Rapid hole-forming construction method of large-diameter deep hole pile foundation under karst geology

A construction method and large-diameter technology, which are applied in drilling equipment and methods, earth-moving drilling, driving devices for rotary combined drilling, etc., can solve the problems of inclined holes in karst caves, affecting the progress of the project, and low slag discharge efficiency. , to achieve the effect of being conducive to civilized construction, speeding up construction progress, and fast hole forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

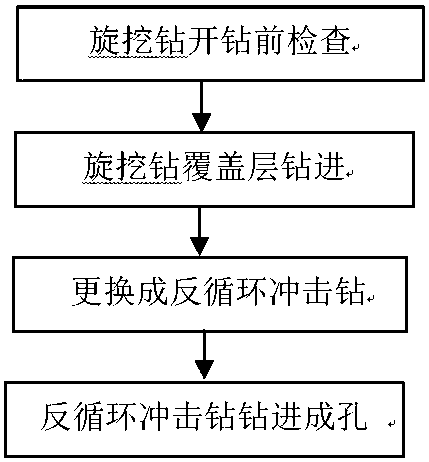

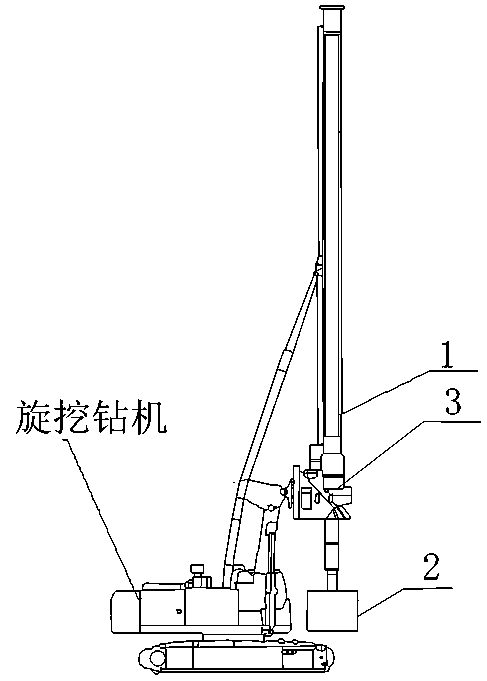

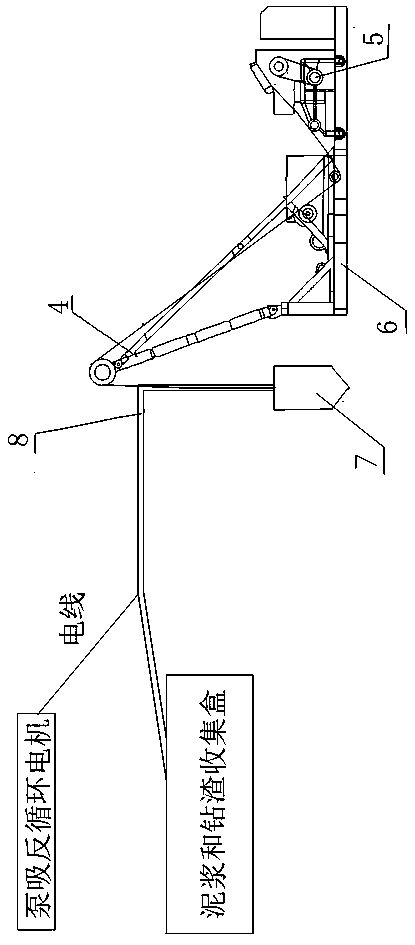

[0030] A rapid hole-forming construction method for large-diameter deep-hole pile foundations under karst geology. The combined construction technology of "rotary drilling + reverse circulation percussion drilling" is used for the construction of large-diameter deep-hole pile foundations under karst geology. Excavating and drilling for rapid construction; after the rotary drilling construction is completed, move to the next pile for overburden drilling, and then use the 85t crawler crane to lift the reverse circulation percussion drilling relay to drill the karst geological layer until the hole is formed.

[0031] A. Inspection before drilling of rotary drilling;

[0032] Check before starting: Before the rotary drill is in place, all parts must be inspected and repaired. The drill bit diameter of the rotary drill must me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com