Sheet-metal screen panel of back projected television and manufacture method thereof

A manufacturing method and TV technology, applied to color TV parts, TV system parts, TVs, etc., can solve the problems of high production costs, save mold costs, improve market competitiveness, and save non-ferrous metal materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

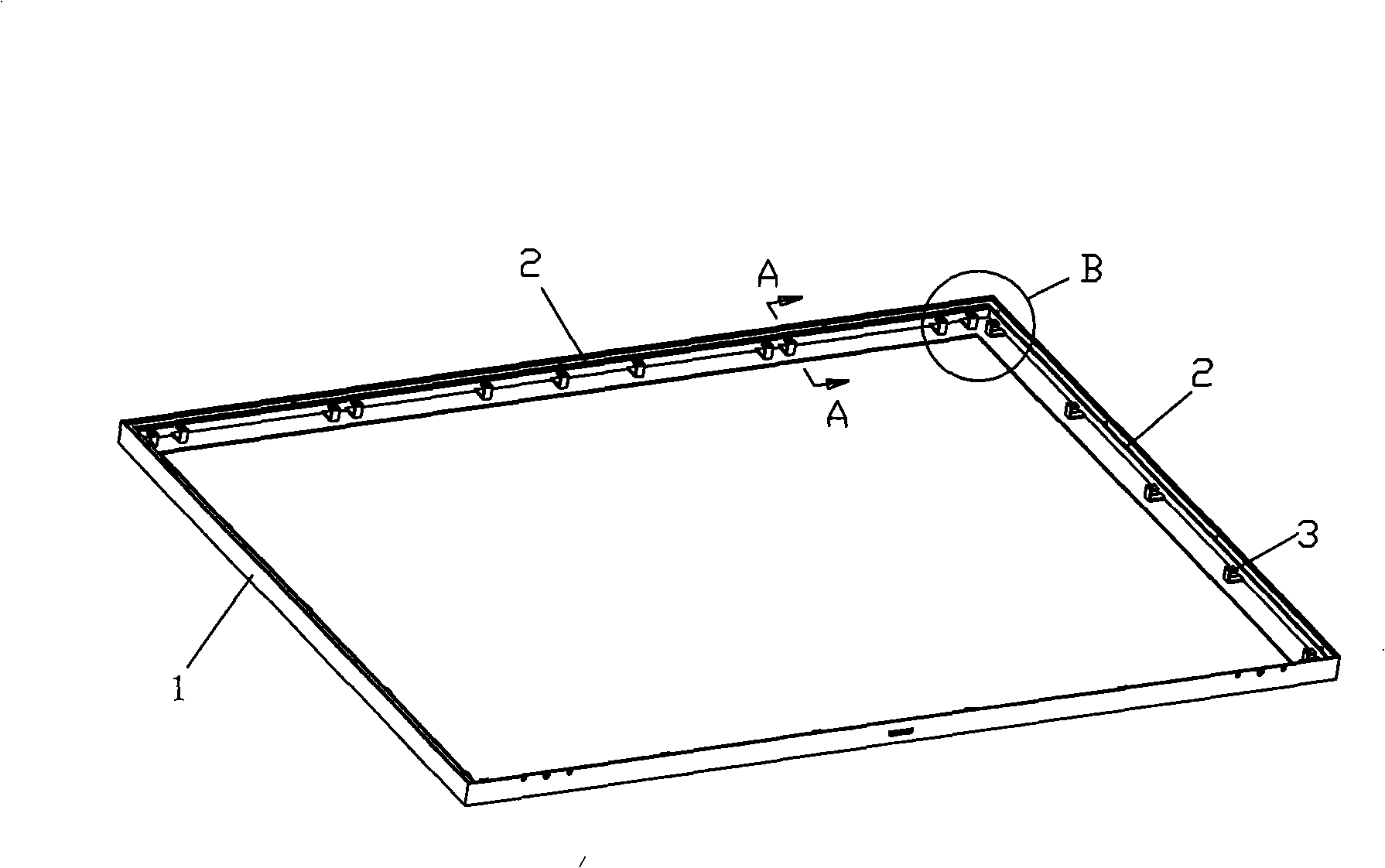

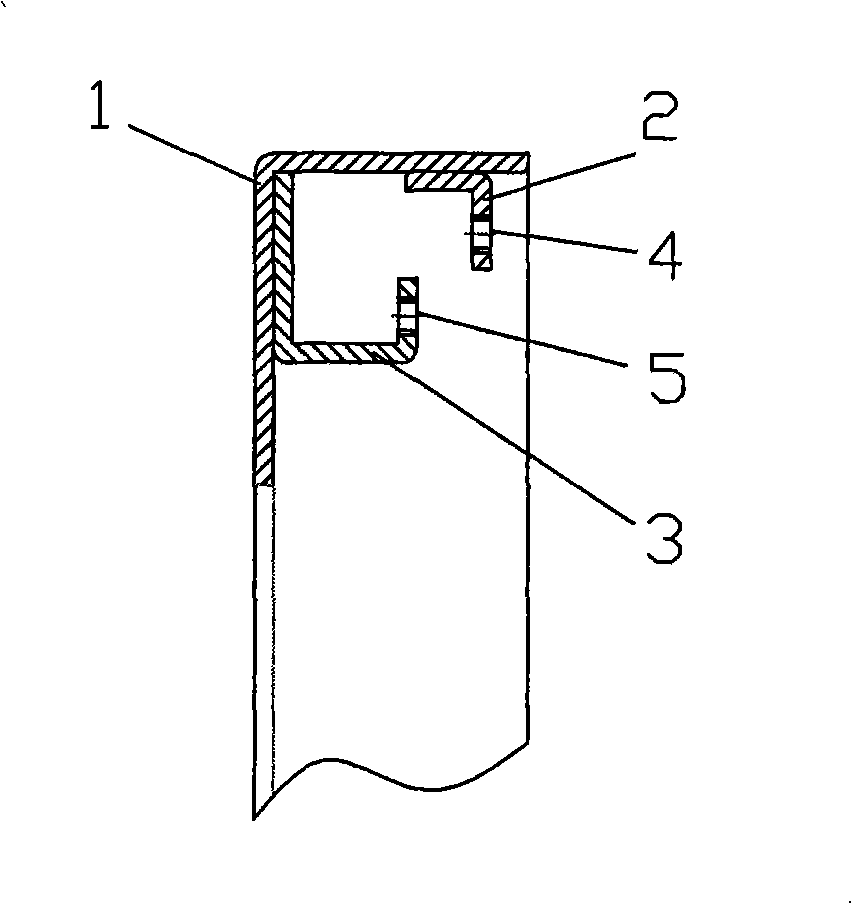

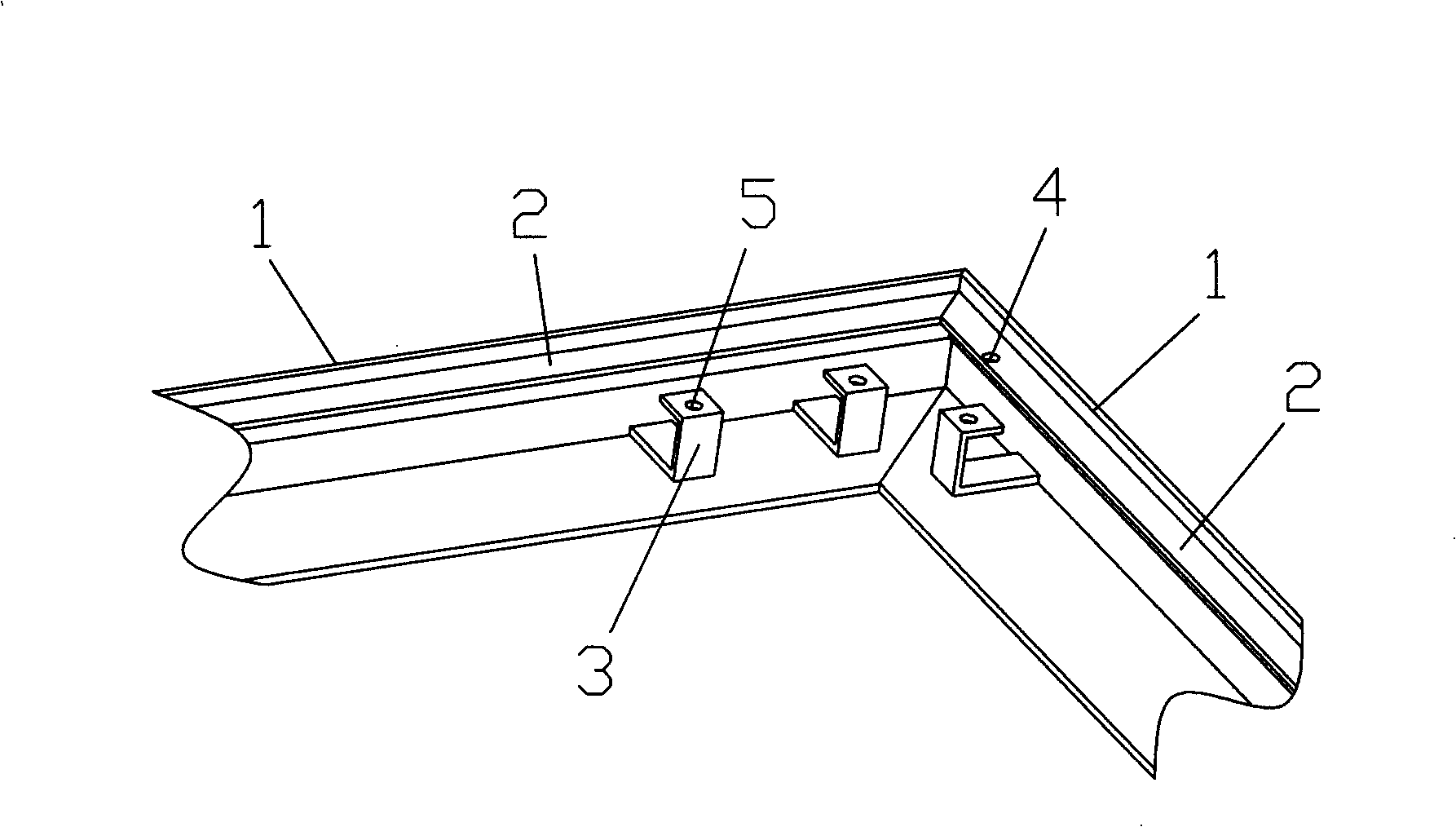

[0021] figure 1 The basic structure of the preferred embodiment of the present invention is shown. The sheet metal screen frame of the rear projection TV set includes upper, lower, left, and right frame strips bent by sheet metal technology. The frame bars are welded to form a rectangular screen frame 1 . see figure 2 , image 3 , the inside of the folded edge perpendicular to the plane of the screen frame 1 on the frame strip is provided with a bent back cover fixing strip 2, and the back cover fixing strip 2 is parallel to the plane of the rectangular screen surface frame 1 There are screw holes 4 for locking the back cover on the folded edge, and the double-bending screen pressure strips are provided at intervals on the folded edge parallel to the plane of the screen surface frame 1 on the surface frame strip. Fixing seat 3, the outward flanging on this screen bead fixing seat has the screw hole 5 of locking screen bead. The surface frame strip, the back cover fixing s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com