Mix-in-place train for bituminous pitch cold second birth cement fragmental stone

A cold recycling and cement technology, which is applied in cement mixing devices, chemical instruments and methods, control devices, etc., can solve problems affecting the efficiency of road surface repair, pollute the environment, and high costs, and achieve civilized construction, investment savings, and improvement. The effect of the old road level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

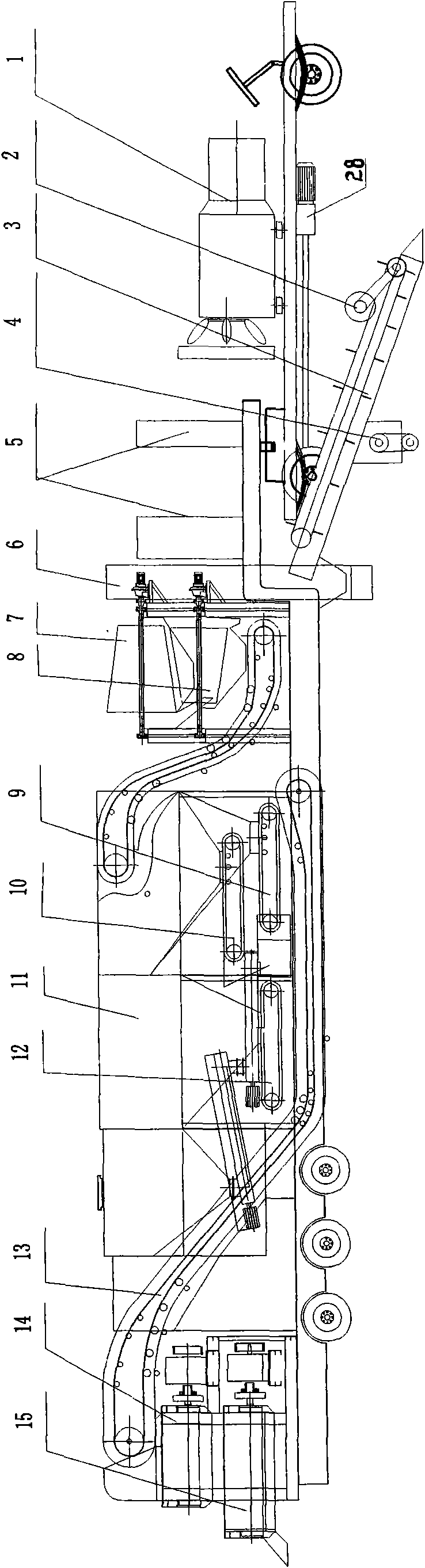

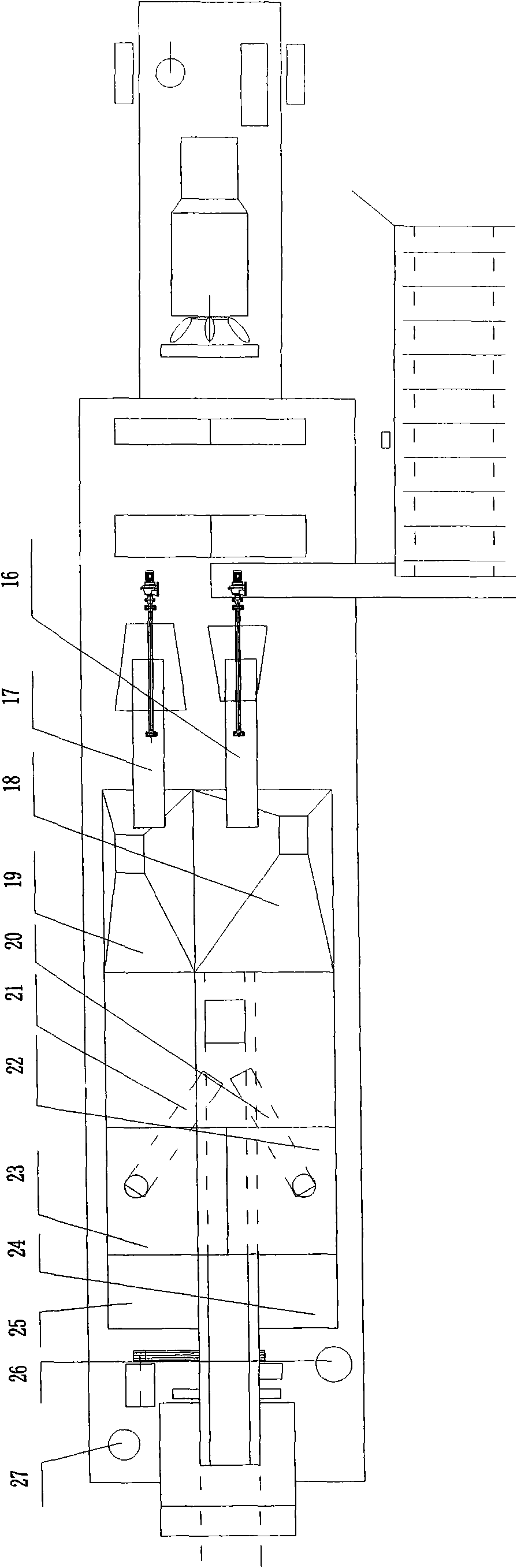

[0012] figure 1 , figure 2 Shown is the preferred technical solution of the present invention, the asphalt cold recycled cement gravel mixing train includes a scraper feeder 3 equipped with a feeding motor 2 and a walking frequency conversion motor 4, a generator set 1 and a traction frequency conversion motor are installed The traction trolley and the flatbed car are formed, and the flatbed trolley is connected with the traction support of the traction trolley. A power control cabinet 5, a water tank 24, a metering water pump 26, an emulsified asphalt tank 25, an emulsified asphalt pump 27, a primary round screen 7, a secondary round screen 8, a fine aggregate hoist 16, a coarse Aggregate hoist 17, fine aggregate electronic feeder 9, coarse aggregate electronic feeder 10, fine aggregate recovery bin 18, coarse aggregate recovery bin 19, primary mixing pot 14, secondary mixing pot 15, Side feeding belt conveyor 6, total conveying belt 13, the discharge port of said total co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com