Large-scale seed precipitation tank body mounting construction method

An installation method and slotting technology, applied in the direction of alumina/aluminum hydroxide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

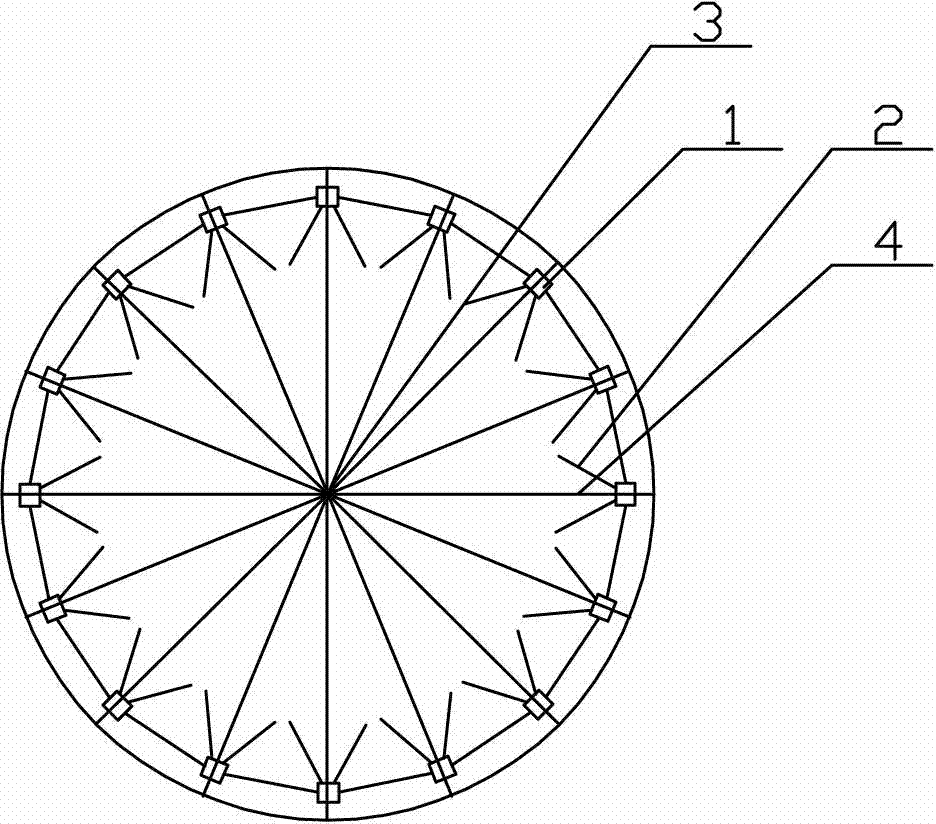

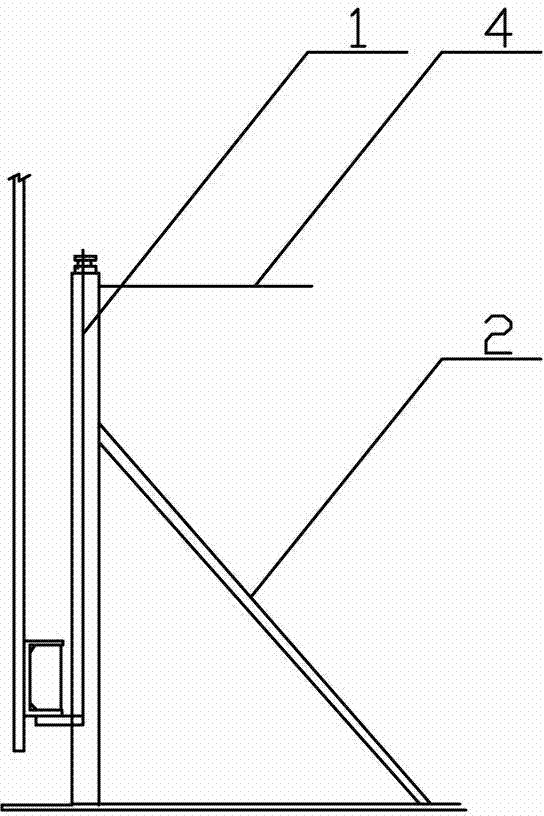

[0020] Such as figure 1 and figure 2 As shown, the present invention provides a kind of large-scale seed sub-tank installation method, including the following steps:

[0021] A. Accept the prefabricated tank bottom plate, tank wall plate and tank body installation foundation according to the design requirements, and weld and install the tank bottom plate according to the traditional method;

[0022] B. Evenly arrange n hydraulic lifting pillars on the same circumference of the tank body at a distance of 200mm from the inner wall of the tank to ensure that a single hydraulic lifting pillar is not overloaded. A mast is vertically arranged in the center of the tank body, and the top of the mast and each hydraulic lifting pillar pass through the wire rope. secondary steel bar;

[0023] According to the actual situation, the lifting capac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com