Construction method of steel-jacketed steel steam direct burial pipeline

A technology for pipeline construction and steel sheathing, which is used in pipeline laying and maintenance, pipes/pipe joints/fittings, and mechanical equipment. Sign accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

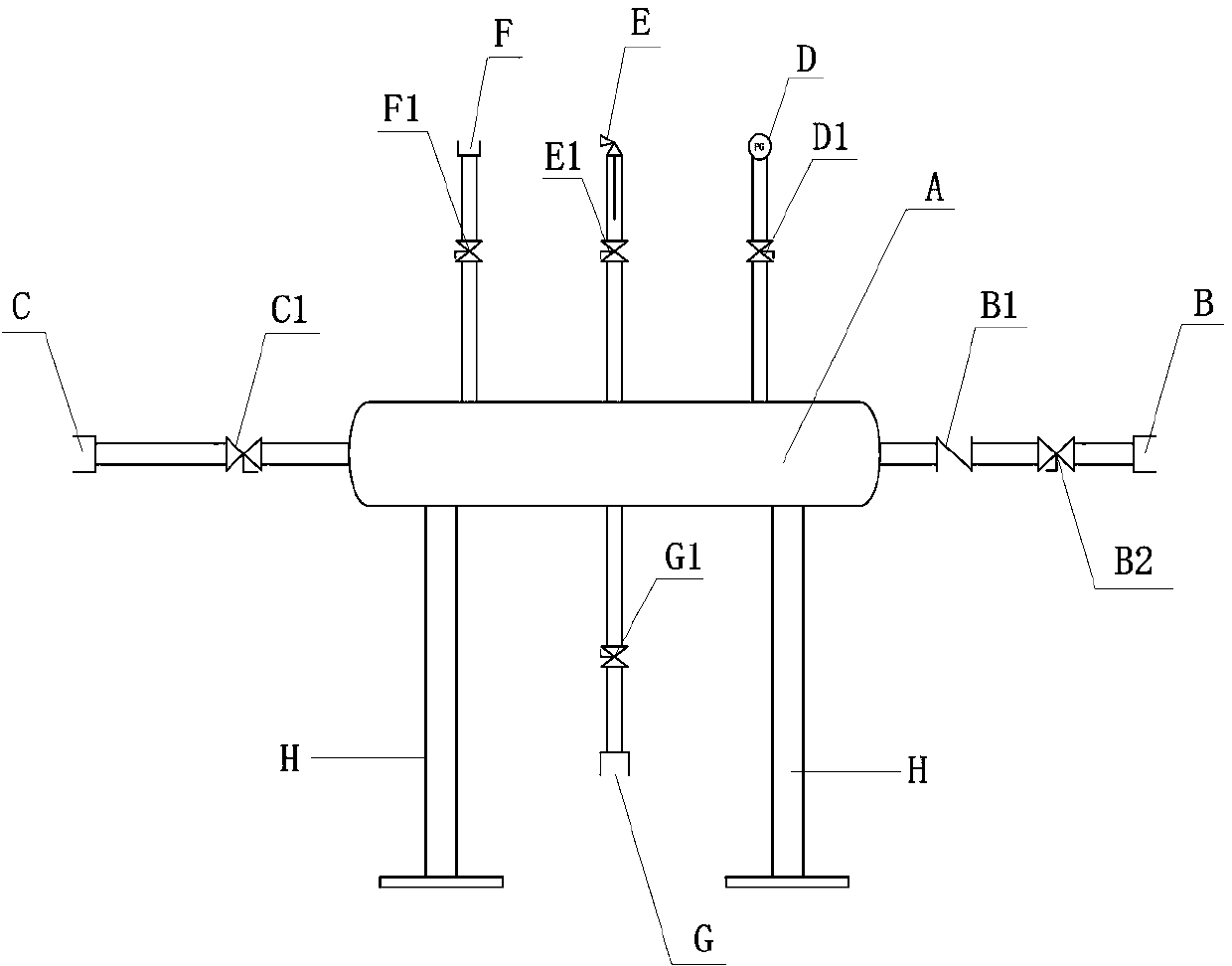

[0081] Below in conjunction with accompanying drawing, the present invention will be further explained and illustrated:

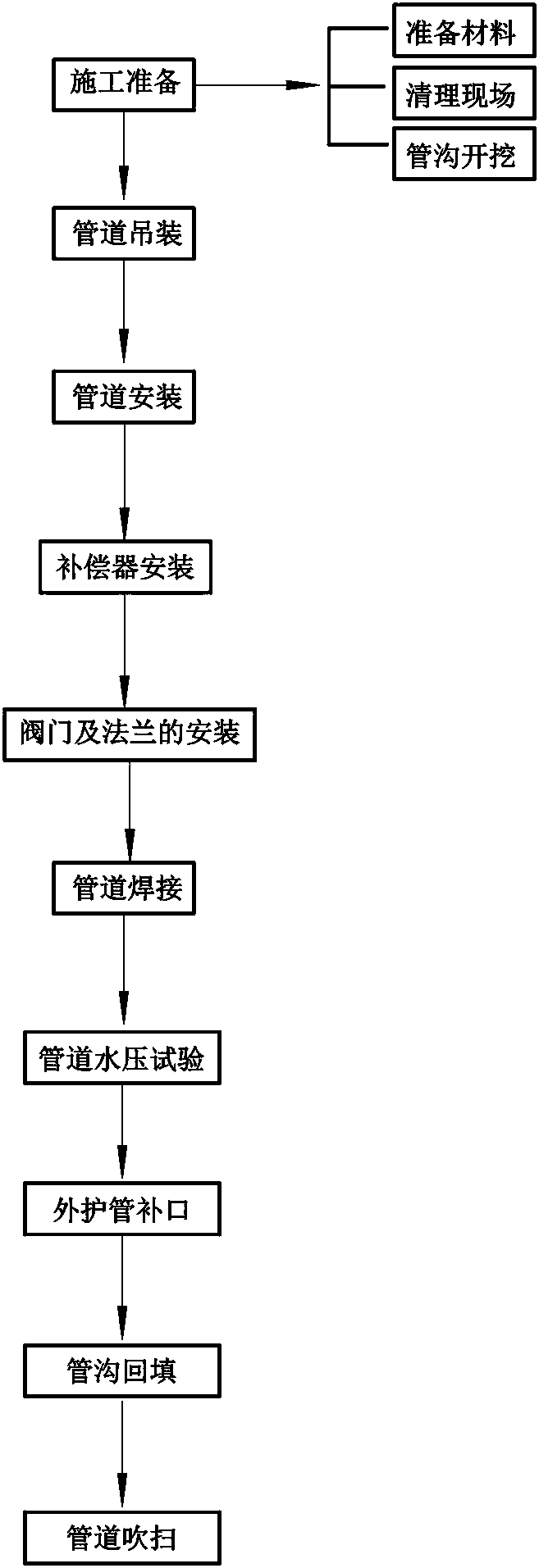

[0082] see figure 1 with figure 2 , a steel jacket steel steam direct buried pipeline construction method is characterized in that: comprising the following steps:

[0083] A. Construction preparation:

[0084] 1) Prepare the materials required for construction, and check and accept the pipelines, pipe fittings, pipeline accessories and valves required for construction;

[0085] 2) Clear the obstacles on the construction site, and measure and set out the construction site;

[0086] a. Select different excavation sections according to factors such as construction site conditions, structure burial depth, soil quality, and presence or absence of groundwater;

[0087] b. Determine the construction measures such as the bottom width of the pipe ditch, the slope of the pipe ditch, the side slope, the position of the platform, the width of the upper mouth, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com