Wall cement mortar spraying machine

A technology of cement spraying and spraying gun, which is applied in the direction of construction and building structure to achieve the effect of high efficiency, convenient construction management and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

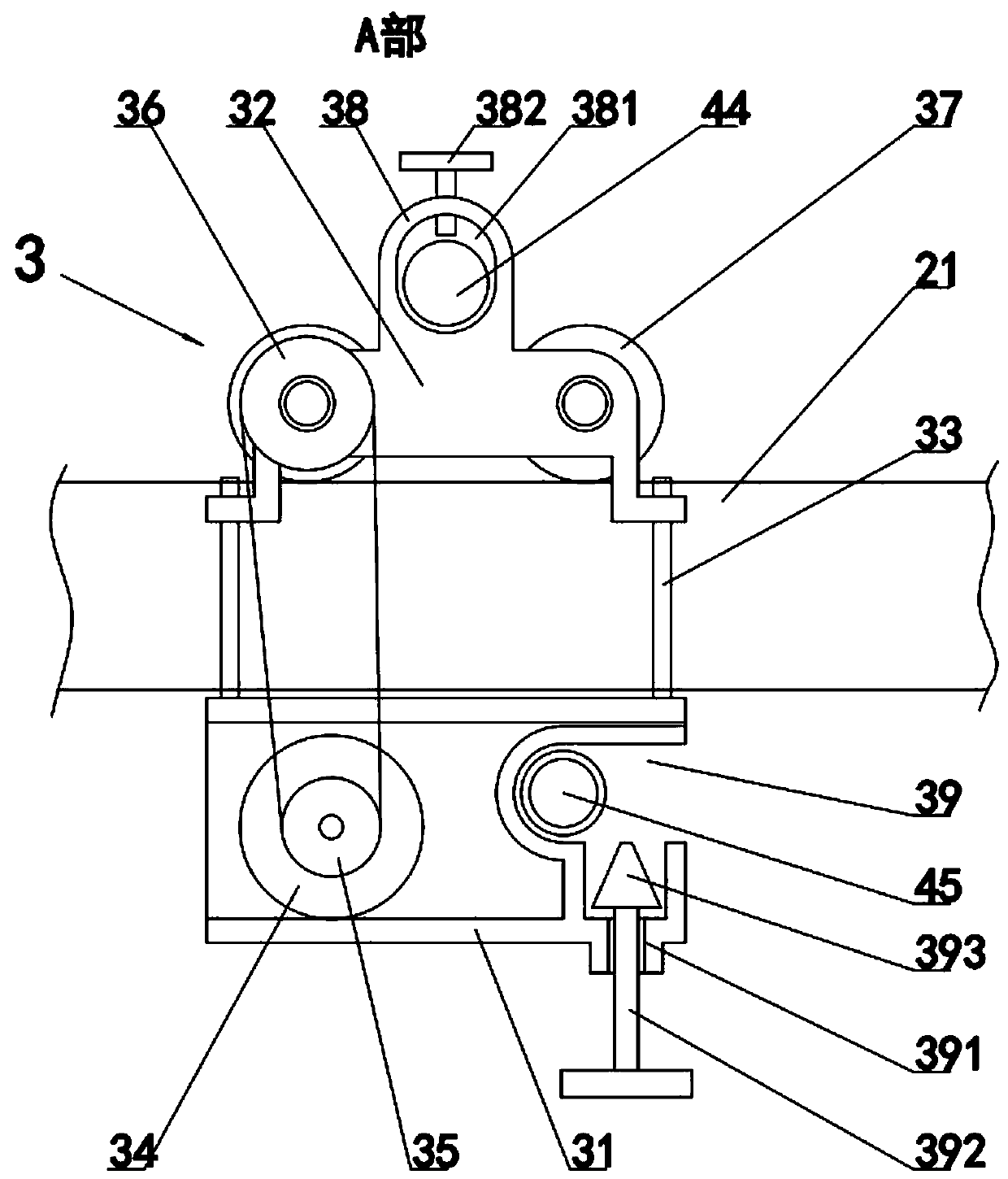

[0027] Embodiment 1: This project is constructed on the walls, beams, and columns of the building. Before spraying, the floating slurry and dust on the wall surface should be cleaned, and water should be moistened to make preparations before spraying (the surface of the masonry wall Dust, dirt, oil stains have been cleaned, and the brick wall has been watered and moistened the day before). Medium sand for grouting, ordinary Portland cement for cement, and high-quality qualified products for interface agent, in which the ingredients of sand, cement, and interface agent are mixed according to the ratio of 0.3-0.5:1.4-1.7:1 to form a paste and placed in the slurry In the box 41, the shape of the slurry box 41 is rectangular or cylindrical. It is best to install a stirring mechanism. If there is no stirring mechanism installed, the above-mentioned mixture needs to be stirred evenly in advance to form a uniform paste. The top of the slurry box 41 is equipped with a stirring mechanis...

Embodiment 2

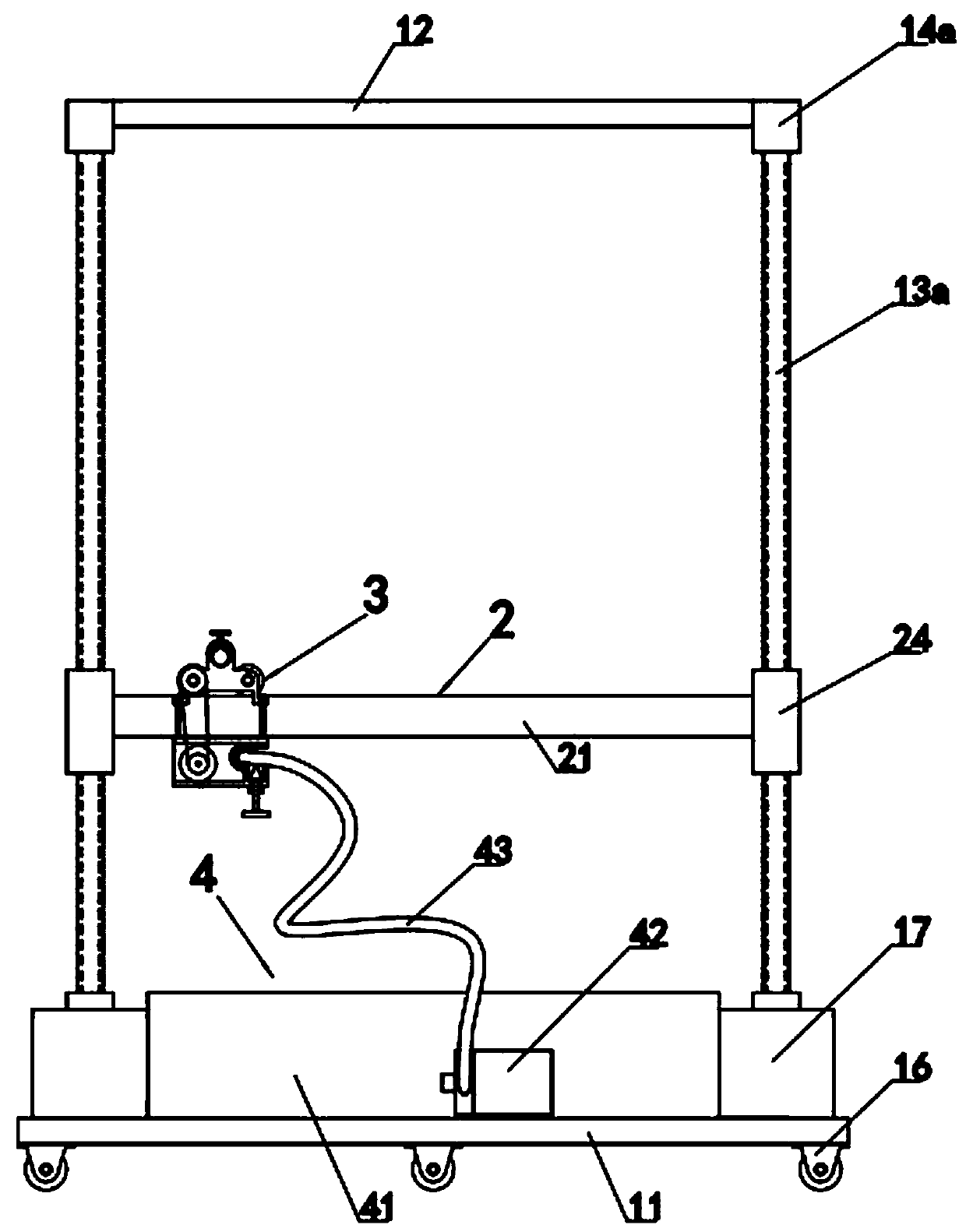

[0035] Embodiment 2: Another wall cement spraying machine, such as Figure 4 and Figure 5 As shown, the machine includes an outer frame 1, a lifting mechanism 2, a traverse mechanism, a spraying mechanism 4, a traction lifting mechanism 5, and the like.

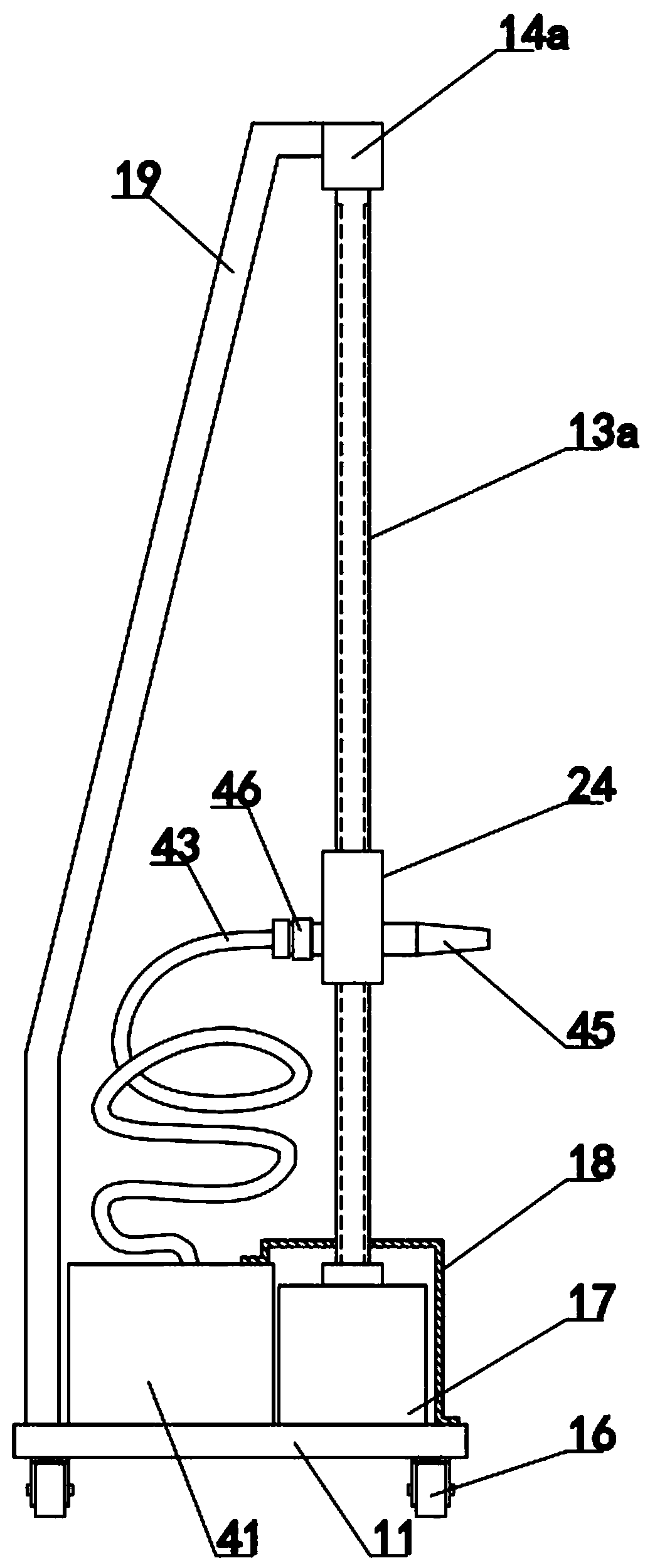

[0036] Wherein the outer frame 1 is a frame with a rectangular or trapezoidal structure fixed above the base 11 . The frame includes at least a top beam 12 and a vertical slide rail 13 . The bottom or both sides of the base 11 are also equipped with road wheels 16, and the road wheels 16 can adopt electronically controlled road wheels, that is, a motor is installed on the rotating shaft of part or all of the road wheels, and the complete machine is driven to traverse by controlling the rotation of the motor. The frame also includes fixed rear frames 19 fixed on both sides of the upper rear end of the base 11, and the lower ends of the vertical slide rails 13 on both sides are respectively fixed with the upper front end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com