Single-pile-casing construction method for static pressure sinking pipe carrier cast-in-place pile

A construction method and cast-in-place pile technology, applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems such as the inability to realize the construction of carrier piles into piles, the difficulty in meeting the anti-uplift requirements, and the impact on the progress of the project, so as to shorten the construction period, Easy operation and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

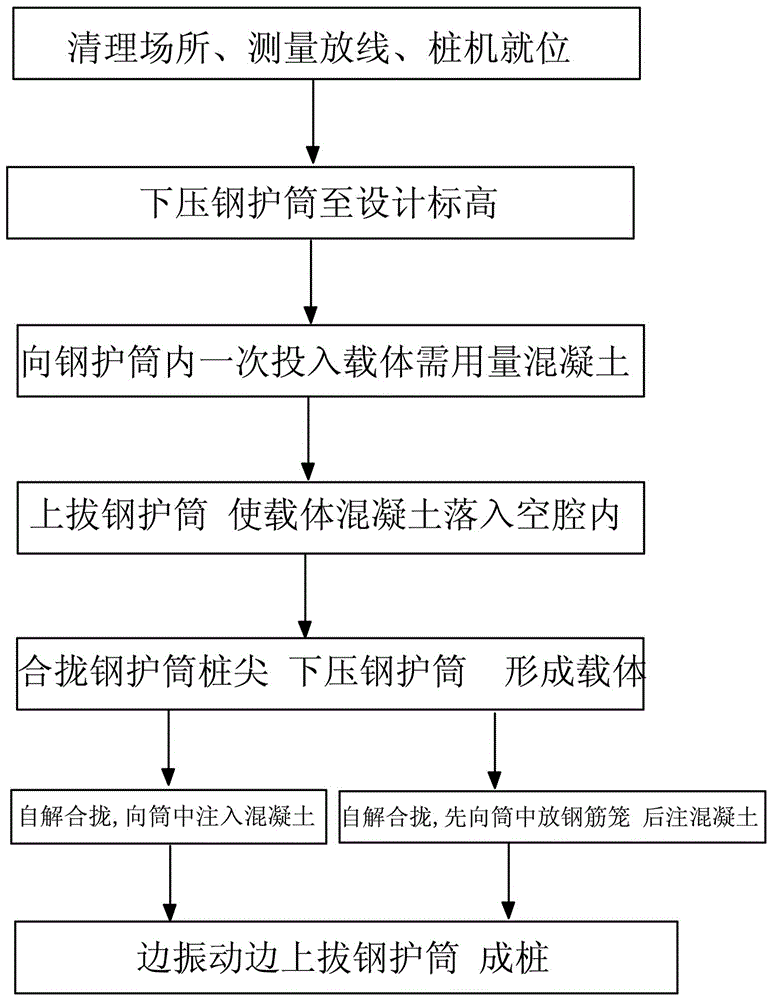

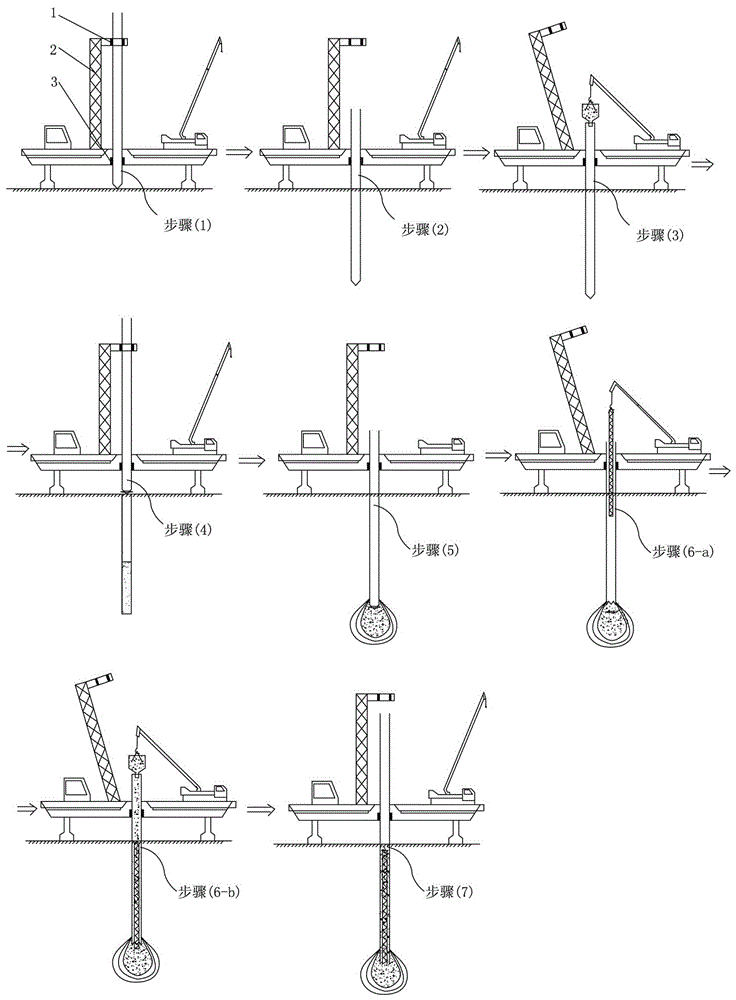

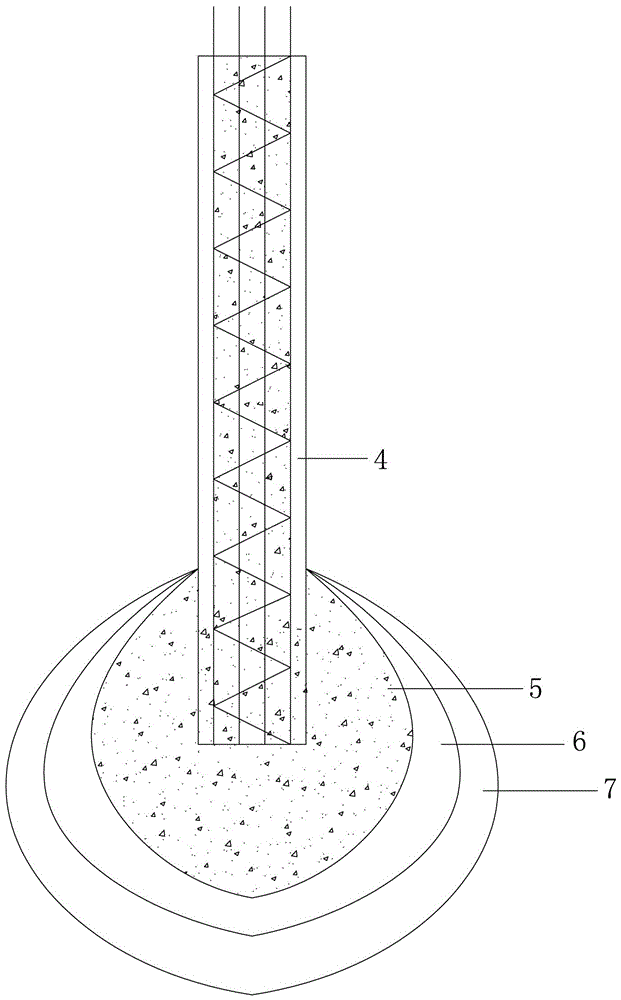

[0043] Below in conjunction with accompanying drawing and specific implementation the present invention is described in further detail:

[0044] In the following description, some exemplary embodiments of the present invention are described by way of illustration only, and those skilled in the art will recognize that various Modifications or equivalents of the described embodiments may be made by way of example, and the drawings and description are therefore illustrative in nature and not intended to limit the scope of the claims.

[0045] The embodiment of the method of the present invention preferably adopts the hugging type static pile driver, and a significant advantage of using the hugging type static pile driver is that the length of the pile body made is not limited by the height of the frame. When making short and medium piles, it can also be used Figure 10 The top pressure type static pile driver of the example, the top pressure type static pile driver adopts the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com