Cellular spliced floor member with triangular grid structure and its splicing method

A technology of honeycomb and triangular mesh, applied in the direction of floors, building components, building structures, etc., to achieve the effects of architectural design and shape changes, rapid construction, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

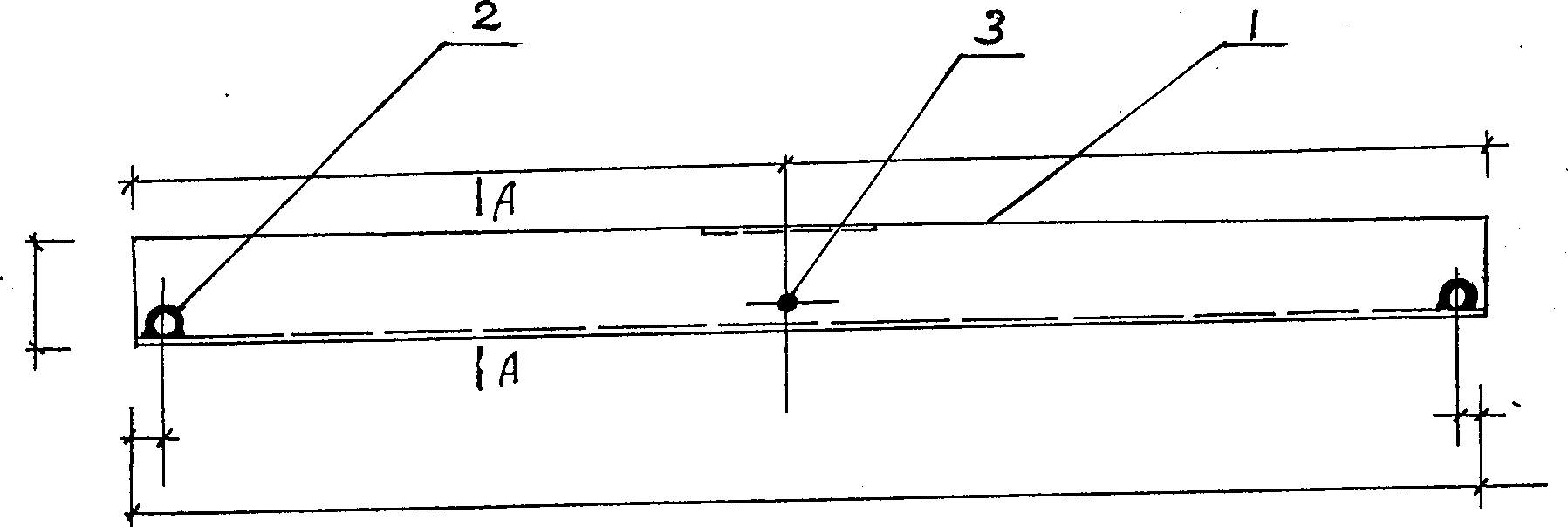

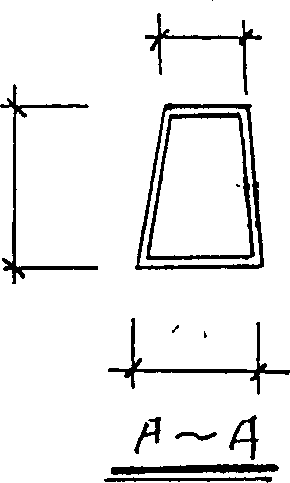

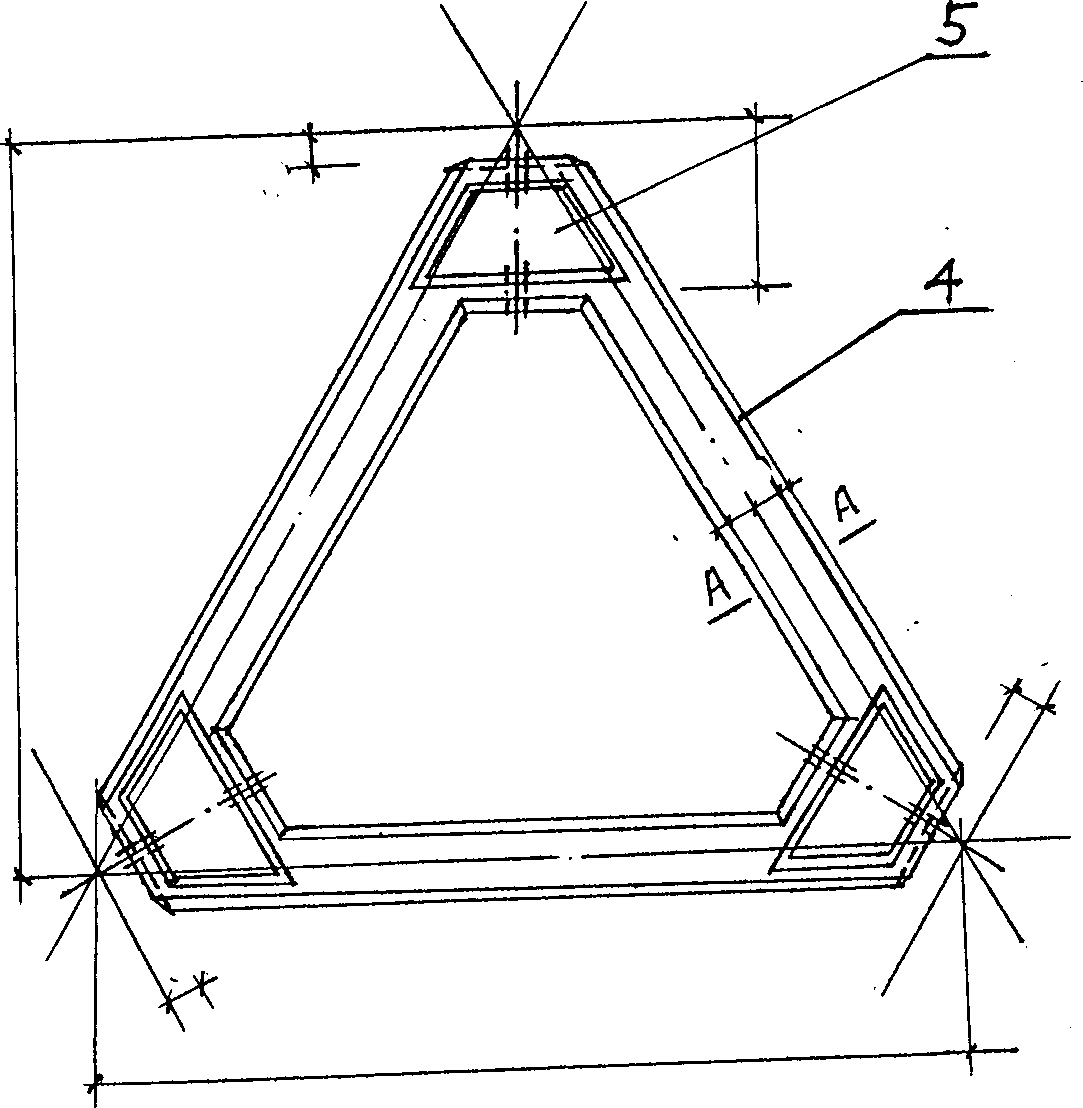

[0020] As shown in the figure: the triangular grid honeycomb floor member of the present invention is composed of main ribs 1, node connectors 6, triangular frame auxiliary ribs 4 and triangular honeycomb floor 7. Assembly 101M 2 floor such as Figure 10 As shown, 114 main ribs, 52 node connectors, 66 triangular frame auxiliary ribs, and 276 triangular honeycomb floor slabs are used. The size of the components used is: each triangular honeycomb floor slab is an equilateral triangle, with a side length of 900mm, a height of 780mm, and a thickness of 120mm; the main rib is a hollow steel structure with a length of 1800mm. 100mm, height 120mm, thickness 5mm; auxiliary rib trapezoidal section height is 120mm, upper bottom is 50mm, lower bottom is 100mm; middle diameter of node connector is 200mm, height is 120mm, steel plate thickness is 6mm, rib thickness is 114mm, hinge pin hole The diameter is 30mm. When assembling, first position the node connector 6 with the adjustable sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com