Patents

Literature

33results about How to "Speed to market" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

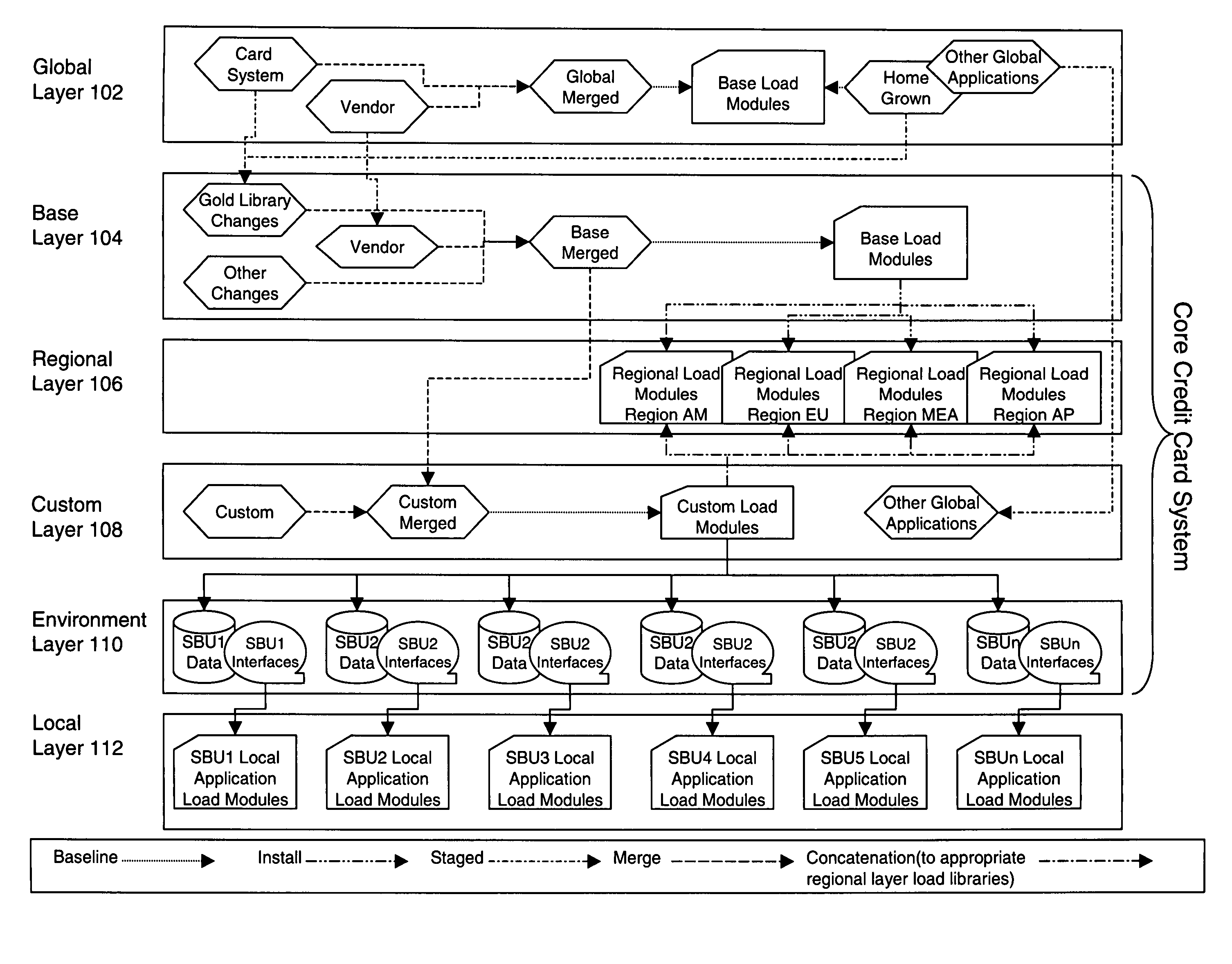

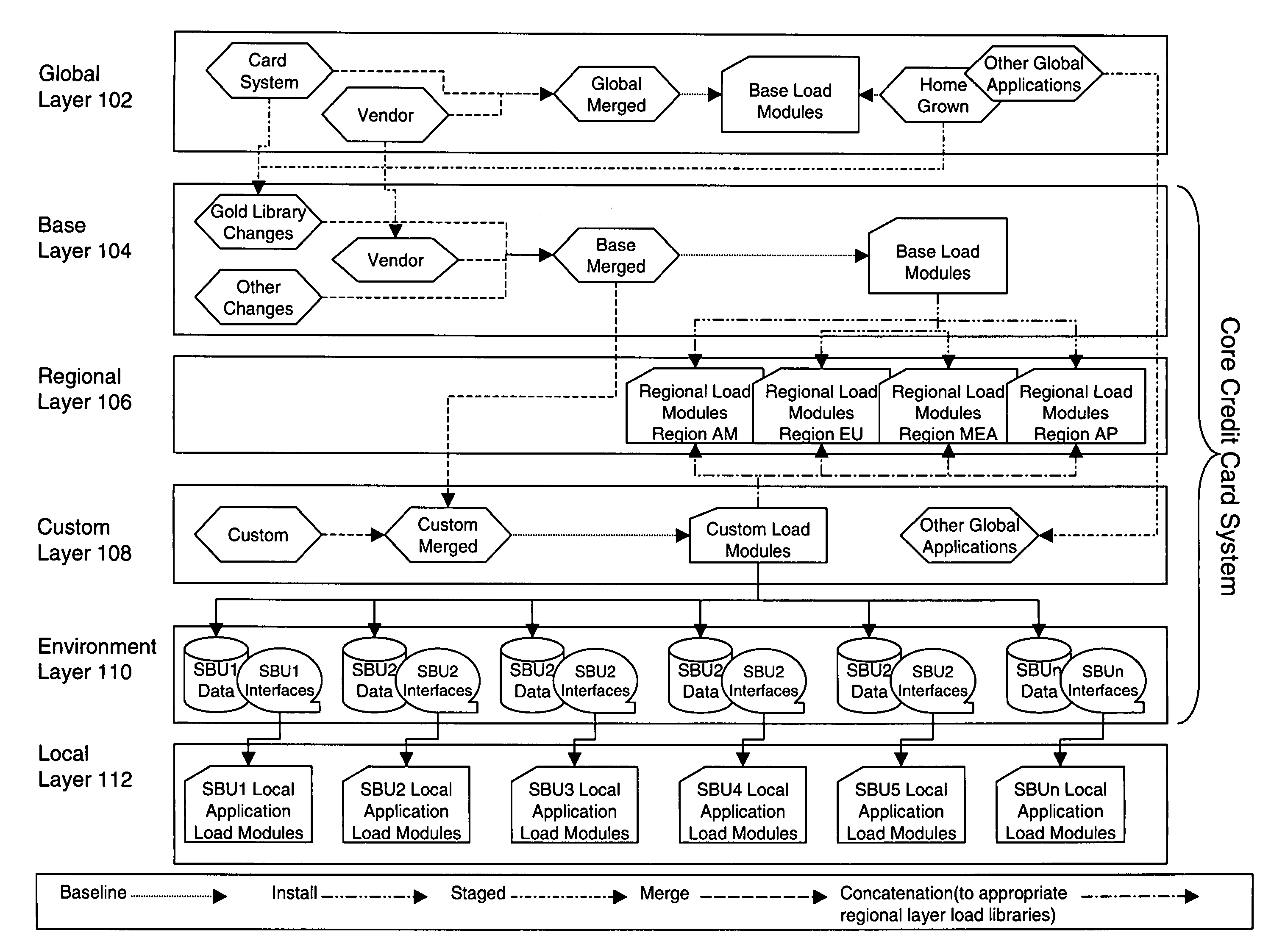

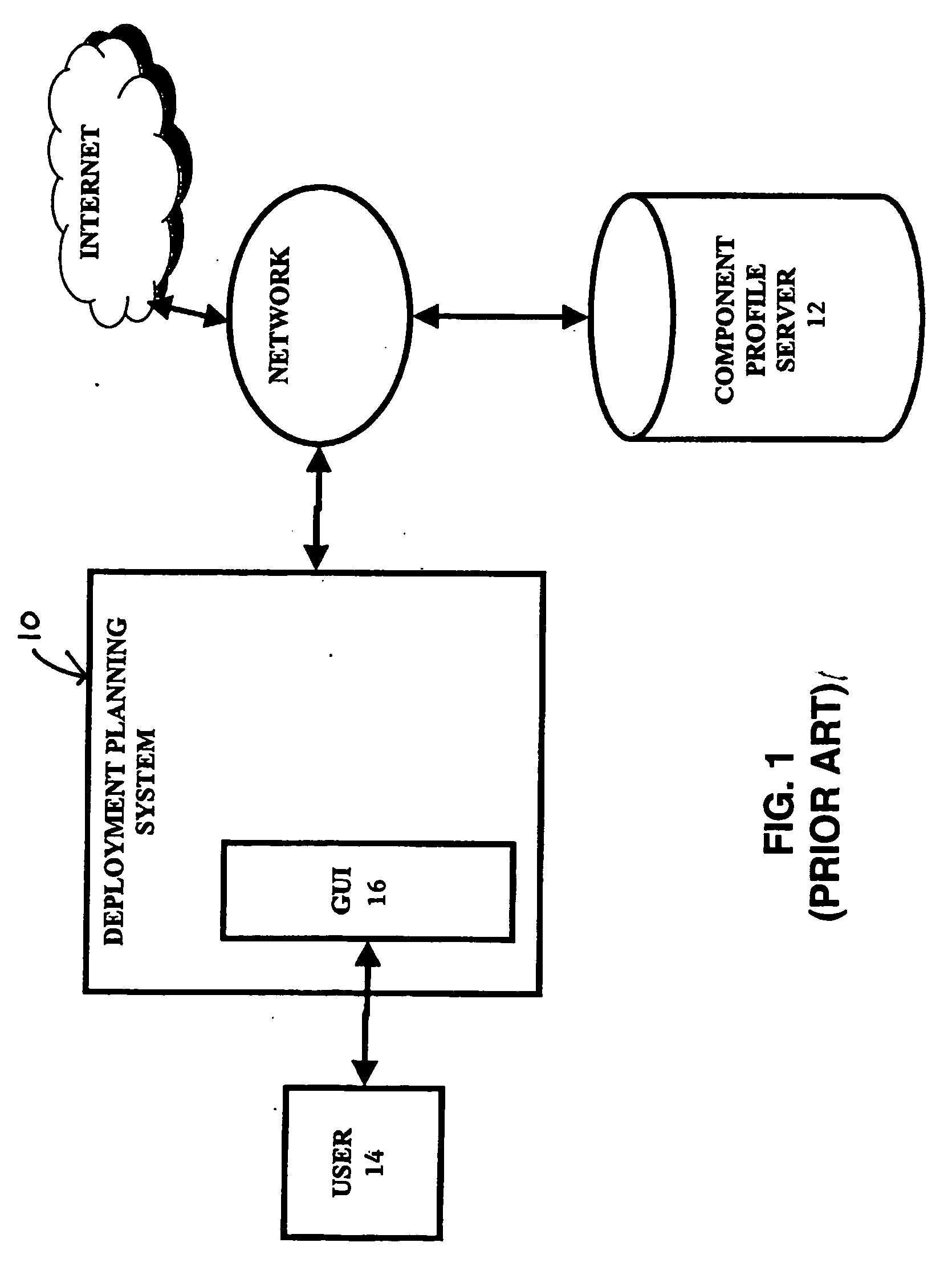

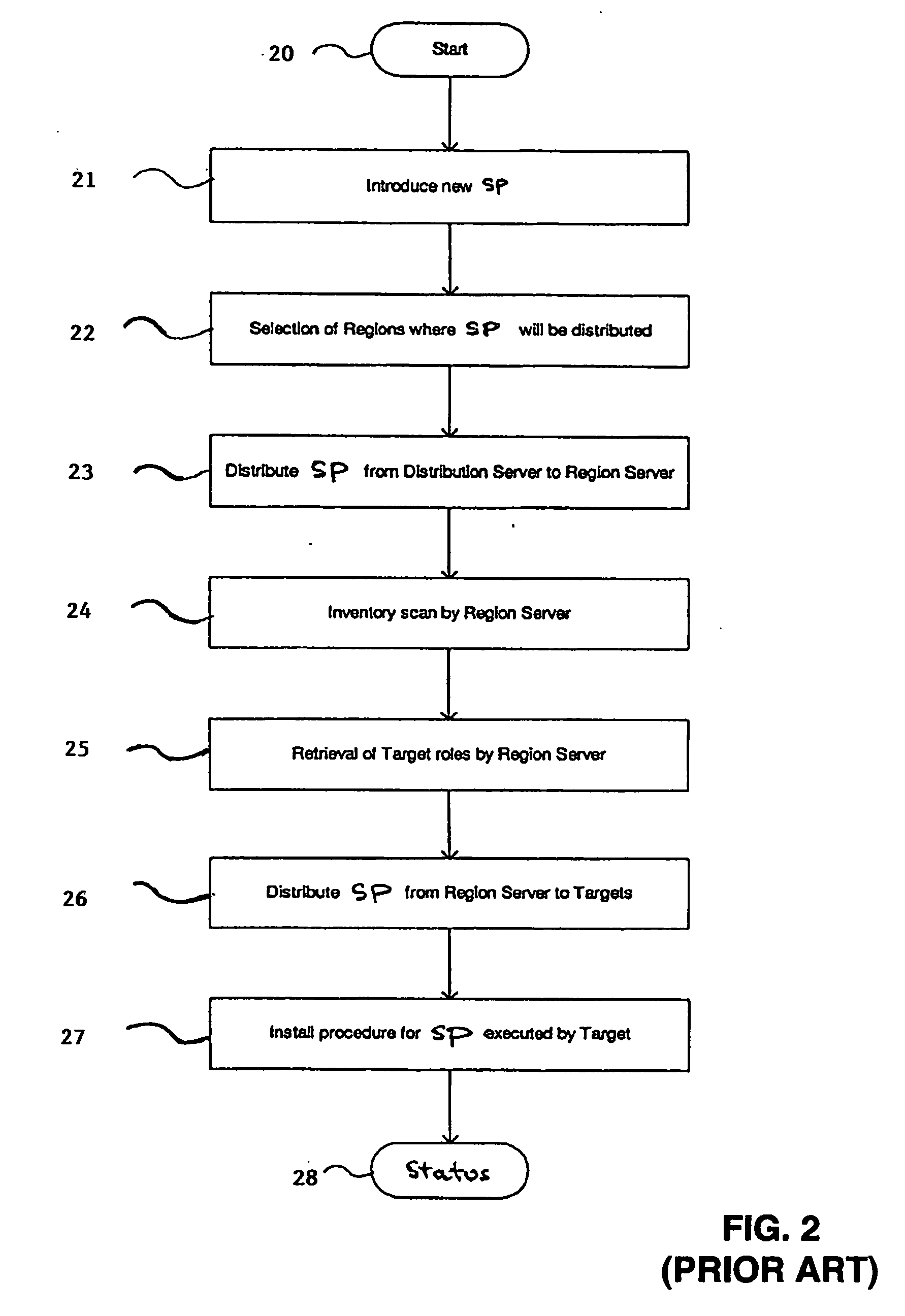

Computer software implemented framework for configuration and release management of group systems software, and method for same

ActiveUS7937685B2Speed to marketMeet processing needsFinanceError detection/correctionRelease managementSource code

A global framework multi-layer computer based architecture is provided. The global framework may include a single set of libraries that contains common source code applicable to substantially all business processing systems using the global framework. The global framework may include individual source code libraries that contain modifications specific to a business processing system to meet the local needs of that business processing system. The business processing systems may execute the custom and base libraries through concatenation of the libraries.

Owner:HSBC TECH & SERVICES (USA) INC

Computer software implemented framework for configuration and release management of group systems software, and method for same

ActiveUS20060155768A1Speed to marketMeet processing needsFinanceError detection/correctionRelease managementSource code

A global framework multi-layer computer based architecture is provided. The global framework may include a single set of libraries that contains common source code applicable to substantially all business processing systems using the global framework. The global framework may include individual source code libraries that contain modifications specific to a business processing system to meet the local needs of that business processing system. The business processing systems may execute the custom and base libraries through concatenation of the libraries.

Owner:HSBC TECH & SERVICES (USA) INC

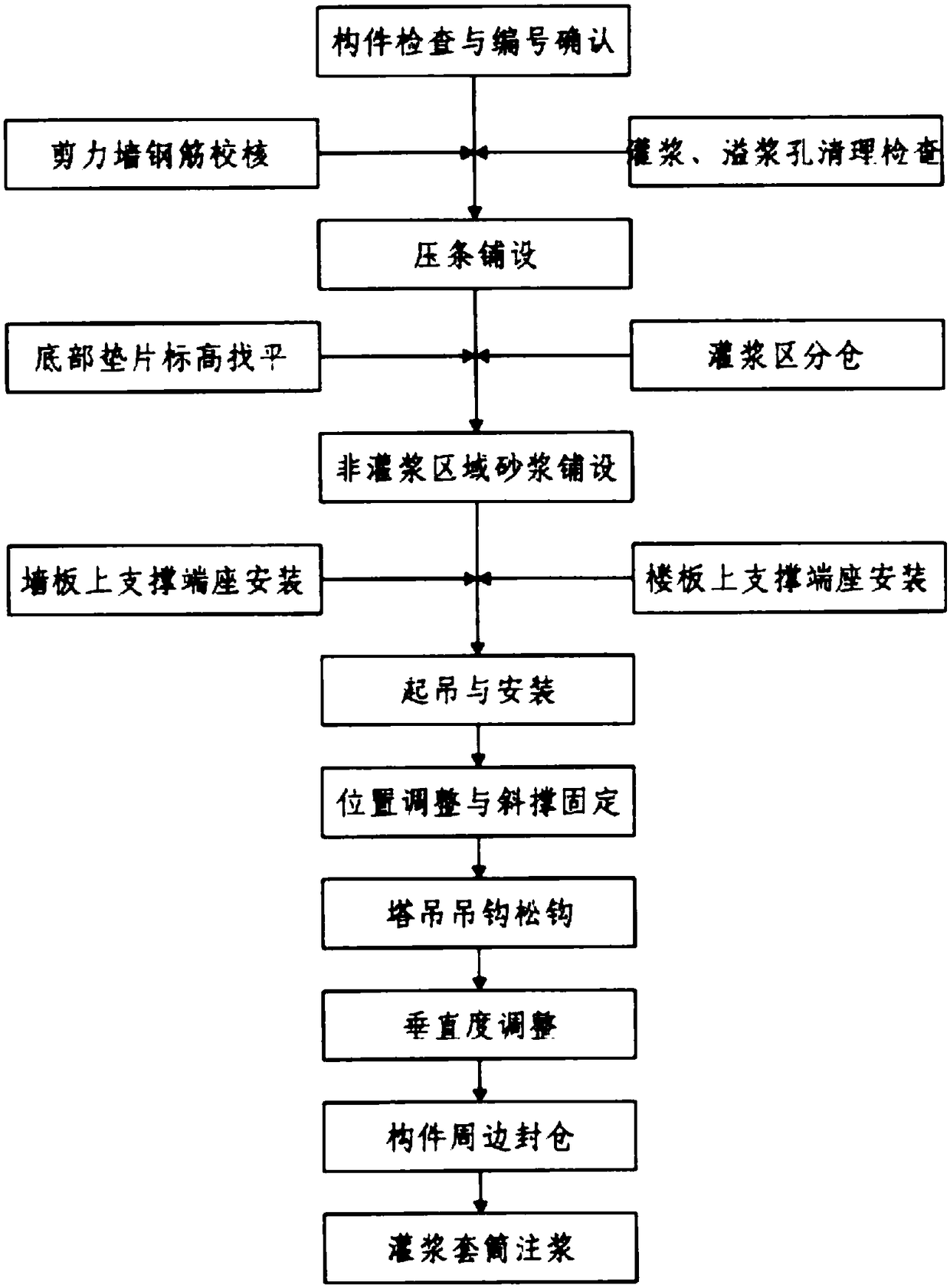

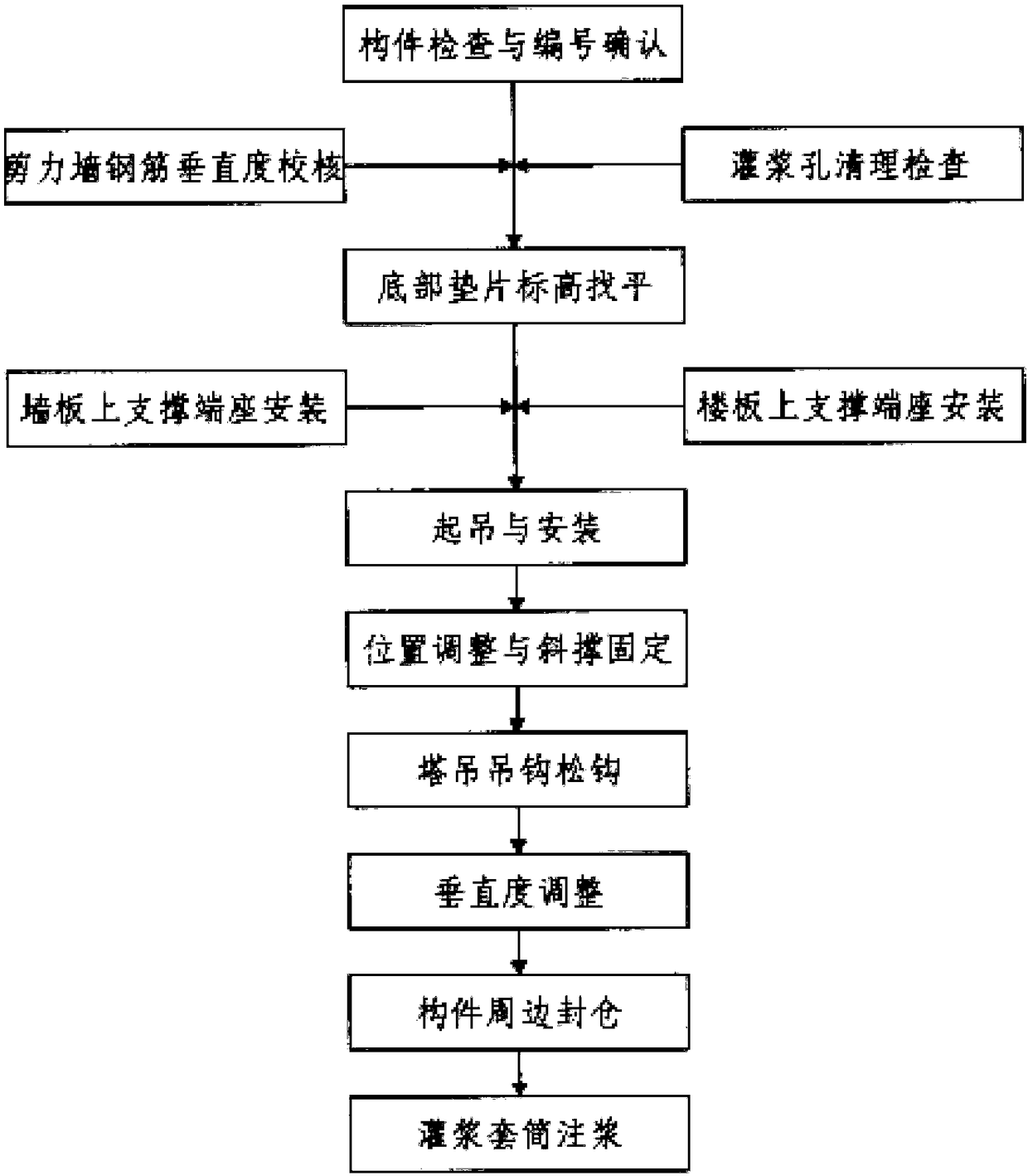

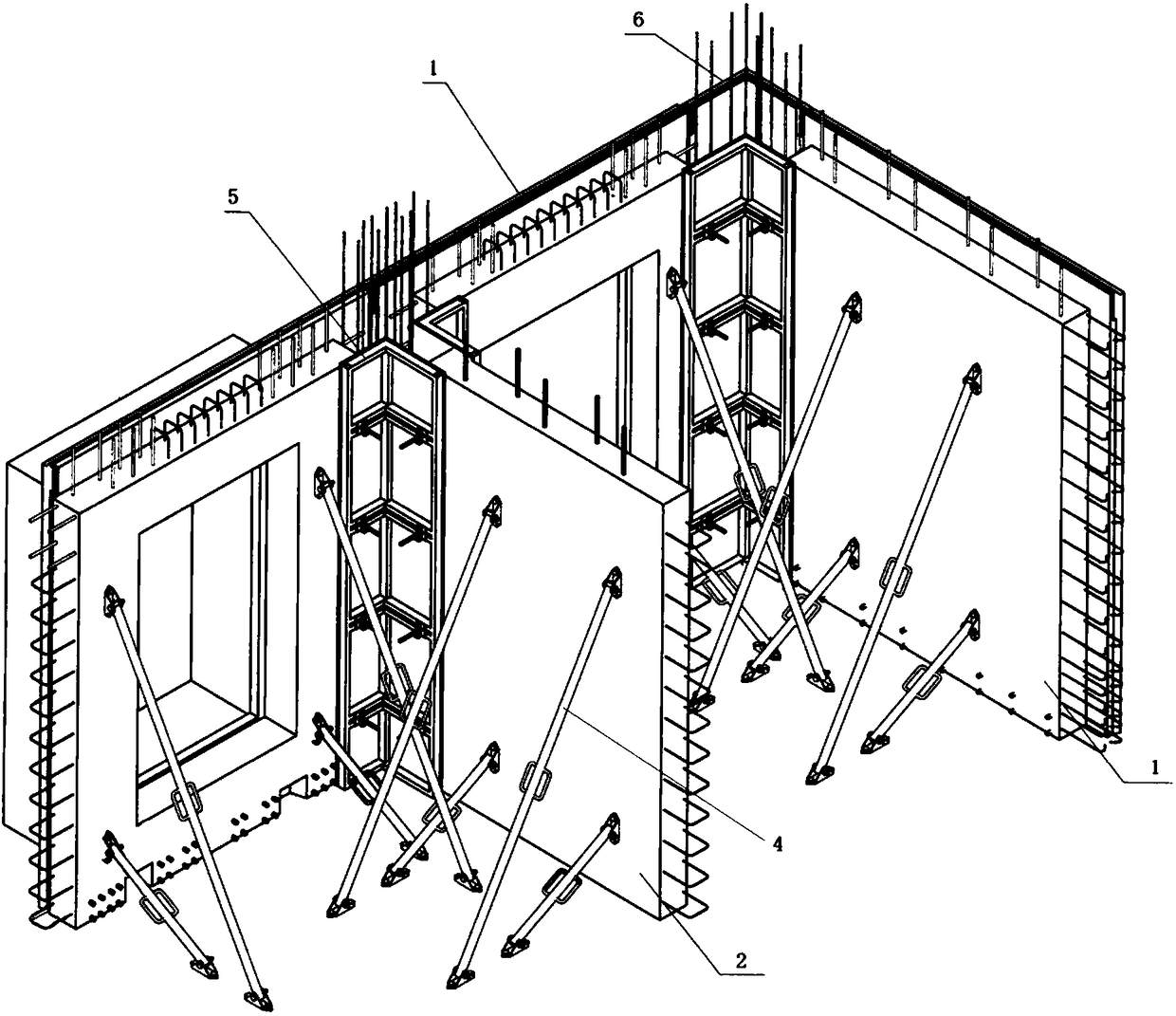

Construction method of prefabricated wallboard

InactiveCN108118900AImprove construction qualitySpeed up the progress of the projectBuilding material handlingTower craneWall plate

The invention discloses a construction method of a prefabricated wallboard. The construction method of the prefabricated wallboard comprises the following steps of 1, numbering the prefabricated wallboard after the wallboard is prefabricated in a factory, and transporting the prefabricated wallboard to a site; 2, checking components and confirming the number; 3, before hoisting, constructing the bottom laying position of the prefabricated wallboard; 4, hoisting and installing the prefabricated wallboard, wherein before the prefabricated wallboard is hoisted, upper and lower supporting end bases of an inclined strut are firstly installed, after the prefabricated wallboard is hoisted, the prefabricated wallboard is adjusted in position and is connected with the inclined strut to be fixed, then a tower crane hook is unhooked, the perpendicularity of the prefabricated wallboard is adjusted, finally, the periphery of the prefabricated wallboard is sealed, and a grouting sleeve is utilized to conduct mortar injecting. By means of the construction method of the prefabricated wallboard, a component assembly mode is adopted, a structural wallboard is divided into multiple blocks, after being prefabricated in the factory, the prefabricated wallboard is hoisted and installed on spot, and certain construction treatment is conducted, which helps to improve the construction quality, accelerate the engineering progress, and improve the building quality.

Owner:BEIJING URBAN CONSTR NORTH CONSTR

Special culture medium for improving tissue culture propagation speed of haworthia succulent plants and tissue culture method

InactiveCN105010147AIncrease reproduction speedReduce the cost of tissue culturePlant tissue cultureHorticulture methodsAdditive ingredientHaworthia

The invention provides a special culture medium for improving the tissue culture propagation speed of haworthia succulent plants and a tissue culture method. The special culture medium is characterized in that the ingredients of the special culture medium include a basic culture medium and low-dosage 2,4-D. The tissue culture method comprises the following steps of 1 explant selection and sterilization, 2 inoculation and aseptic strain establishment and 3 transfer and expanding propagation. The problem of low tissue culture propagation speed of the haworthia succulent plants can be solved, the propagation speed of the haworthia plants is remarkably improved, the cost of the whole tissue culture is reduced, and the marketing speed of products is improved.

Owner:泓柯(天津)农业科技有限公司

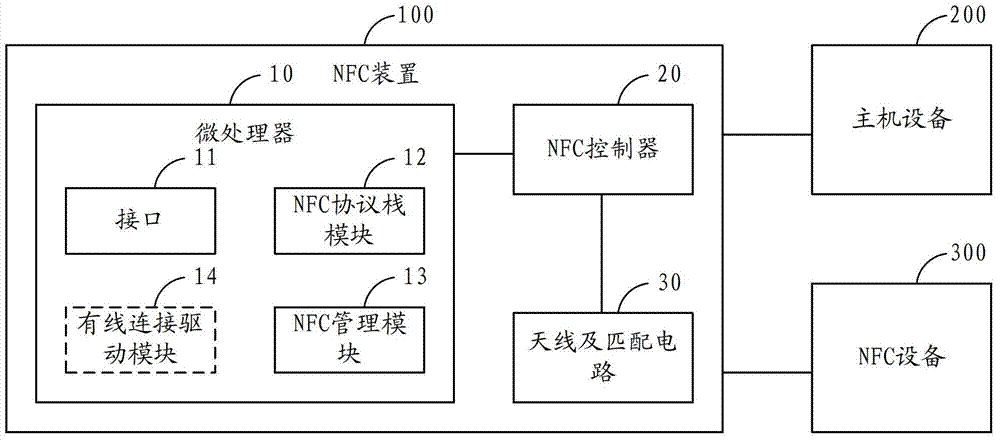

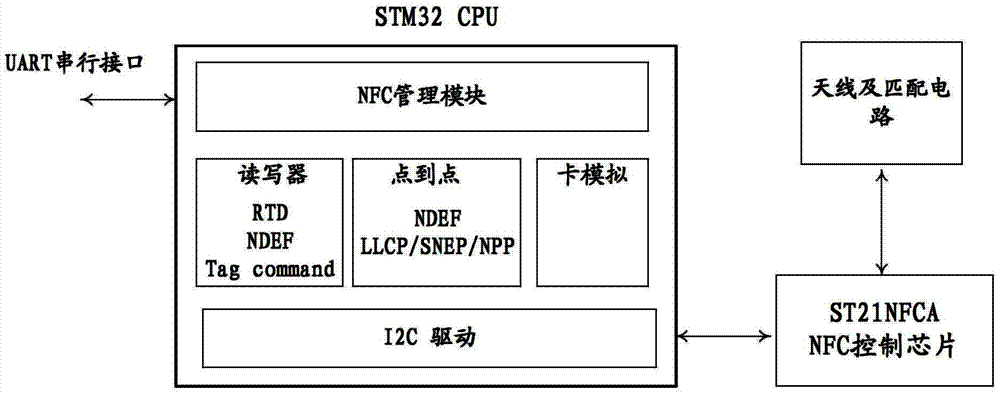

NFC (Near Field Communication) device

InactiveCN103701505AReduce workloadSpeed to marketNear-field systems using receiversNear field communicationProtocol stack

Owner:SHANGHAI STOLLMANN COMM TECH

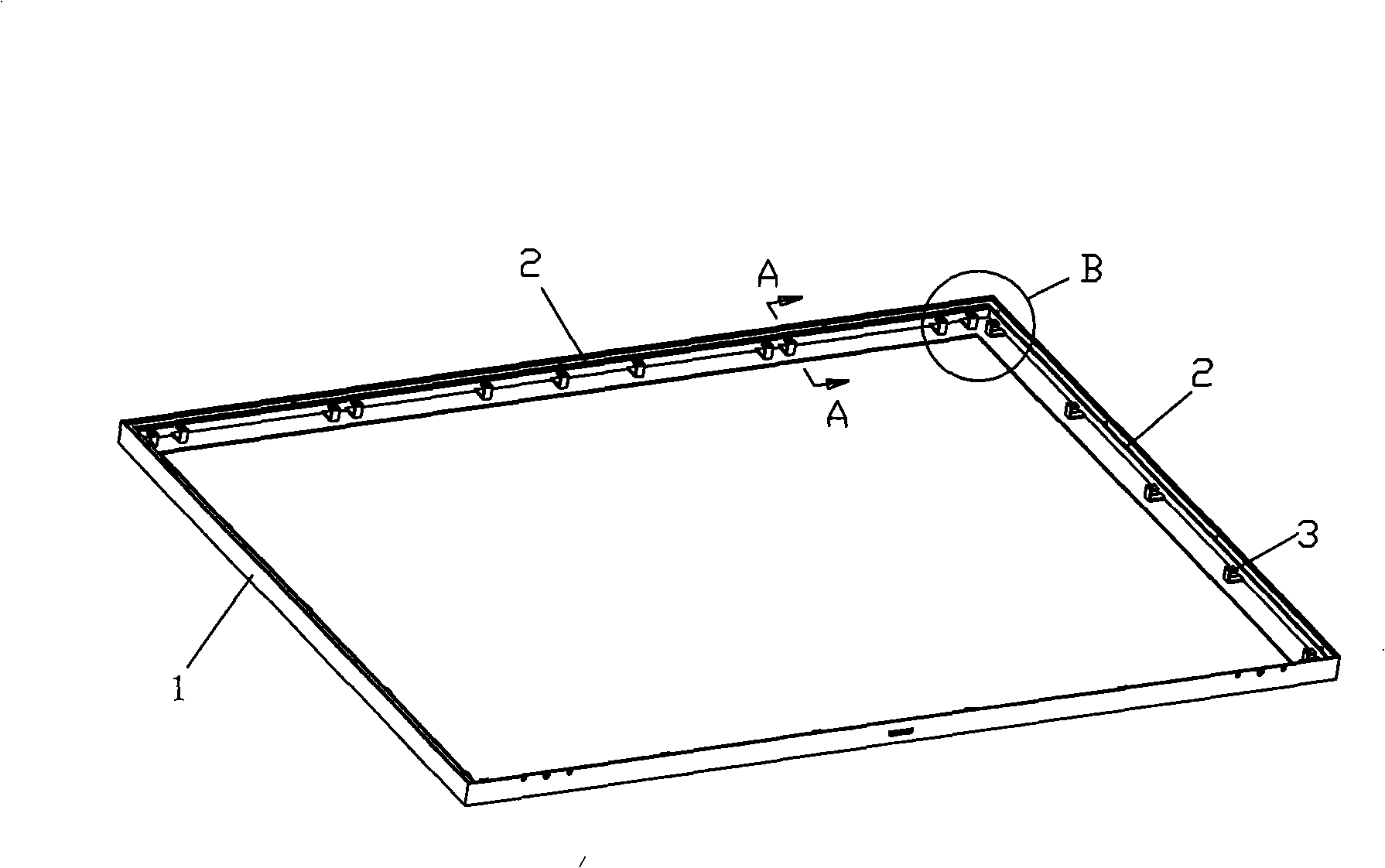

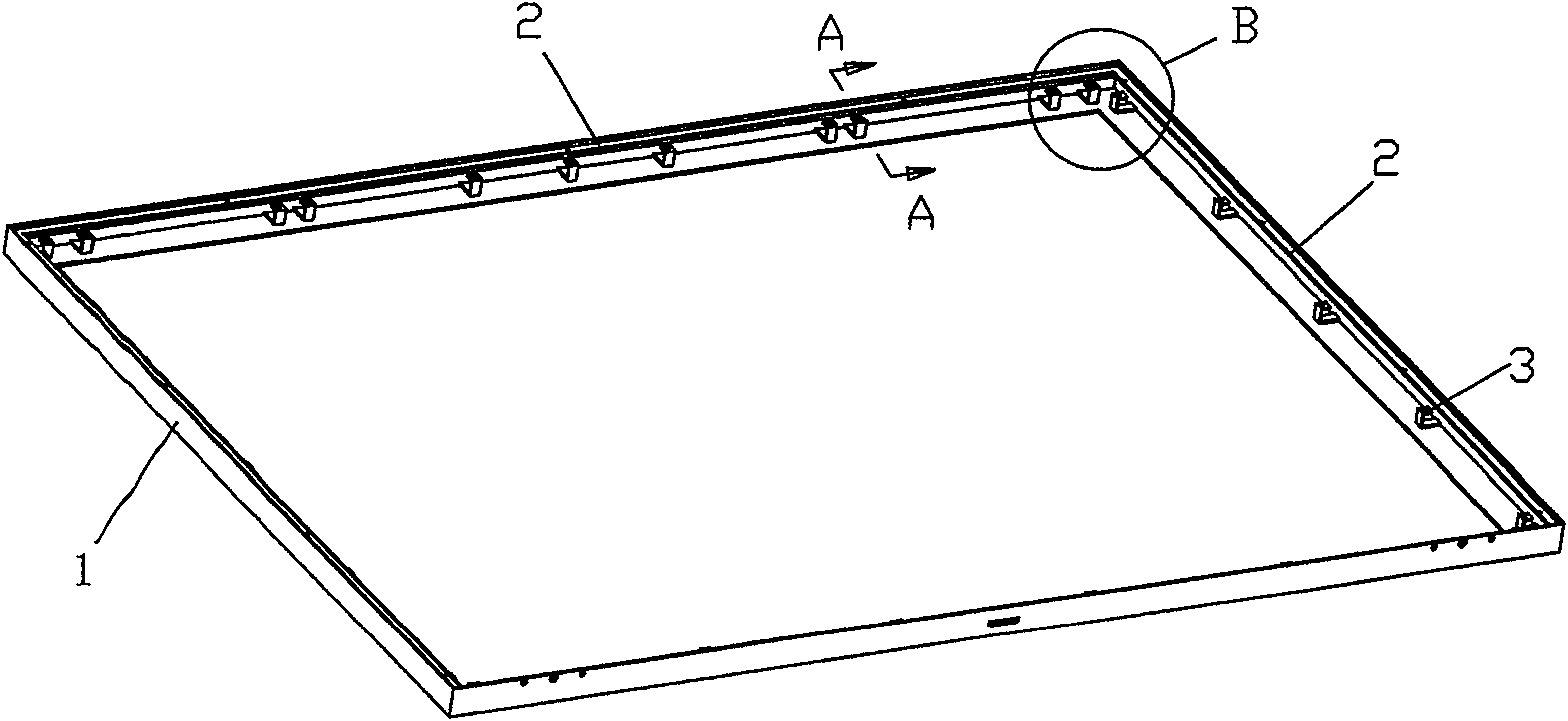

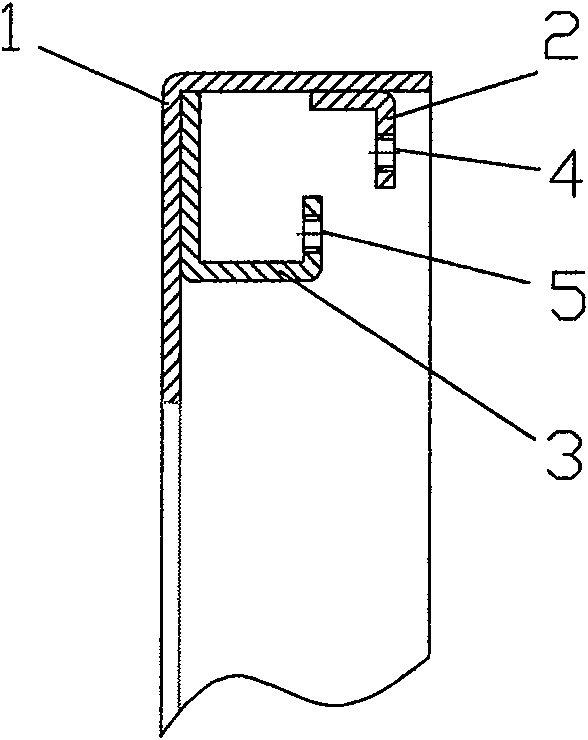

Sheet-metal screen panel of back projected television and manufacture method thereof

InactiveCN101309381ASave mold costSave non-ferrous metal materialsTelevision system detailsColor television detailsEngineeringRear-projection television

The invention discloses a sheet metal screen surface frame of a rear projection television, including that the sheet metal is bent and butt jointed to form a surface frame strip of the rectangle screen surface frame; a folded rear cover fixing strip is arranged on the surface frame strip and is vertical to the inner side of the fold edge of the plane of the screen surface frame; a plurality of rear cover locking screw holes are in staggered arrangement on the rear cover fixing strip; a plurality of double folding screen layering strip fixing bases are in staggered arrangement on the surface frame strip and is in parallel with the inner side of the fold edge of the plane of the screen surface frame; a plurality of screw hole for locking the screen layering strips are in staggered arrangement on the screen layering strip fixing bases. The invention also discloses a manufacturing method of the sheet metal screen surface frame of the rear projection television. The sheet metal screen surface frame and the manufacturing method adopt the common sheet metal, use the sheet metal process to manufacture screen surface frame of the large-size rear projection television, saves the mould cost and the non-ferrous materials in the traditional process greatly and reduces the production cost; thereby, the market competitive power of the large-size rear projection television is improved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

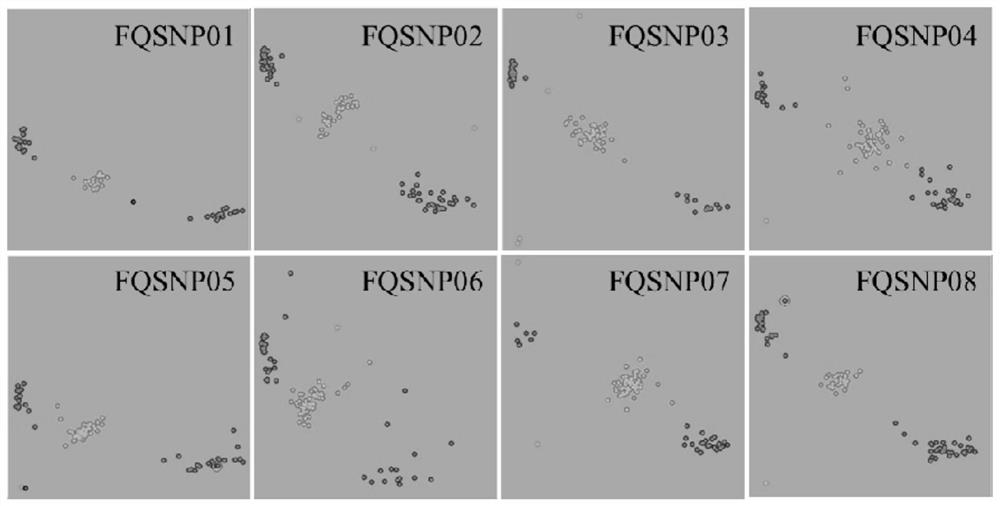

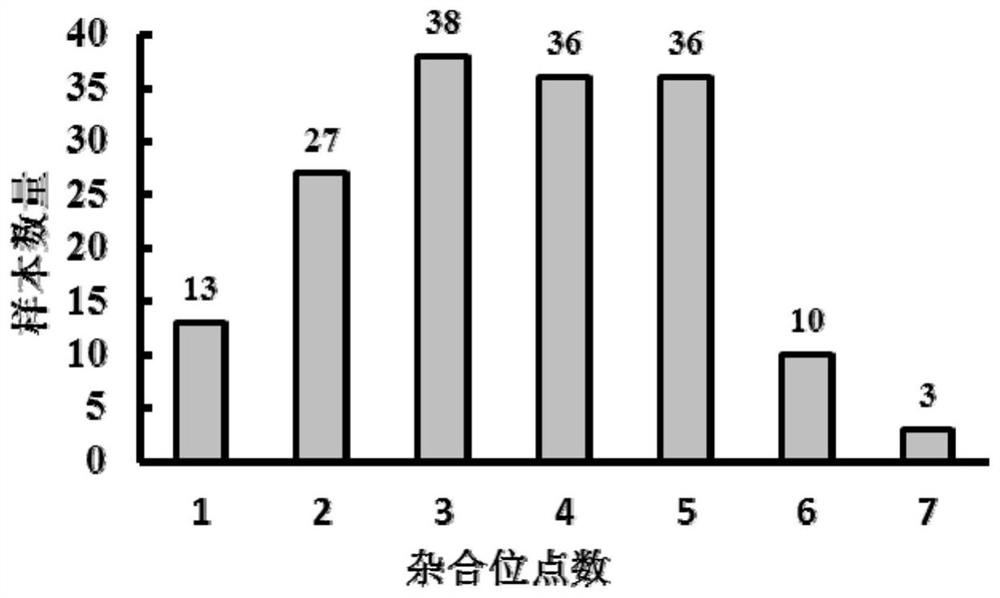

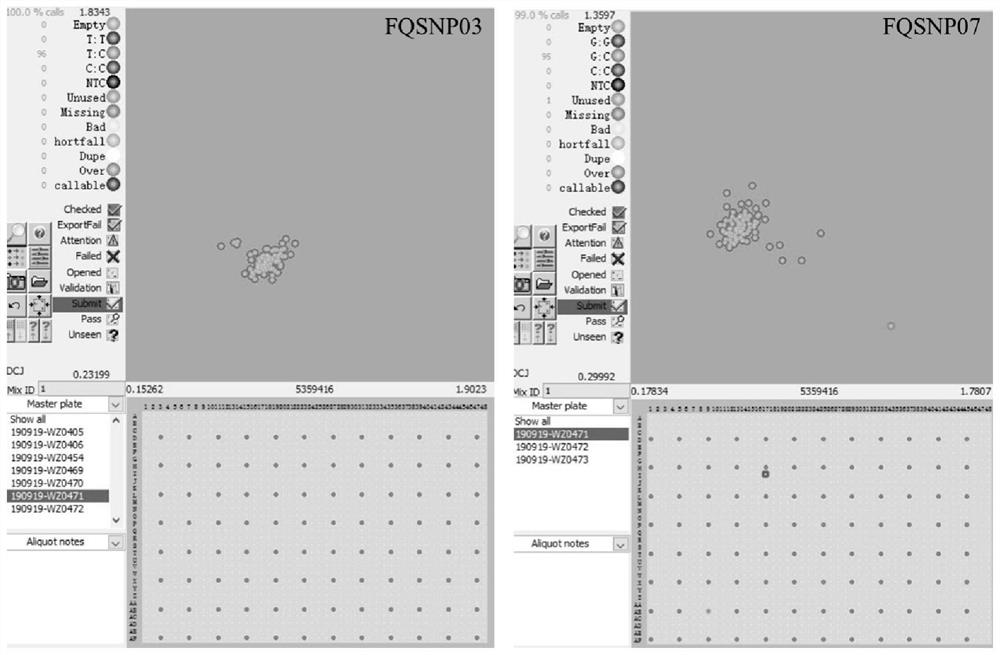

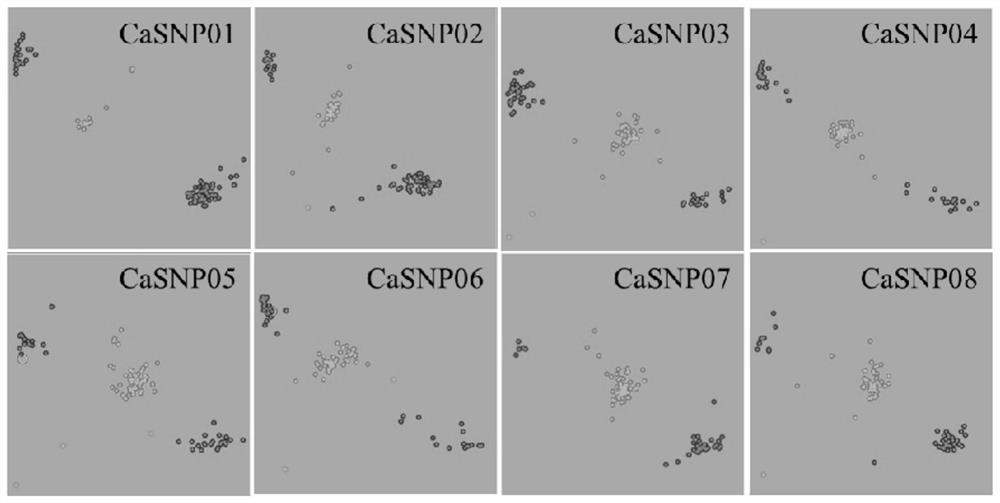

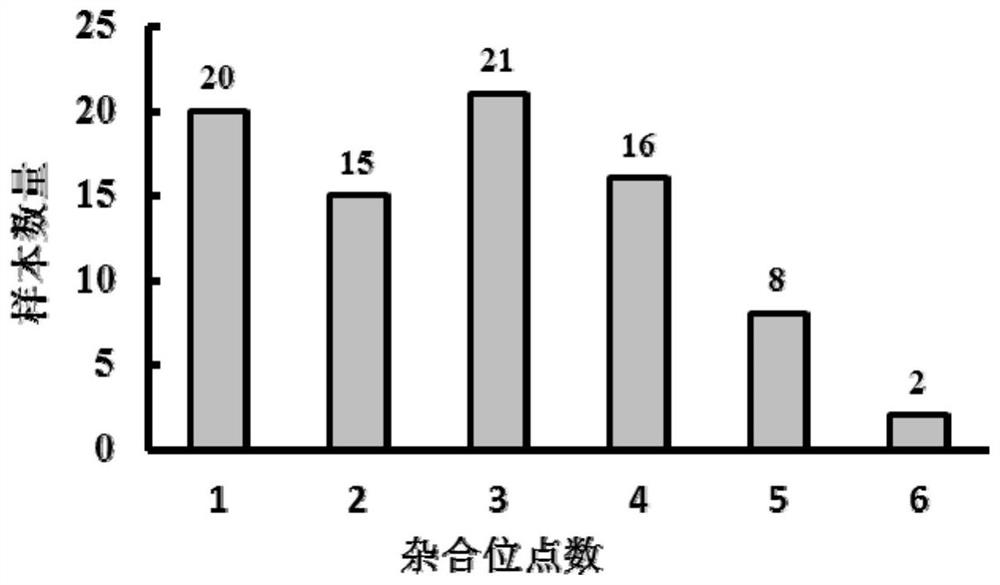

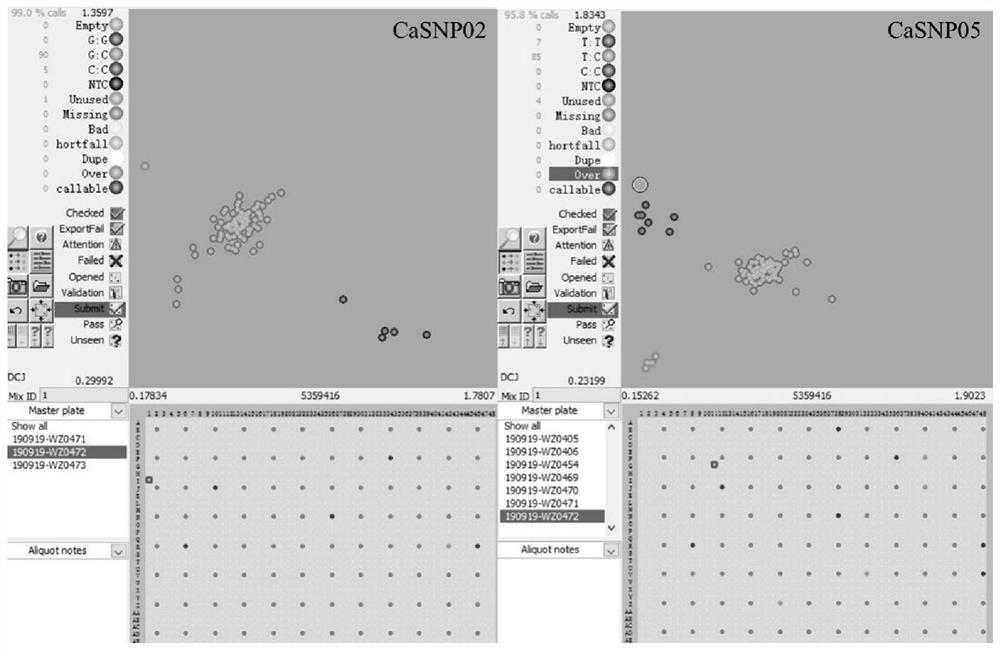

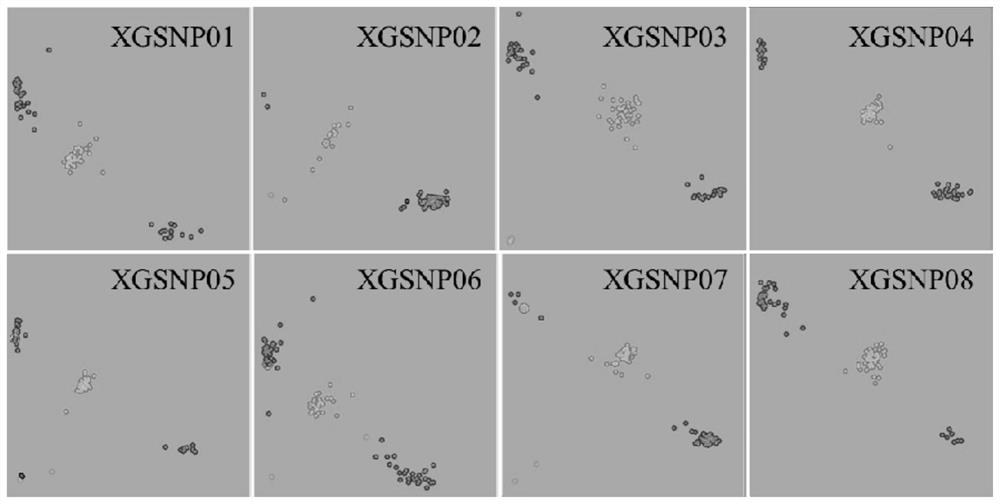

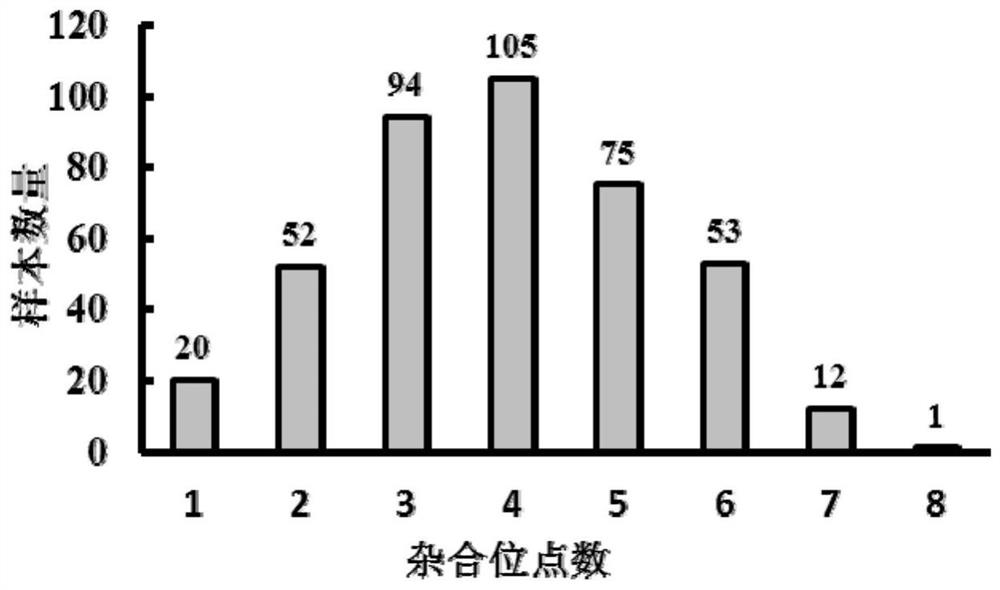

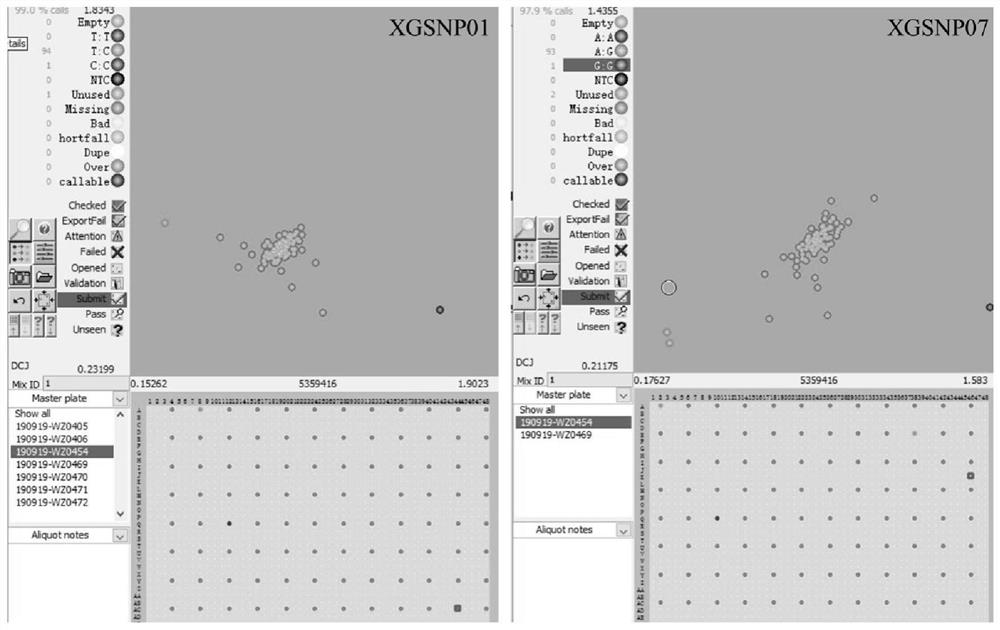

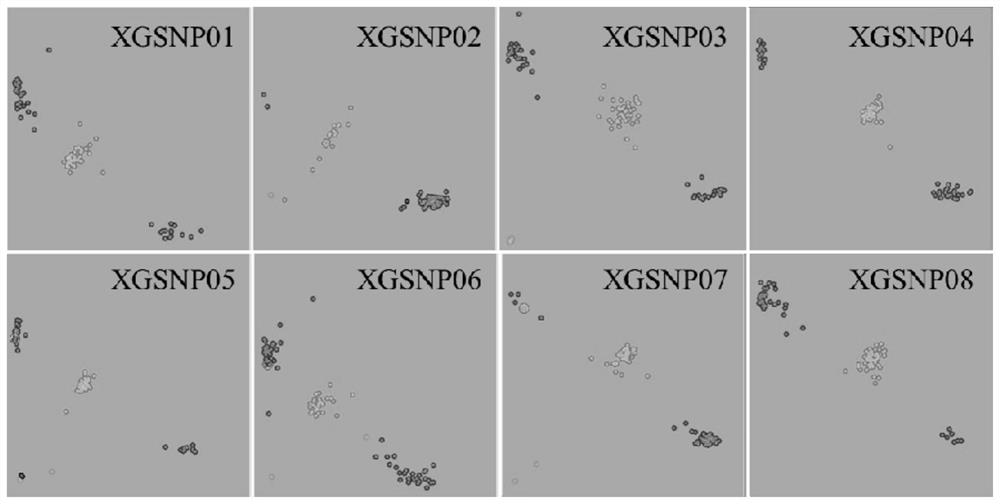

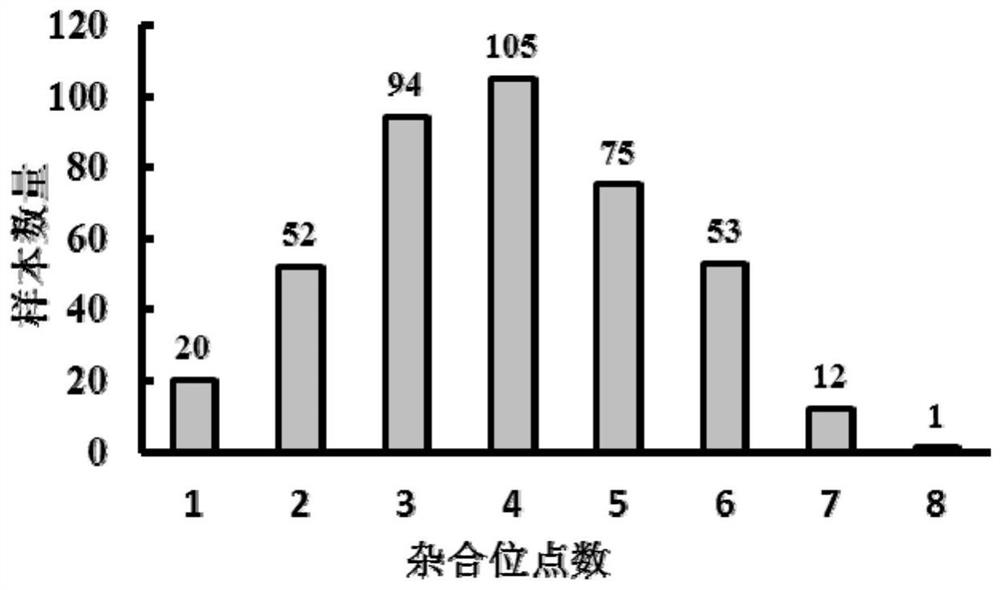

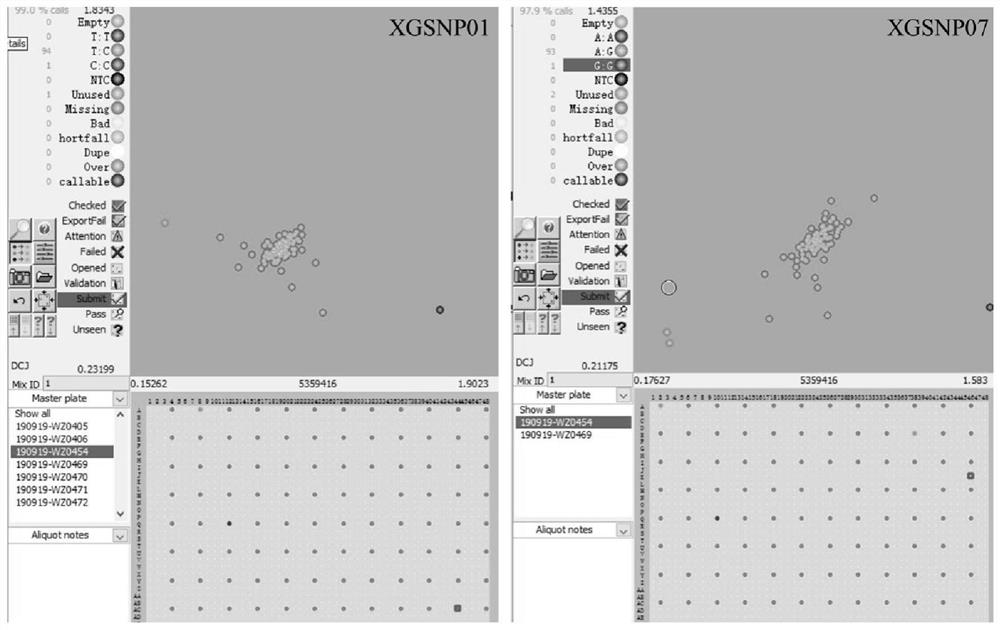

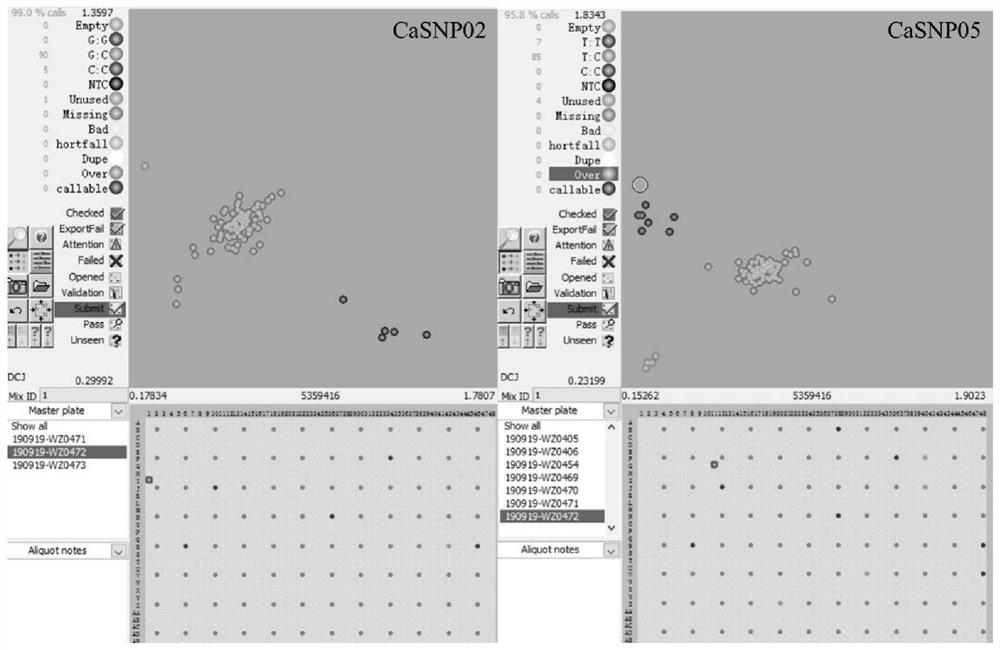

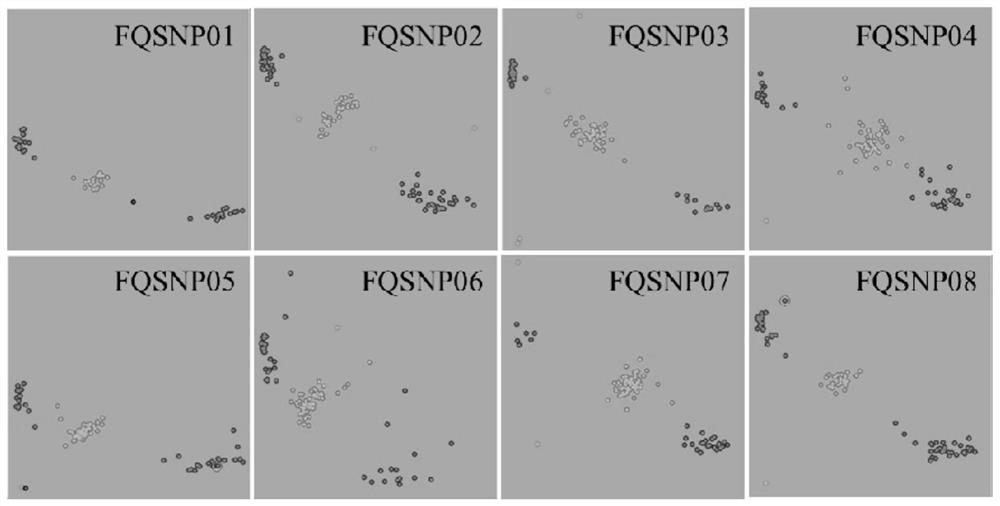

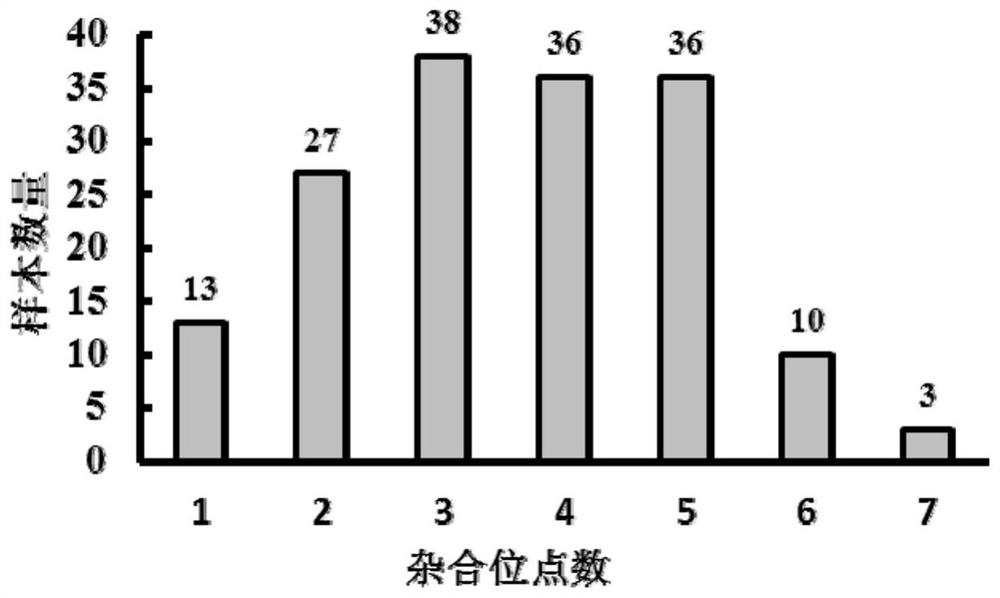

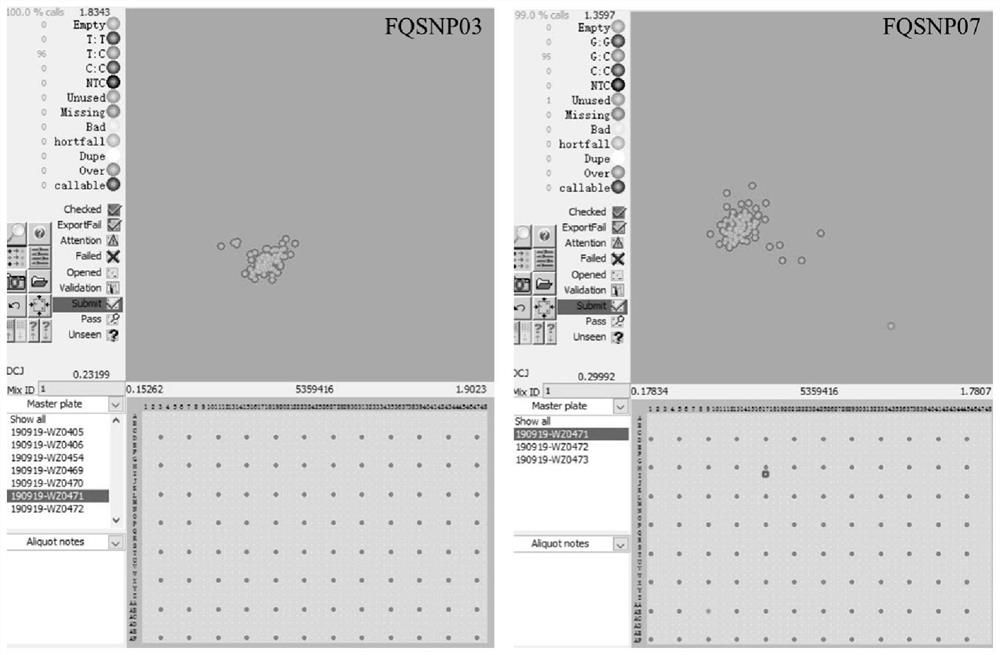

SNP loci and primer groups for identifying purity of tomato hybrid and application

ActiveCN112195264ASpeed to marketImprove throughputMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyNucleotide

The invention discloses a method for identifying the purity of tomato hybrids and an SNP primer combination used by the method. The SNP primer combination provided by the invention is composed of eight primer groups, wherein each primer group consists of three primer sequences and is used for amplifying one SNP locus; and the nucleotide sequences of the primers are sequentially shown as SEQ ID NO:1 to SEQ ID NO: 24. The SNP primer combination can be used for early identification in the seed or seedling stage of tomato hybrids, the purity of the hybrids is guaranteed, the rights and interestsof producers and breeders are practically protected, and technical support is provided for seed quality management of tomato varieties. The method provided by the invention has the advantages of highefficiency, accuracy, low cost and the like, and has a very wide application prospect.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

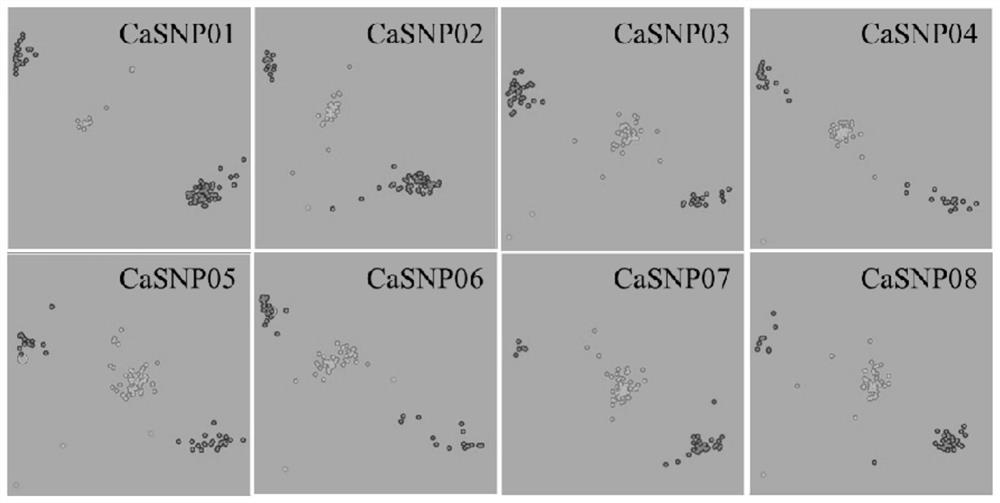

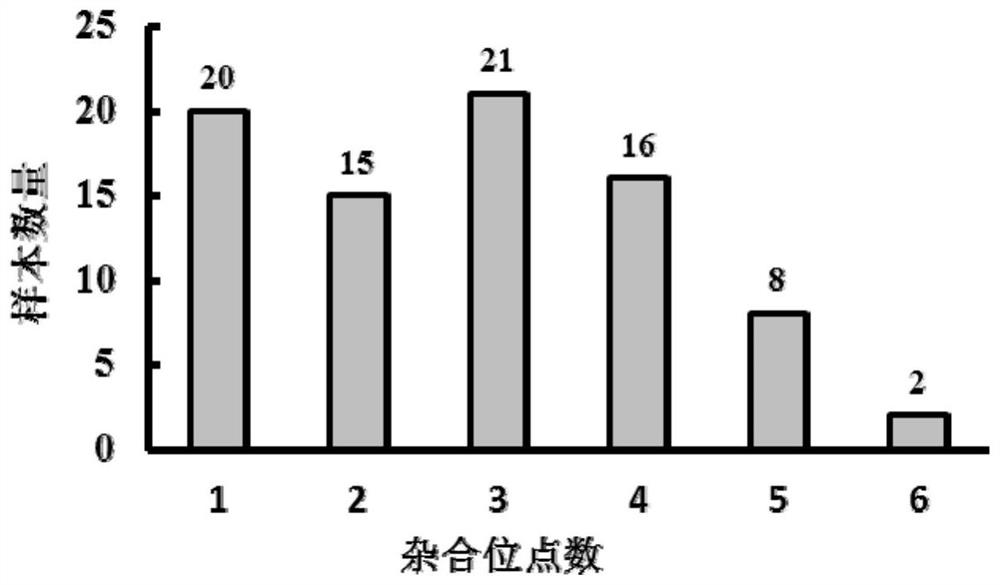

SNP loci and primer groups for identifying purity of pepper hybrids and application

ActiveCN112195265ASpeed to marketImprove throughputMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyNucleotide

The invention discloses a method for identifying the purity of pepper hybrids and an SNP primer combination used in the method. The SNP primer combination provided by the invention is composed of eight primer groups, wherein each primer group consists of three primer sequences and is used for amplifying one SNP locus; and the nucleotide sequences of the primers are sequentially shown as SEQ ID NO:1 to SEQ ID NO: 24. The SNP primer combination is confirmed to be suitable for purity identification of 82 pepper varieties, is stable and accurate in detection effect and high in detection speed, can be identified in seeds or seedling stage, is suitable for high-throughput detection equipment, is simple to operate, is time-saving and labor-saving, has a wide application prospect, and can providetechnical support for seed quality management of the pepper varieties.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Instant pickled Chinese leek roots

InactiveCN107495229AGuaranteed crisp tasteShorten marinating timePackage sterilisationFood ingredientsMedicineRaw material

The invention provides instant pickled Chinese leek root vegetables. Natural Chinese leek roots or roots of organically-planted vegetables namely Chinese leek are used as raw materials, and the instant pickled Chinese leek root vegetables are pickled through the following work procedures and steps of (1) performing sorting; (2) performing air-drying; (3) performing blending: adding high-alcohol brewed Baijiu (38-65vol) and brewed white vinegar; (4) performing pickling: loading the blended Chinese leek roots in a ceramic jar, performing water sealing, and performing pickling at the temperature of 12-36 DEG C for 40-20 days; and (5) performing seasoning, and performing vacuum packaging.

Owner:发贵科技(贵州)有限公司

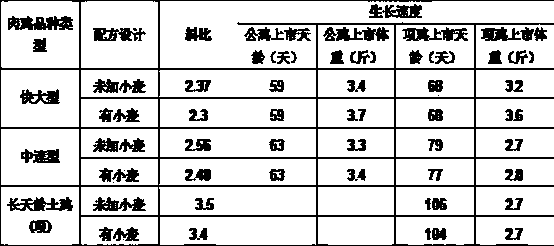

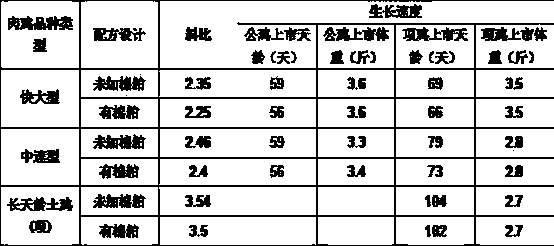

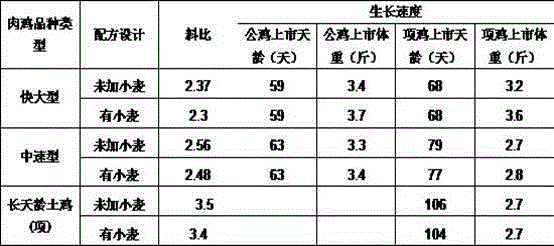

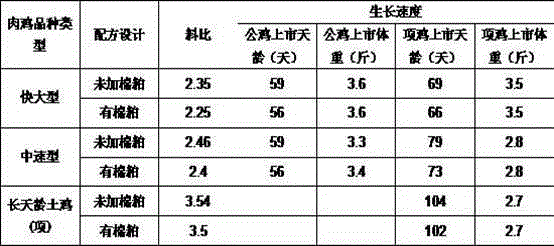

Method for feeding three-yellow broiler chickens

ActiveCN104170789AIncrease drinking waterReduced feed intakeAnimal husbandryBiotechnologyHigh humidity

The invention discloses a method for feeding three-yellow broiler chickens. The method comprises three stages. In the first stage, young chickens are fed with three-yellow broiler chicken feeds in which corn is partially replaced with wheat according to a proportion of 5-10 percent from May to August and are fed with three-yellow broiler chicken feeds in which soybean meal is partially replaced with cottonseed meal according to a proportion of 2-4 percent from November to March of the next year. In the second and third stages, middle-aged chickens and adult chickens are fed with three-yellow broiler chicken feeds in which the corn is partially replaced with the wheat according to a proportion of 10-28 percent from May to August and are fed with three-yellow broiler chicken feeds in which the soybean meal is partially replaced with the cottonseed meal according to a proportion of 2-8 percent from November to March of the next year. Due to the adoption of the method for feeding the three-yellow broiler chickens by using the raw material components, the phenomena of heat stress and cold stress on the three-yellow broiler chickens under the weather conditions of high temperature, high humidity and low temperature are effectively eliminated, the health conditions of the three-yellow broiler chickens are improved, the immunity is enhanced, the digestion capacity and the absorption capacity are improved, the marketing speed of the three-yellow broiler chickens is increased, the material ratio is controlled, the feeding cost is reduced, and culture benefits are effectively increased.

Owner:WENS FOODSTUFF GRP CO LTD

Manufacture method of sheet-metal screen panel of back projected television

InactiveCN100568937CFlexible cuttingFast weldingTelevision system detailsColor television detailsNonferrous metalLarge size

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

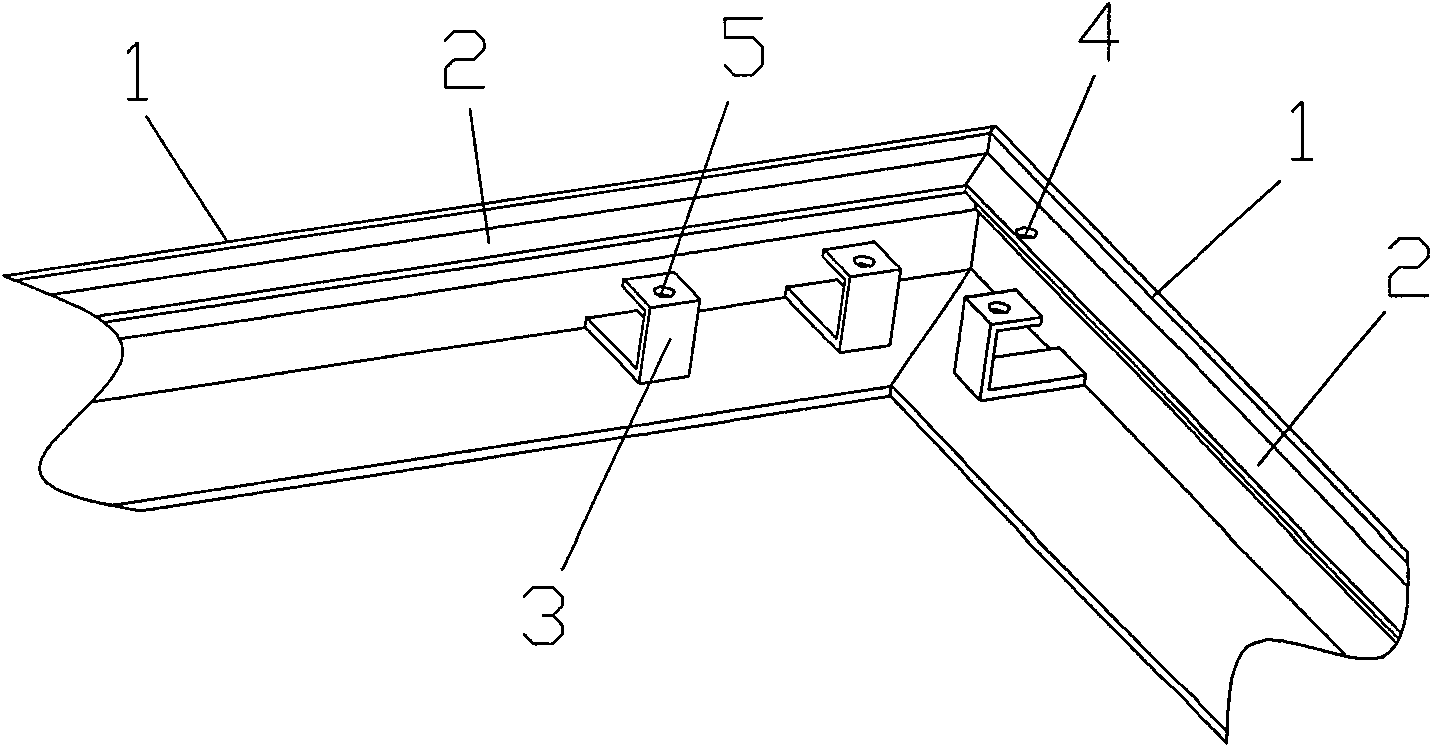

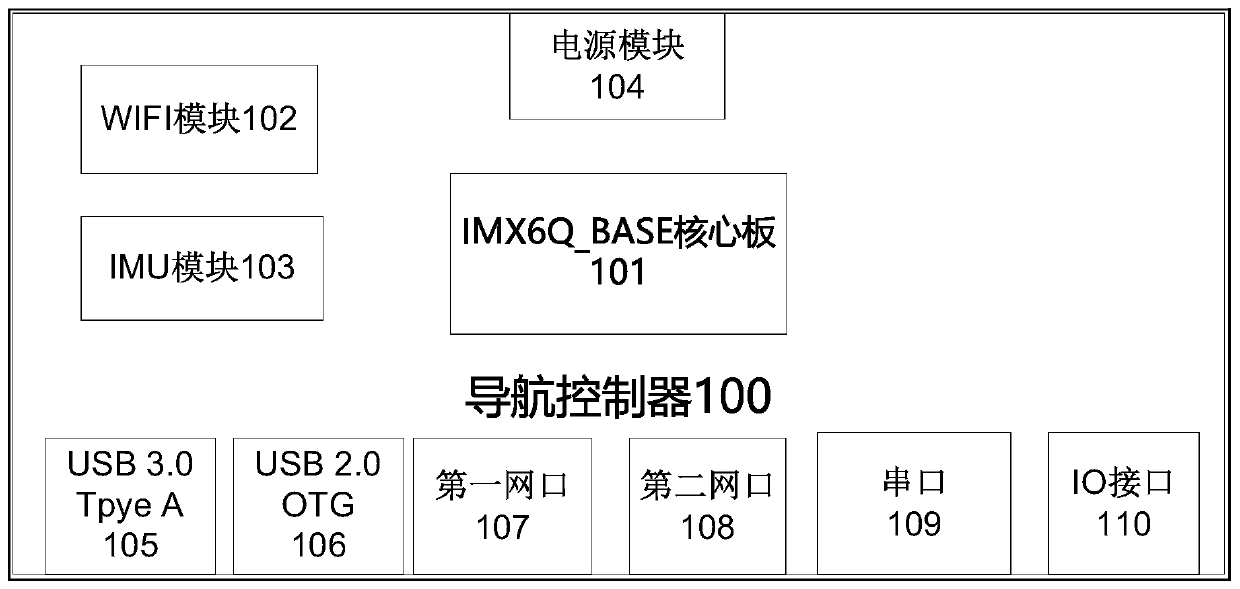

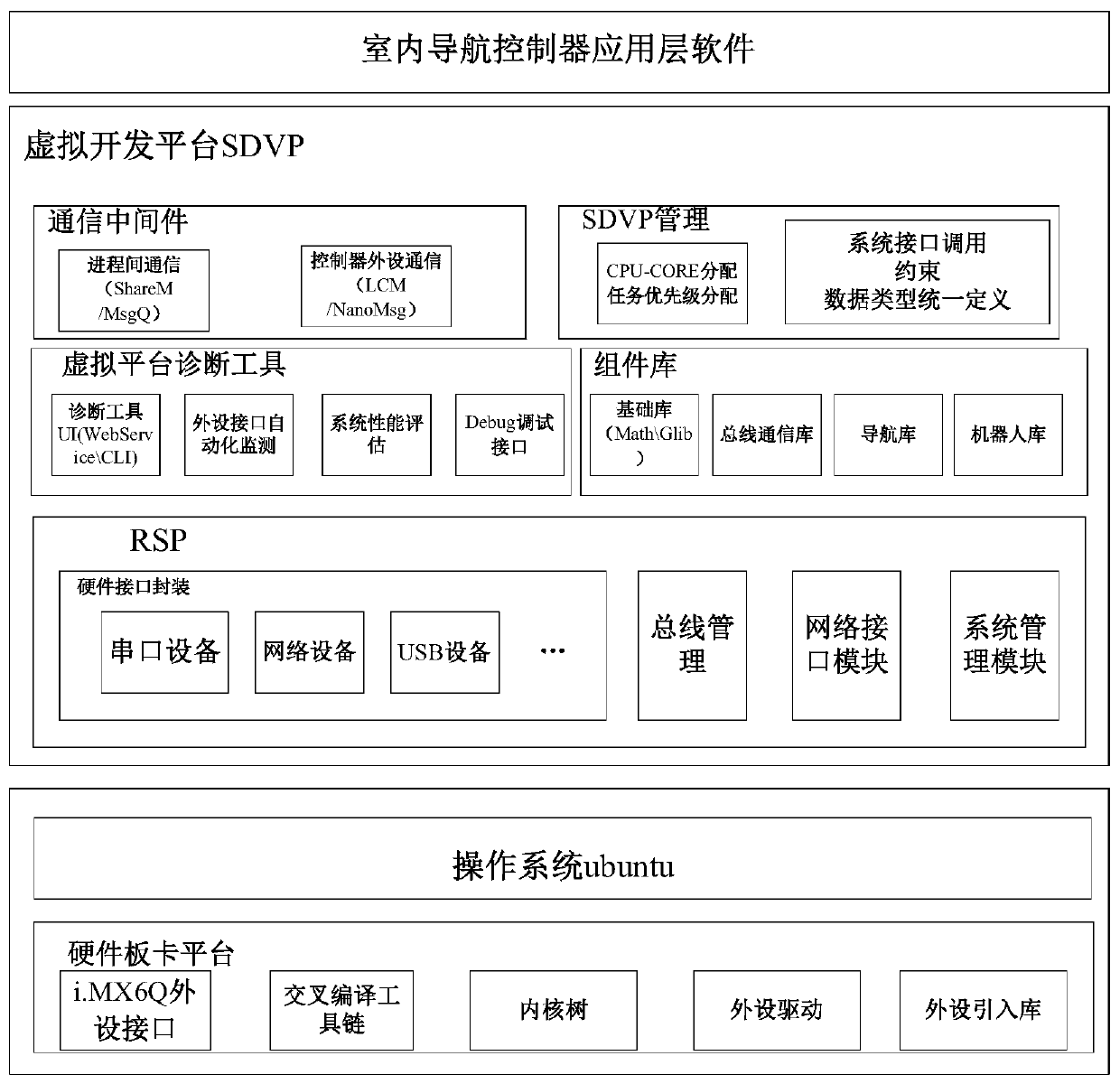

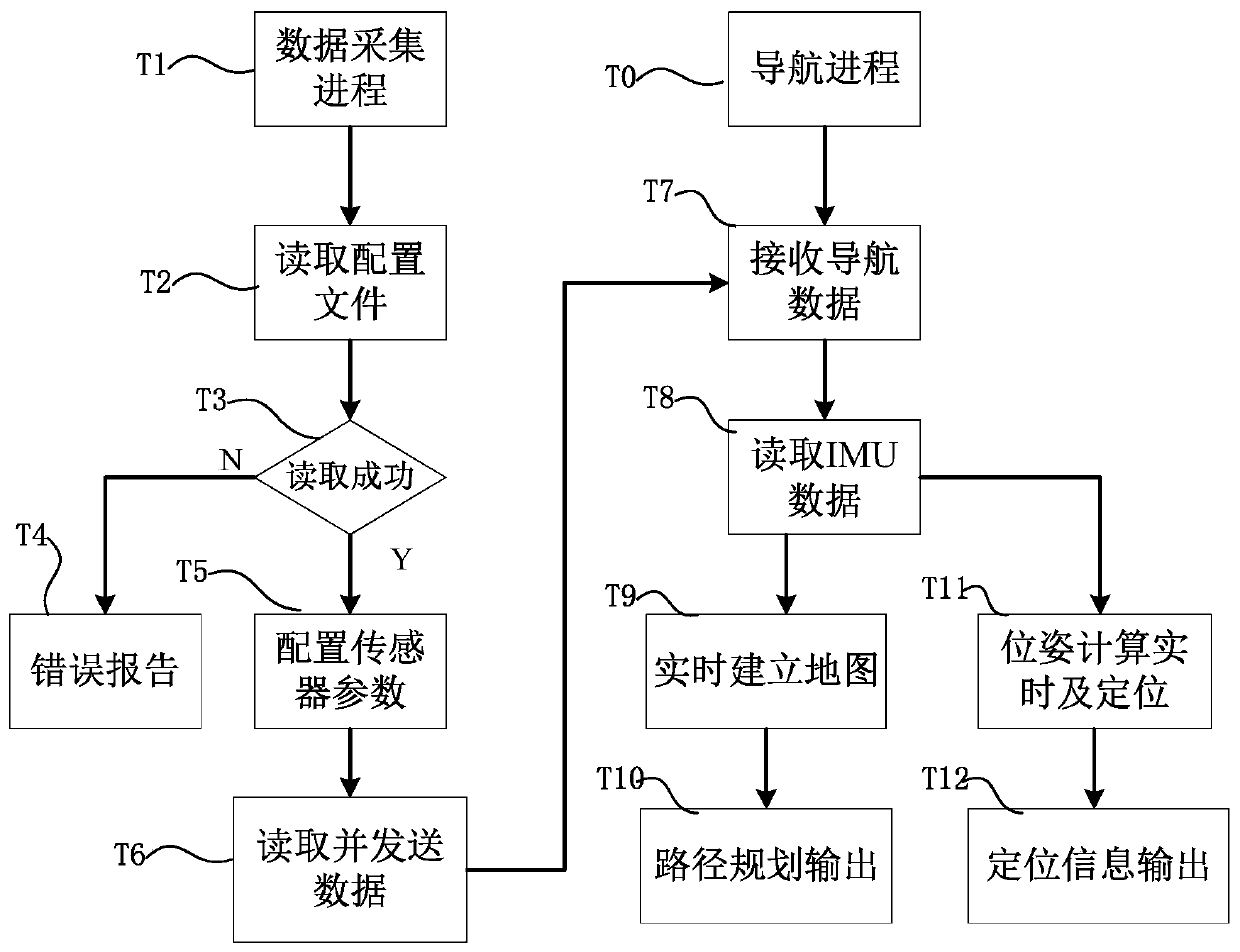

Navigation method and navigation controller of indoor service robot

PendingCN111380527AReduce overheadQuick responseNavigational calculation instrumentsEmbedded systemExecution control

The embodiment of the invention discloses a navigation controller and a navigation method of an indoor service robot. The navigation controller comprises: a core board which comprises a processor anda minimum system related to the processor and is used for executing control and processing work; a wireless communication module connected with the core board and used for wireless communication; an inertial navigation sensor connected with the core board and used for sensing the pose of the indoor service robot; a power supply module used for supplying power to each module of the navigation controller; and a plurality of peripheral interfaces used for connecting a plurality of peripherals. The navigation controller of the indoor service robot is designed in a modular mode, can be matched withvarious sensing means, and is more complete in function and more excellent in performance.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

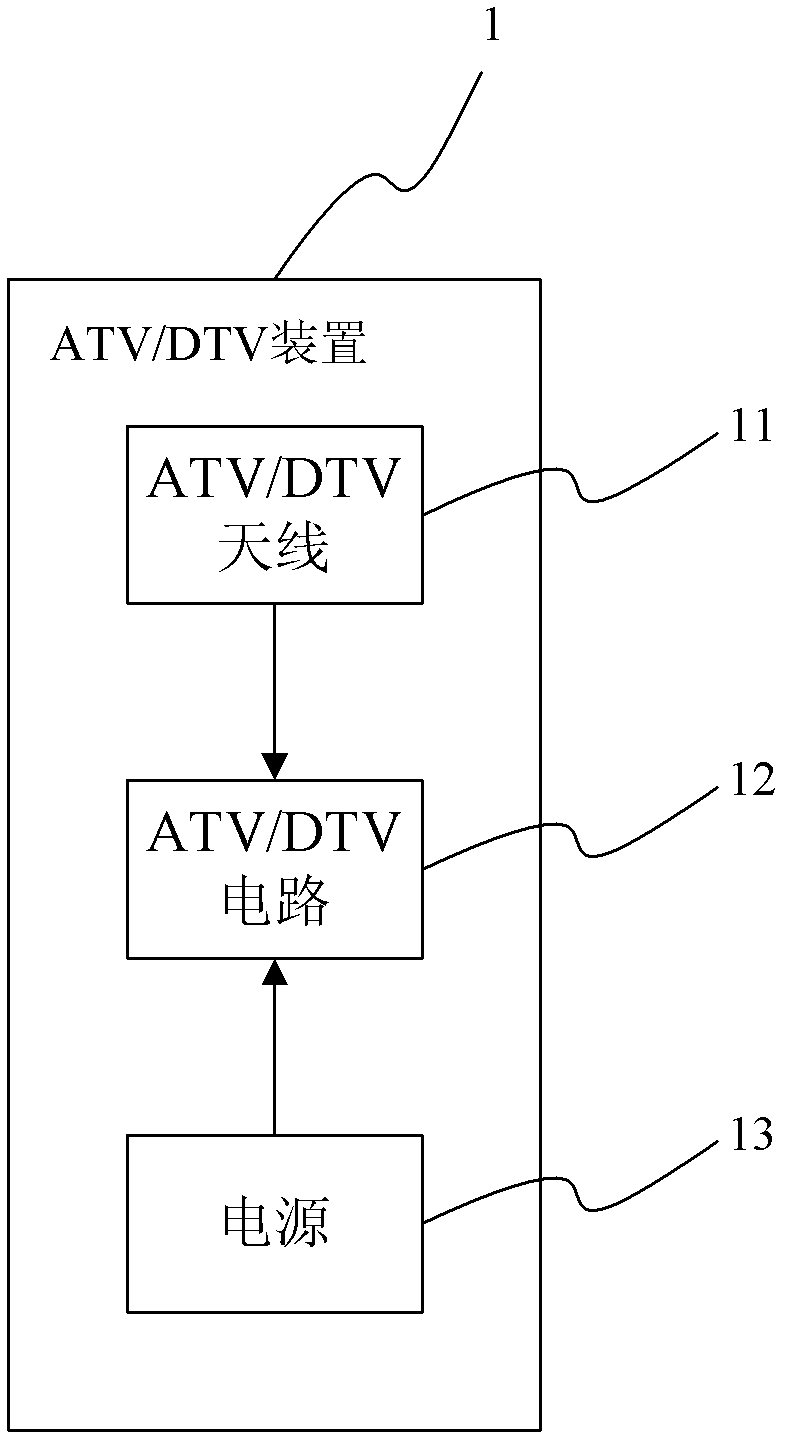

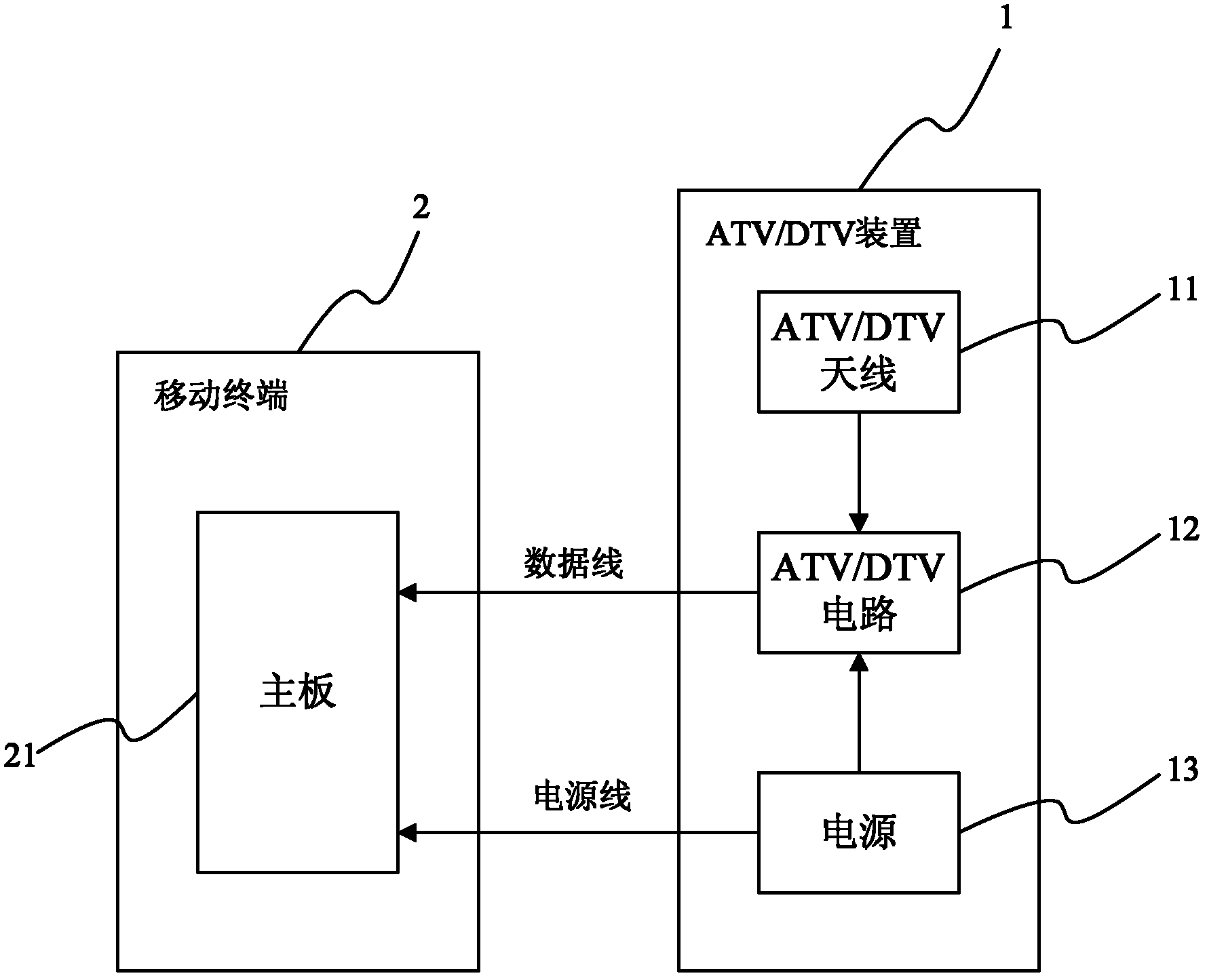

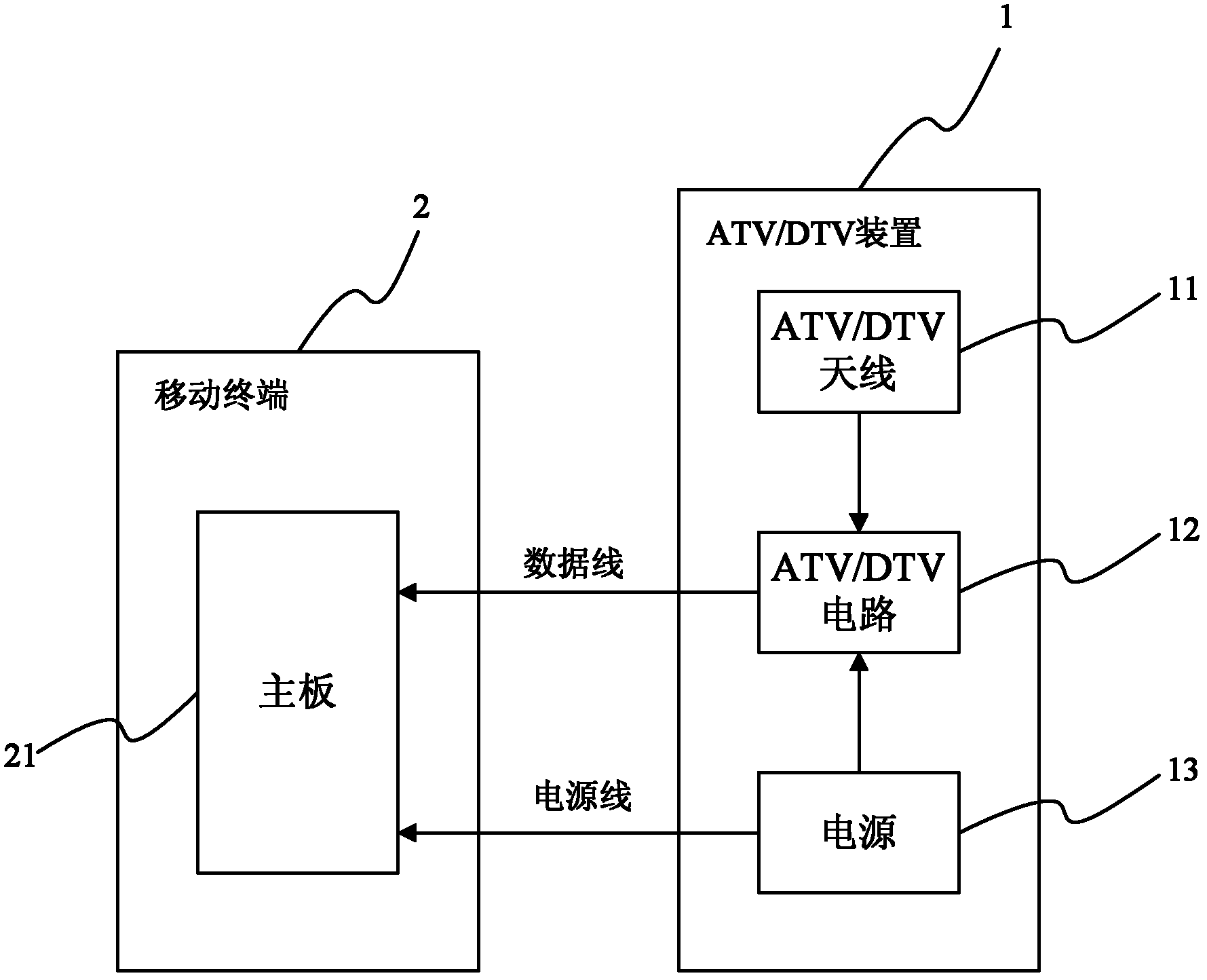

Analogue television (ATV)/digital television (DTV) device and mobile terminal

InactiveCN102497583AShorten development timeIncrease speed to marketSelective content distributionAnalog televisionCable television

The invention discloses an analogue television (ATV) / digital television (DTV) device, which comprises a power supply, an ATV / DTV antenna and an ATV / DTV circuit, wherein the ATV / DTV antenna is used for receiving an analogue television signal and a digital television signal; and the ATV / DTV circuit is used for decoding the analogue television signal and the digital television signal, and is positioned between the ATV / DTV antenna and the power supply. The invention also discloses a mobile terminal connected with the ATV / DTV device. By the ATV / DTV device, debugging time for realizing an ATV / DTV function on the conventional mobile terminal is saved, and the structure design of the mobile terminal is optimized, so that the miniaturization of the mobile terminal is realized. In addition, the power supply integrated by the modular ATV / DTV device can serve as a standby battery of the mobile terminal.

Owner:HUAQIN TECH CO LTD

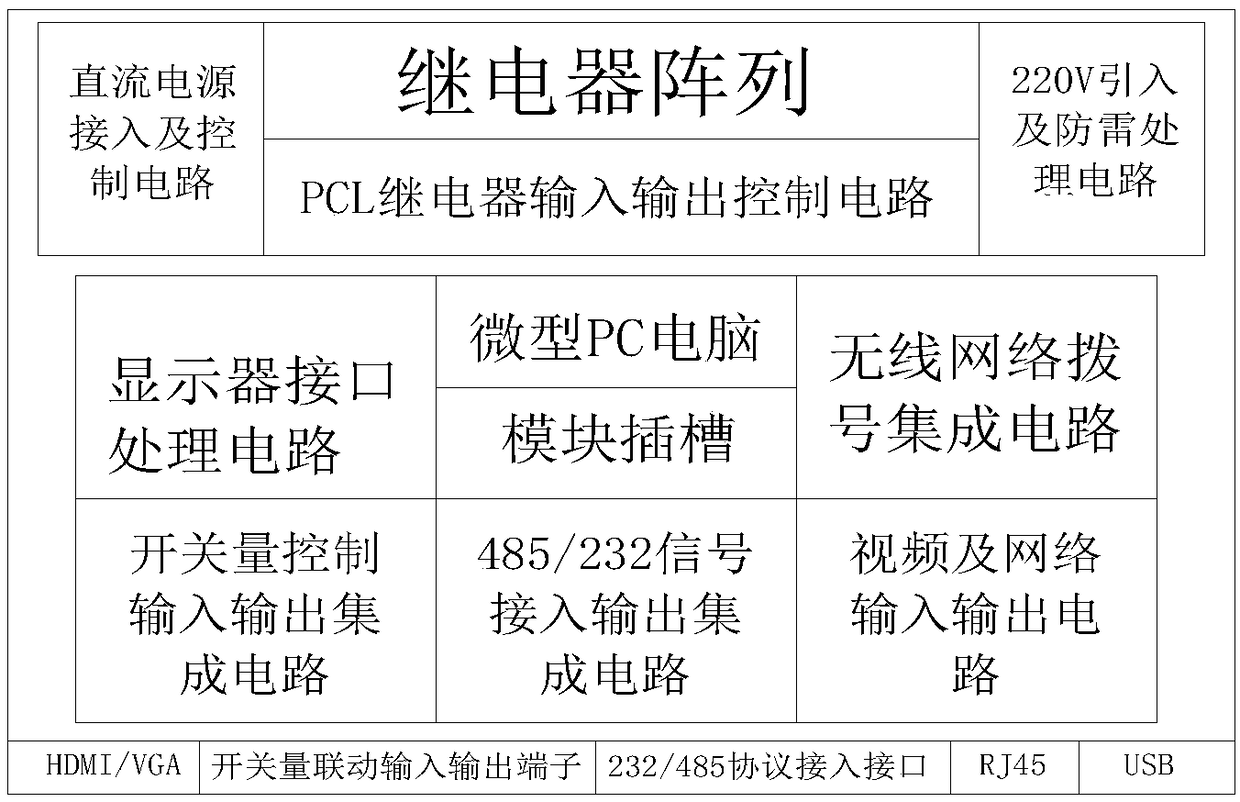

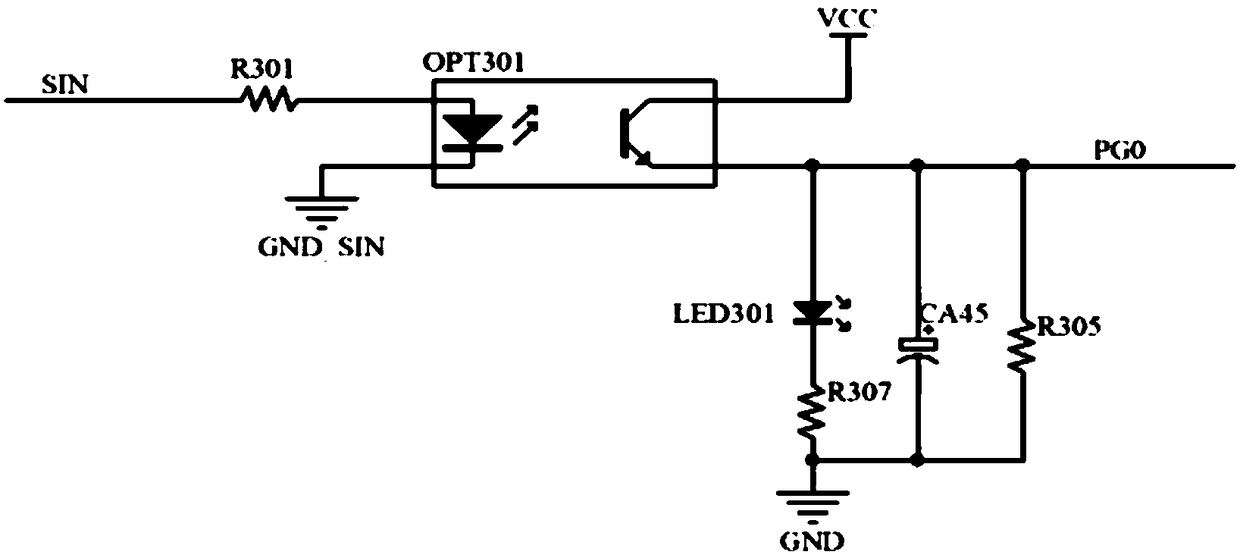

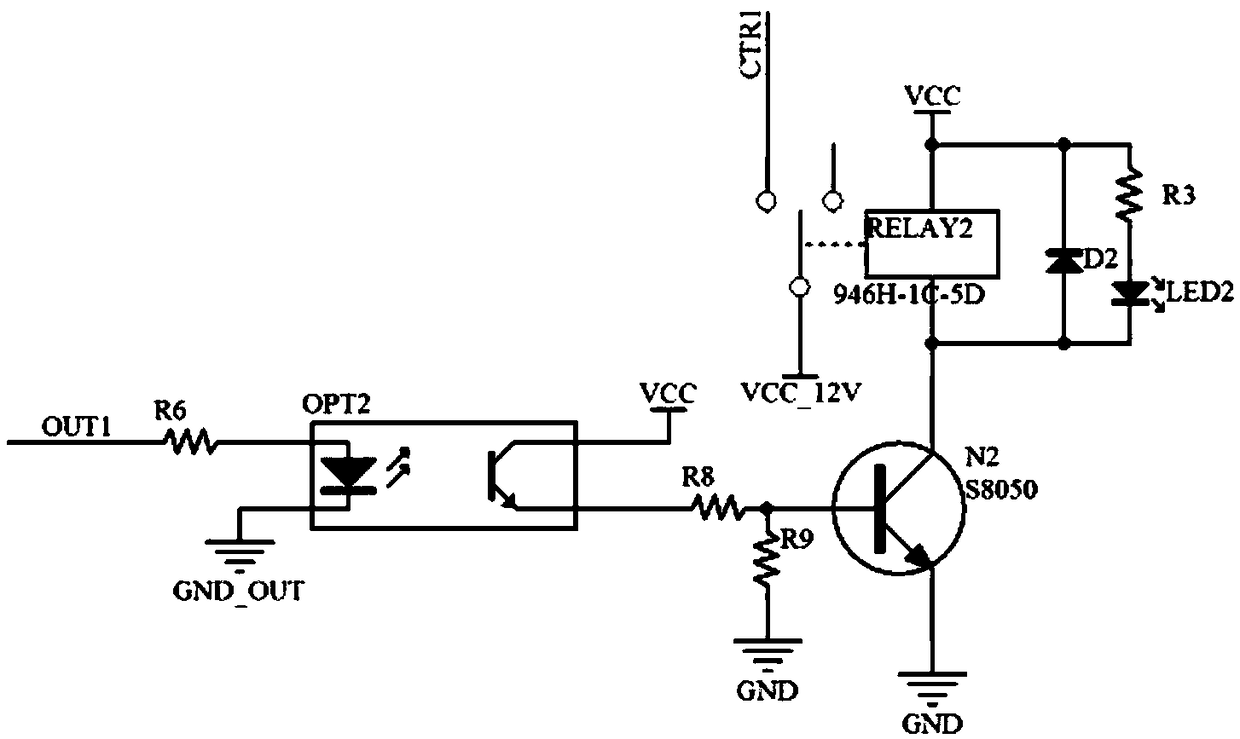

Micro PC-based Internet of Things centralized control system and method thereof

PendingCN108931952ASave manpower and material costsShorten the timeProgramme controlComputer controlCommunication interfaceControl system

The invention relates to a micro PC-based Internet of Things centralized control system and a method thereof. The micro PC-based Internet of Things centralized control system comprises a special cabinet; the cabinet is internally provided with a micro PC; the special cabinet is provided with a number of slots with uniform sizes and uniform interfaces, and pluggable function modules corresponding to the slots, and the function modules are matched with the slots; the cabinet is also internally provided with a PLC relay input and output control circuit; the control circuit comprises a plurality of output control circuits and a plurality of general input circuits; each circuit comprises an optical isolation structure; each circuit is connected with the micro PC and the other end is connected onto the input and output terminal of the cabinet. The invention also provides a linkage method between function modules. The limitations of the existing Internet of Things control system which has a long development cycle and inconsistent protocols, and requires many people to cooperate in the development can be solved, and an Internet of Things platform with strong universality, multiple expansion functions and unified data protocols and communication interfaces is realized.

Owner:吴登祥

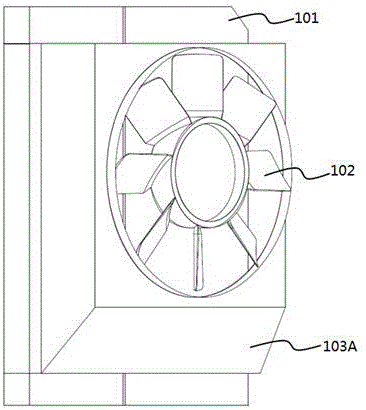

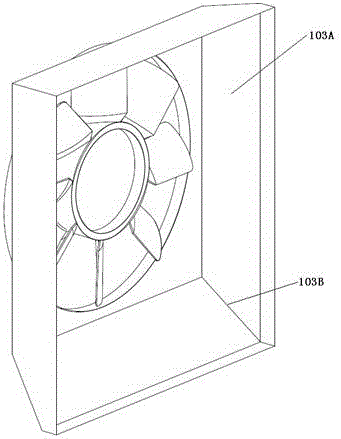

Air guiding hood capable of flow guiding and noise reduction

InactiveCN106050745AReduce manufacturing costSpeed to marketPump componentsPumpsSquare ShapeEngineering

The invention provides an air guiding hood capable of flow guiding and noise reduction. The air guiding hood capable of flow guiding and noise reduction comprises a box body. The box body comprises a top plate and a plurality of side plates. A round ventilation opening is formed in the top plate. The bottom surface enclosed by the plurality of side plates is of a square shape. The air guiding hood capable of flow guiding and noise reduction further comprises a plurality of air guiding hood plates. The sections of the ends of the air guiding hood plates are of arc shapes and the sections of the other ends of the air guiding hood plates are of straight line shapes. The plurality of air guiding hood plates are connected and formed in the box body closely by welding. The ends, of which sections are of arc shapes, of the air guiding hood plates abut on the round edge of the ventilation opening to form a standard roundness in an enclosing manner and the ends, of which sections are of straight line shapes, of the air guiding hood plates abut on the bottom surface of box body to form a standard squareness in an enclosing manner. The air guiding hood provided by the invention is in a smooth transition and streamline polyhedron structure in the direction that the air guiding hood faces a runner inwardly, so that a relatively stable flow field can be built in the air guiding hood and at the same time the air guiding hood with excellent performance can be produced without the need for developing moulds.

Owner:广西一联邦农业科技有限公司

Chicken summer heat stress resistant feed and preparation method thereof

InactiveCN105876224AAddress heat stressGood for healthFood processingAnimal feeding stuffBiotechnology[Candida] apicola

The present invention discloses a chicken summer heat stress resistant feed and a preparation method thereof. The chicken summer heat stress resistant feed is prepared from the following raw materials in parts by weight: 500-600 parts of fresh cassava residues, 1.5-2.5 parts of sodium citrate, 54-58 parts of palm meal, 34-37 parts of tofu residues, 23-25 parts of chicken blood powder, 7-9 parts of kiwi fruit juice, 3-4 parts of barbeque sauce, 18-21 parts of purple sweet purple flour, 7-9 parts of black sesame powder, 12-15 parts of cabbage powder, 4-6 parts of pear peel powder, 27-32 parts of herba lophatheri, 25-28 parts of olive leaves, 3-4 parts of tomato puree, 2-3 parts of chicken bone oil, 0.3-0.5 part of candida utilis, 3-4 parts of common andrographis herb, 2-3 parts of fructus forsythiae, 2-3 parts of folium isatidis, 53-56 parts of barley flour, 3-4 parts of black date powder, 7-9 parts of wax gourd powder, 4-5 parts of glucose syrup, and 1-2 parts of mullite powder. The feed can effectively solve the heat stress phenomenon of chickens under high temperature and high humidity environments in summer, improve the health conditions of the chickens, improve the metabolism levels of the chickens, and enhance the constitution of the chickens.

Owner:ANHUI WANGWANG FOWL IND

SNP loci and primer groups for identifying purity of tomato hybrids and application

ActiveCN112195263AAccurate identificationSpeed to marketMicrobiological testing/measurementDNA/RNA fragmentationNucleotide sequencMolecular biology

The invention discloses a method for identifying the purity of watermelon hybrids and an SNP primer combination used in the method. The SNP primer combination provided by the invention is composed ofeight primer groups, wherein each primer group consists of three primer sequences and is used for amplifying one SNP locus; and the nucleotide sequences of the primers are sequentially shown as SEQ IDNO: 1 to SEQ ID NO: 24. The SNP primer combination can be used for early identification in the seed or seedling stage of watermelon hybrids, the purity of the hybrids is ensured, the rights and interests of producers and breeders are practically protected, and technical support is provided for seed quality management of watermelon varieties. The method provided by the invention has the advantagesof high flux, accuracy, low cost, simplicity in operation, manpower and material resource saving and the like, and has a very wide application prospect.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

A method for judging the precipitation during the shelf life of vinegar

ActiveCN105675459BSolve the problem of inaccurate precipitationSolve inaccurateMaterial analysisPrecipitationSample tracking

The invention discloses a method for judging precipitation conditions of vinegar during the shelf life.The method comprises the steps that the vinegar is taken, edible salt is added, the mixture is mixed to be uniform, a sterilized transparent container is filled with the mixture and sealed, then the mixture is placed into an incubator at the temperature of 37-60 DEG C and stands still at the constant temperature, and the precipitation conditions of the vinegar are observed within different time periods.By means of the method, the precipitation conditions of the vinegar during the shelf life can be accurately judged within a short time, and the problem of poor timeliness caused by long-time reserved sample tracking is avoided.

Owner:GUANGDONG MEIWEIXIAN FLAVORING & FOOD +1

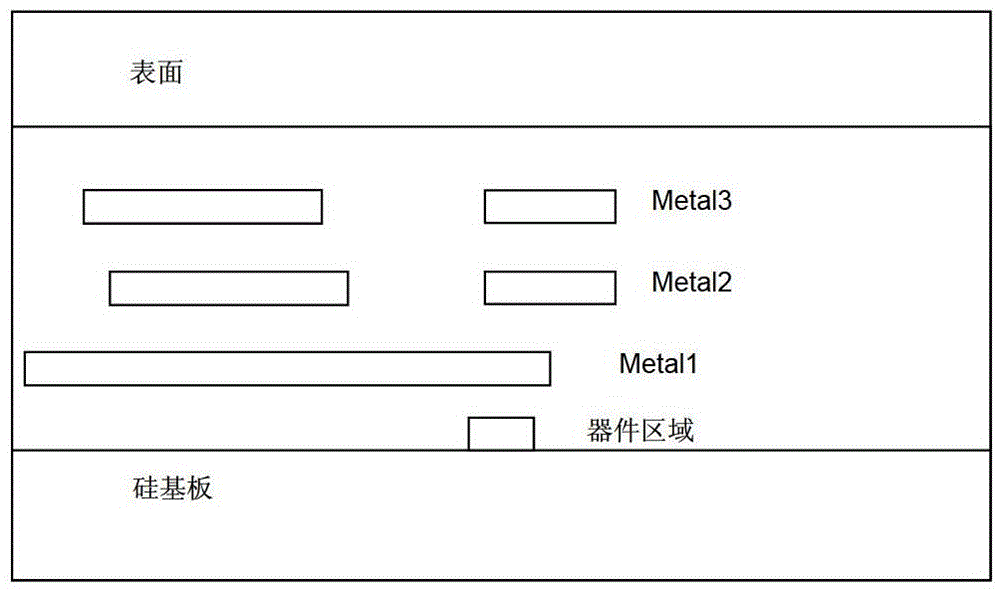

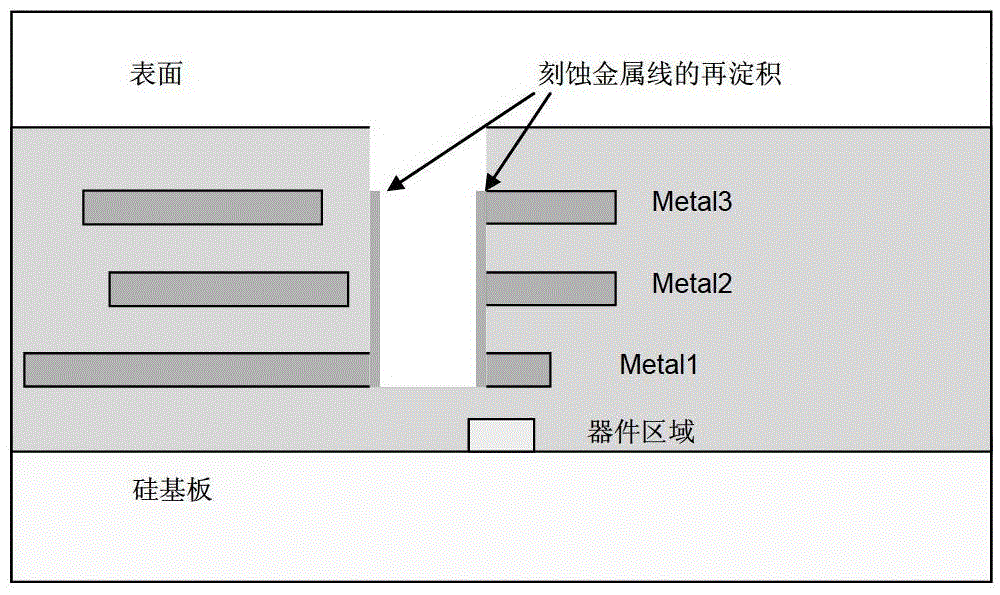

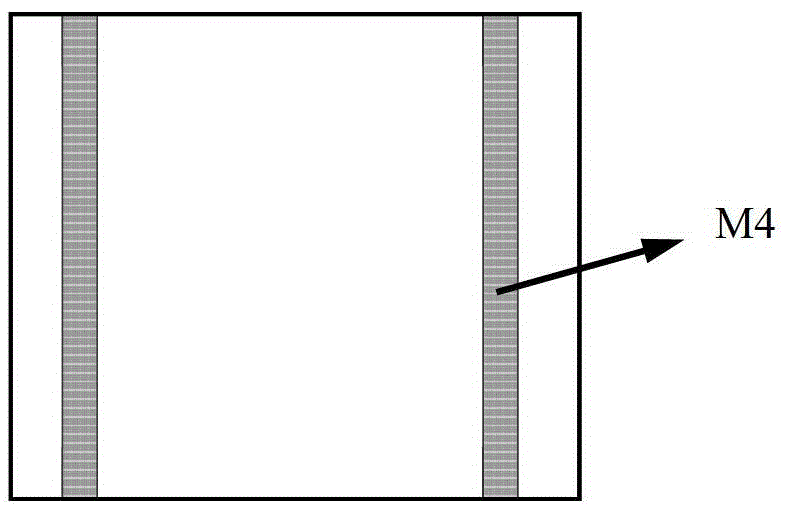

Cutting method of lower layer metal wiring

ActiveCN103681230BImprove repair efficiencyIncrease success rateSolid-state devicesSemiconductor/solid-state device manufacturingEtchingIon beam

The invention discloses a safe and precise cutting method for lower metal arranged wire. The safe and precise cutting method comprises the following steps: step one, using a focused ion beam technology according to the following procedures to realize cutting of the lower metal wires: during etching, enabling an IEE (Insulator Enhanced Etching) needle to enter a reaction chamber without opening a valve of the needle, etching under the conditions that the residence time of an iron beam on each pixel is 1 microsecond and the area overlapping proportion is 50%, wherein the size of the outermost etching frame is more than 10mm * 10mm, the size of a new etching frame every time is needed to be at least 10% less than that of the previous frame, the new etching frame does not include metal wires exposed by the previous etching frame, the etching end point is the next layer of exposed metal wires at the position with an interval of more than 1mm with the exposed metal wires so as to expose the metal wires to be cut; step two, cutting the metal wires, etching for 20-50 seconds, and cutting the metal wires; step three, finally cleaning all etching frames through the enhanced etching mode by using a beam current between 500pA and 1000pA. With the adoption of the safe and precise cutting method, the line repair efficiency and success rate of chips are improved, thus, the debugging process during the initial stage of chip design is greatly quickened, the speed of failure analysis is increased, the speed of entering the market of the product is increased, and the mass production yield of chips is increased.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

A SNP locus, primer set and application for identifying the purity of watermelon hybrids

ActiveCN112195263BAccurate identificationSpeed to marketMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyNucleotide

The invention discloses a method for identifying the purity of watermelon hybrids and the SNP primer combination used therefor. The SNP primer combination provided by the present invention is composed of 8 primer sets; each primer set is composed of 3 primer sequences, which are used to amplify a SNP site; the nucleotide sequences of each primer are sequentially as shown in SEQ ID NO: 1 to Shown in SEQ ID NO:24. The SNP primer combination can be used for early identification at the seed or seedling stage of watermelon hybrids to ensure the purity of the hybrids, effectively protect the rights and interests of producers and breeders, and provide technical support for the quality management of watermelon varieties. The method provided by the invention has the advantages of high throughput, accuracy, low cost, simple operation, saving manpower and material resources, etc., and has very broad application prospects.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

Haw products and preparation method thereof

Owner:BEIJING YUSHIYUAN FOOD

A kind of raising method of three yellow broiler chickens

ActiveCN104170789BIncrease drinking waterReduced feed intakeAnimal husbandryBiotechnologyHigh humidity

The invention discloses a method for raising three-yellow broiler chickens, which comprises the following stages: chick stage: from May to August, the chicken feed of three-yellow broiler chickens is partially replaced by wheat (according to the proportion of 5-10%); November ~In March of the following year, the three-yellow broiler chicken feed that partially replaces soybean meal with cotton meal (2-4%) is used for feeding. Medium chicken stage and large chicken stage: From May to August, use wheat (according to 10-28% ratio) to partially replace corn feed for three yellow broiler chickens; from November to next March, use cottonseed meal (according to 2-28%) 8% ratio) partly replaces soybean meal for feeding three-yellow broiler chicken feed. Due to the feeding method of the three yellow broiler chickens with the above raw material components, the heat stress and cold stress of the three yellow broiler chickens in high temperature, high humidity and low temperature weather are effectively solved, and the health status and resistance of the three yellow broiler chickens are improved. Enhanced, improved digestion and absorption capacity, accelerated its speed to market, controlled feed ratio, saved feeding costs, and effectively improved breeding benefits.

Owner:WENS FOODSTUFF GRP CO LTD

Method and system for realizing process automation in finance and tax management by using automatic control technology

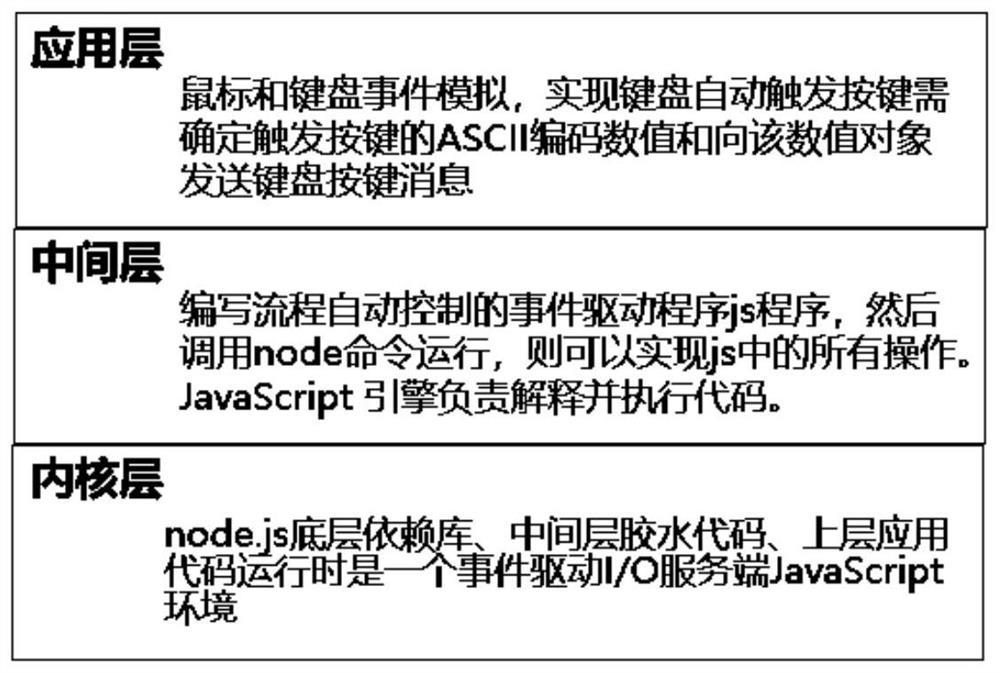

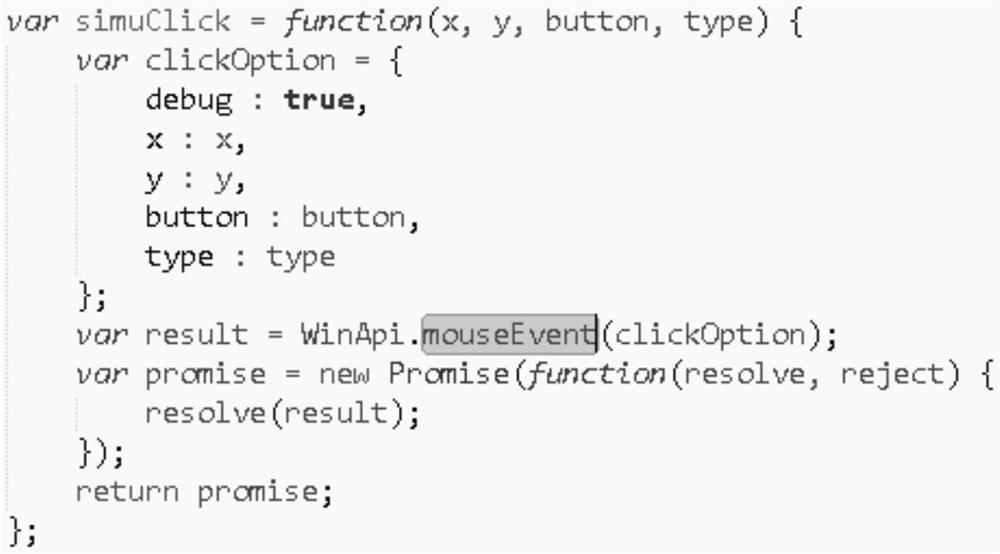

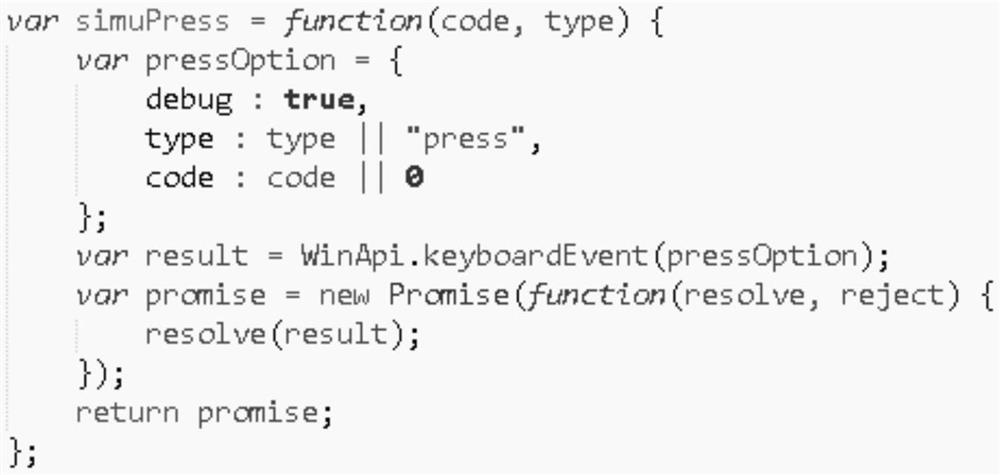

PendingCN113076087ASimple processReduce labor costsFinanceOffice automationAutomatic controlMiddle tier

The invention provides a method and system for realizing process automation in finance and tax management by an automatic control technology. The method comprises the following steps: an environment architecture configuration step: configuring technical architectures of an application layer, a middle layer and a kernel layer, and carrying out node.js environment configuration; and a bottom layer control step: controlling the mouse to move on the window of the application program through the program or automatically clicking a button, a hyperlink and a window object in the application program, and controlling the keys in the keyboard to automatically go up and down through the program. According to the method, the labor cost is reduced, automatic operation of manual tasks is achieved through software automation script repetition, a large amount of manpower is not needed any more, and only a small number of service management personnel and operation maintenance personnel are needed. The operation can be monitored, each step of the robot for assisting the enterprise to optimize the process can be monitored and recorded, and the process improvement of the enterprise is facilitated while rich audit records are stored.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD

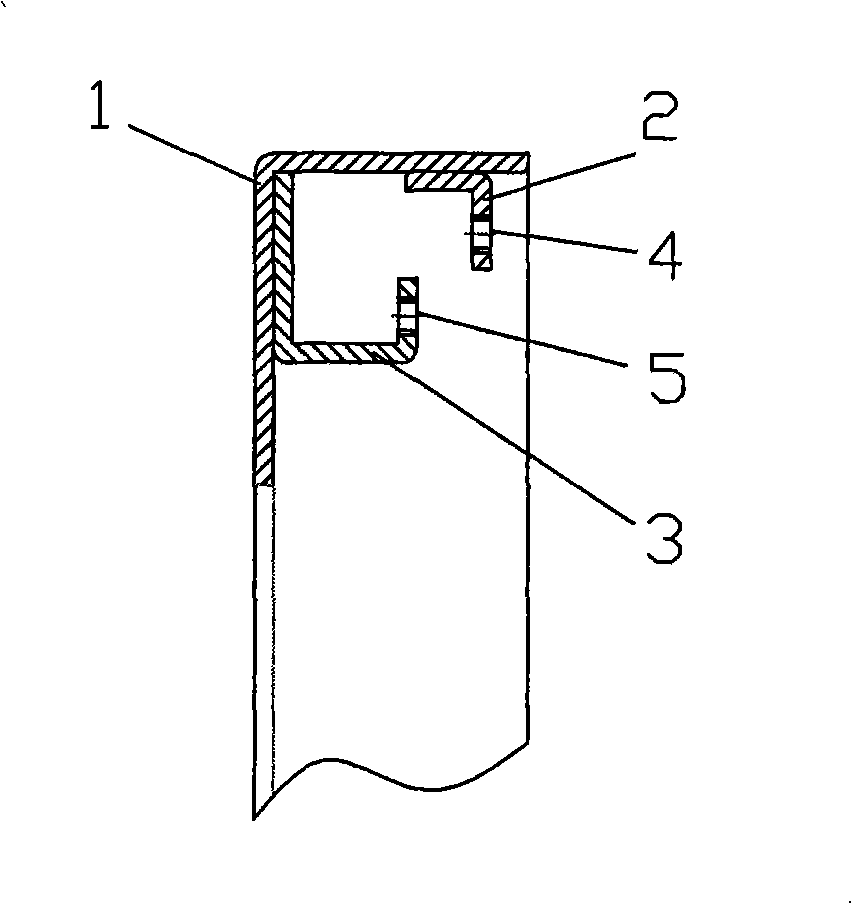

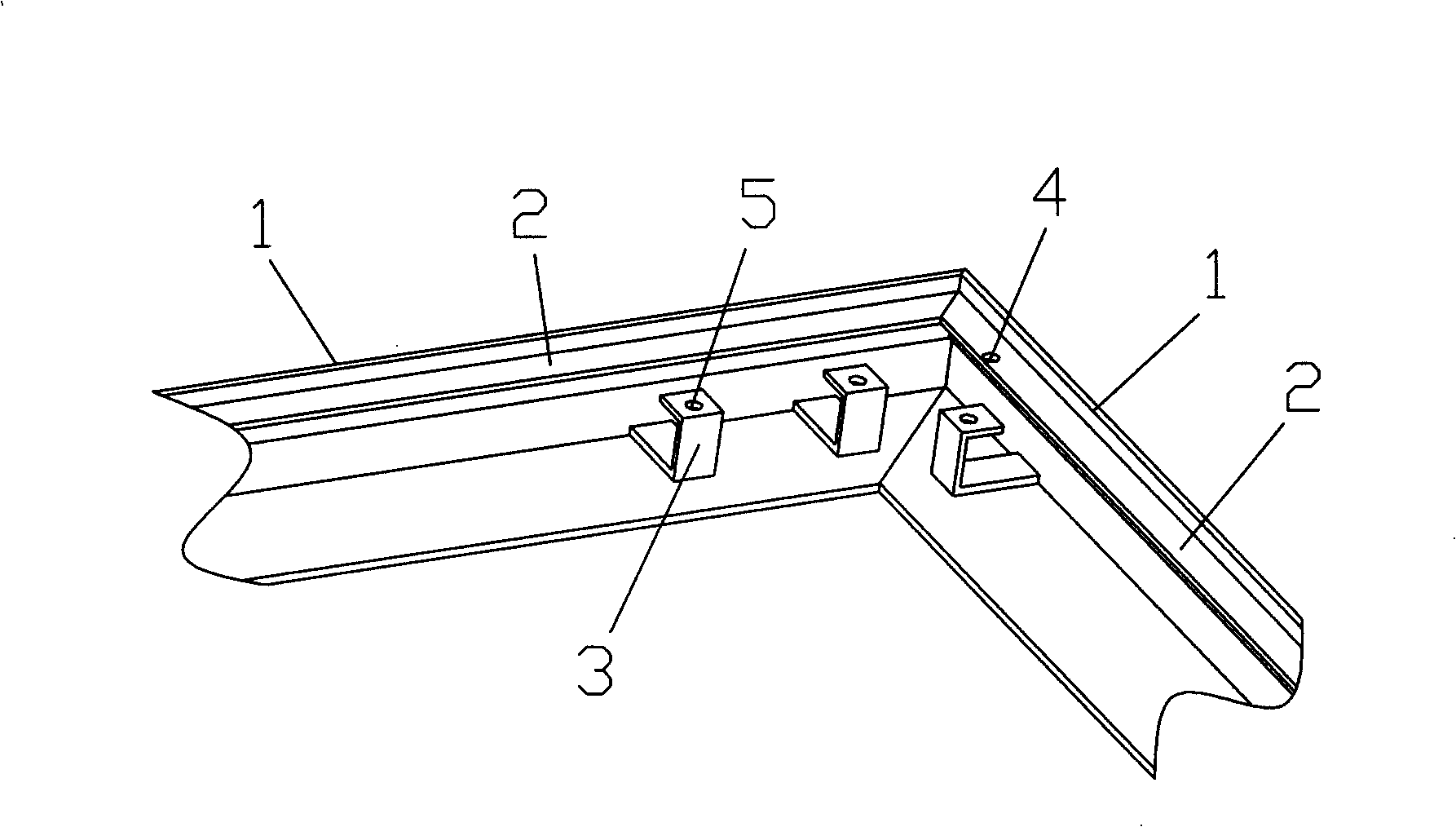

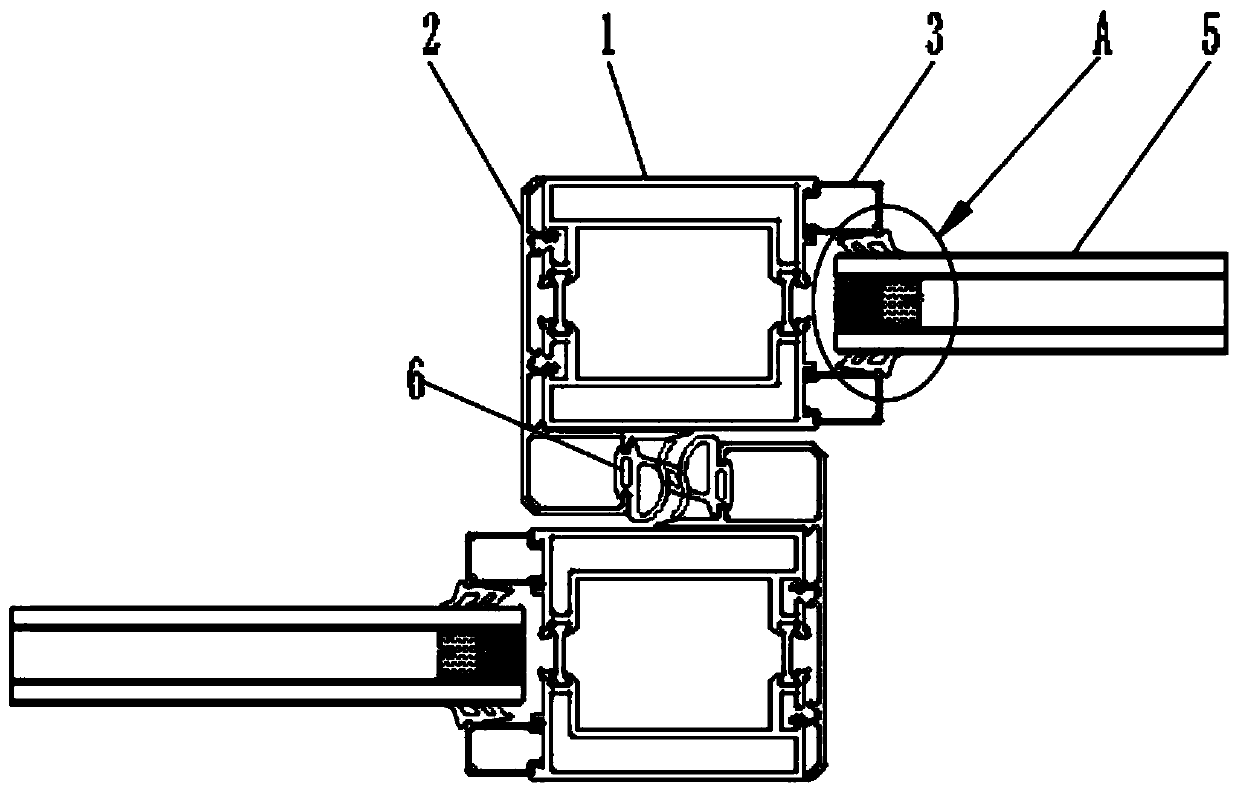

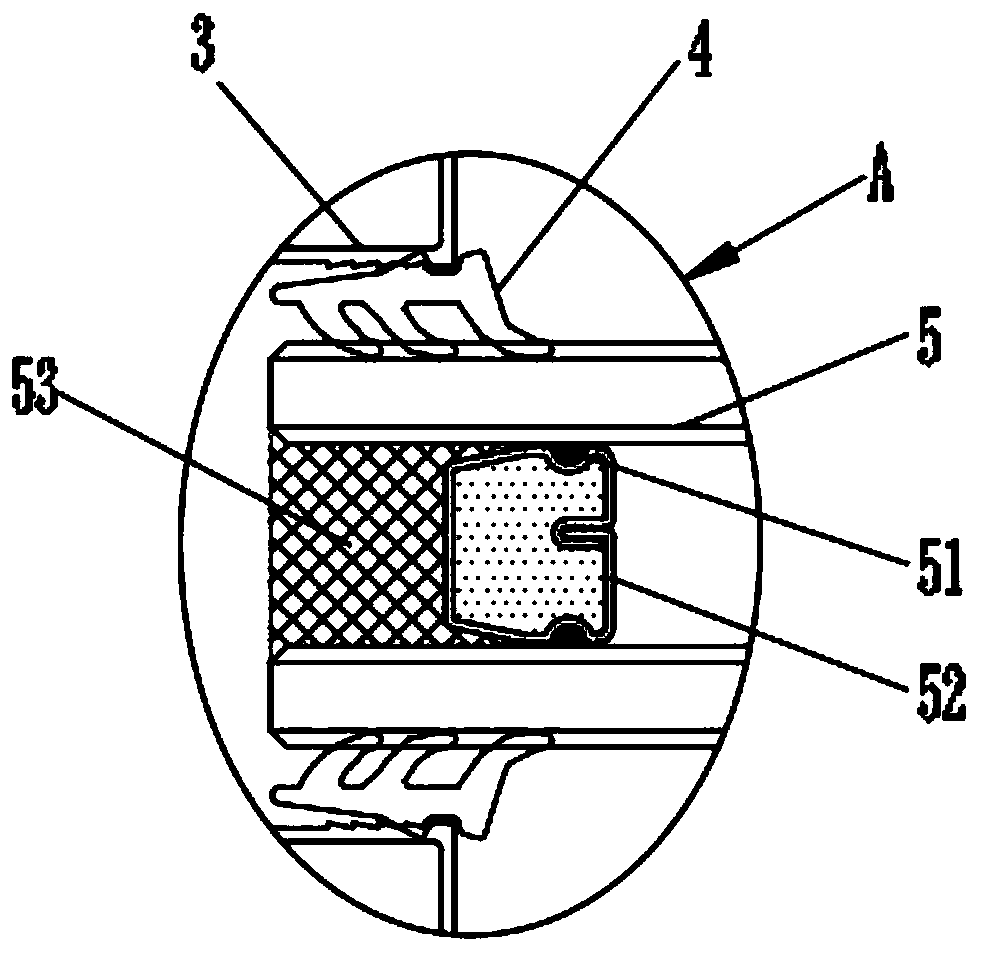

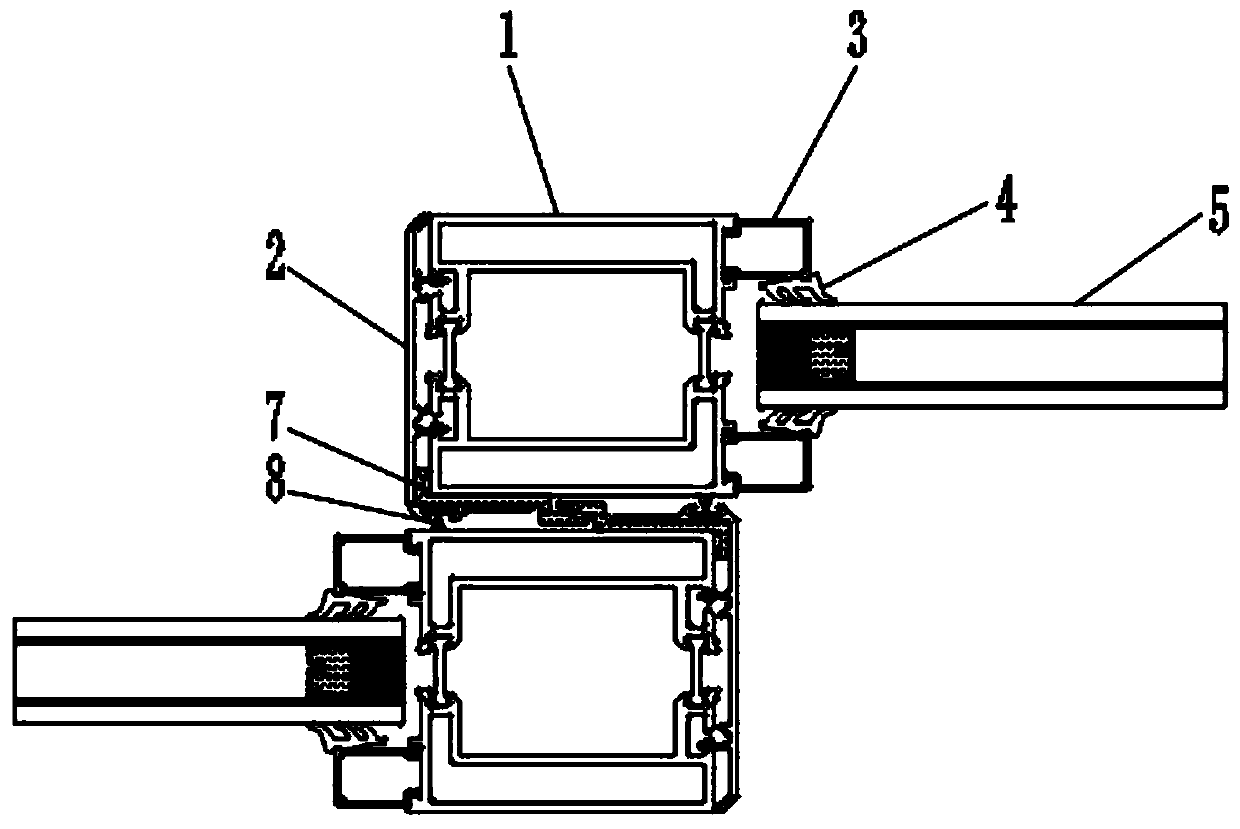

Broken-bridge aluminum profile

PendingCN111255340AReduce the number of moldsReduce spendingSealing arrangementsGlass pane fixingStructural engineeringMechanical engineering

The invention relates to the technical field of broken-bridge aluminum, in particular to a broken-bridge aluminum profile. The defects that in the prior art, the number of made molds of broken-bridgealuminum door and window is large, the manufacturing cost is high, the modification is difficult, the circle of appearing on the market is long, and the applicability is poor are overcome. The broken-bridge aluminum profile comprises broken-bridge aluminum, the left end of the broken-bridge aluminum is fixedly provided with a variable-end-face connecting piece, and the right end of the broken-bridge aluminum is fixedly provided with a variable pressing strip. According to the scheme, the broken-bridge aluminum, the variable pressing strip, a tightening rubber strip and hollow glass are designed to be manufactured and produced as standard components, by changing the structure of the variable-end-face connecting piece to be matched with the broken-bridge aluminum, a plurality of structural forms can be formed, the overall mold making quantity of the heat insulation broken-bridge aluminum door and window is reduced, the expense of the molds is reduced, the cost is effectively reduced, dueto the fact that the main profile of the heat insulation broken-bridge aluminum door and window is single, the producing, machining and assembling difficulty is reduced, the producing, machining andmanufacturing cost is reduced, the end face design is flexible, the later modification is convenient and fast, the speed of a new product to the market is accelerated, and the applicability is good.

Owner:奥飞久通智能科技(常州)股份有限公司

A SNP locus, primer set and application for identifying the purity of pepper hybrids

ActiveCN112195265BSpeed to marketImprove throughputMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyNucleotide

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

A SNP locus, primer set and application for identifying the purity of tomato hybrids

ActiveCN112195264BSpeed to marketImprove throughputMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyNucleotide

The invention discloses a method for identifying the purity of tomato hybrids and the SNP primer combination used therefor. The SNP primer combination provided by the present invention is composed of 8 primer sets; each primer set is composed of 3 primer sequences, which are used to amplify a SNP site; the nucleotide sequences of each primer are sequentially as shown in SEQ ID NO: 1 to Shown in SEQ ID NO:24. The SNP primer combination can be used for early identification at the seed or seedling stage of tomato hybrids, ensures the purity of hybrids, effectively protects the rights and interests of producers and breeders, and provides technical support for the quality management of tomato varieties. The method provided by the invention has the advantages of high efficiency, accuracy, low cost, etc., and has very broad application prospects.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

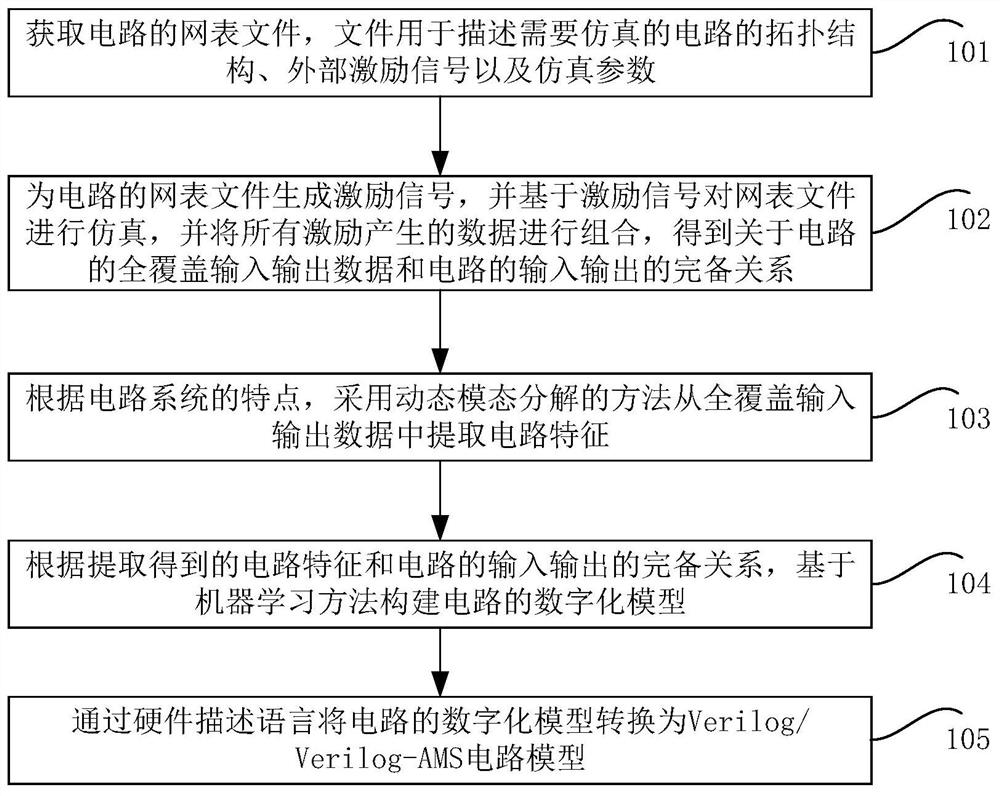

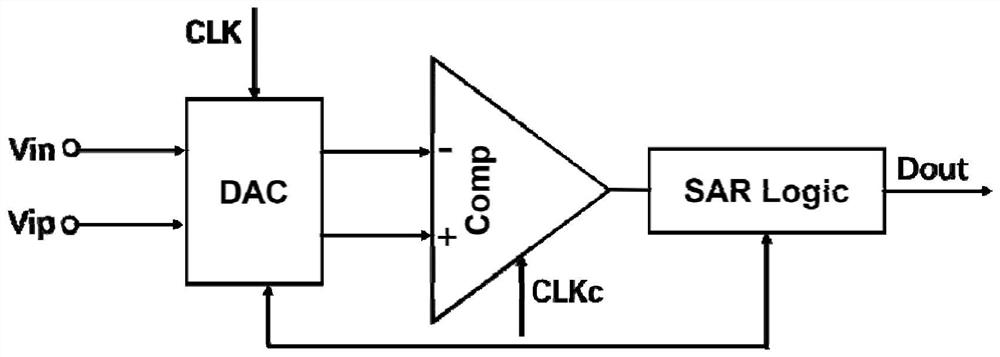

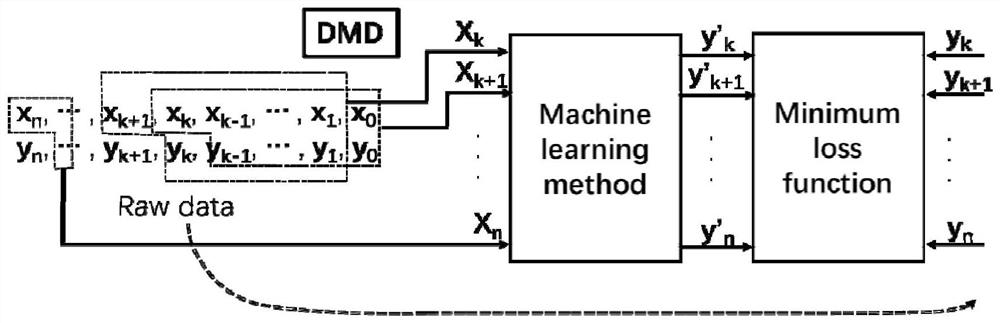

Digital modeling method and device for mixed signal circuit

ActiveCN112883672BReduced simulation timeSpeed to marketDesign optimisation/simulationCAD circuit designMathematical modelSoftware engineering

Owner:TSINGHUA UNIV

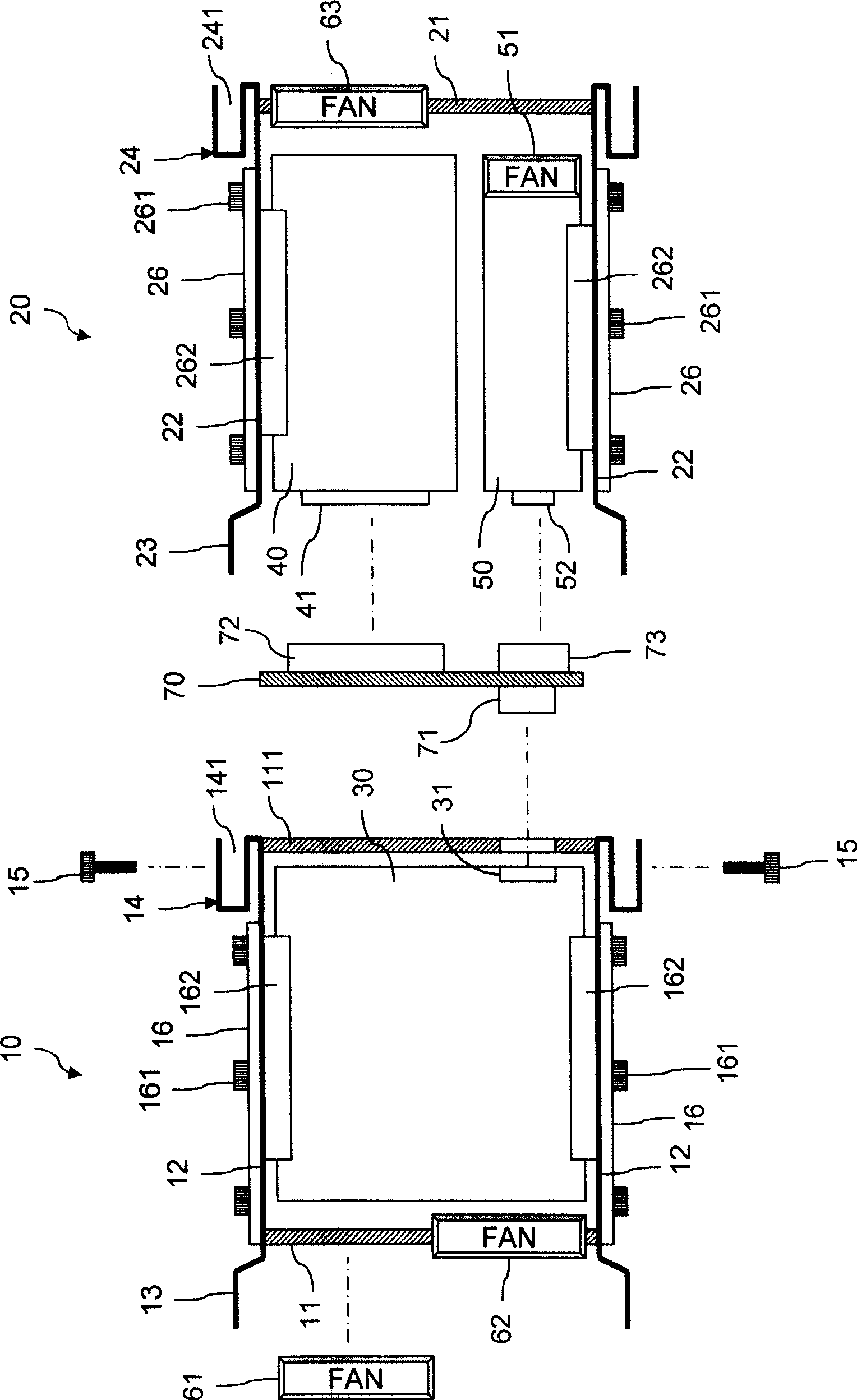

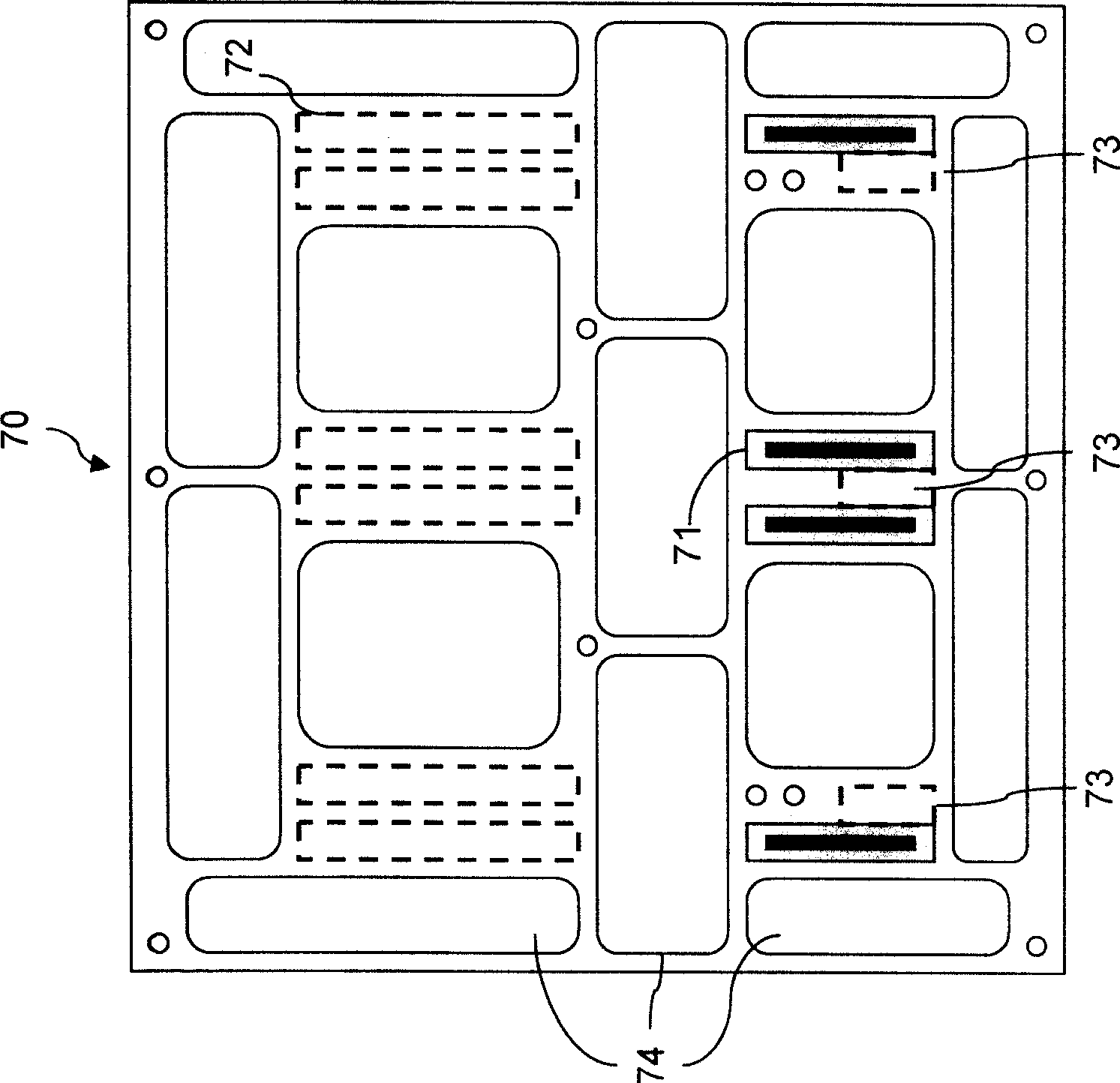

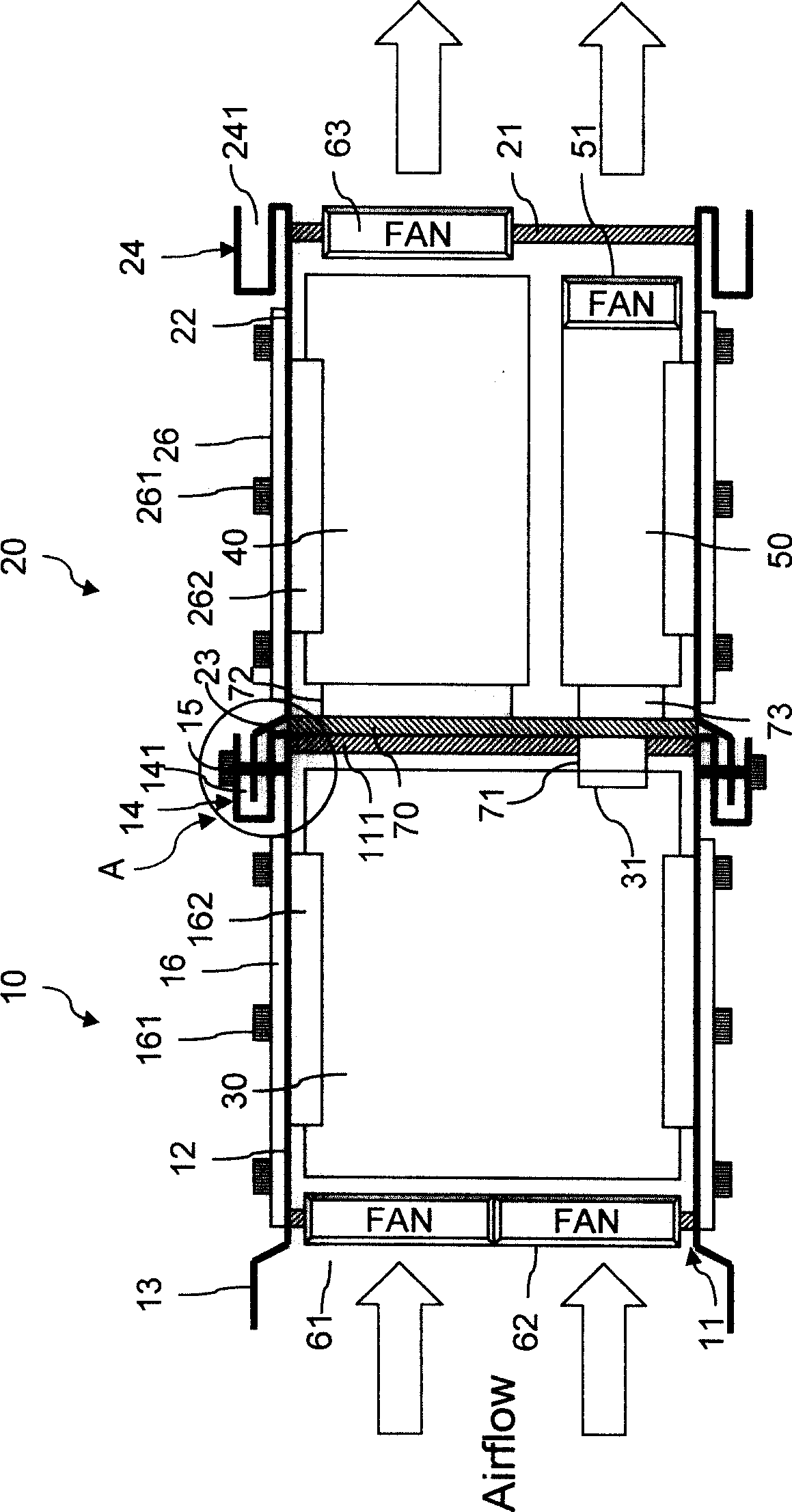

Reconfigurable chassis module

InactiveCN100520679CMeet needsChange depthDigital processing power distributionModular unitDielectric plate

Owner:HUANDA COMPUTER (SHANGHAI) CO LTD

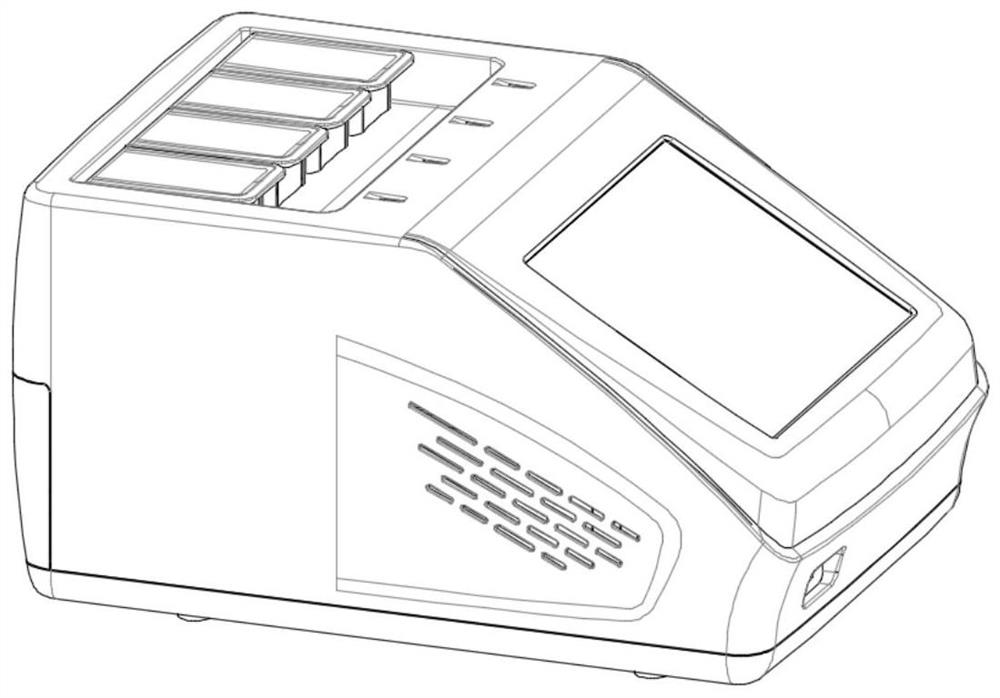

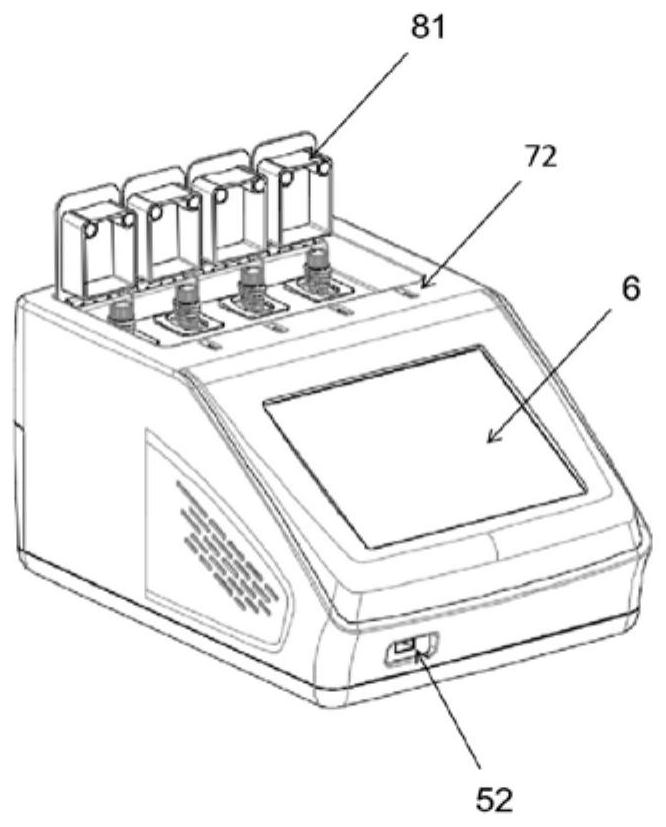

Reaction module and corresponding multiple and multi-channel real-time fluorescent nucleic acid detector

PendingCN112694972ASpeed to marketReduce work intensityBioreactor/fermenter combinationsBiological substance pretreatmentsNucleic acid detectionFluorescence

The invention relates to a reaction module for a multiple and multi-channel real-time fluorescent nucleic acid detector. The reaction module is a compact overall structure and formed by a heating member assembly and an optical fiber pair; the heating member assembly includes a heating module, a cooling module and a temperature controlling panel; the heating module includes heating pieces used for inserting and heating reaction tubes; the cooling module includes a fan used for reducing temperatures; and the optical fiber pair includes incident optical fiber and emergent optical fiber in mutually parallel. A multiple and multi-channel real-time fluorescent nucleic acid detector adopting the reaction module is also related. The detector includes a light source excitation and fluorescence detection assembly, a motion assembly, a computer and an external power supply; and the heating pieces, the fan and the optical fiber pair are located in the space enclosed by shell plate of the reaction module. Therefore, requirements for detecting few samples while arriving can be met; and conditions can be created for the nucleic acid detector to enter primary inspection institutions and small and medium-sized hospitals and be used for bedside detection.

Owner:默礼生物(杭州)有限公司

Reconfigurable chassis module

InactiveCN101126947AMeet needsChange depthDigital processing power distributionModular unitEmbedded system

A scalable computer system includes a reconfigurable chassis module, plural hardware units and one or more inter-plane. The chassis module has plural modular units for configuring the hardware units therein respectively. Each of the modular units has dedicated framework to attach the inter-plane or dedicated fans. The inter-plane is to connect with the separated hardware units between the modular units. Each of the modular units is equipped with compatible male and female joints to engage with each other. Certain fastening assemblies may be applied to secure male-male or female-female joints, thereby enabling the modular units to be front-to-back and / or side-by-side connections.

Owner:HUANDA COMPUTER (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com