Air guiding hood capable of flow guiding and noise reduction

An air guide hood and noise reduction technology, applied in the field of air guide hood, can solve the problems of high cost, low wind speed, and inability to discharge hot air from heat exchangers in time, so as to reduce production costs and accelerate the speed of listing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

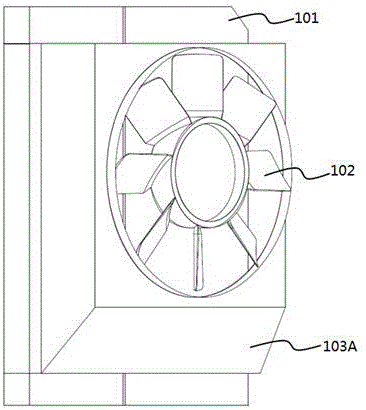

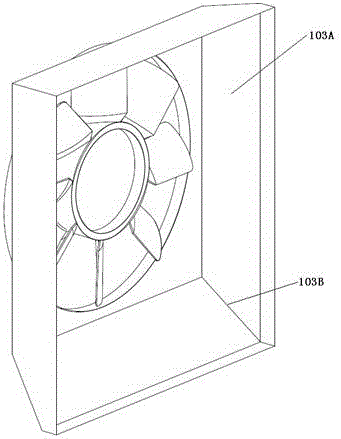

[0020] Such as Figure 1-2 As shown, the existing box-type air guide cover includes a top plate and four side plates 103A, the top plate is provided with a circular ventilation opening, and the fan 102 is arranged in the circular ventilation opening. The four side plates extend from the top plate to the bottom surface at a certain angle, and the bottom surface surrounded by the four side plates is also in a square shape. The angle can be 90 degrees, or any shape within 90-180 degrees. Moreover, the angles between each side panel 103A and the top panel may be different.

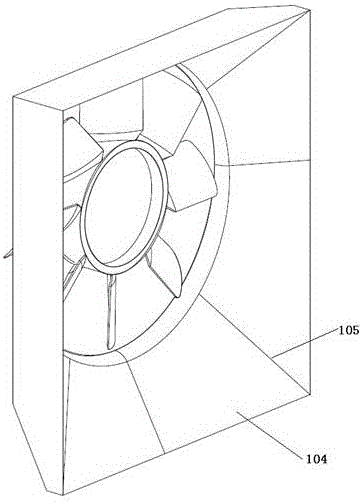

[0021] Such as image 3 As shown, the deflectable and noise-reducing air guide of the present invention is transformed from the box-type air guide in the prior art. It includes a plurality of wind deflector plates 104, one end of the wind deflector plate 104 has a circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com