Premanufactured superimposed rib floor for assembly-type steel structure house

A technology of superimposing floor slabs and steel structures, which is applied in the direction of floors, building components, building structures, etc., can solve the problems of large amount of wet work, achieve the effects of reducing wet work, saving resources, and increasing construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below with reference to accompanying drawing and embodiment:

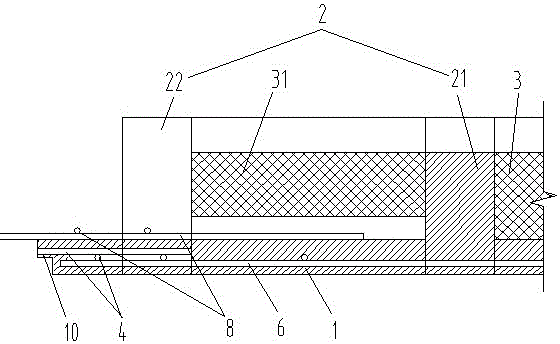

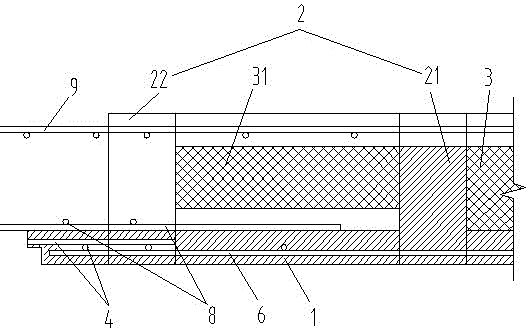

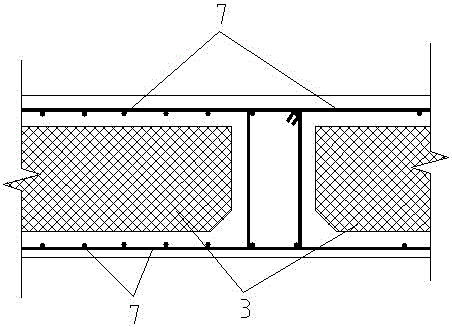

[0046] attached Figure 1-7 It can be seen that a prefabricated laminated ribbed floor slab for a prefabricated steel structure house includes:

[0047] The prefabricated laminated floor 1 is arranged at the bottom, and the upper part of the prefabricated laminated floor 1 is provided with a rib beam 2;

[0048] The space surrounded by the rib beam 2 is provided with a filling box 3;

[0049] The rib beam 2 is prefabricated reinforced concrete;

[0050] The connection between the prefabricated laminated densely ribbed floor slab and the steel beam is cast on site between the rib beam and the steel beam, and the rest of the rib beam 2 and the prefabricated laminated floor 1 are precast.

[0051] The thickness of the prefabricated laminated floor is 60mm thick;

[0052] The width of the rib beam is 120mm, and the height is the same as the thickness of the lamina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com