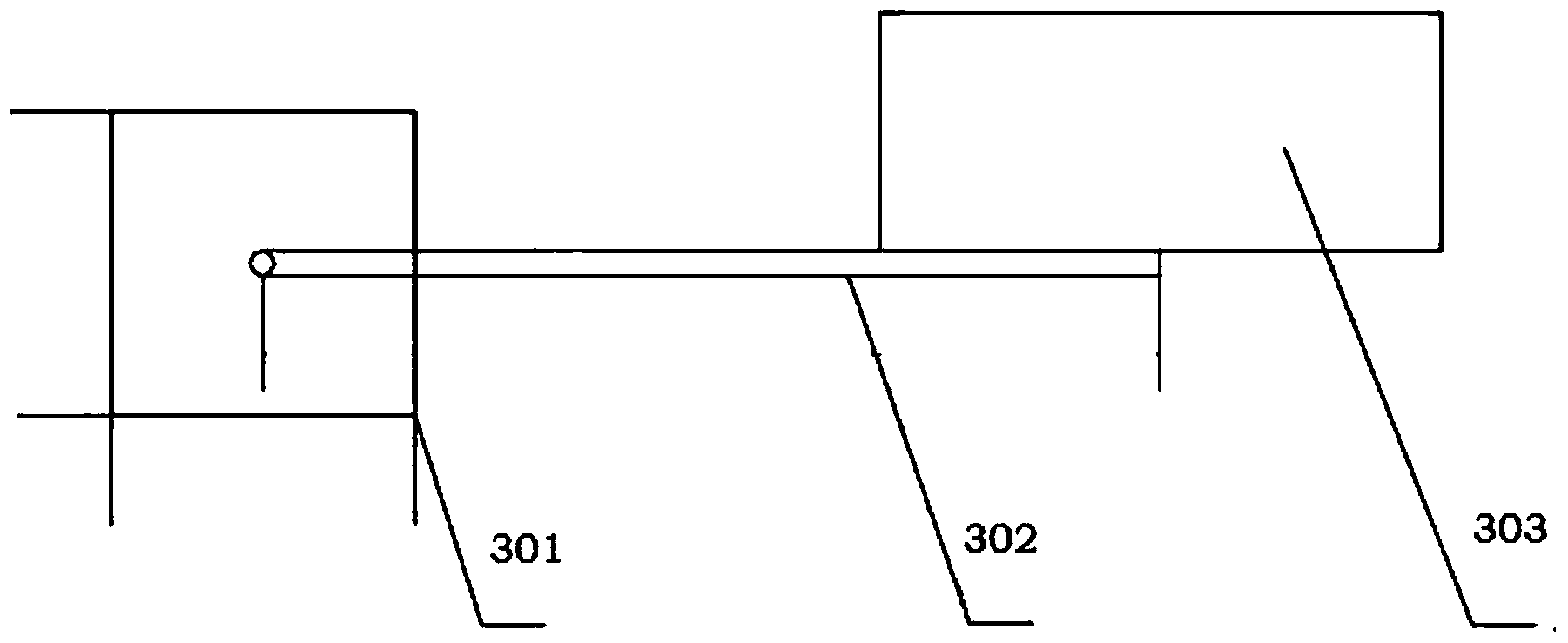

Connecting method of prefabricated composite multi-ribbed floor slabs and steel beams of assembly type steel structure house

The invention relates to a connecting method of prefabricated composite multi-ribbed floor slabs and steel beams of an assembly type steel structure house. Ribbed beams and steel beams at the joints of the multi-ribbed floor slabs and the steel beams are cast in place, and the fire prevention effect of the connecting joints of steel columns and the steel beams and the fire prevention effect of the steel beams are achieved; the multi-ribbed floor slabs are filled with light materials, and the heat insulation effect is achieved; and prefabricated composite multi-ribbed floor slab components are produced in advance and mounted in the field, the field construction speed is increased, lots of revolving materials such as supporting steel tubes, battens, web filmed multilayer boards and bamboo plywood are reduced, the construction speed is increased, and the construction cost is lowered.

Owner:CHINA 22MCC GROUP CORP

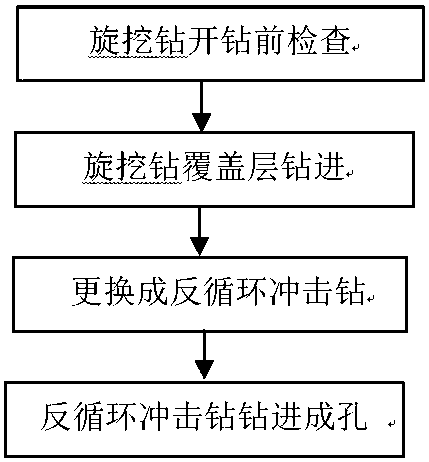

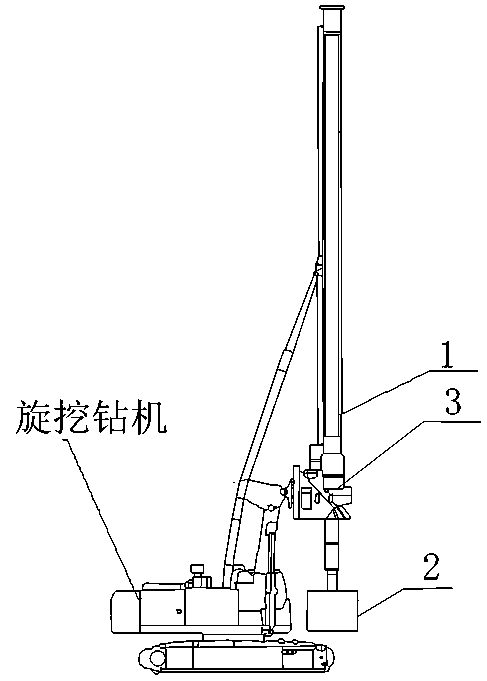

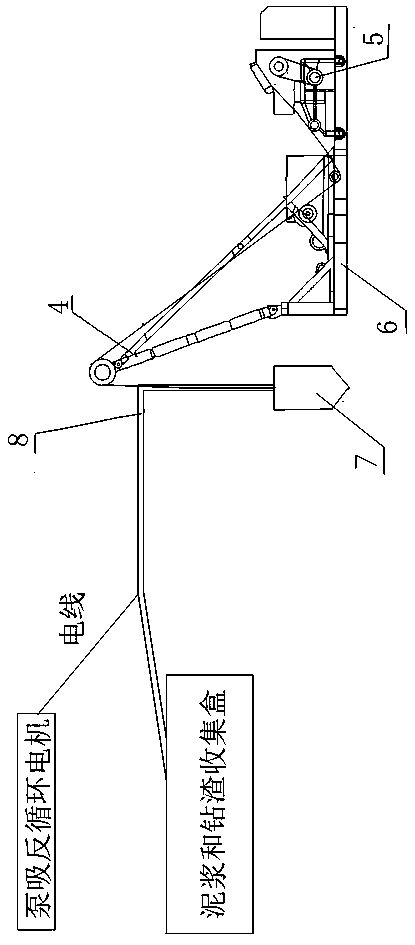

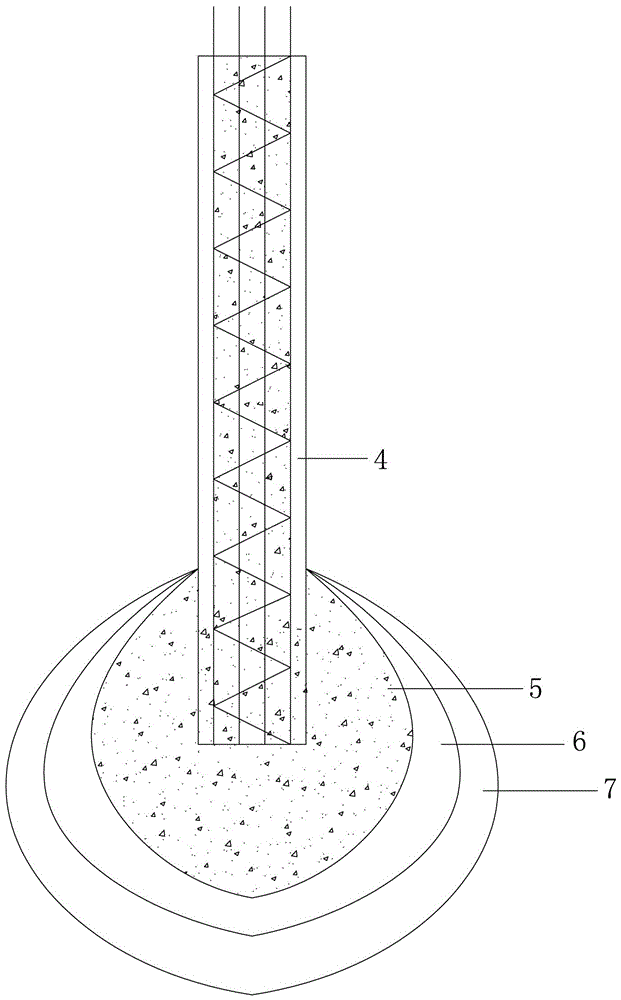

Rapid hole-forming construction method of large-diameter deep hole pile foundation under karst geology

InactiveCN111594041AEasy to moveAvoid drilling difficulties, low efficiency and other problemsDrilling drivesFlushingKarstEconomic benefits

The invention discloses a rapid hole-forming construction method for a large-diameter deep hole pile foundation under karst geology. 'Rotary drill and reverse circulation impact drill' combined relaydrilling is performed, a rotary drill rapidly performs drilling construction of a covering layer, and a reverse circulation impact drill is used for relay construction when a karst geological layer isdrilled. The combined construction process gives full play to the advantages of the two kinds of drills under the situations of different geological conditions and hole depths, the advantages are complemented with each other, and the construction efficiency and economic benefits of the large-diameter deep hole pile foundation under the karst geology are improved. Drilling of single drilling equipment is converted into combined drilling of the two different kinds of drilling equipment, the construction progress of the pile foundation is greatly accelerated under the condition of ensuring the hole-forming quality of the pile foundation, meanwhile, environmental friendliness is better achieved, civilized construction is facilitated, input of personnel and mechanical equipment is reduced, andthe good economic benefits are generated.

Owner:THE 5TH ENG MBEC

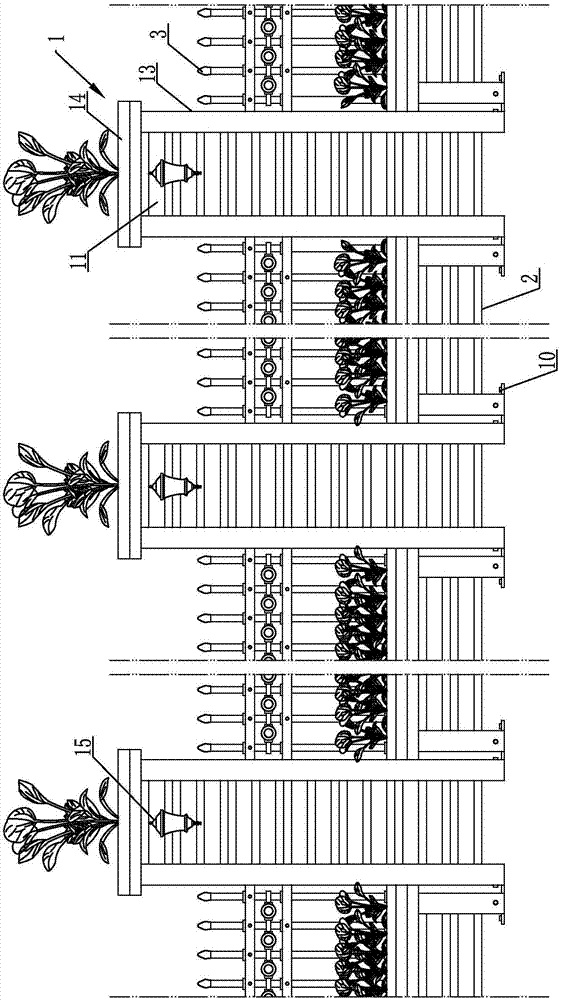

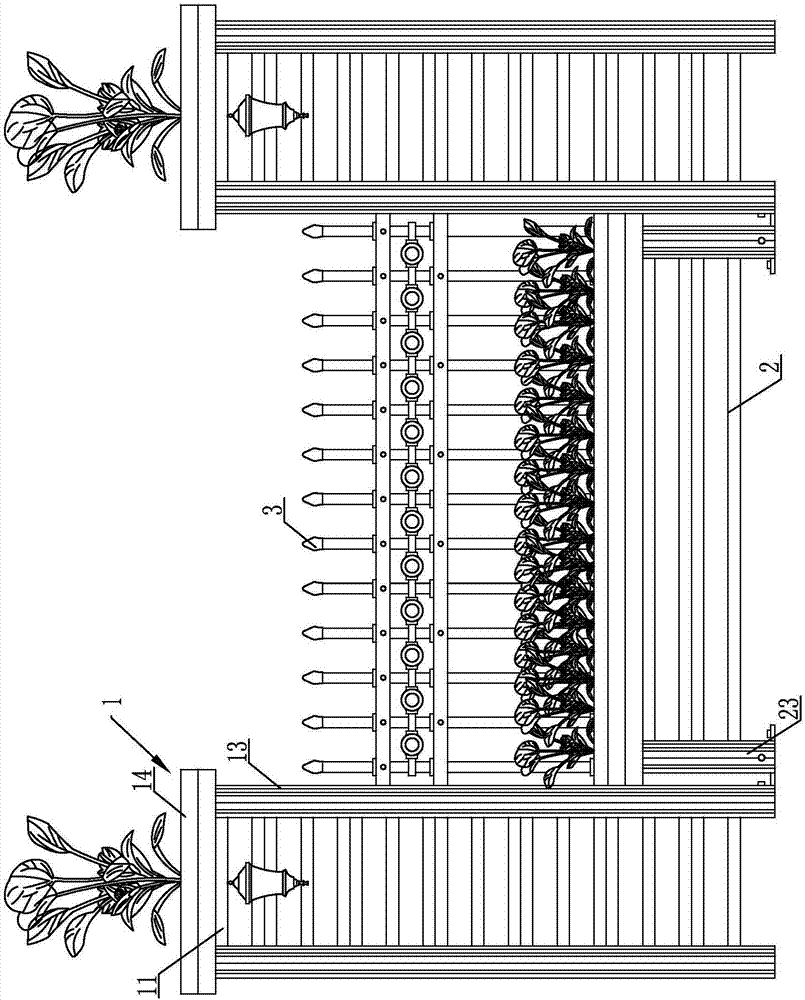

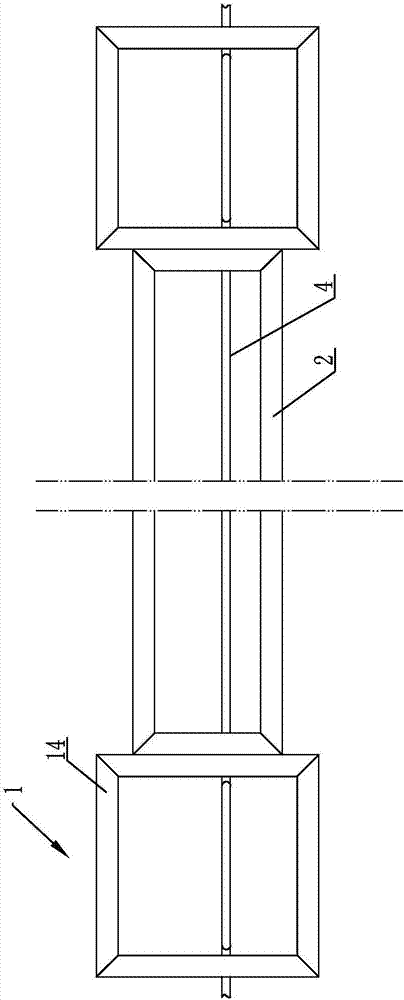

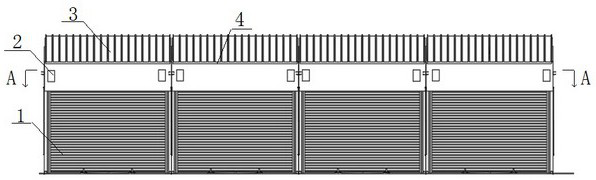

Flower box guardrail-type enclosing wall

InactiveCN106948652AQuick installationImprove construction qualityFencingReceptacle cultivationWallingFlower box

The invention discloses a flower box guardrail type fence, which comprises box-type uprights arranged at intervals, a low-wall flower box is arranged between the bottoms of two adjacent box-type uprights, and two box-type box-type boxes above the low-wall flower boxes There are guardrails between the columns, and the two ends of the guardrails are detachably connected to the corresponding box-type columns. The low-wall flower boxes are filled with nutrient soil for planting environmentally friendly landscapes. The low-wall flower boxes are connected to the adjacent A connecting and fixing device is provided between the box-type uprights; the present invention can ensure the improvement of construction quality, has high overall safety, is beneficial to speed up engineering installation, has high efficiency, and realizes disassembly and installation immediately, and the wall body can be moved, which has the advantages of It is conducive to the protection of the environment, reduces the waste of resources, does not disturb the people during construction, does not generate construction waste, and can be reused, which is conducive to promoting the development of energy saving, emission reduction and low carbon, and greatly reduces the incidence and danger of construction accidents.

Owner:刘保祥

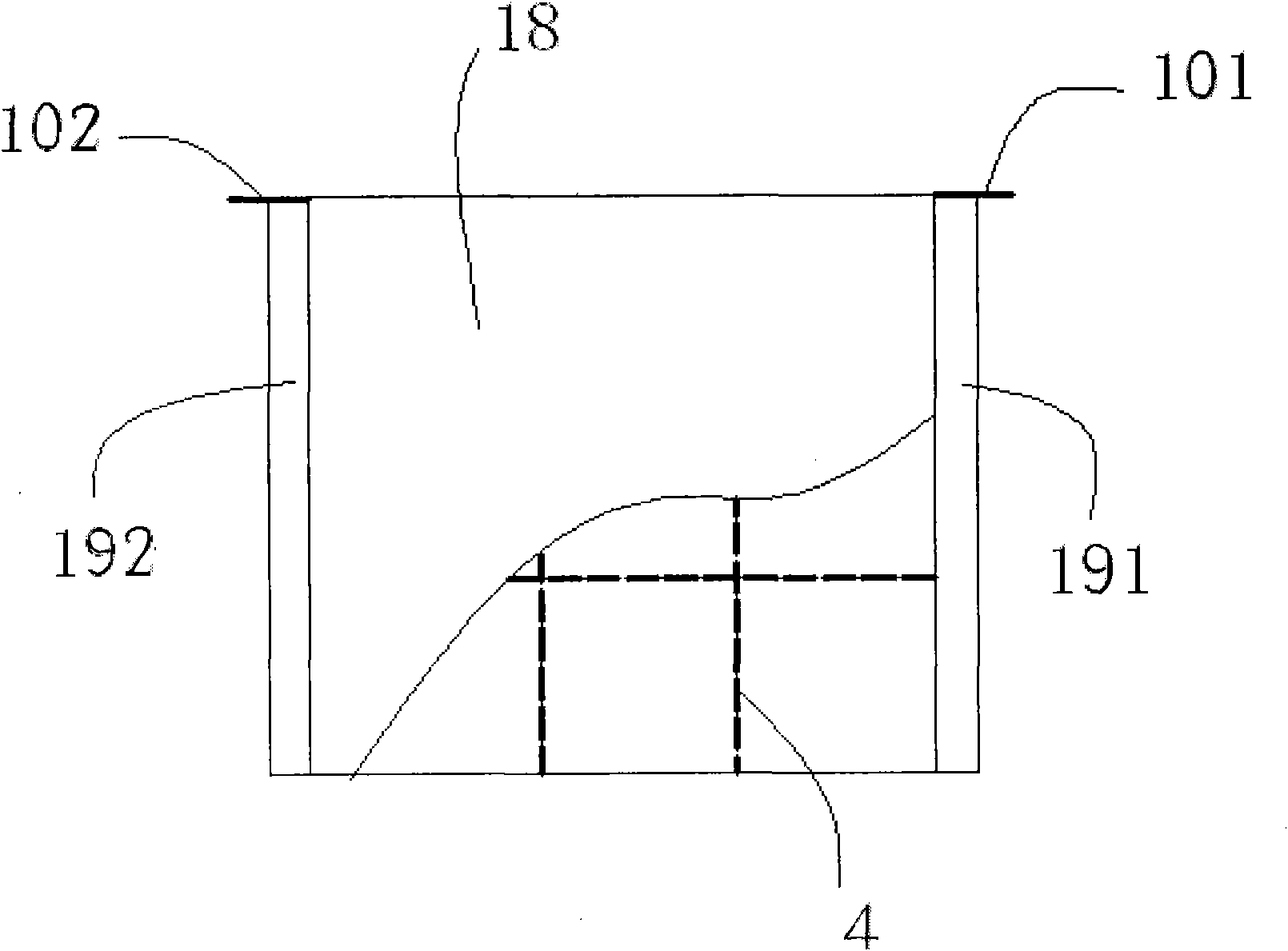

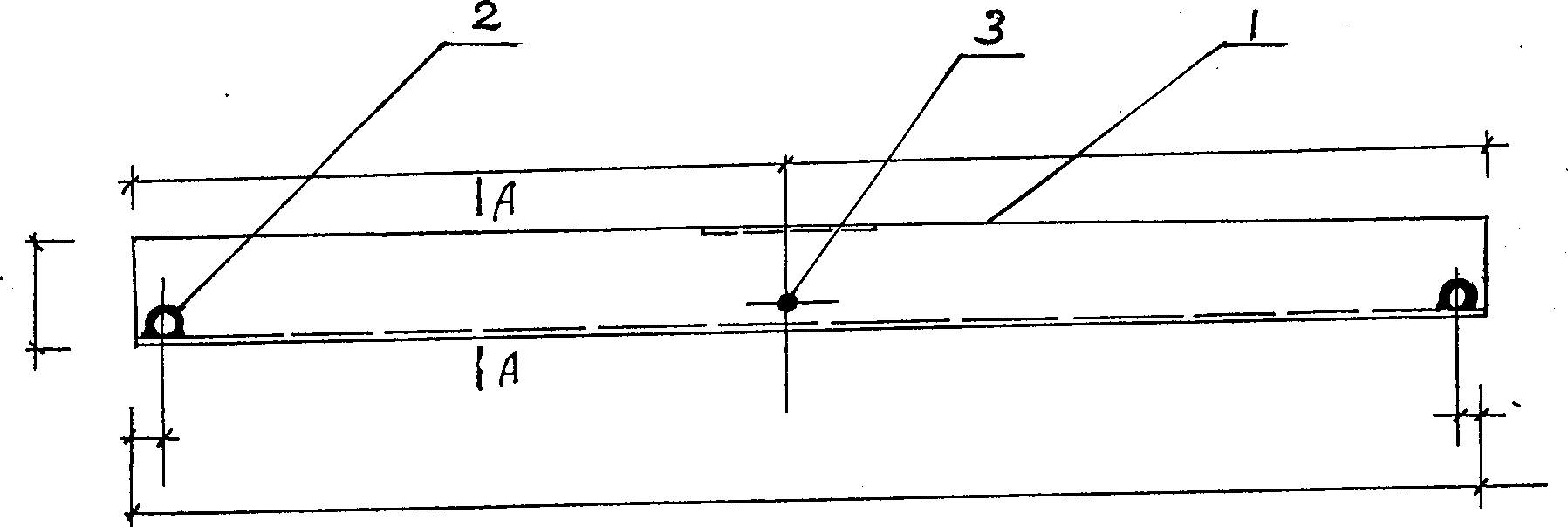

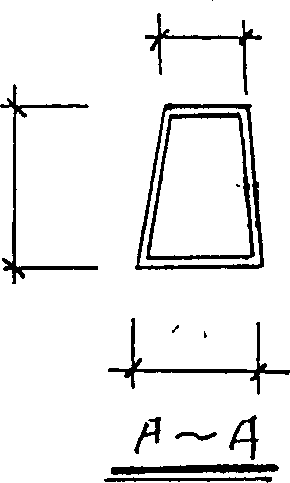

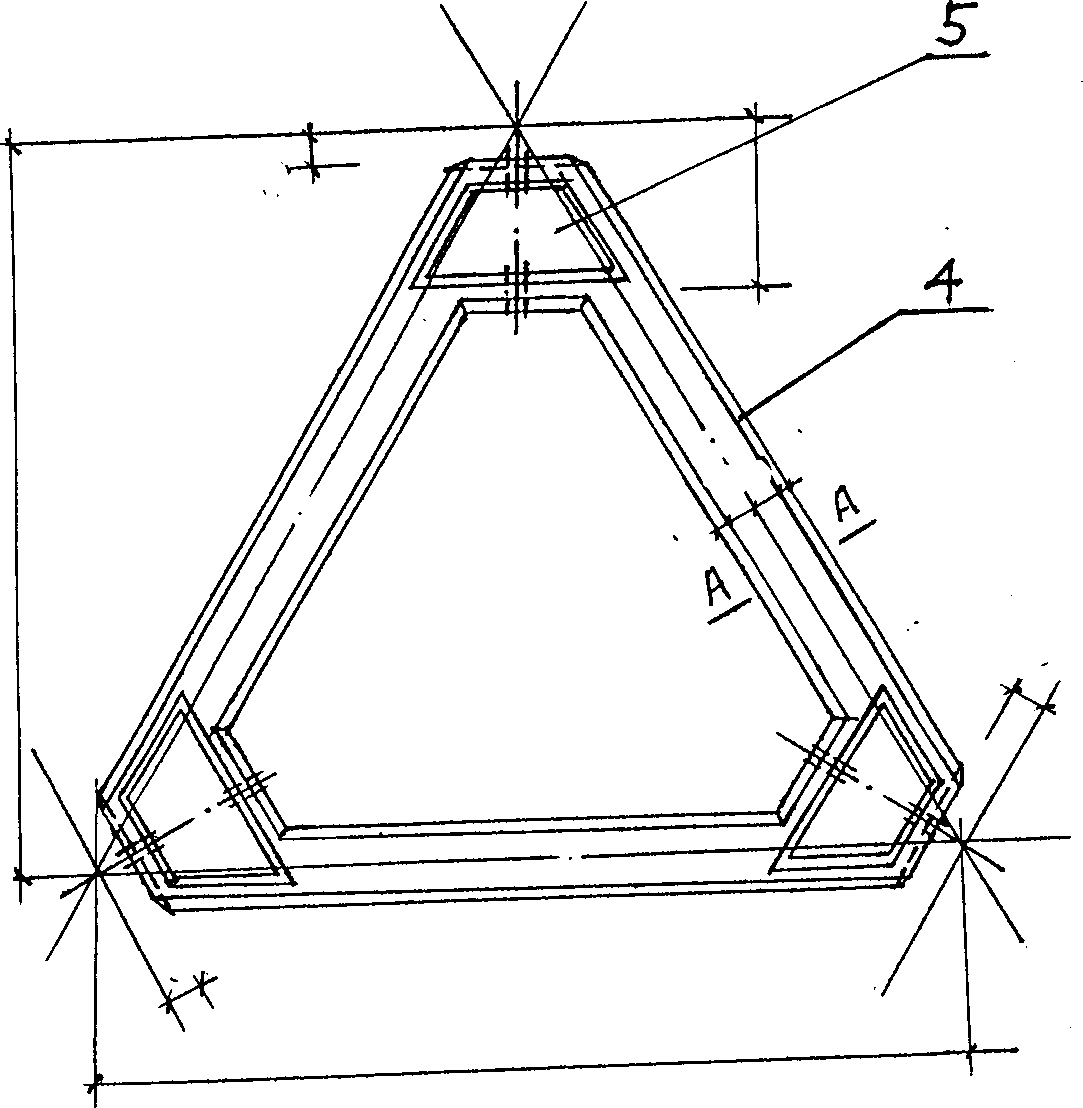

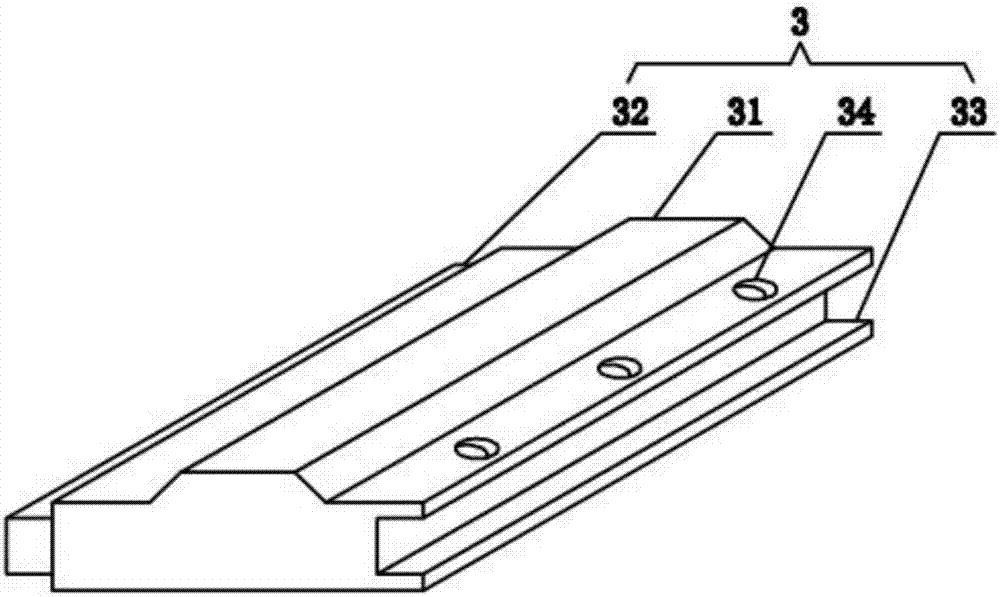

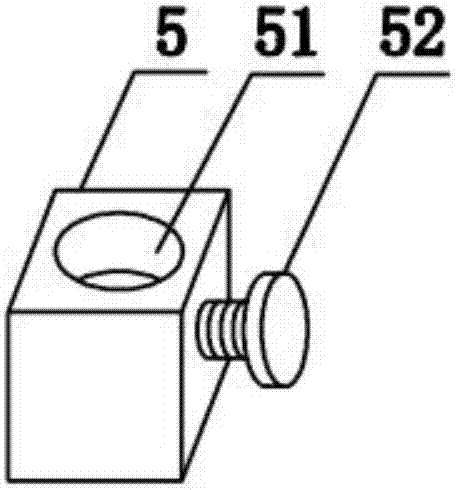

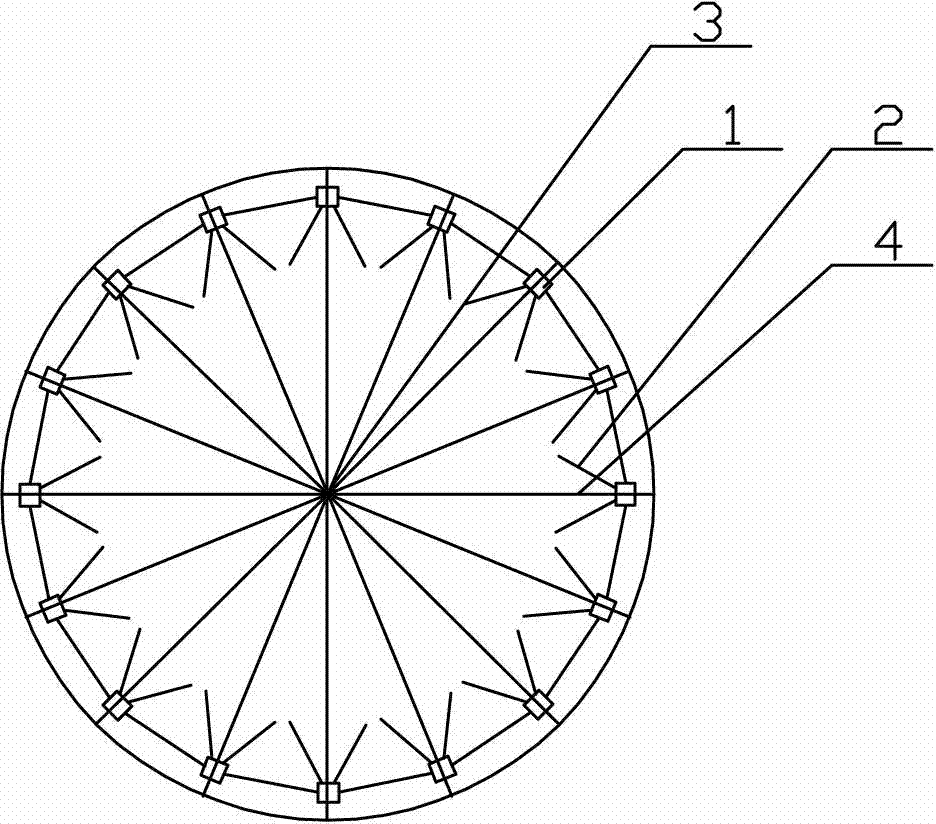

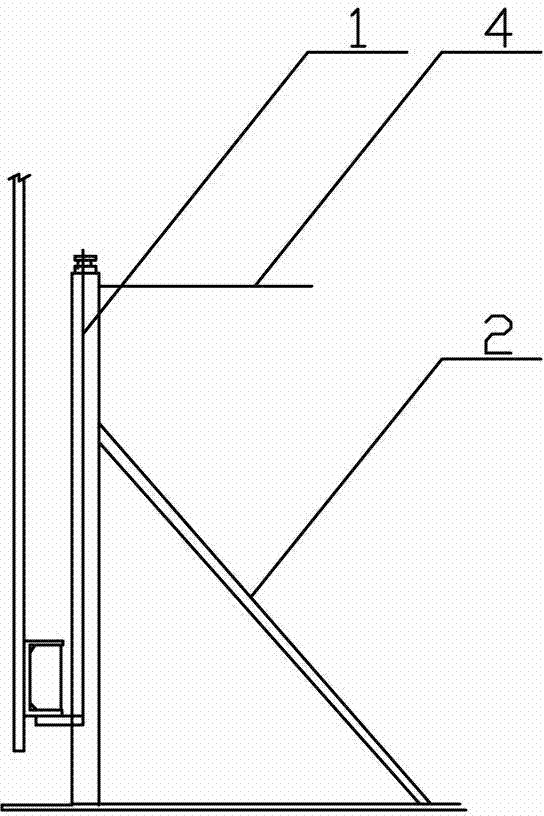

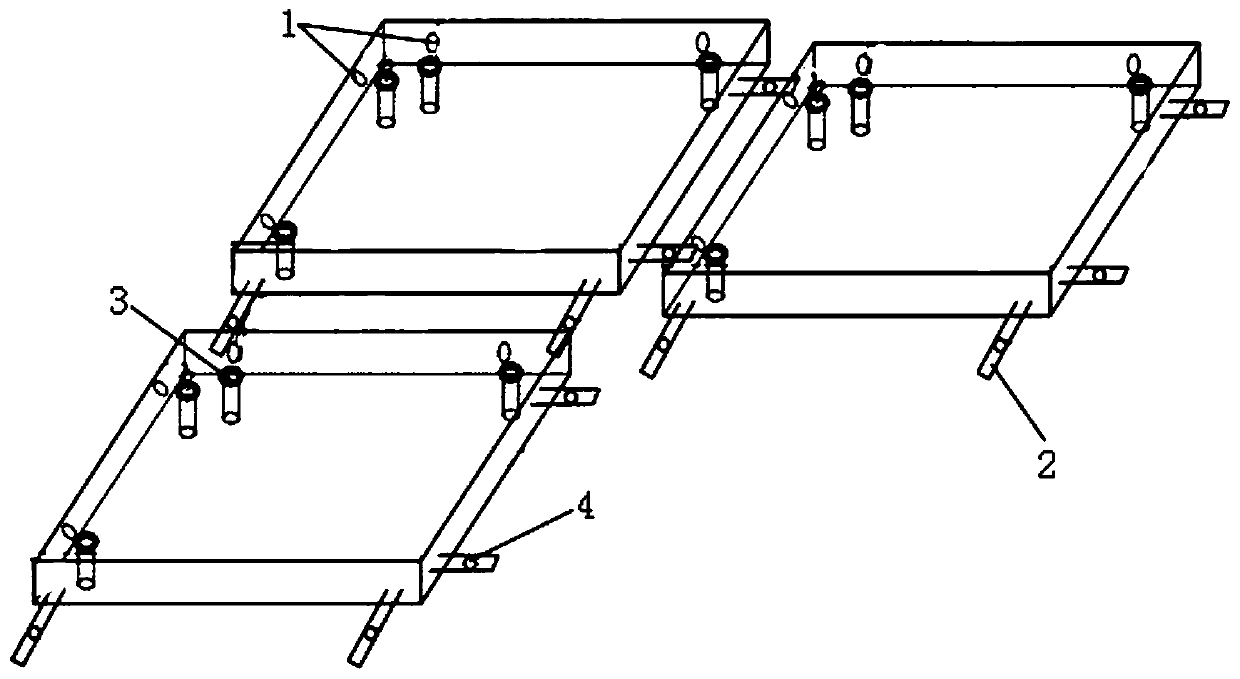

Cellular spliced floor member with triangular grid structure and its splicing method

InactiveCN1342823AConducive to civilized constructionRealize componentizationFloorsFloor slabBuilding unit

A cellular spliced floor member with triangular grid structure is composed of main ribs, node connectors, triangular-frame secondary ribs and triangular floor slabs. Its splicing method includes suchsteps as positioning the node connectors with adjustable supporting piles, sequentially connecting main ribs to form triangular structure, lowering the height of supporting piles for contacting with node connectors, regulating overall arch flexibility, connecting secondary ribs, lowering the height of supporting piles, installing triangular floor slabs pouring concrete and plastering. The invention makes building unit to be manufactured in factory possibly. Its advantages are low cost and high construction speed.

Owner:陈星

Retaining-wall reinforcement cage for traversing underground pipelines and construction method thereof

ActiveCN108867622ASolve construction difficultiesAvoids the need to span pipelinesBulkheads/pilesInterference factorSmall footprint

The invention discloses a retaining-wall reinforcement cage for traversing underground pipelines and a construction method thereof. The retaining-wall reinforcement cage comprises a reinforcement cageframework, primary suspension point groups and secondary suspension point groups, wherein the secondary suspension point groups are arranged on two sides of one end of the reinforcement cage framework; and the primary suspension point groups are arranged at an end of the reinforcement cage framework between the secondary suspension point groups. The construction method comprises the steps of slotting, suspending movement by use of the primary suspension point groups, suspending movement by use of the secondary suspension point groups and final accomplishment of construction. Owing to variations of positions of suspension points and transverse swinging movement in a slot, the retaining-wall reinforcement cage is prevented from stretching across the underground pipelines. The problem that aretaining wall is difficult to construct in a pipeline dense area can be effectively solved. The retaining-wall reinforcement cage has the advantages that an occupied area is small, a site is easy toarrange, the progress of works is high, interference factors are less and exiting facilities around are guaranteed to be in a perfect condition.

Owner:ZHONGJIAN SUIDAO CONSTR CO LTD +1

Flow construction method for forming cast-in-place bored pile for gravel-decomposed rock stratum in double-machine combined mode

InactiveCN106677166AAvoid pollutionOvercome pollution and other deficienciesRotary drillingRotary-drilling machinesEngineeringRebar

The invention discloses a flow construction method for forming a cast-in-place bored pile for a gravel-decomposed rock stratum in a double-machine combined mode. The flow construction method comprises the steps that a high-power hydraulic spiral drilling machine is adopted to conduct drilling; drilling is conducted to the design pile bottom elevation; the requirements of a design and related specifications for the length of the pile and a bearing course at the pile end are met; pore-forming is finished; a drilling rod is lifted out; residue soil produced by pore-forming with the high-power hydraulic spiral drilling machine is layered again and poured in a pile hole through equipment such as an excavator, the speed rate of backfill is controlled, and the filling quality of backfill soil to the pile hole is guaranteed; after a pile position is rechecked and set out again, a long spiral drilling machine is adopted to conduct drilling again on the backfill hole position and pile body concrete is pumped into the pile hole through the end of a drilling rod of the long spiral drilling machine; the pouring top face of the pile body concrete is 0.5-1 m higher than the design pile top elevation; after pumping is finished, a reinforcement cage is lowered to the design elevation trough the method that after vibrating, the reinforcement cage is inserted into the pile body concrete; and the steps are repeated, so that pile-forming flow construction is realized through the combination of the high-power hydraulic spiral drilling machine and the long spiral drilling machine.

Owner:江苏省岩土工程公司

Method for blocking large-pipe-diameter rainwater pipeline through short air bag

The invention discloses a method for blocking a large-pipe-diameter rainwater pipeline through a short air bag. The method includes the following steps that firstly, the pipeline is strengthened, and a foundation pit is excavated; secondly, impurities are removed; thirdly, the short air bag is arranged, and fixing is firm; fourthly, the short air bag is connected with an air compressor; fifthly, a three-way air valve is checked; sixthly, pressurizing and inflating are conducted; seventhly, sealing is achieved; eighthly, after work is completed, the three-way air valve is adjusted, and exhausting is conducted; ninthly, the short air bag is pulled out. According to the method for blocking the large-pipe-diameter rainwater pipeline, the short air bag is used for blocking the drain pipeline, the problems that that great danger exists in the brick wall detaching work, blocked residues can be hardly removed thoroughly, rubbish mixed in fluid in the pipeline may block the pipeline, and the use safety of the pipeline is affected are solved, the purchase cost and the use cost are saved, the time cost of the construction progress is saved, various costs are reduced, the construction cost is reduced, the economic benefits are improved, underground unmanned work is achieved, the safety of workers is ensured, and the construction period is shortened.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP OF THE FIFTH ENG +1

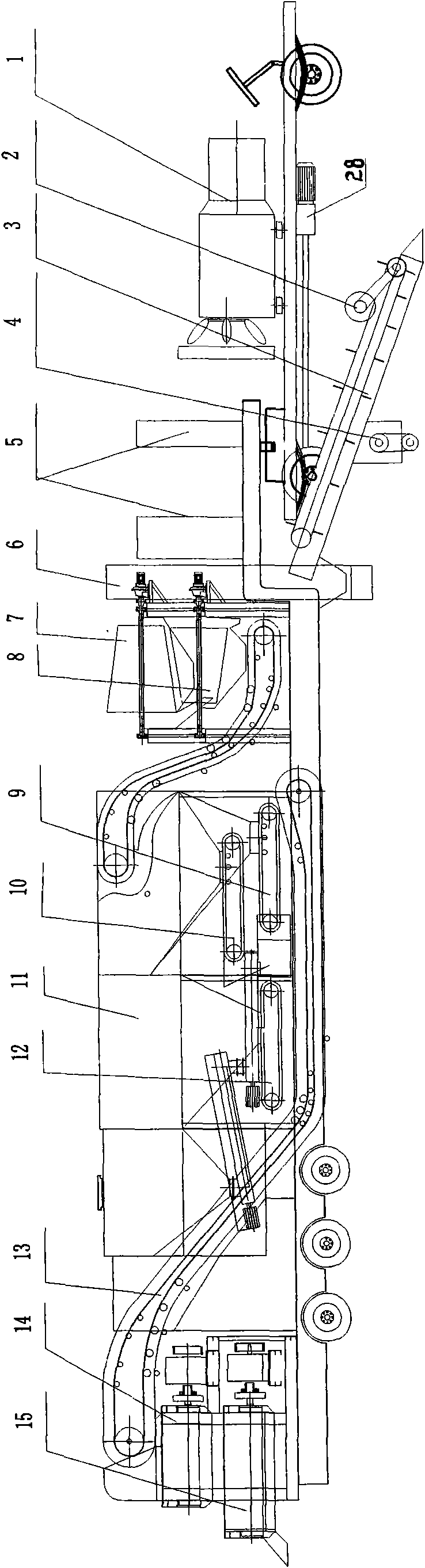

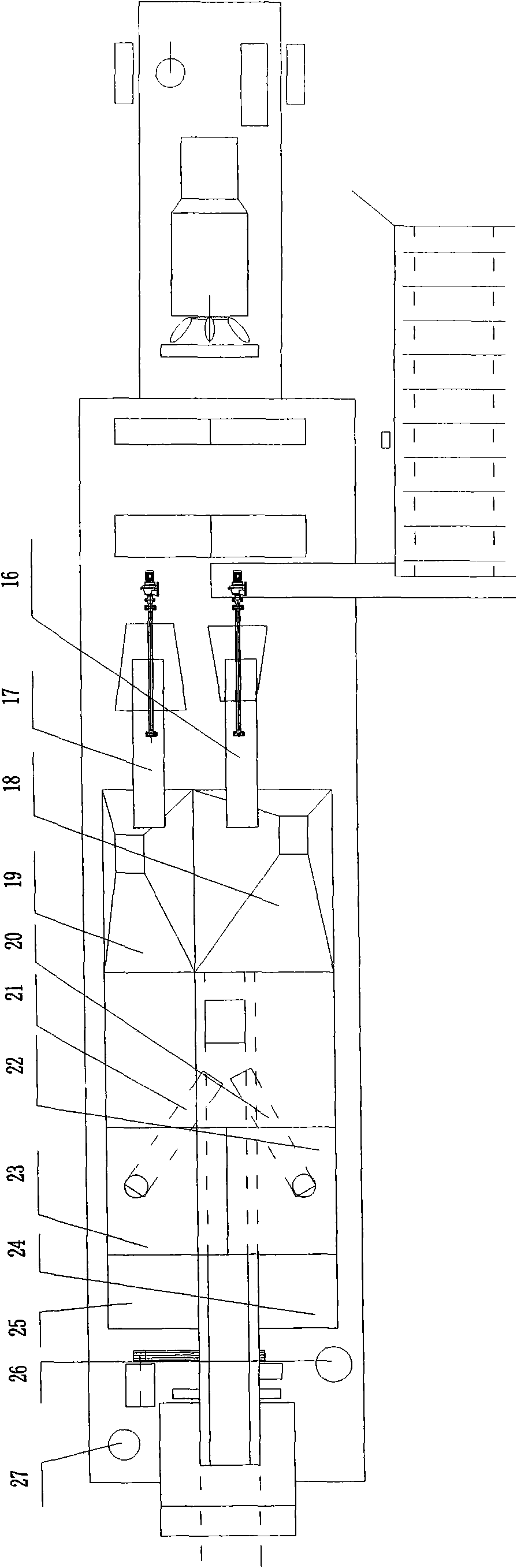

Mix-in-place train for bituminous pitch cold second birth cement fragmental stone

InactiveCN101549529AImprove the level ofPrecise thickness controlMixing operation control apparatusRoads maintainenceCrushed stoneEngineering

The present invention discloses a mix-in-place train for bituminous pitch cold second birth cement fragmental stone which includes a scratch board feeder, an electric generating set on the train body, a power control cabinet, a water tank, a metering water pump, an emulsified bitumen tank, an emulsified bitumen pump, a powder screening machine, a stirring machine, a side charging belt conveyor and a total conveying belt, the train body also is equipped with a cement silo, a mineral powder tank, an aggregate recovering bin, a new aggregate bin, and down part of above container outlet are equipped with a cement and mineral powder metering screw conveyer connected with the total conveying belt for weight class matching, a recovering aggregate and a new aggregate electric feeder; the power control cabinet electrical connects with a walking variable frequency motor of the scratch board feeder, and electrical connects with the metering water pump, the emulsified bitumen pump, the recovering aggregate and new aggregate electric feeder, the cement and mineral powder metering screw conveyer. The recovering technique does not need cleaning, transporting, breaking and heating waste material which shortens construction period, saves material and transportation cost, and is easy to drive synchronously and disassembled.

Owner:HENAN TONGHE HIGHWAY MAINTENANCE PROJECT +1

Steel structure simple house capable of being rapidly dismounted and mounted

InactiveCN106988426AFactory highImprove completenessBuilding constructionsBrickArchitectural engineering

The invention discloses a steel structure simple house that can be quickly disassembled and assembled in the technical field of steel structures, which includes a frame, a support rod is installed on the top of the frame, a sliding block is sleeved on the support rod, and the left and right sides of the sliding block The side is movably connected with a bracket, the left side of the bracket is movably connected with the first roof, the right side is movably connected with the second roof, the first roof and the second roof are connected by hinges, and the first roof and the second roof are movably connected. The bottom of the second roof is connected with a support column, and the bottom end of the support column is fixed to the top of the frame. The light steel structure fittings of the present invention have a high degree of industrialization and mechanization, a high degree of commercialization, and a fast on-site construction speed without affecting It is conducive to civilized construction to nearby residents. Compared with traditional brick-concrete structure houses, the wall thickness is smaller, which can increase the effective use area, and the light steel structure houses are light in weight and have good shock absorption performance.

Owner:华新顿现代钢结构制造有限公司

Large-scale seed precipitation tank body mounting construction method

InactiveCN103754908AReduce the amount of work at heightImprove construction progressAluminium oxides/hydroxidesAluminum industryRebar

The invention relates to a seed precipitation tank construction method in an aluminum industry, and particularly relates to a large-scale seed precipitation tank body mounting construction method comprising the following steps: A, a tank bottom plate is mounted by a traditional method; B, hydraulic lifting pillars are uniformly arranged at a same circumference of the interior of a tank body, a mast is vertically arranged at the center of the interior of the tank body, and the top of the mast is connected with each of the hydraulic lifting pillars by a steel wire rope or a steel bar; C, a topmost ring of cylinder section and a tank top structure are assembled and welded on the periphery of the hydraulic lifting pillars, and the inner wall of the cylinder section is welded with a lifting-up bearing plate connected with the hydraulic pillars; D, the welded cylinder section is synchronously lifted up, a next section of cylinder section is welded, and the cylinder sections are assembled; E, the step D is repeated until welding of the whole cylinder sections is completed; and F, the lowest-part cylinder section and a bottom plate are connected and aligned, the auxiliary devices are dismounted, and the construction is completed. The construction method adopting the technical scheme of the invention has small requirements on a field, and is low in operation difficulty and high in construction efficiency.

Owner:CHONGQING NO 3 CONSTR +2

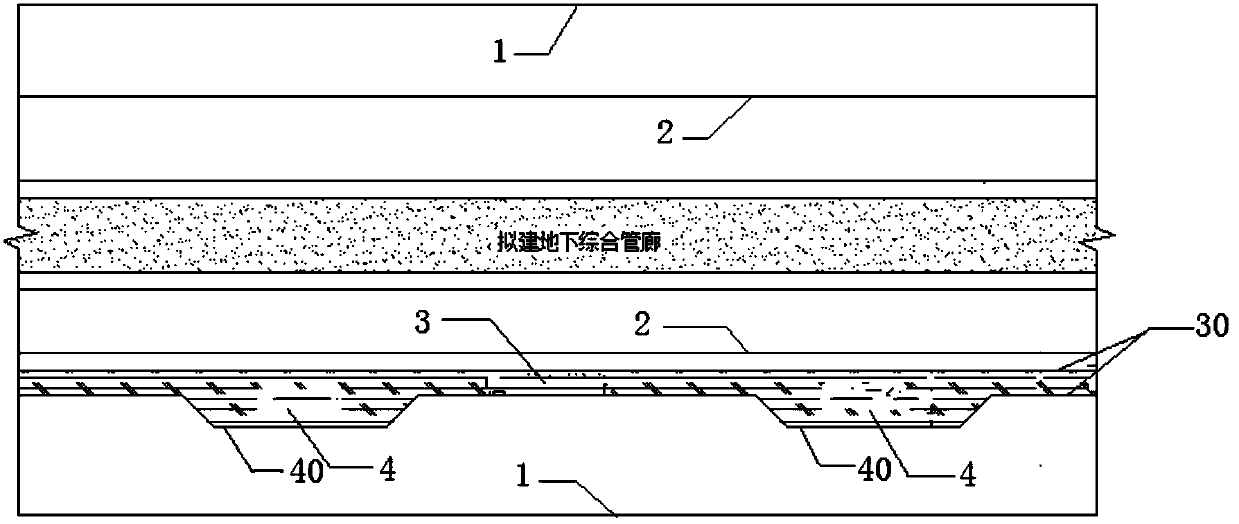

Assembly type concrete pavement and construction method

InactiveCN110306396AReduce pollutionEffective protectionCable installations in surface ductsSingle unit pavingsResource utilizationRoad surface

The invention provides an assembly type concrete pavement and a construction method. The pavement comprises a soil layer and a concrete layer, wherein the concrete layer is laid on the soil layer, a cable groove is formed in a certain distance below the soil layer, a cable is arranged in the cable groove in a penetrating mode, the concrete layer is formed by splicing a plurality of concrete prefabricated plates, the concrete prefabricated plates are of rectangular plate-shaped structures, horizontal socketing holes are formed in the one side end surfaces and the rear end surfaces of the concrete prefabricated plates, connecting rods are arranged on the other side end surfaces and the front end surfaces of the concrete prefabricated plates, first socketing openings are arranged at the positions, corresponding to the horizontal bearing holes, of the top surfaces of the concrete prefabricated plates, the connecting rods are configured with the horizontal bearing holes, the connecting rodsare provided with second socketing openings, and the first bearing sockets and the bearing sockets are connected with socketing columns in a configured mode. According to the pavement and the method,the construction efficiency is improved, the construction cost is reduced, the construction noise is reduced, and the resource utilization rate is improved.

Owner:CHINA FIRST METALLURGICAL GROUP

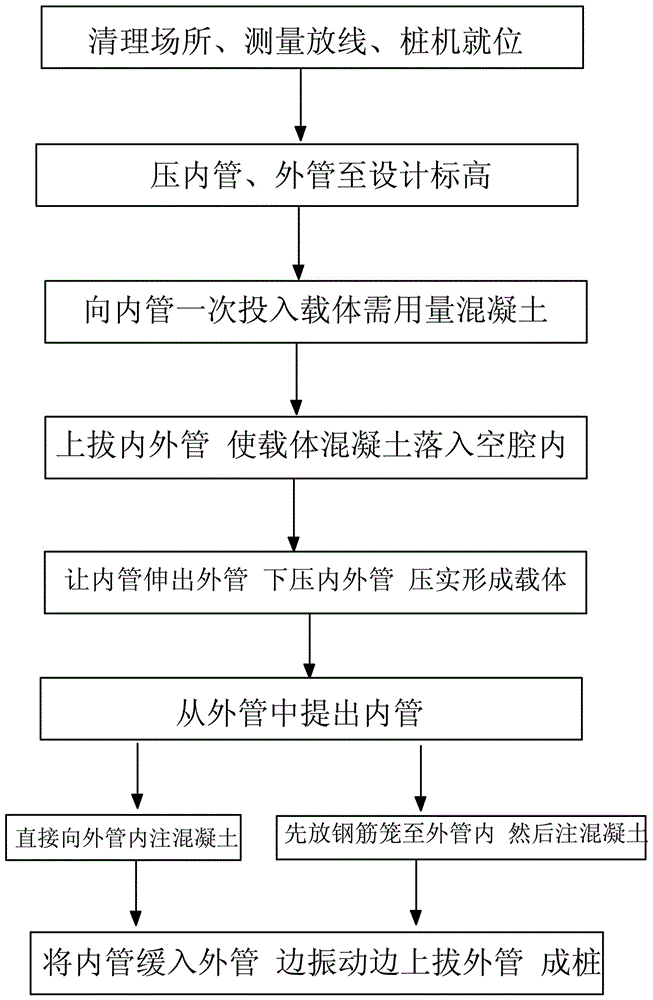

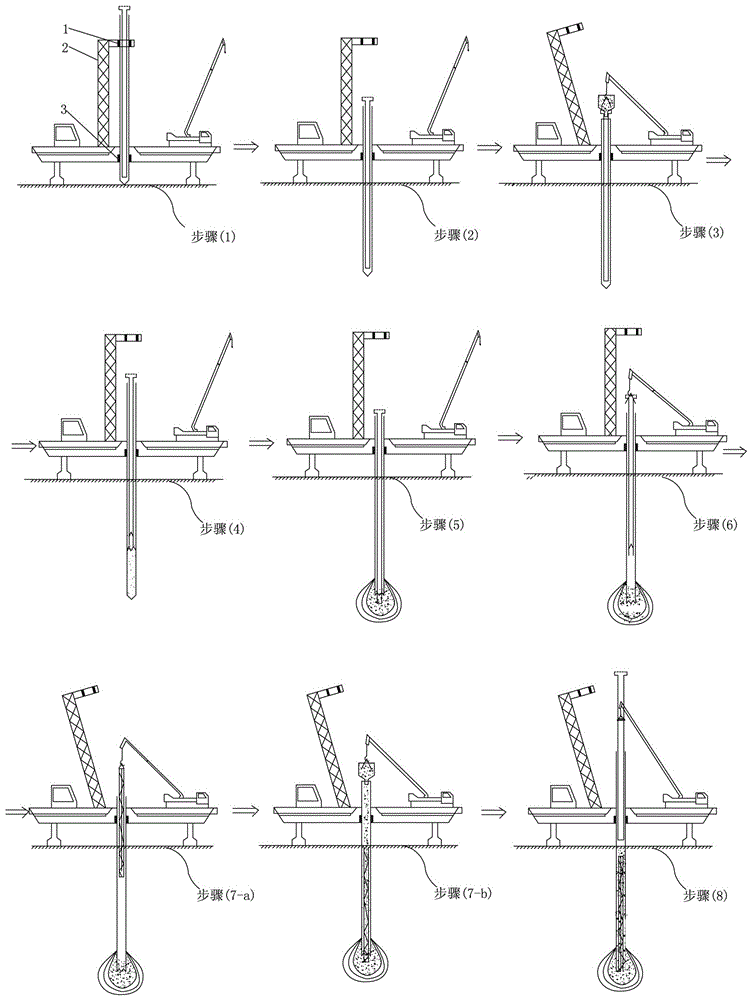

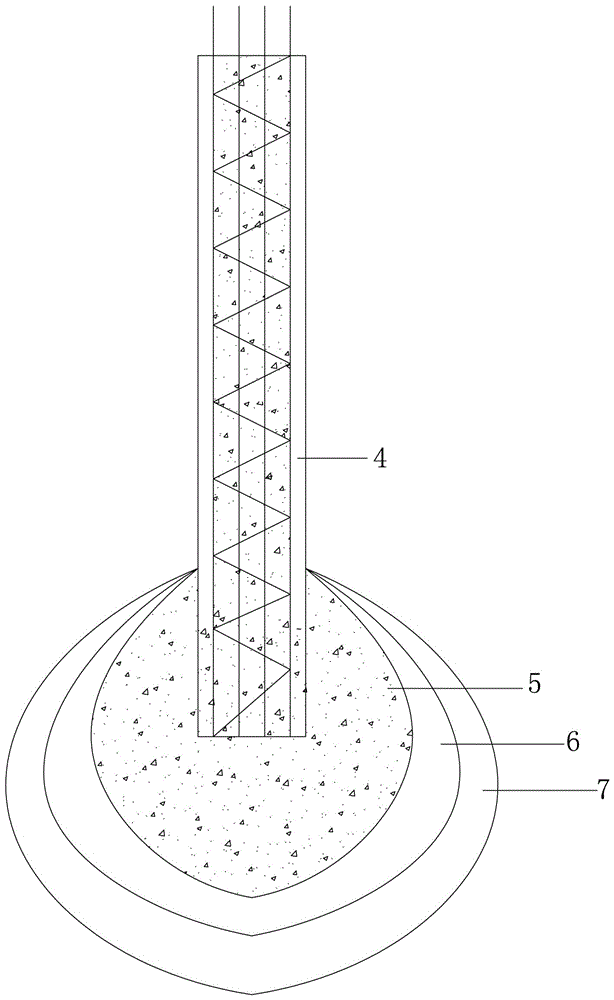

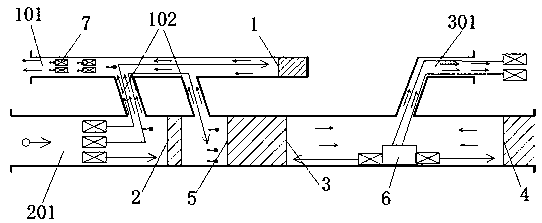

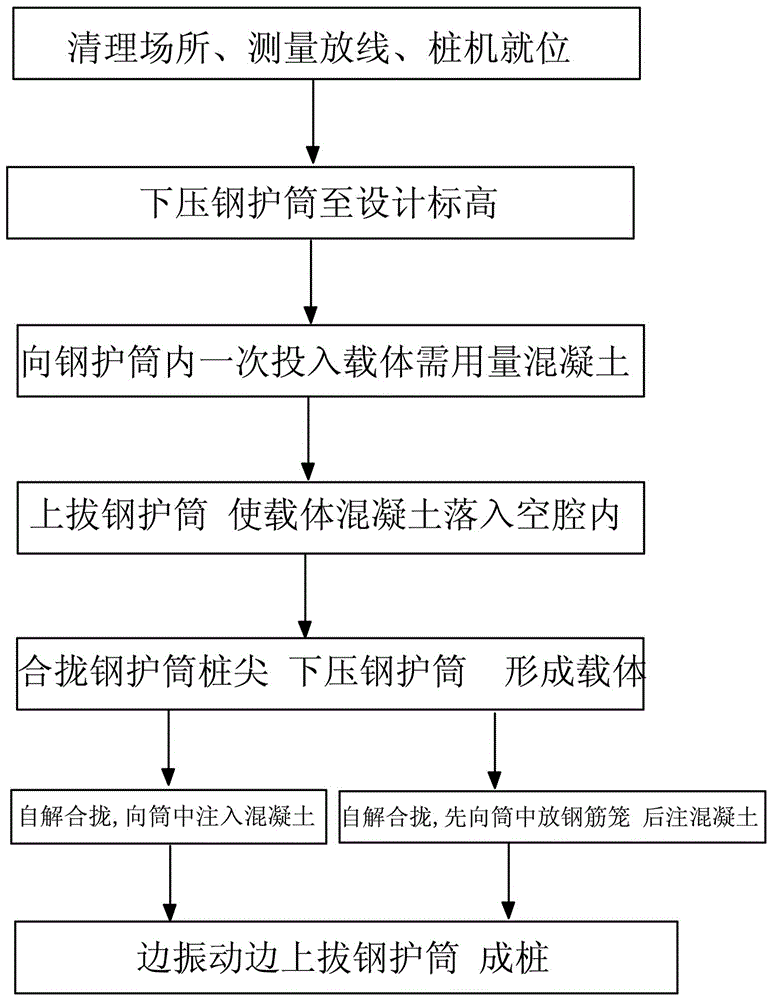

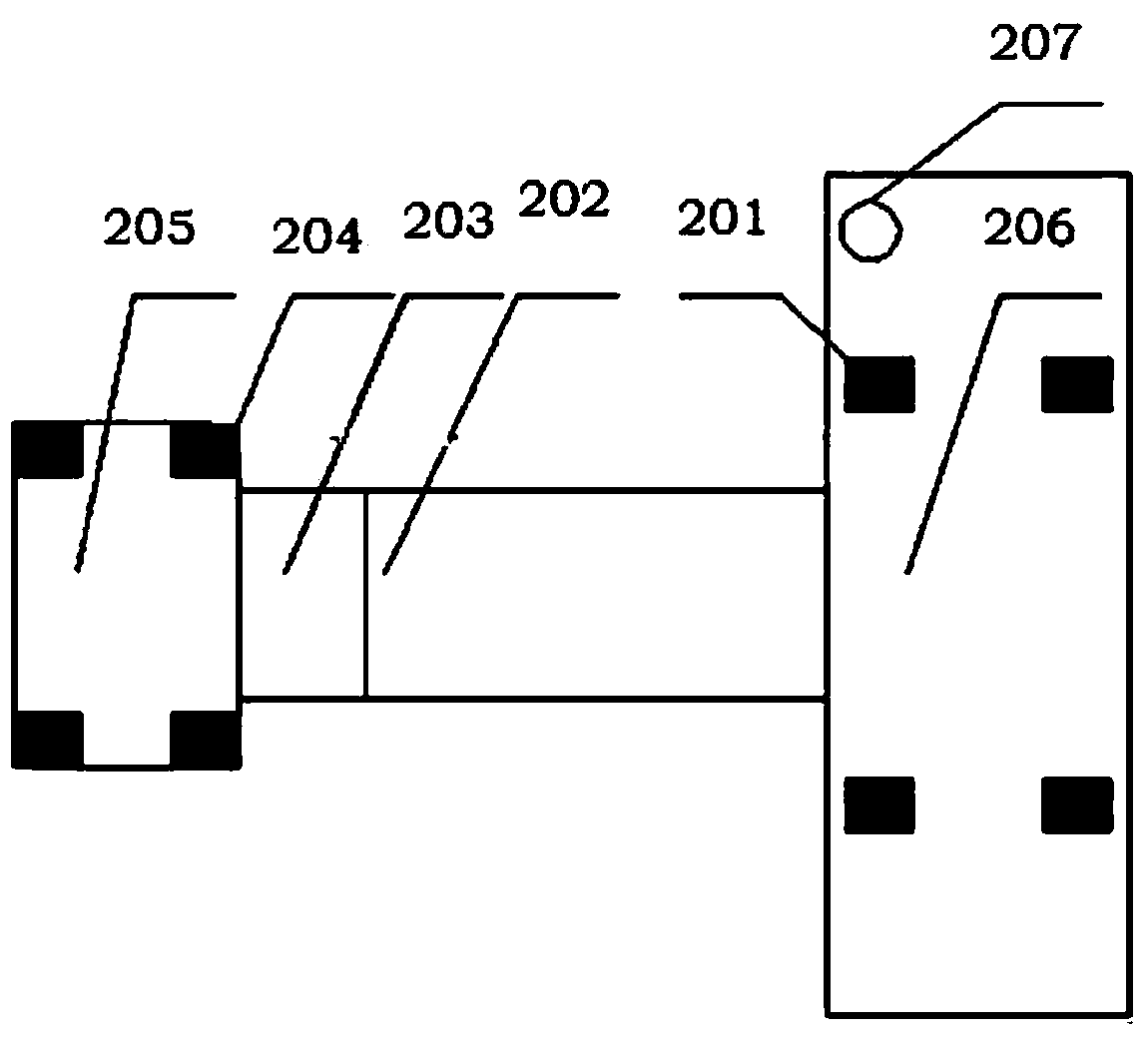

Double-pipe construction method for static pressure pipe-sinking carrier cast-in-place pile

InactiveCN105926594AImprove bearing capacityOvercome the defects of pile forming processBulkheads/pilesDouble tubeArchitectural engineering

The invention provides a double-pipe construction method for a static pressure pipe-sinking carrier cast-in-place pile. The carrier pile is manufactured through a static pile driver, an inner pipe and an outer pipe. Throwing of a carrier concrete material is completed at a time, the pile-forming period is shortened, energy is saved, and the environment is protected; and the pull resistance of the manufactured pile is improved remarkably. The double-pipe construction method includes the following steps that firstly, a site is cleaned, surveying and setting-out are conducted, and the pile driver is moved to a station; secondly, the inner pipe and the outer pipe are pressed to the designed elevation; thirdly, concrete required by a carrier is thrown into the inner pipe at a time; fourthly, the inner pipe and the outer pipe are up-pulled to the set height together, and a space formed when the inner pipe and the outer pipe are up-pulled can be filled with the carrier concrete automatically; fifthly, the inner pipe is lowered, the bottom end of the inner pipe extends out of the bottom end of the outer pipe, the inner pipe and the outer pipe are pressed downwards, the downward pressing force and the elevation reach the preset numerical value, and the expanded carrier is formed; sixthly, the inner pipe is lifted out of the outer pipe; seventhly, concrete is poured into the outer pipe, or a reinforcement cage is placed in the outer pipe firstly, and pile body concrete is poured; and eighthly, the inner pipe is put into the outer pipe, the outer pipe is up-pulled while vibrating, and the pile is formed.

Owner:朱龙

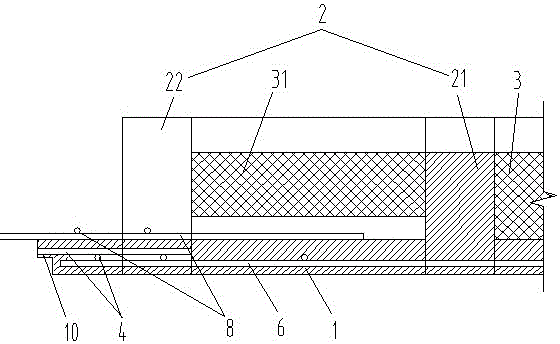

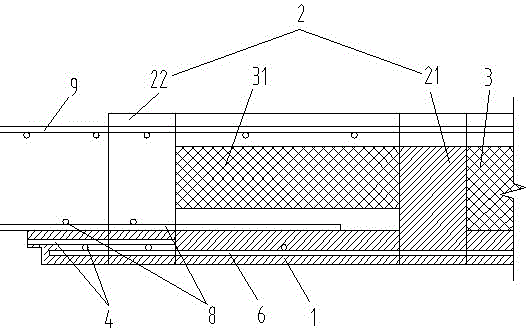

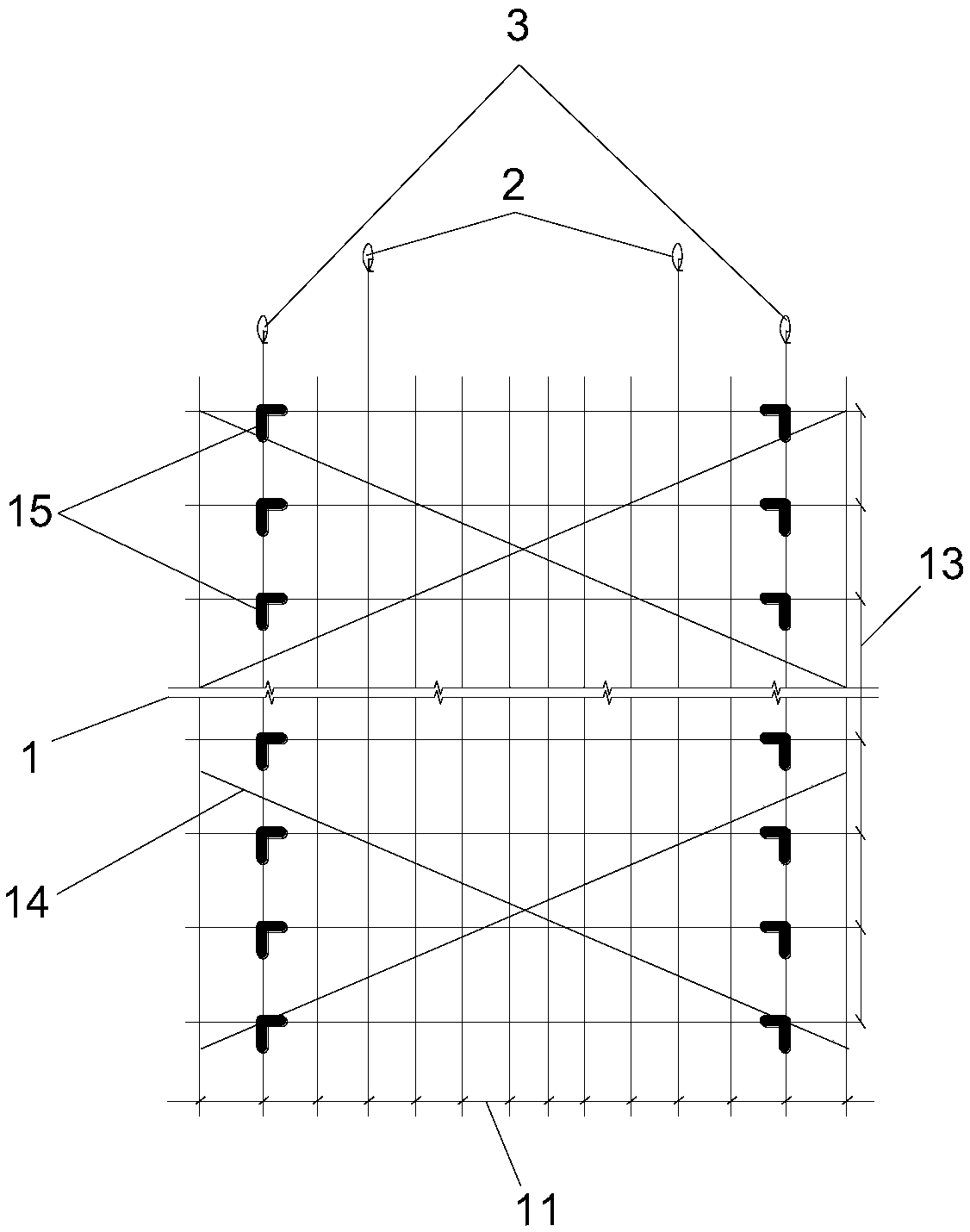

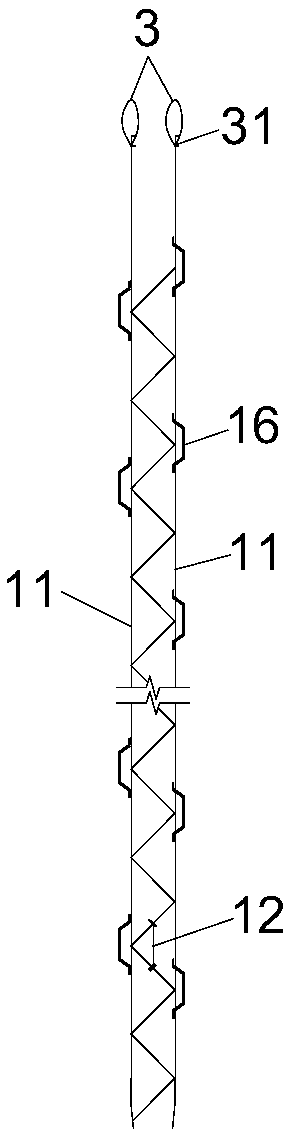

Premanufactured superimposed rib floor for assembly-type steel structure house

The invention relates to a premanufactured superimposed rib floor for an assembly-type steel structure house. The premanufactured superimposed rib floor comprises a premanufactured superimposed floor at the bottom, wherein rib beams are arranged on the upper part of the premanufactured superimposed floor; a filling box body is arranged in a space defined by the rib beams; the rib beams are made of prefabricated reinforced concrete; cast-in-situ is adopted among the rib beams and steel beams at connection parts of the premanufactured superimposed rib floor and the steel beams; and the other rib beams and the premanufactured superimposed floor are cast in advance. According to the premanufactured superimposed rib floor for the assembly-type steel structure house, cast-in-situ is adopted for the rib beams and the steel beams at the connection parts of the premanufactured superimposed rib floor and the steel beams, so that a fireproof problem of connection joints of steel posts and the steel beams and the steel beams; the rib floor filled with light materials is adopted, so that a heat preservation effect is realized; premanufactured superimposed rib floor components are produced in a factory in advance, and are assembled on site, so that on-site construction speed is improved; circulation materials like a great number of supporting steel tubes, wood beams, web film multi-layer plates or bamboo plywood and the like are reduced; construction speed is improved; and construction cost is lowered.

Owner:CHINA 22MCC GROUP CORP

Ventilation and dustproof method used for tunnel construction

The invention provides a ventilation and dustproof method used for tunnel construction. The ventilation and dustproof method comprises the following steps that 1, air ducts are arranged at the front of excavation working faces of a flat pilot tunnel, a main hole, and an inclined shaft and move forward with moving forward of each working face; 2, after the main hole is connected with a first transverse passage, a draught fan is arranged at the intersection of the main hole and the first transverse passage, the air ducts are respectively arranged on the second working face and the first workingface of excavation, and a jet flow draught fan is arranged in the flat pilot tunnel to induce airflow to a tunnel opening; and excavation is conducted to the two sides of the main hole after the inclined shaft communicates the main hole; and 3, two transverse passages nearest to the second working face are reserved between the main hole and the flat pilot tunnel, and the draught fan moves with excavation of the main hole to the intersection of the NTH transverse passage and the main hole. According to the ventilation and dustproof method, the air ducts and draught fans are arranged on the fiveworking faces of tunnel construction and excavation for ventilation and circulation, the position is adjusted and a line is laid according to the construction steps by using the air ducts and the draught fans, air duct direction turning and tapoff of the multiple air ducts in a tunnel with the complex structure are realized, and the loss of wind power is greatly reduced.

Owner:THE 2ND ENG CO LTD OF CHINA RAILWAY 17 BUREAU GRP

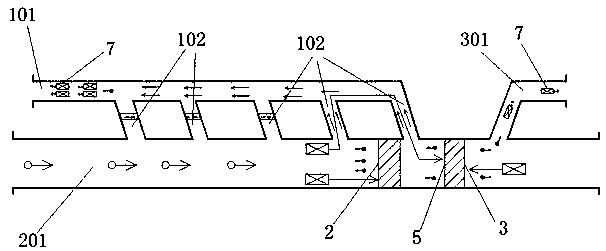

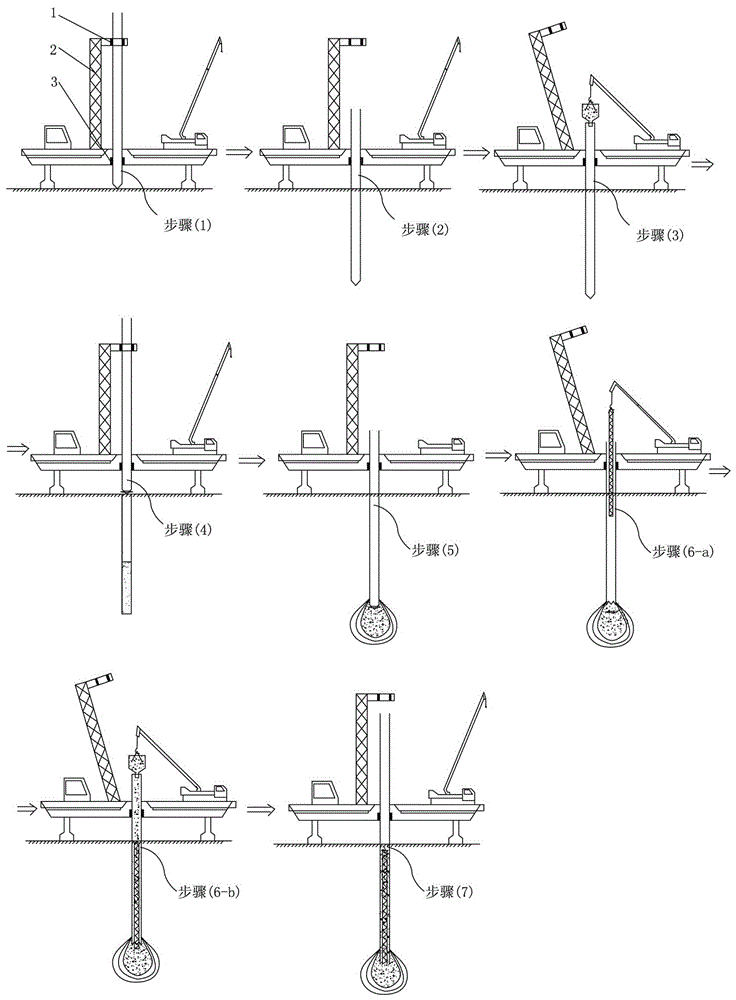

Single-pile-casing construction method for static pressure sinking pipe carrier cast-in-place pile

The invention discloses a single-pile-casing construction method for a static pressure sinking pipe carrier cast-in-place pile. A static pile driver and a single pile casing can be used for manufacturing the carrier pile; carrier concrete materials are put in at a time, the construction speed is obviously increased, and energy conservation and environment friendliness are achieved; and the pulling resistance of the carrier pile manufactured through the static pile driver and the single pile casing is obviously improved. The method includes the following steps that firstly, a field is cleaned, surveying and setting out are conducted, and the static pile driver is moved to a station; secondly, the steel pile casing provided with a conical valve pile tip is pressed to the designed elevation; thirdly, concrete with the amount needed by a carrier is put into the steel pile casing at a time; fourthly, the steel pile casing is pulled upwards to be exposed out of the ground, and the space formed by upward pulling of the steel pile casing is automatically filled with the put-in carrier concrete ; fifthly, the pile tip is closed, the steel pile casing is pressed downwards, the downward pressing force and the elevation reach preset values, and the carrier concrete is compacted to form an expanded carrier; sixthly, closing is automatically relieved, pile body concrete is poured, or a reinforcement cage is firstly placed, and then concrete is poured; and seventhly, the steel pile casing is pulled out of the ground while vibration is conducted, and the pile is formed.

Owner:朱龙

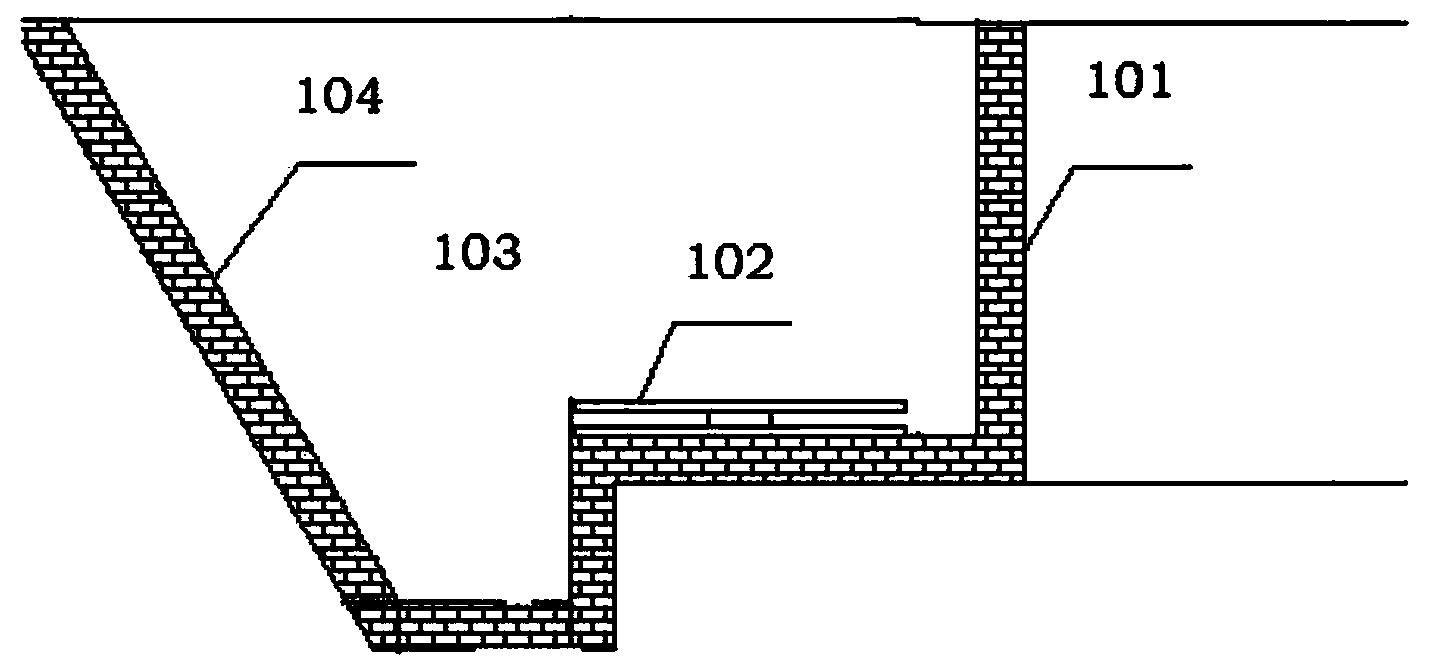

Construction method utilizing forced mixer and devices used in same

InactiveCN103590604ASolve the situation that cannot be arrangedReduced installation areaBuilding material handlingArchitectural engineeringStructural engineering

The invention relates to a construction method utilizing a forced mixer and devices used in the construction method. The construction method comprises the first step of surveying and setting out, the second step of grooving a foundation pit of the forced mixer and performing surveying, positioning, leveling and setting out, the third step of performing slope excavation on a transportation rail, the fourth step of constructing a bed course, wherein the a concrete bed course is poured at the bottom of the constructed bed course, the fifth step of building walls and plastering the walls, and the sixth step of pouring concrete, wherein the foundation pit of the forced mixer is of a concrete pouring structural style. The construction method utilizing the forced mixer and devices used in the construction method have the advantages that the problem that a mixer construction system cannot be arranged because of being limited by the site of municipal engineering is solved, the installing area is reduced so that the devices can be installed in a narrow site, and site area is saved; due to mechanized construction, construction time is effectively shortened, construction efficiency is improved, and labor intensity is relieved; compared with other concrete systems, flowing dust pollution does not exist, and civilized construction is facilitated; besides, one-off amount of mixing is small, so that errors are small, and material distribution can be automatically completed.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

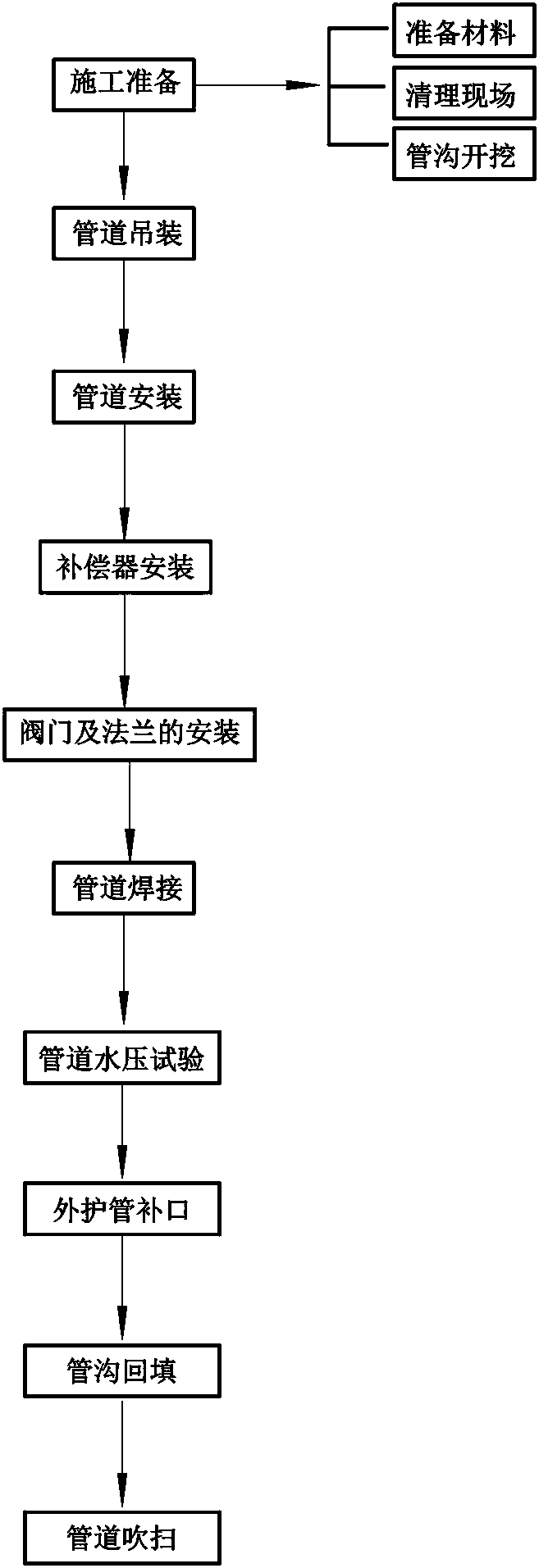

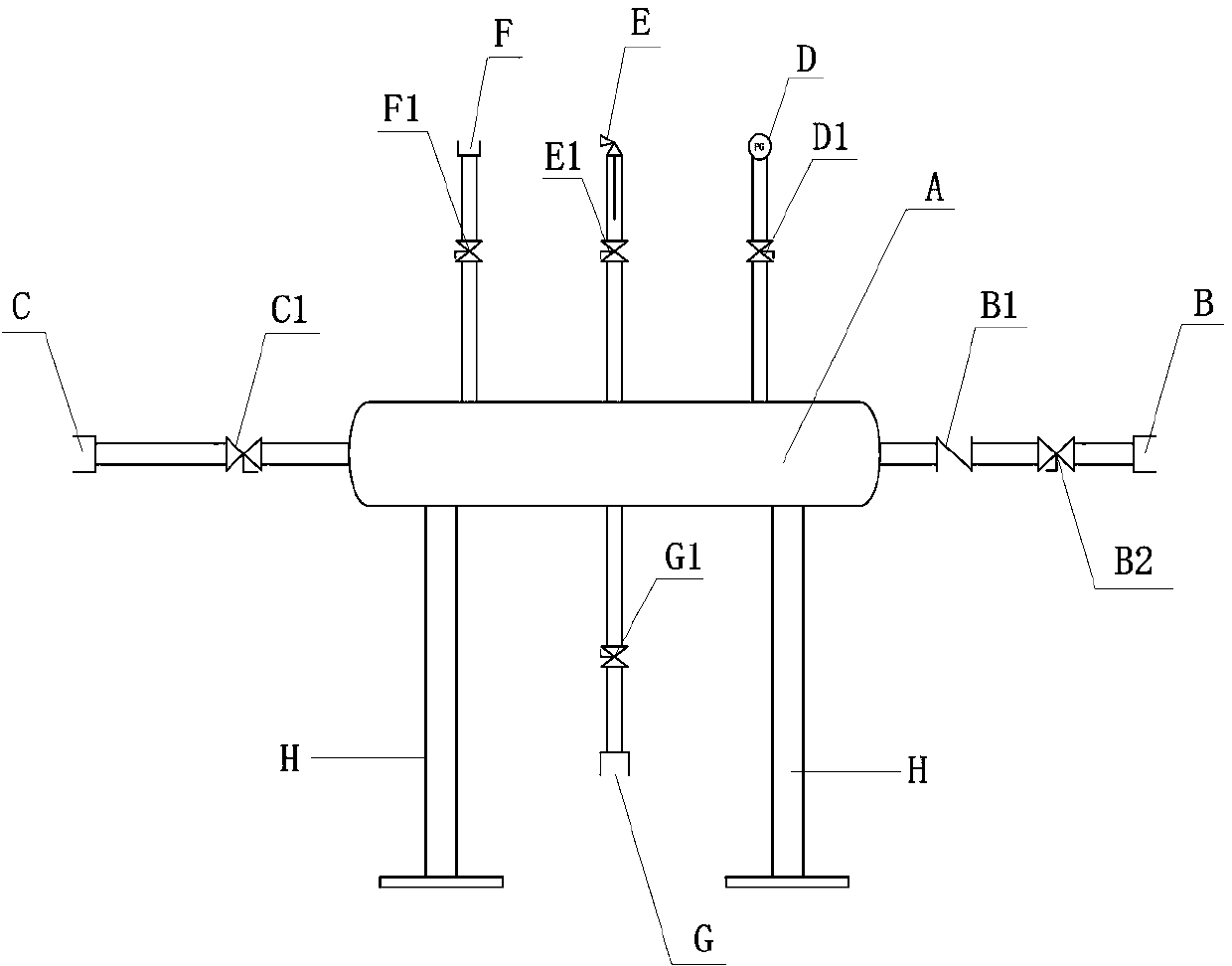

Construction method of steel-jacketed steel steam direct burial pipeline

InactiveCN111188945ANo stuck phenomenonThe switch degree indicator mark is accuratePipe laying and repairSocial benefitsArchitectural engineering

The invention discloses a construction method of a steel-jacketed steel steam direct burial pipeline. The method comprises the following steps of construction preparation, pipeline transportation andhoisting in place, working pipe butt-joint installation, working pipe butt-joint welding, working pipe welded junction inspection, working pipe hydraulic pressure test, outer protection pipe and working pipe temporary fixing and dismounting, working pipe welded junction corrosion prevention and heat preservation, outer protection pipe joint welding, outer protection pipe joint welding inspection,outer protection pipe joint corrosion prevention, pipe ditch backfilling, and working pipe purge. According to the method, the whole set of mature and systematic construction method is continuously improved in the actual installation and construction process, the construction method is detailed in content, reasonable in standard requirement preparation, simple in process and reasonable in procedure, compared with conventional installation, the construction period is shortened, equipment machine-team use is saved, consumed materials are saved, the working efficiency is improved, material lossesare correspondingly reduced, the construction cost is reduced, civilized construction is facilitated, improvement of environmental protection measures is facilitated, labor, equipment and material cost are saved, and good economic benefits, social benefits and environmental benefits are generated.

Owner:POWER CHINA HENAN ENG CO LTD

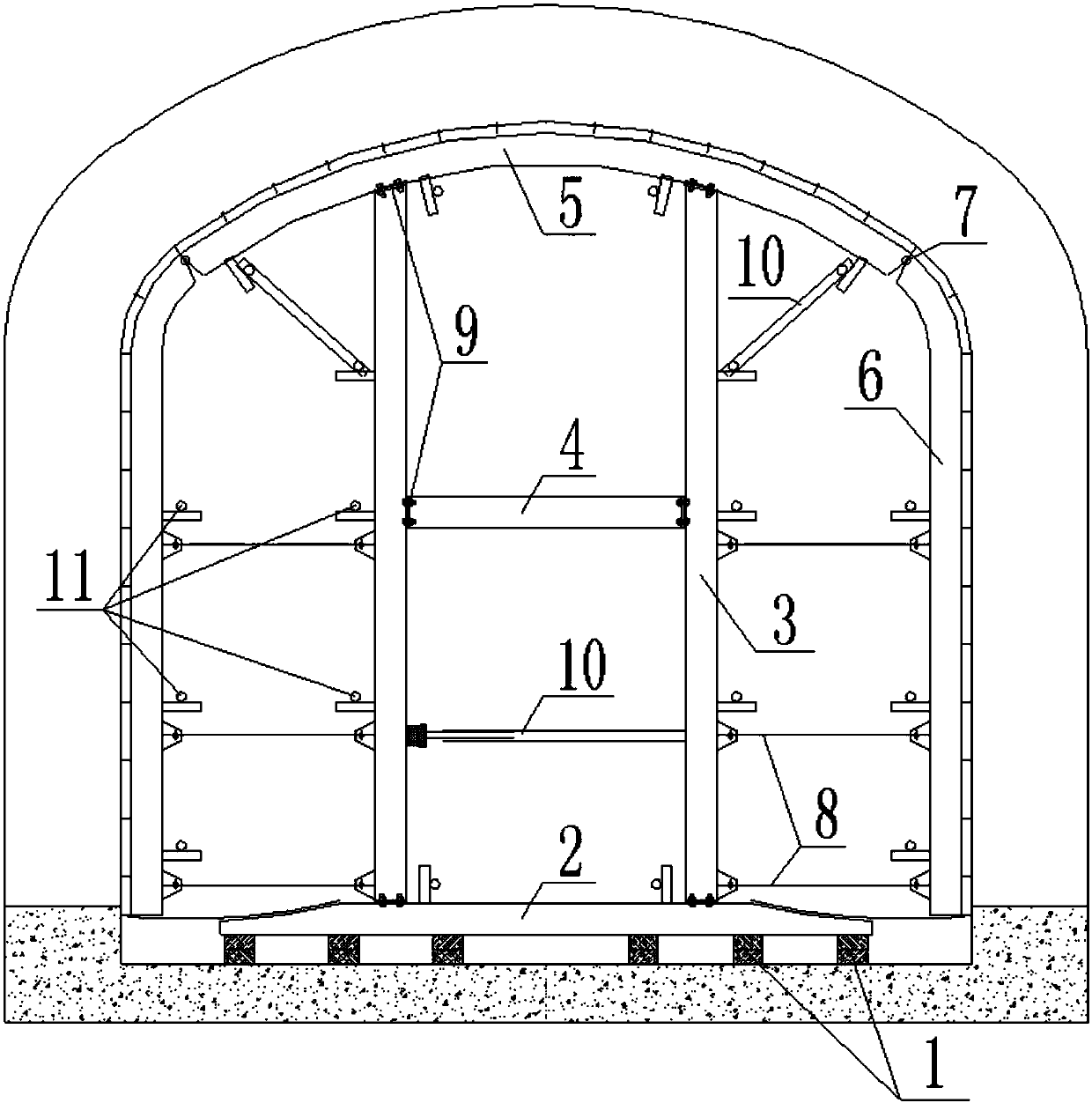

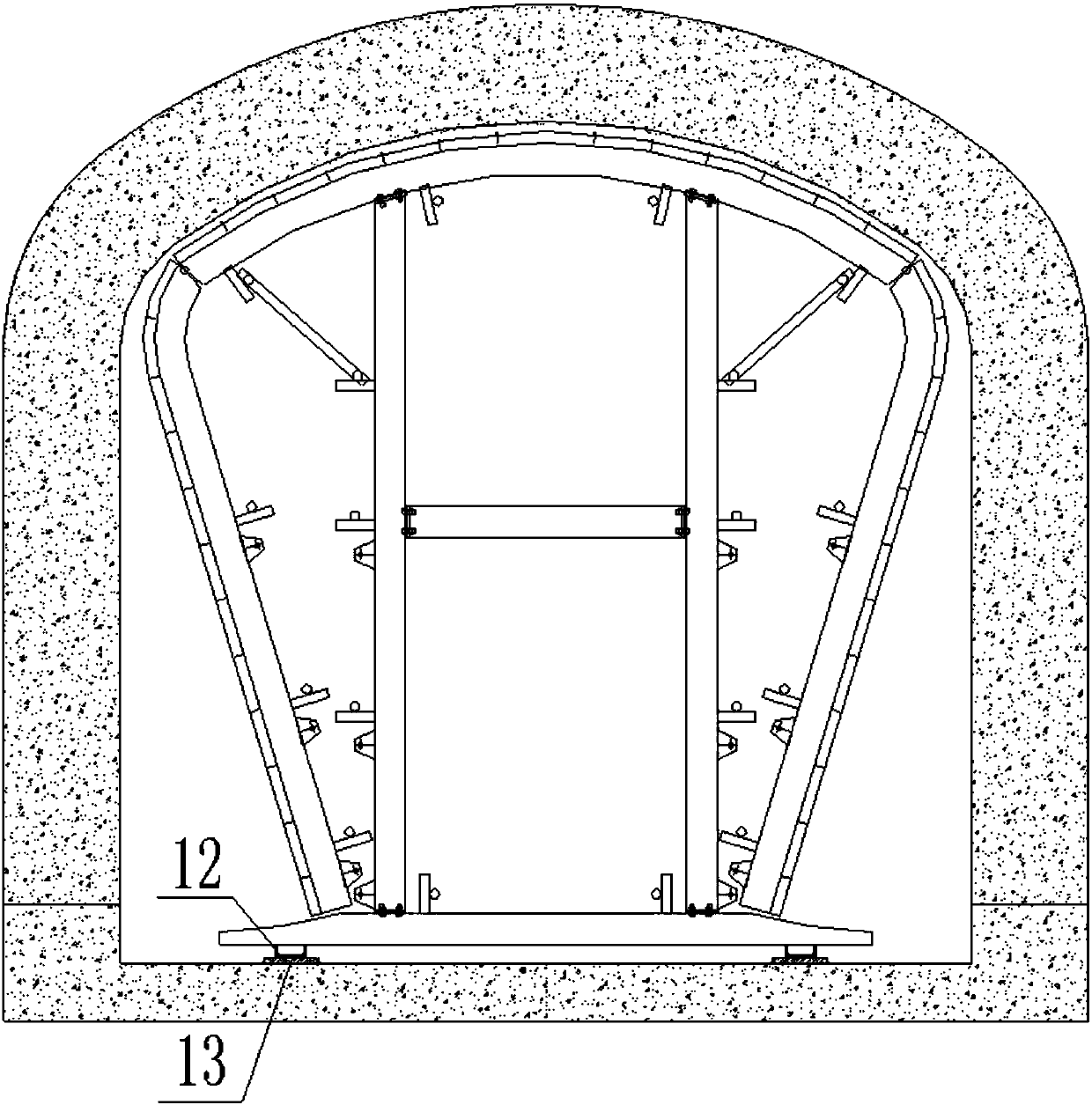

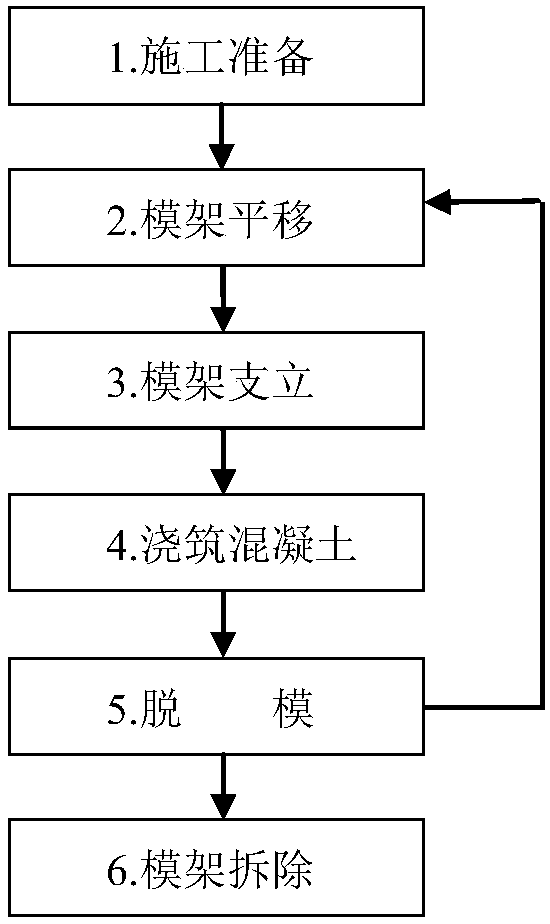

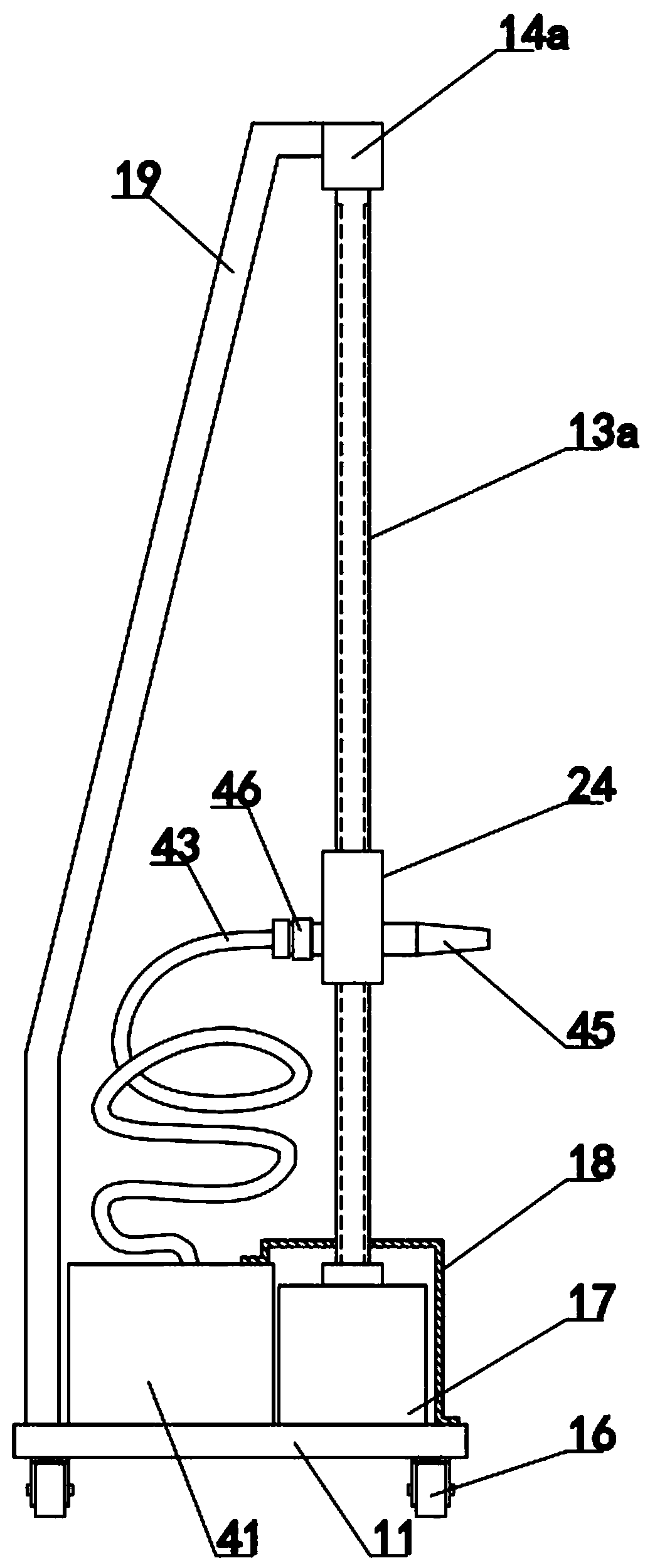

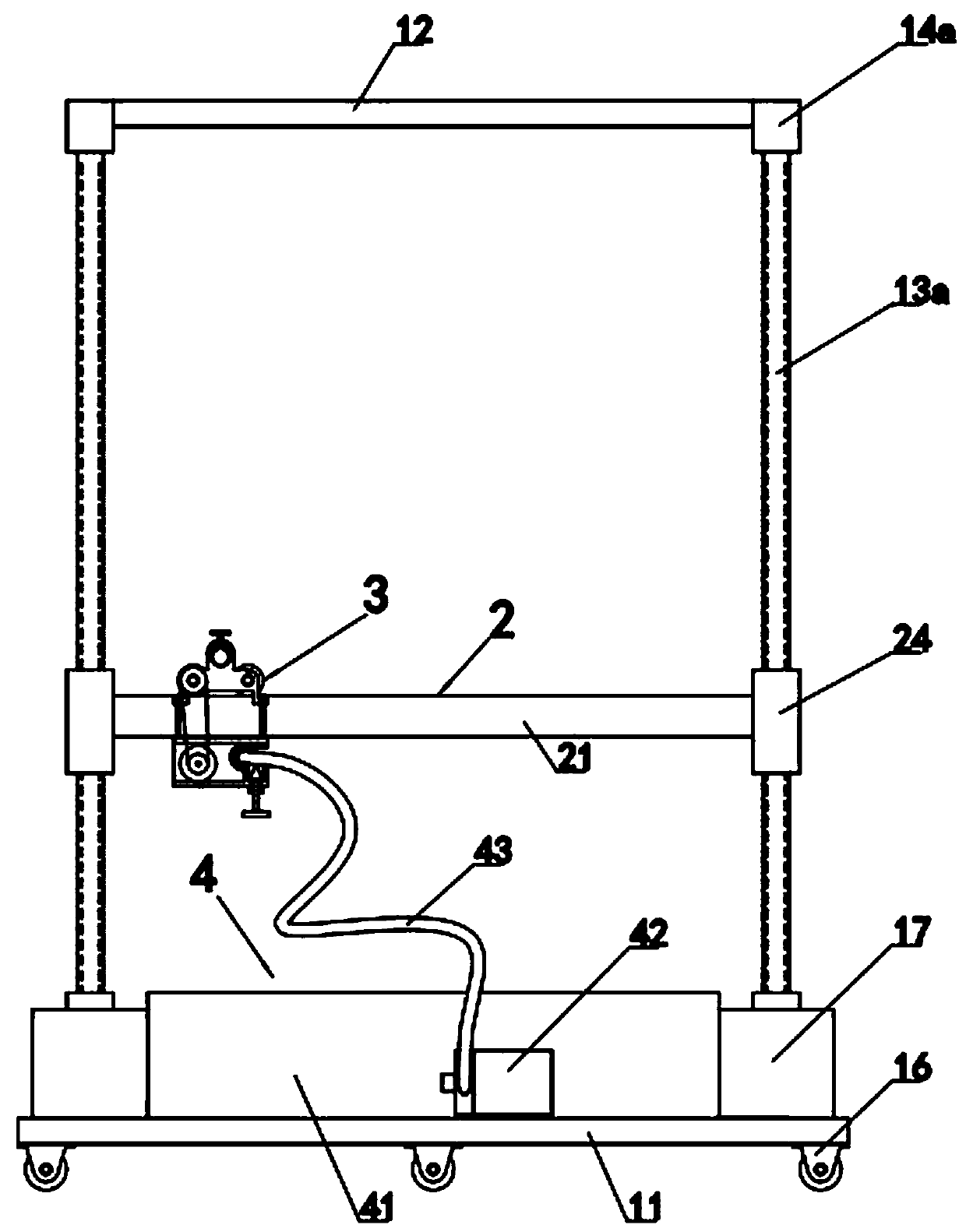

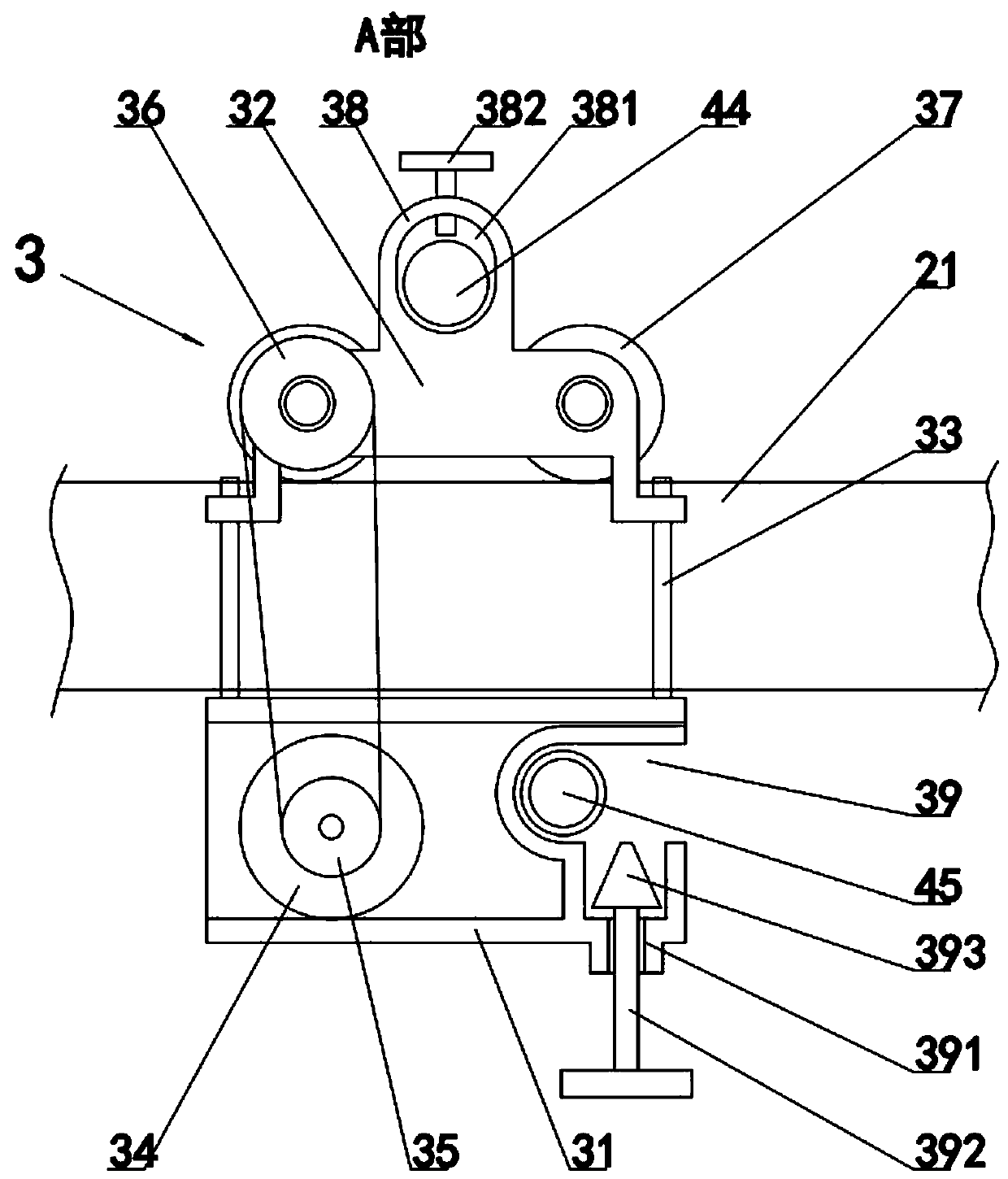

Concrete pouring formwork and construction method thereof

InactiveCN107905252AAvoid falling and deformingFormwork fastArtificial islandsUnderwater structuresSurface flatnessBuilding construction

The invention discloses a concrete pouring formwork and a construction method thereof. The concrete pouring formwork comprises a plurality of formwork main bodies which are sequentially connected; theformwork main bodies comprise bases which can be lifted and moved; the bases are fixedly connected with top arching frames located above the corresponding bases through a plurality of upright columns; the two sides of the top arching frames are hinged with side wall arching frames correspondingly; a plurality of detachable jack screws are connected between each side wall arching frame and the upright column closest to the corresponding side wall arching frame; and a plurality of steel templates are spread on the top arching frames and the side wall arching frames. Frame erecting is rapid, nofrequent disassembly or assembly is required, overall movement and moving in place can be carried out, the concrete surface evenness and the appearance size are easy to control, and the labor and timeare saved. Demoulding is rapid, and the demoulding can be completed simply by disassembling the jack screws and lowering the height of the concrete pouring formwork. Environment protection is facilitated, by adopting the construction method, the frame erecting and the demoulding can be carried out without frequently disassembling the concrete pouring formwork or the steel templates, sundries on aconstruction site are few, an operating space is wide, a rod is clear, and civilization construction is facilitated.

Owner:SUBWAY ENG CO LTD OF CHINA RAILWAY 16TH CONSTR BUREAU +2

Construction process of clean workshop pipeline

InactiveCN110567141AAvoid wastingEasy to controlDucting arrangementsLighting and heating apparatusEngineeringTime cost

The invention discloses a construction process of a clean workshop pipeline. The construction process comprises the following construction steps: 1, prefabricating and installing an external pipelinesupport hanger of a clean room; 2, manufacturing and hoisting an external pipeline of the clean room; 3, welding the pipeline; 4, carrying out argon arc welding; 5, carrying out glue bonding; 6, installing an air pipe of the clean room; 7, testing the pipeline; and 8, preserving heat of the pipeline. Sealing welding, argon arc welding and glue bonding sealing connection are respectively carried out on galvanized steel pipes, stainless steel pipes and PVC pipes in the external pipeline of the clean room, the air pipe of the clean room is installed by adopting cleaning work clothes, gloves and working shoes, and the seal is completed after being connected, so that the built clean room completely meets the requirement of precision machining on a clean room, the sustainability and the high quality of product production are guaranteed, the production effectiveness is improved, unnecessary waste on time and materials are avoided, and the time cost and the economic cost are saved.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +2

Wall cement mortar spraying machine

InactiveCN111335598ASolve vertical transportationReduce labor intensityBuilding constructionsCement mortarMechanical engineering

The invention discloses a wall cement mortar spraying machine. The wall cement mortar spraying machine comprises an outer frame, a lifting mechanism, a transversely-moving mechanism and a mortar spraying mechanism. The top ends of vertical screws a1 on the two sides of the outer frame are sleeved with upper rotary seats a2 correspondingly, the upper rotary seats a2 are fixed to the two ends of a top beam correspondingly, and the top ends of fixing rear frames on the two sides and the corresponding upper rotary seats a2 are fixed together. Nuts at the two ends of a cross beam of the lifting mechanism are mounted on the outer sides of the corresponding vertical screws a1 in a threaded manner. Transversely-moving rollers of the transversely-moving mechanism are supported on the upper side ofa sliding cross beam and can transversely walk, and the transversely-moving mechanism is provided with a pipe clamping mechanism. In the wall cement mortar spraying machine, mortar is directly sprayedto the surface of a structure through a pump, the problem about vertical transportation of the mortar is solved, manual mortar transportation and physical labor such as lime spoon lime delivery, supporting plate lime receiving and trowel plastering are removed, thus, the labor intensity of workers is greatly reduced, the working efficiency is improved, and a far-reaching influence is brought to building construction and management.

Owner:郑州宏拓电子技术有限公司

Temporary road construction method of linear engineering

The invention provides a temporary road construction method of linear engineering. The temporary road construction method comprises the following steps that a temporary road center line is drawn according to requirements, then a construction side line of the temporary road is drawn according to the road center line, and the temporary road is a one-way road; a plurality of construction side lines at a road widening area are determined on the side, away from the linear engineering, of the temporary road in the length direction of the temporary road; roadbeds of the determined temporary road andthe road widening area are flattened and compacted, steel slag is laid in layers, and compacting is carried out in layers; templates are installed at the construction side line positions of the temporary road and the road widening area, concrete is poured in the templates, and then paving, vibrating, leveling and plastering are carried out continuously to enable the surface of a concrete pavementto be flatted; and the road surface is covered and sprinkled with water for maintenance after the construction of the concrete pavement is completed. According to the temporary road construction method of the linear engineering, the temporary road width is reduced, the road widening area is only arranged locally, materials can be saved, the cost can be saved, waste can be reduced, and the impact of temporary road breakage on the environment in the later period can be reduced.

Owner:CHINA HUAYE GROUP +1

Method for protecting walls of punching piles in soft sand geology

InactiveCN107542083AImprove the effect of grouting reinforcementLow costBulkheads/pilesEngineeringGrout

The invention relates to pile foundation construction, in particular to a method for protecting walls of punching piles in soft sand geology. The method comprises the steps that 1, pile positions aremeasured on site according to a blueprint, and the pile positions are marked; 2, a site where piles are planned to be constructed are rolled flat and compacted through an excavator or a forklift, thedegree of compactness of an upper sand layer is ensured, a layer of clay being 30 cm thick covers the sand layer while rolling is performed, the clay is embedded in the sand surface layer, and the surface is made to be closed; 3, steel protection tubes being 2-3 meters long are installed at the pile positions according to different pile diameters, the diameter of the protection tubes is 10 cm larger than the pile diameters, and the portions, exposed out of the ground, of the protection tubes are 200-300 mm; 4, grouting construction is performed outside the protection tubes within the width range of one time of the pile radius with the center of each pile position as the circle center and the corresponding protection tube as the boundary, and the grouting depth is determined by the thickness of the soft sand layer; and 5, maintenance is performed after grouting is completed, and the formal punching pile construction stage is started after grout reaches a certain degree of strength. By means of the method, the problem that hole walls of the punching piles in the soft sand layer are prone to collapsing is effectively solved.

Owner:CHINA MCC20 GRP CORP

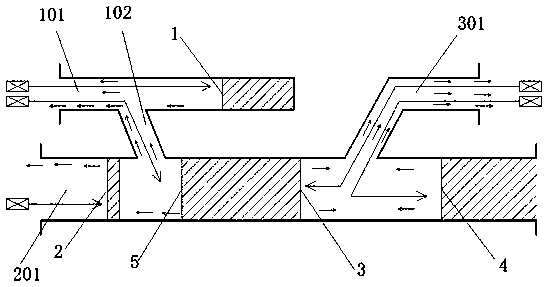

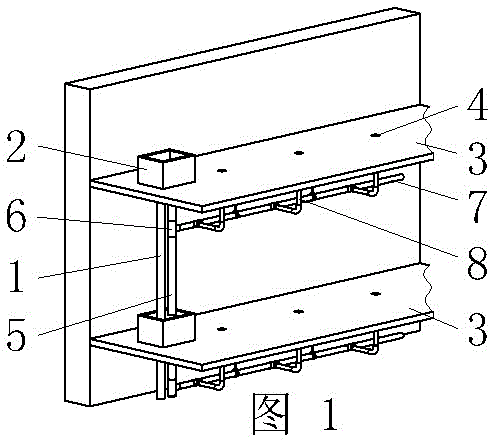

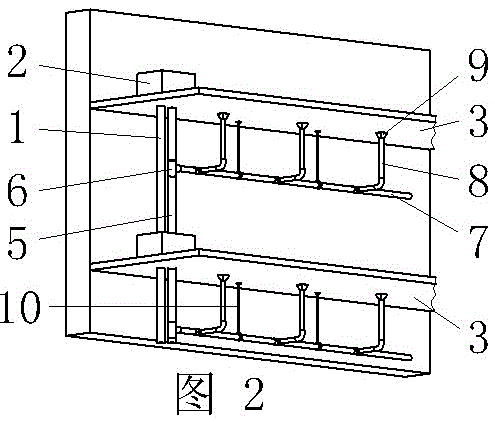

Drainage method and device for floor water during construction of super high-rise buildings

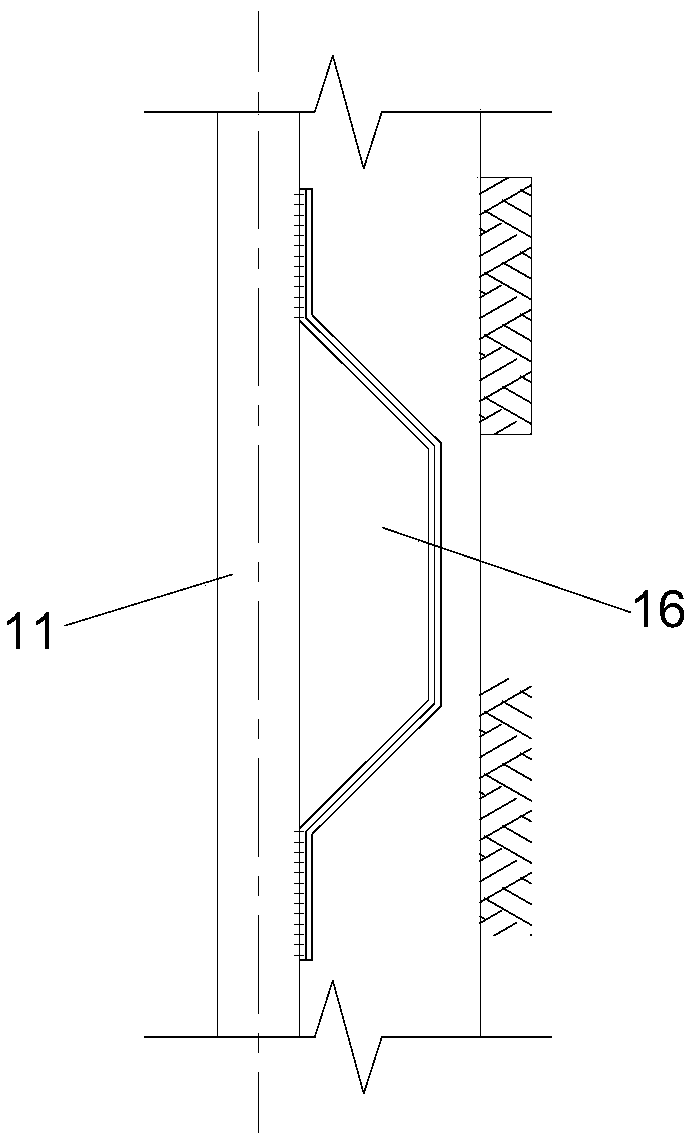

ActiveCN103882918BConducive to civilized constructionReduce drainage costsDomestic plumbingFloor slabWater leak

The invention discloses a method and a device for draining water accumulated on a floor during construction of a super high-rise building. The method is to build a pool at the mouth of the construction water supply pipe on each floor, and a drainage riser leading to the pool on the lower floor is provided at the bottom of the pool, and the water leaked from the water supply pipe is discharged layer by layer to the bottom drainage through the drainage riser. A set of floor drains are arranged at intervals on the edge of each floor slab. The floor drains are connected to the horizontal drainage pipes under the floor slabs, and the horizontal drainage pipes are connected to the vertical drainage pipes. The accumulated water or rainwater during the construction process is drained layer by layer to the bottom floor through the floor drains. gutter. The main function of the invention is to timely and orderly discharge the accumulated water generated on the floors during super high-rise building construction or the accumulated water generated by rainfall from the construction site. It is no longer necessary to use artificial drainage to dump the accumulated water to the outside of the floor directly by using a bucket truck. It will not affect the construction workers below, passing pedestrians and vehicles. Conducive to the civilized construction on site. Can reduce drainage costs.

Owner:CCFED THE FIRST CONSTR & ENG

Turnover type intelligent garbage chamber used on building construction site

PendingCN112520265AReduce weightEasy to useRefuse receptaclesSpecial buildingAutomatic controlRemote control

The invention discloses a turnover type intelligent garbage chamber used on a building construction site. Four garbage chamber bodies are arranged in parallel, a remote control type electric roller shutter door is arranged on each garbage chamber body, guide rails are arranged on the ground of each chamber body and lead to the outside, an electric flatcar is mounted on the guide rails in a matchedmode, wheels of the electric flatcars are matched with the guide rails, a garbage ship is mounted on each electric flatcar, signal induction receivers are arranged on the positions, on the front faces, of the garbage chamber bodies and connected with a controller through wires, and the controller automatically controls the electric roller shutter doors and motors of the electric flatcars to work.The turnover type intelligent garbage chamber is reasonable in structure, easy and convenient to install and operate and convenient to move, standard accessories are adopted, tooled assembling and disassembling are realized, in addition, the intelligent garbage chamber has an automatic control function, the garbage ships automatically move, chamber doors can be automatically opened and closed, then the environmental pollution of the building construction site can be effectively prevented, and environment protection and sanitation as well as civilized construction are achieved.

Owner:中建新疆建工集团第一建筑工程有限公司

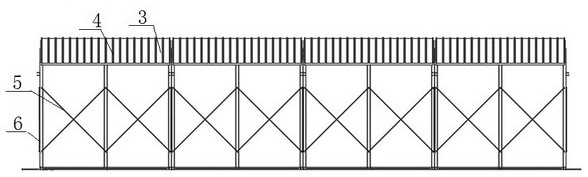

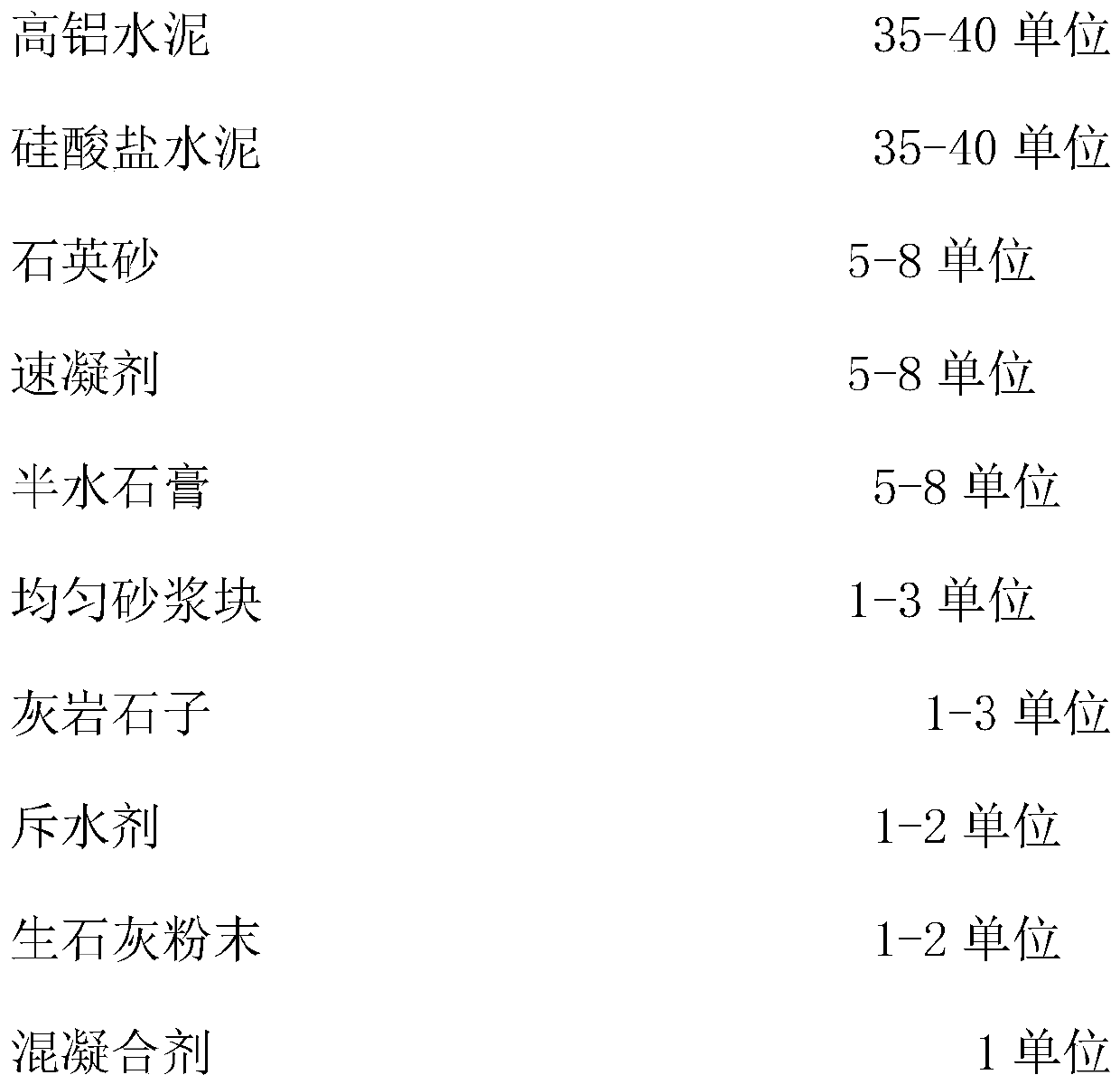

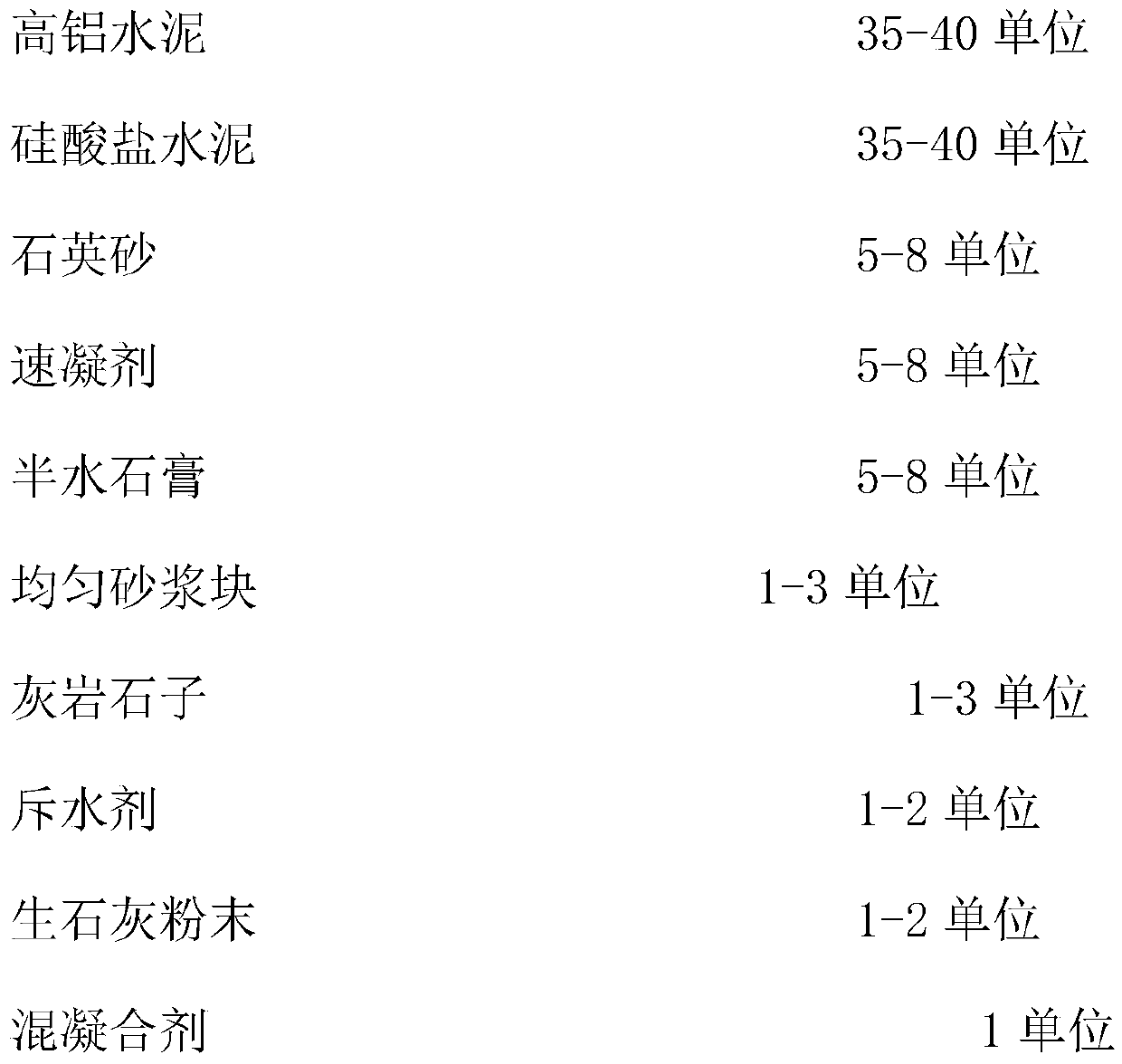

Quick-setting self-leveling material

The invention provides a quick-setting self-leveling material capable of avoiding technical defects in the prior art. A preparation method comprises the following steps: S1, preparing raw materials ofself-leveling uniform mortar blocks, wherein the required raw materials comprise 35 to 40 units of high-alumina cement; 35-40 units of Portland cement; 5-8 units of quartz sand, 5-8 units of an accelerator are added; 5-8 units of semi-hydrated gypsum; 1-3 units of uniform mortar block; 1-3 units of limestone pebble; 1-2 units of a water repellent agent, 1-2 units of quicklime powder and 1 unit ofa coagulation agent; S2, preparing for plugging work after preparation based on the formula proportion in the step S1; S3, carrying out base layer treatment; S4, carrying out sealing treatment; S5, smearing an interface agent; S6, adding water into obtained cement self-leveling powder, and stirring, S7, adding water, and stirring to obtain a slurry; and S8, curing for a certain period. The quick-setting self-leveling material is suitable for rapid high-flatness terraces in airport halls, large restaurants, large markets, department companies, conference halls, exhibition centers, large offices, parking lots and the like, the application range is extremely wide, and the market prospect is promising.

Owner:广东火仑建材科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com