Quick-setting self-leveling material

A self-leveling and fast technology, applied in the field of self-leveling, can solve the problems that affect the quality of the project, the rate of condensation is low, and the anti-condensation raw materials cannot be well exerted, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A quick-setting self-leveling method comprising the following steps:

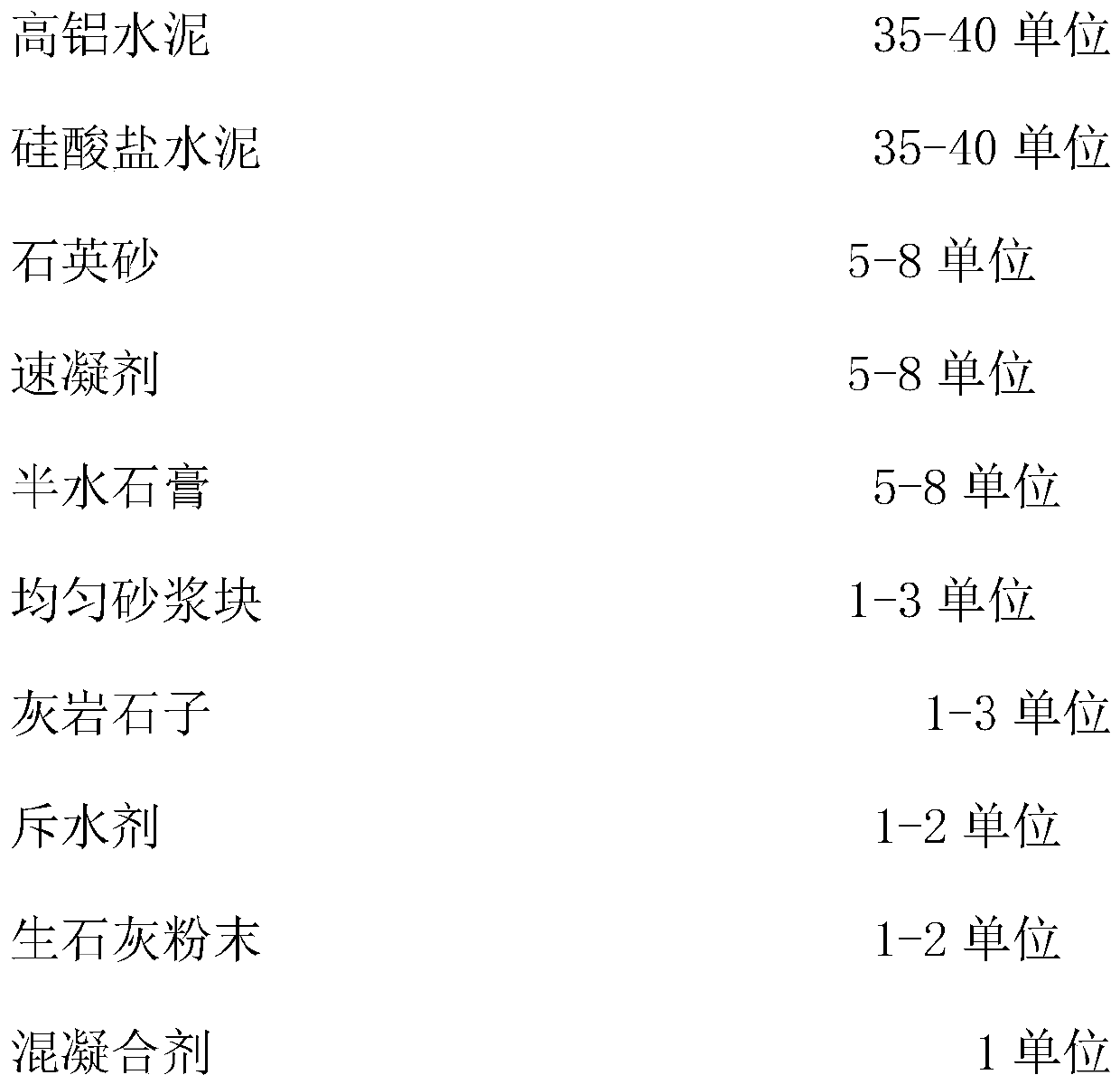

[0029] S1, preparing raw materials for self-leveling uniform mortar blocks, the required raw material formula is:

[0030]

[0031] S2, after completing the formula ratio of step S1, the plugging work will be prepared.

[0032] S3, prepare the grass-roots treatment after completing the step S2.

[0033] S4, after finishing S3 grass-roots processing, it should be closed for processing.

[0034] S5, after completing step S4, apply an interface agent on the base surface to be constructed.

[0035] S6, after step S5 is completed and the interface agent is dried, the cement self-leveling powder is added with water and stirred.

[0036] S7, after completing the above step S6, after the cement self-leveling powder is mixed with water to form a slurry, the pouring can begin.

[0037] S8, after completing the above steps of S7, maintain for a certain period.

[0038] The sealing work, including doors,...

Embodiment 2

[0048] A quick-setting self-leveling method comprising the following steps:

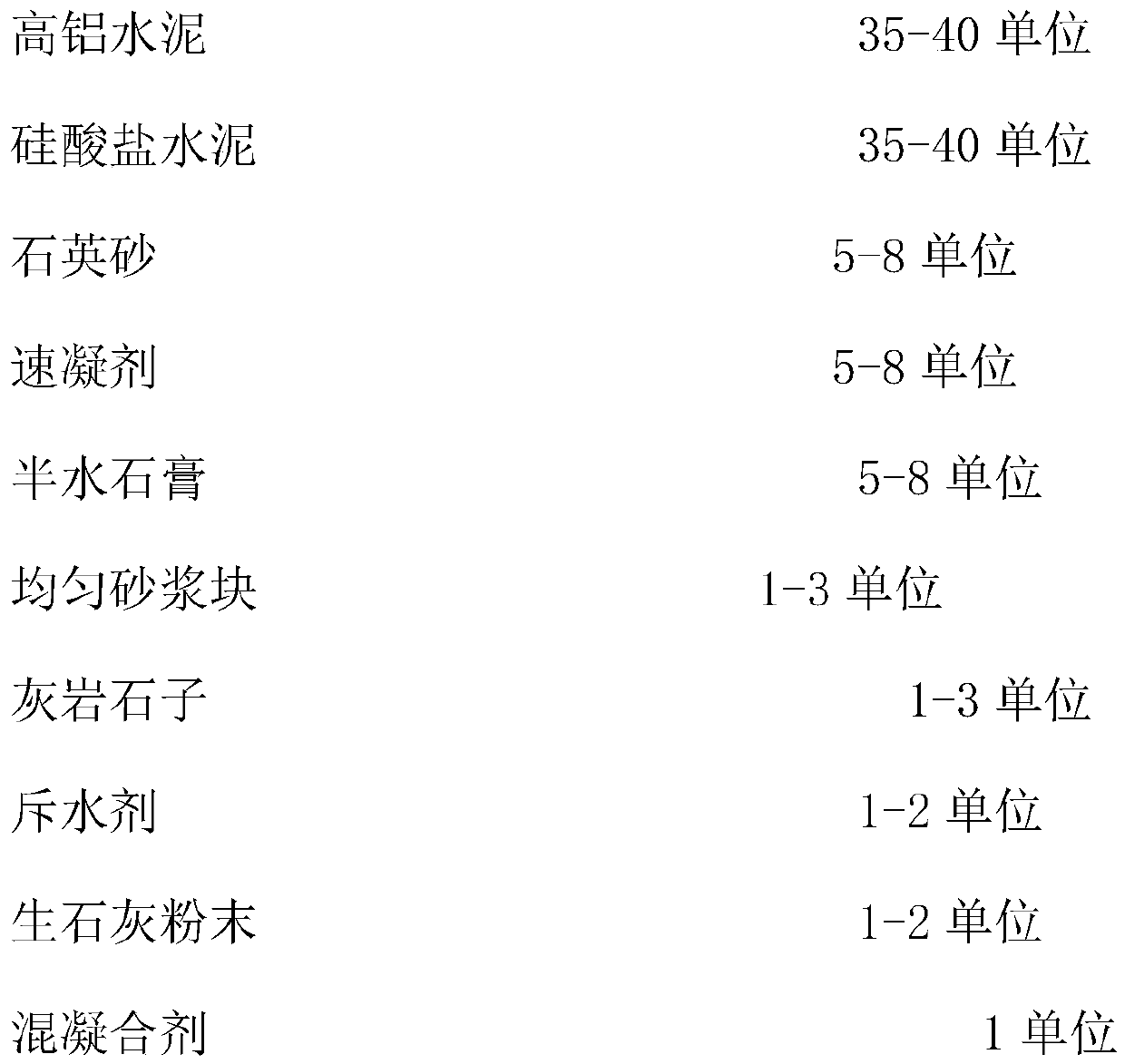

[0049] S1, preparing raw materials for self-leveling uniform mortar blocks, the required raw material formula is:

[0050]

[0051] S2, after completing the formula ratio of step S1, the plugging work will be prepared.

[0052] S3, prepare the grass-roots treatment after completing the step S2.

[0053] S4, after finishing S3 grass-roots processing, it should be closed for processing.

[0054] S5, after completing step S4, apply an interface agent on the base surface to be constructed.

[0055] S6, after step S5 is completed and the interface agent is dried, the cement self-leveling powder is added with water and stirred.

[0056] S7, after completing the above step S6, after the cement self-leveling powder is mixed with water to form a slurry, the pouring can begin.

[0057] S8, after completing the above steps of S7, maintain for a certain period.

[0058]The sealing work, including doors, ...

Embodiment 3

[0068] A quick-setting self-leveling method comprising the following steps:

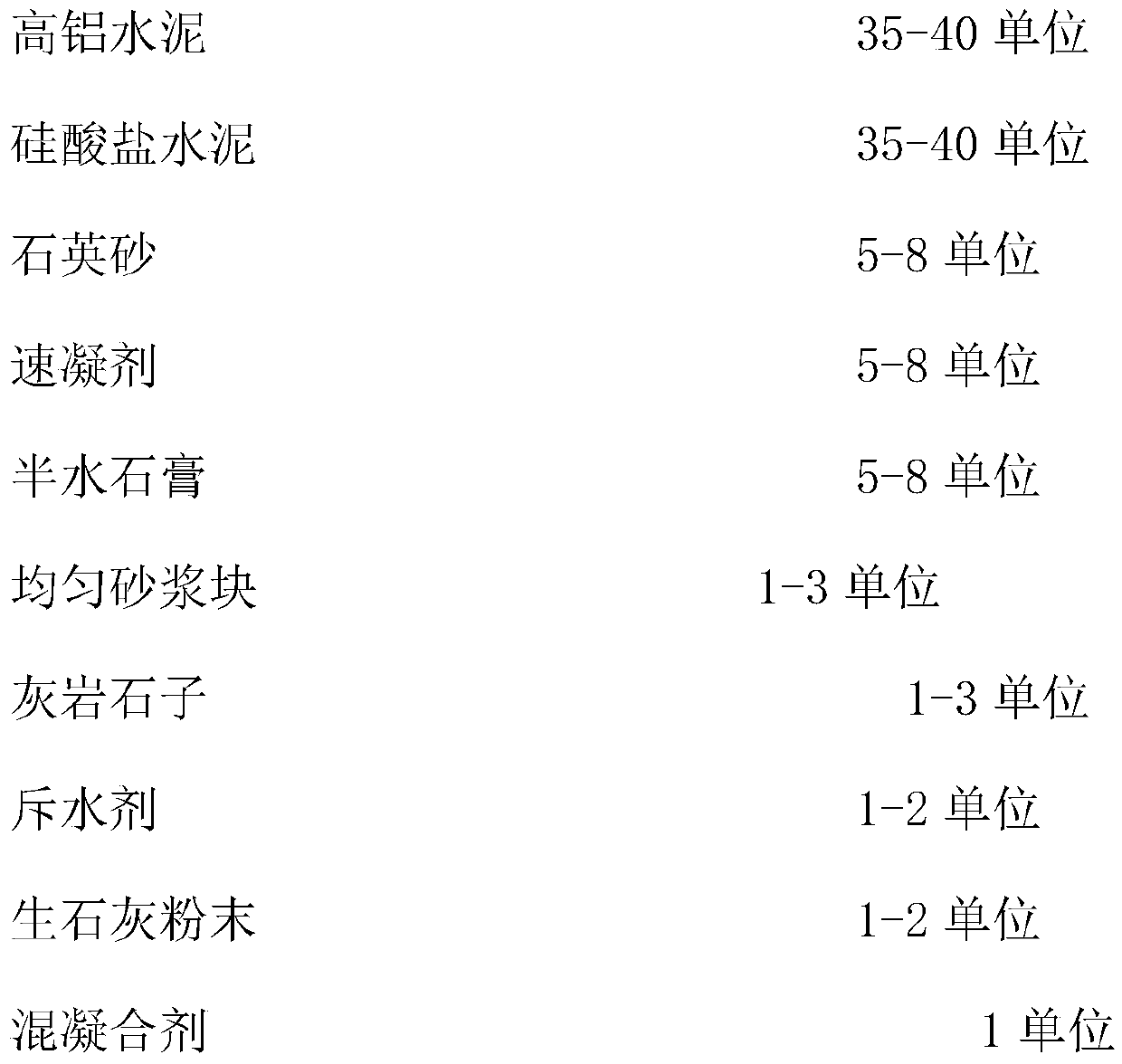

[0069] S1, preparing raw materials for self-leveling uniform mortar blocks, the required raw material formula is:

[0070]

[0071]

[0072] S2, after completing the formula ratio of step S1, the plugging work will be prepared.

[0073] S3, prepare the grass-roots treatment after completing the step S2.

[0074] S4, after finishing S3 grass-roots processing, it should be closed for processing.

[0075] S5, after completing step S4, apply an interface agent on the base surface to be constructed.

[0076] S6, after step S5 is completed and the interface agent is dried, the cement self-leveling powder is added with water and stirred.

[0077] S7, after completing the above step S6, after the cement self-leveling powder is mixed with water to form a slurry, the pouring can begin.

[0078] S8, after completing the above steps of S7, maintain for a certain period.

[0079] The sealing work, incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com