Self-leveling waterproof mortar of imitated stone facing and construction process of waterproof mortar

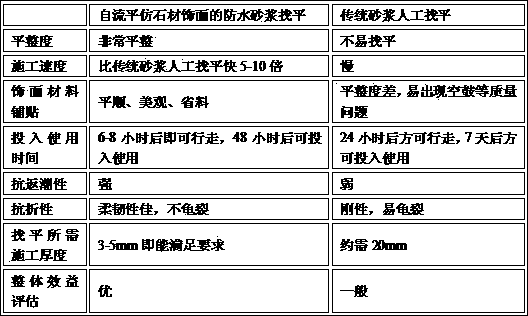

A waterproof mortar and self-leveling technology, which is applied to floors, buildings, building structures, etc., can solve the problems of affecting the appearance, affecting the construction process and the time when the project is put into use, and low early strength, so as to achieve a clean and tidy construction site. It is conducive to civilized construction and the effect of uniform and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0035] A self-leveling waterproof mortar imitating stone facing, the self-leveling waterproof mortar imitating stone facing consists of the following components in parts by weight: cement: 250 parts, heavy calcium carbonate: 50 parts, natural colored sand : 900 parts, cellulose ether: 2 parts, wood fiber: 3 parts, PP fiber: 1 part, latex powder: 18 parts, natural rock flakes for real stone paint: 2 parts; the ratio of water to material is 4.2L / 25KG.

[0036] The cement is P.O 42.5 cement; the heavy calcium carbonate is 400 mesh; the natural color sand is 70 mesh quartz sand, the particle size is below 0.4mm; the viscosity of cellulose ether is 40000mPa.S; the latex powder is 6012E latex powder;

[0037] A construction process of self-leveling waterproof mortar imitating stone veneer, comprising the following steps:

[0038] 1. Surface treatment:

[0039] Remove the oil stains, stains and loose objects on the base layer, and use mortar or special putty to level the holes or gr...

specific Embodiment 2

[0044] A self-leveling waterproof mortar imitating stone facing, said self-leveling waterproof mortar imitating stone facing consists of the following components in parts by weight: cement: 300 parts, heavy calcium carbonate: 80 parts, natural colored sand : 1000 parts, cellulose ether: 8 parts, wood fiber: 8 parts, PP fiber: 3 parts, latex powder: 25 parts, natural rock flakes for real stone paint: 8 parts; the ratio of water to material is 4.5L / 25KG.

[0045] The cement is ordinary silicon cement; the ground calcium carbonate is 400 mesh; the natural color sand is 140 mesh quartz sand, and the particle size is below 0.4mm;

[0046] The viscosity of cellulose ether is 40000mPa.S; the latex powder is acrylic latex powder.

[0047] A construction process of self-leveling waterproof mortar imitating stone veneer, comprising the following steps:

[0048] 1. Surface treatment:

[0049] Remove the oil stains, stains and loose objects on the base layer, and use mortar or special p...

specific Embodiment 3

[0054] A self-leveling waterproof mortar imitating stone facing, the self-leveling waterproof mortar imitating stone facing consists of the following components in parts by weight: cement: 280 parts, heavy calcium carbonate: 70 parts, natural colored sand : 940 parts, cellulose ether: 6 parts, wood fiber: 5 parts, PP fiber: 2 parts, latex powder: 21 parts, natural rock flakes for real stone paint: 5 parts; the ratio of water to material is 4.3L / 25KG.

[0055] The cement is high alumina cement; the heavy calcium carbonate is 400 mesh; the natural color sand is 110 mesh quartz sand with a particle size below 0.4mm; the viscosity of cellulose ether is 40000mPa.S; the latex powder is acrylic latex powder.

[0056] A construction process of self-leveling waterproof mortar imitating stone veneer, comprising the following steps:

[0057] 1. Base surface treatment:

[0058] Remove the oil stains, stains and loose objects on the base layer, and use mortar or special putty to level the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com