Patents

Literature

72results about How to "Solve labor shortage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

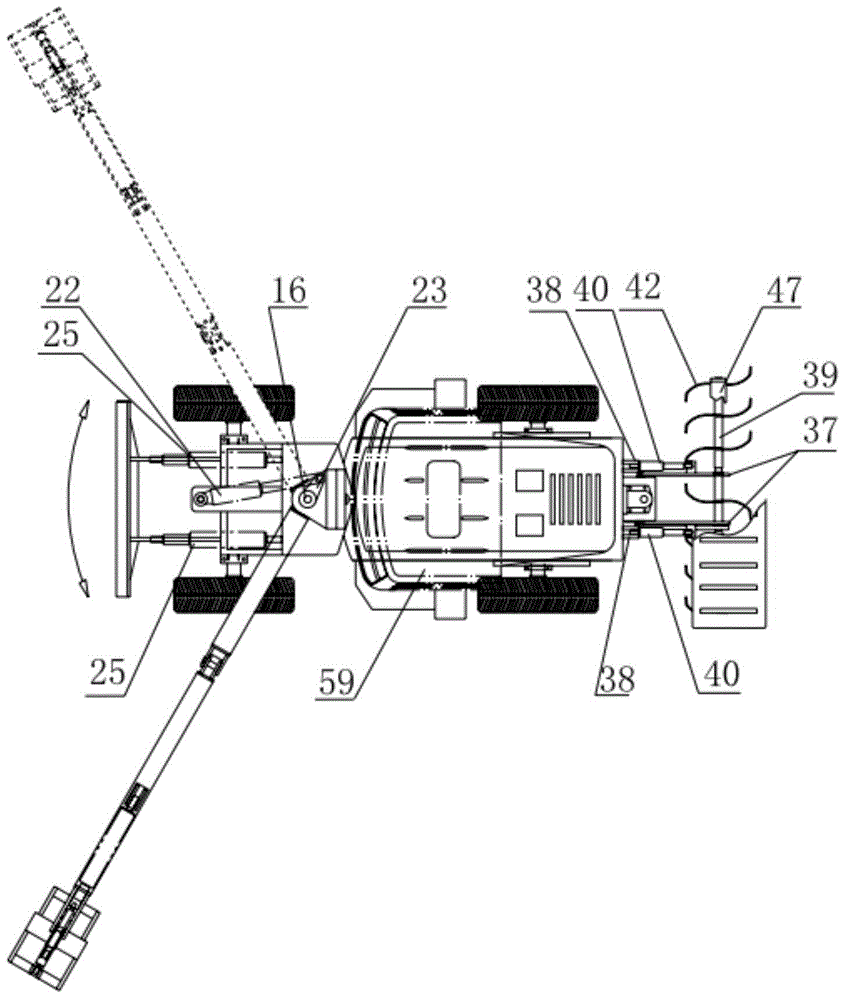

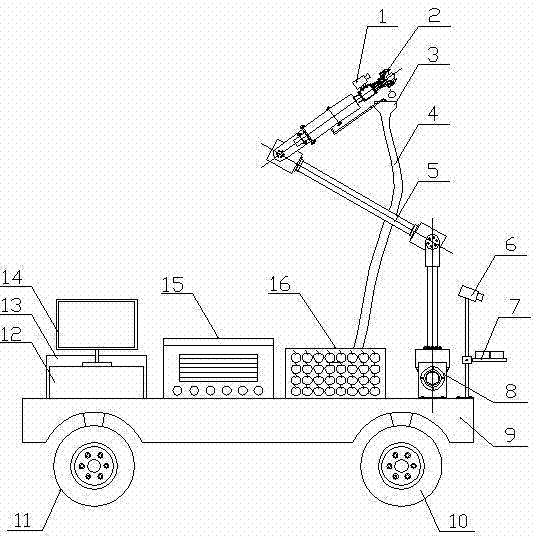

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866AReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

Owner:NANJING AGRICULTURAL UNIVERSITY

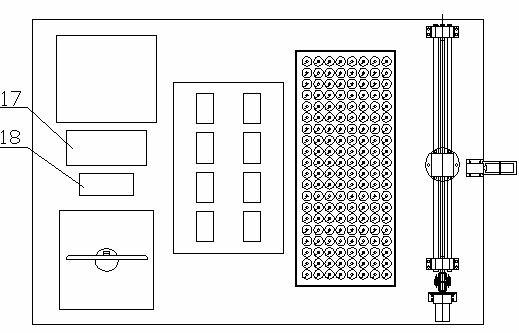

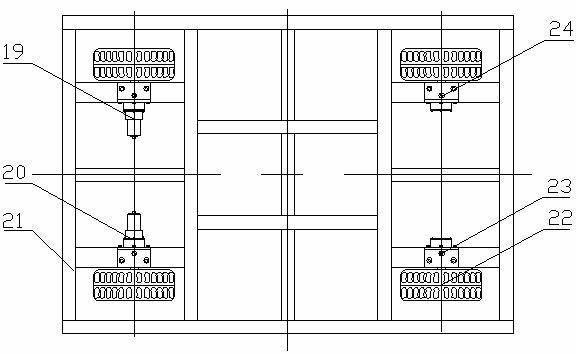

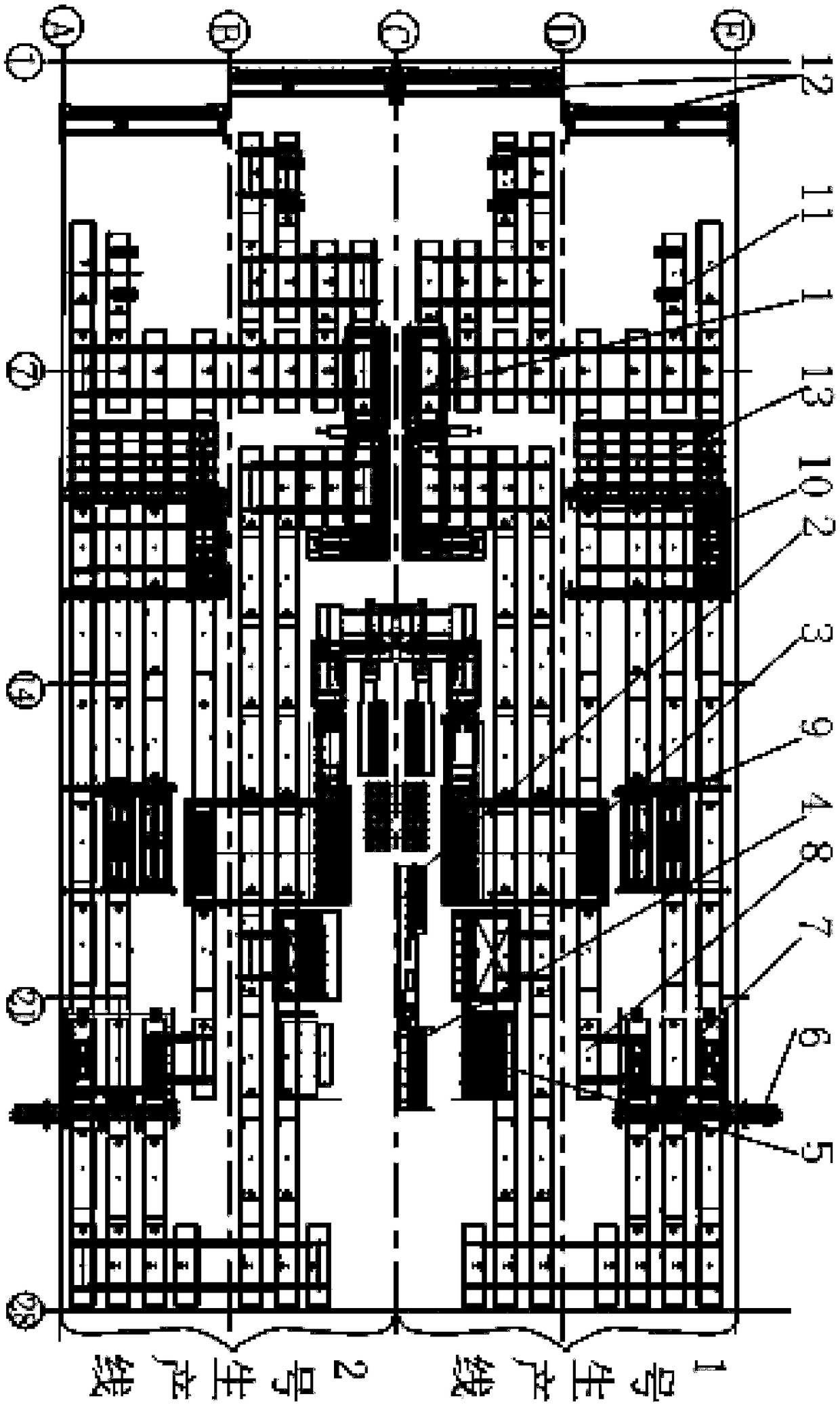

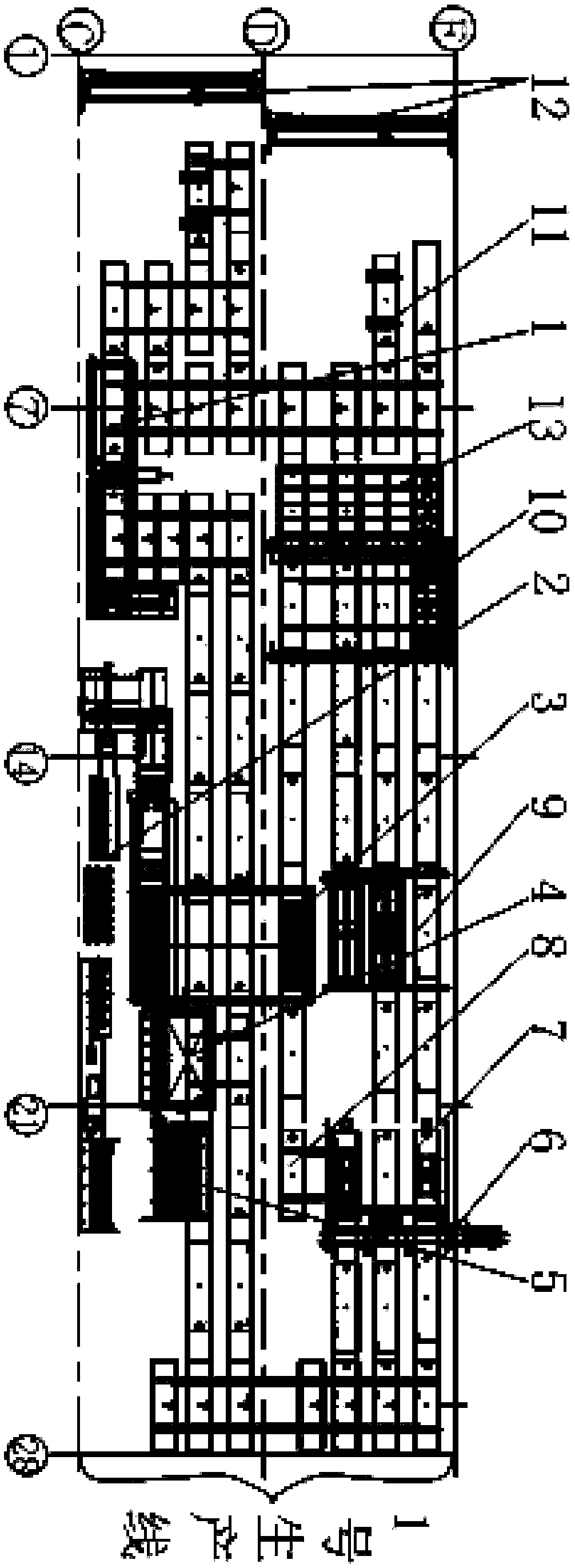

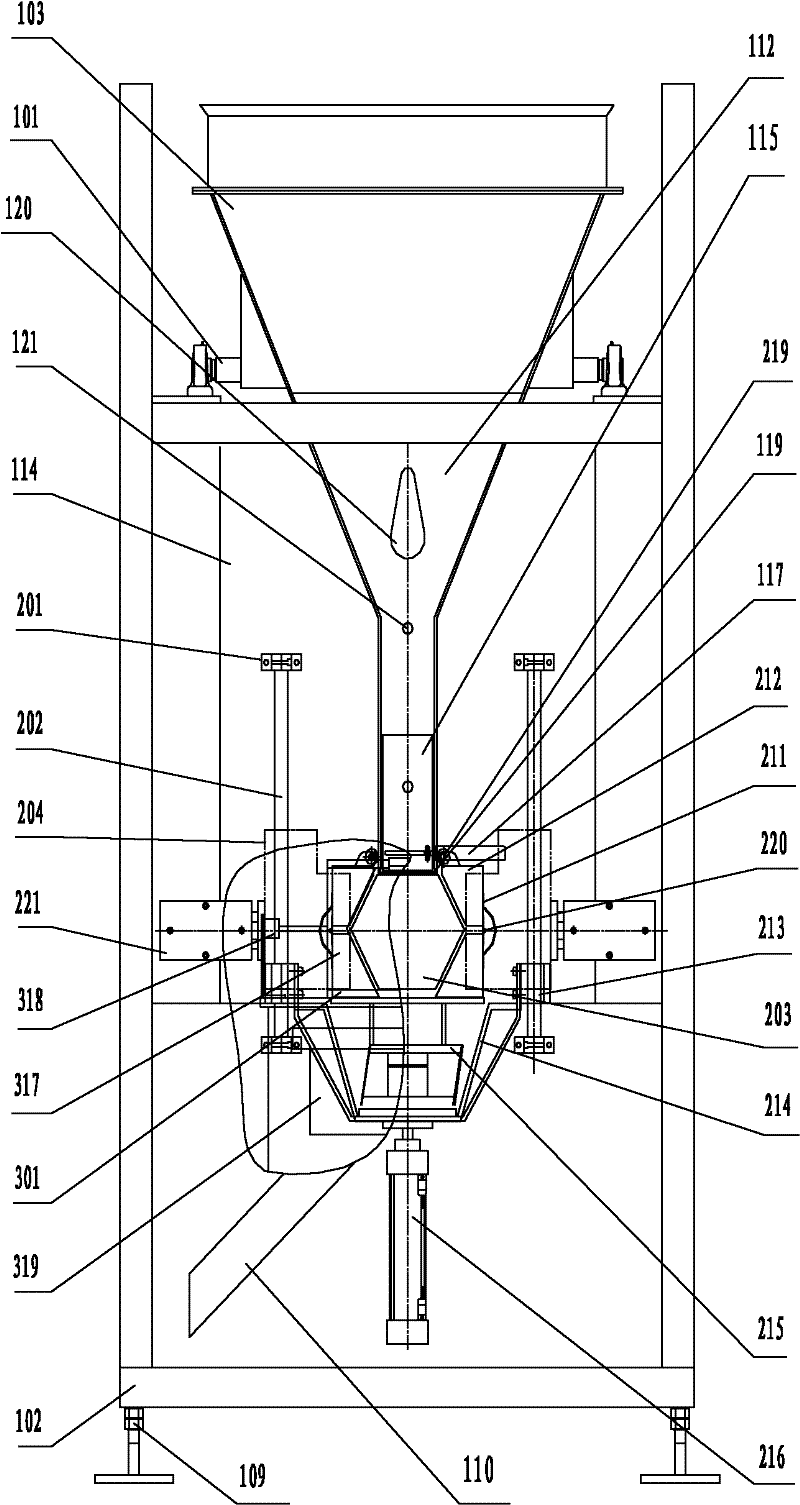

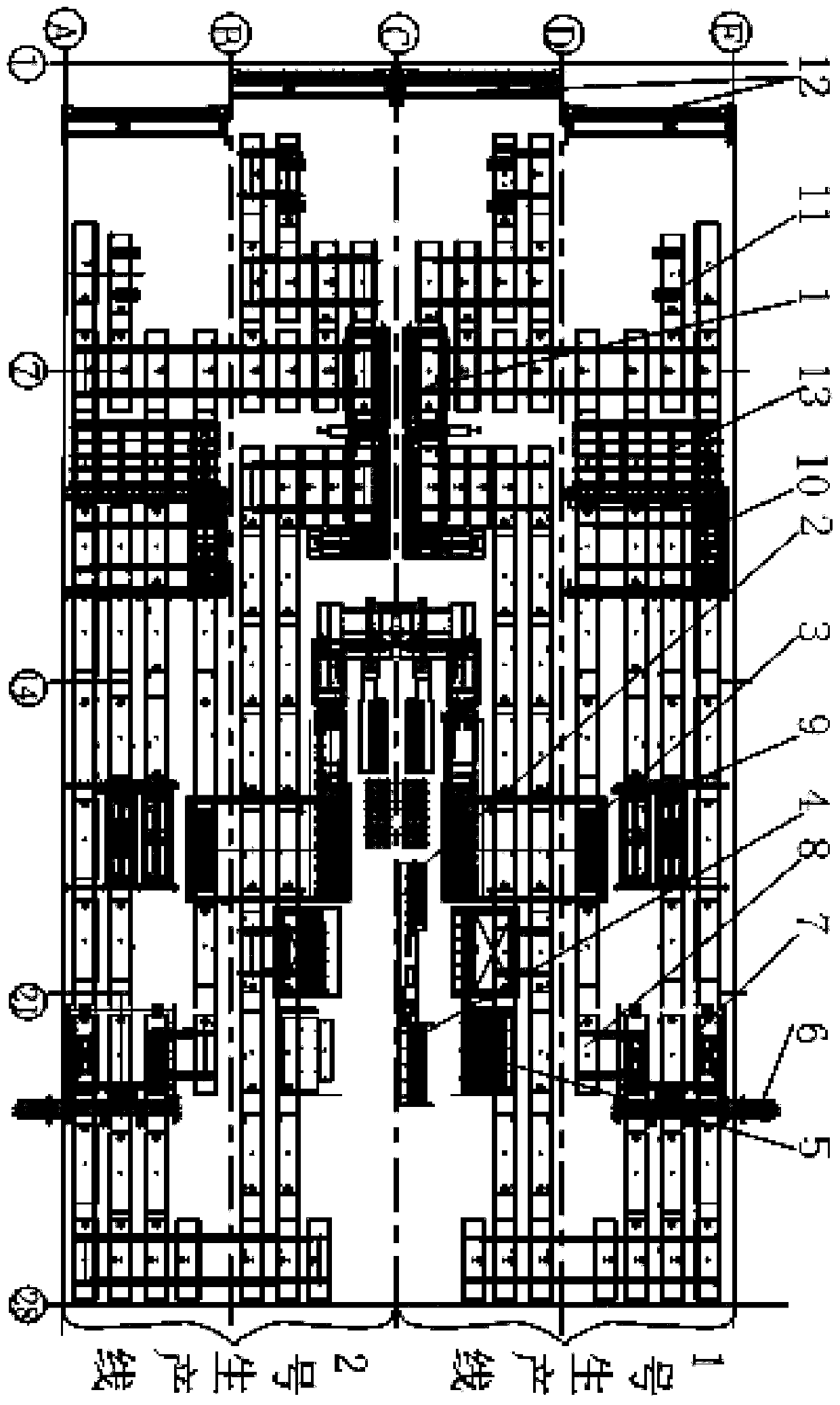

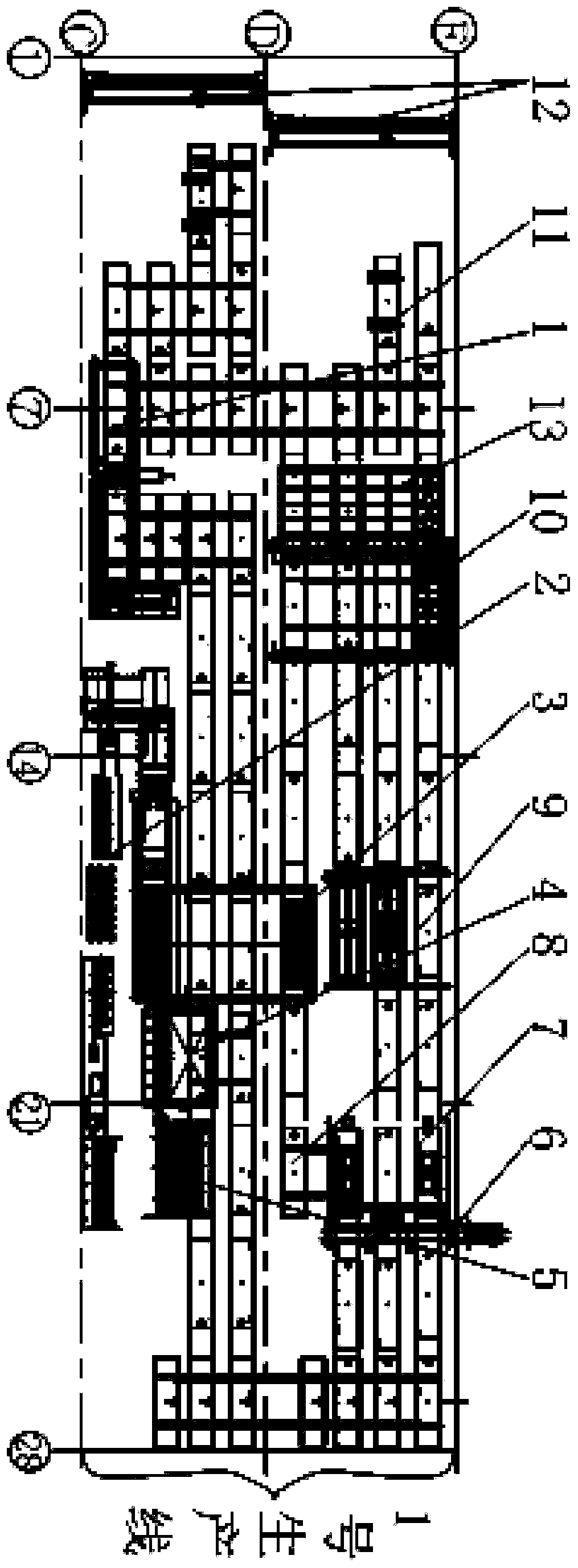

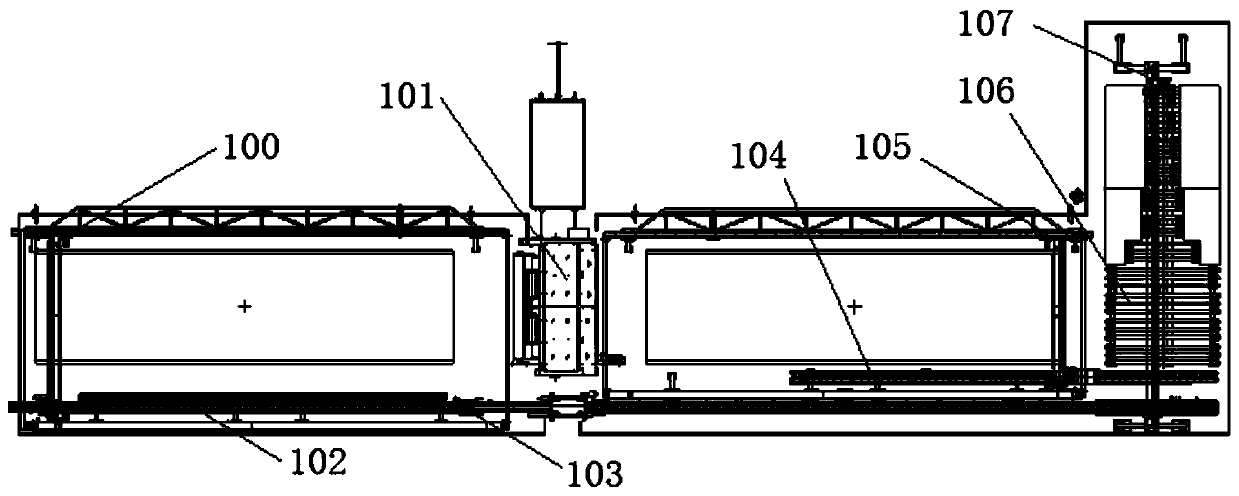

Intelligent production lines capable of producing standard PC components of multiple species and production process

ActiveCN108890850ARealize diversified productionReduce manufacturing costDischarging arrangementCeramic shaping plantsProduction lineMaterial distribution

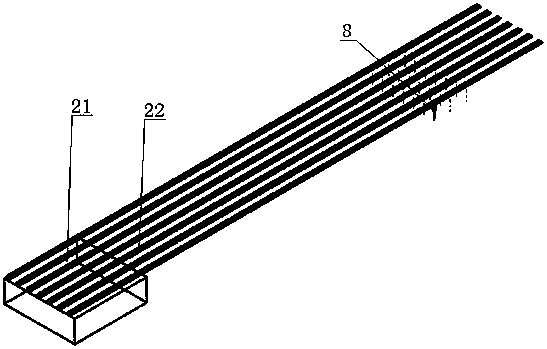

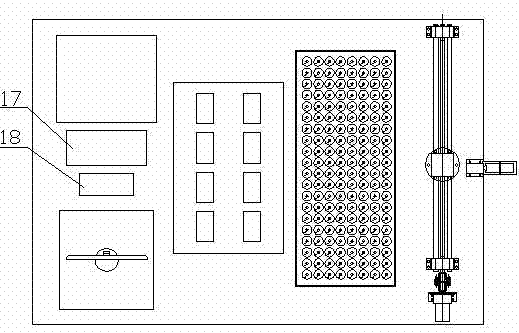

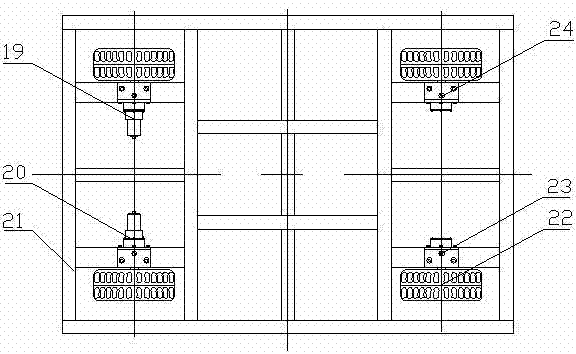

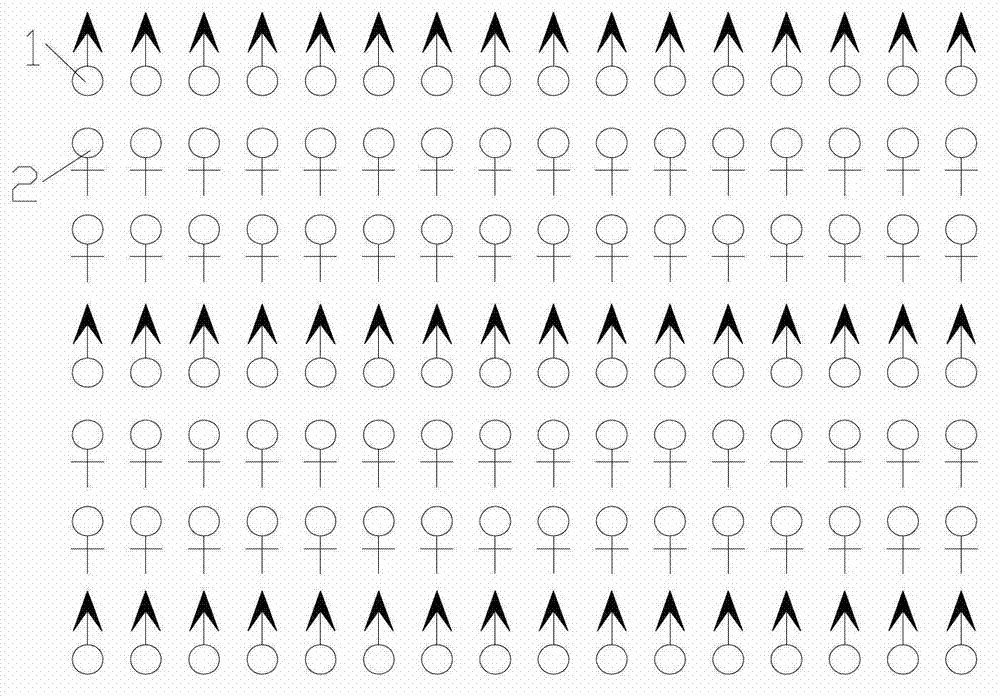

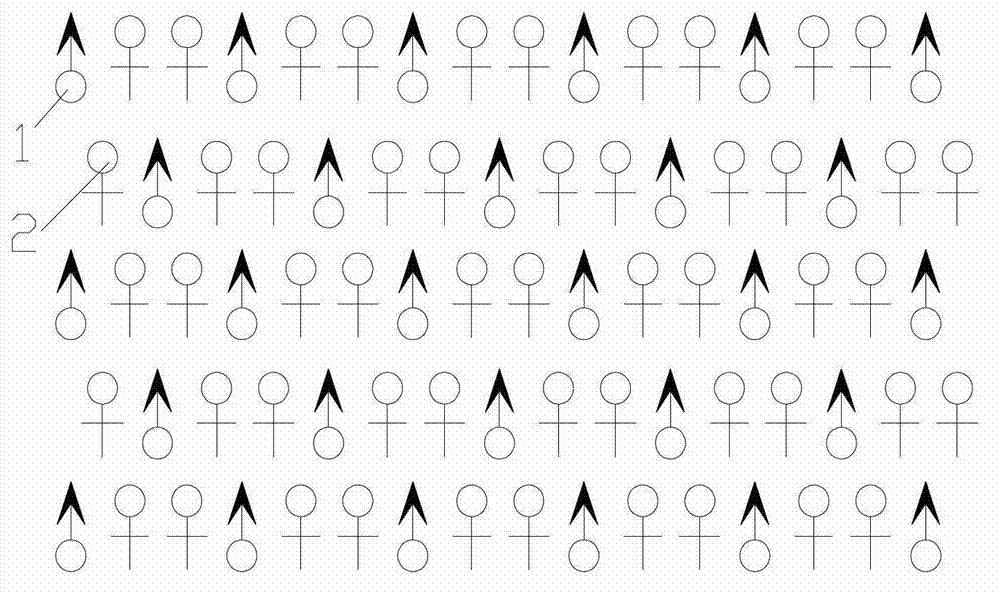

The invention provides an intelligent production lines capable of producing standard PC components of multiple species and production process. Two intelligent production lines are arranged between anA shaft to a C shaft and between the C shaft to an E shaft respectively, are symmetric relative to the C shaft, and are installed between 1-28 axis of each span; each production line comprises a moldplacing device, a mesh bar processing device, a truss bar processing device, a material distribution machine, a turnover machine, a curing kiln, a stacker and a tipper. According to the production lines, three kinds of standard PC components of laminated slabs, superposed shear walls with no heat preserving function and superposed shear walls with a heat preserving function can be produced simultaneously by a single production line, and an information system is utilized to achieve whole process control of designing, producing and transporting to further reduce labor force. Only eighteen workers are needed to work on the intelligent production line in a working time period, the number of the workers is only one fourth of that of a traditional PC production line, current worker shortage is prevented, the labor intensity is reduced, the product quality and production efficiency are improved, and the production cost of enterprises is reduced.

Owner:美好建筑装配科技有限公司

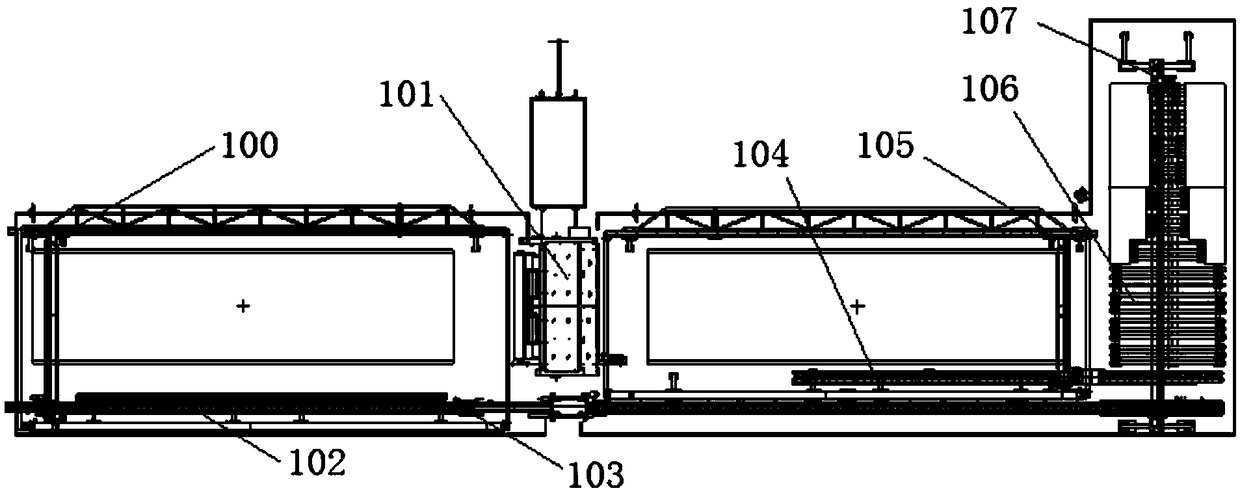

Construction method for prefabricated assembly type subway station

InactiveCN104153389AFast constructionSmall footprintArtificial islandsUnderwater structuresSubway stationRoad surface

The invention discloses a construction method for a prefabricated assembly type subway station, and belongs to the technical field of rail transit. The construction method comprises the steps of 1, setting the width of each ring of the prefabricated assembly type subway station to be 2 m, wherein each ring is composed of seven prefabricated parts; 2, adopting the fine leveling strip method in a base cushion layer; 3, constructing a reaction frame; 4, assembling base plate prefabricated parts; 5, assembling side wall prefabricated parts; 6, assembling top plate prefabricated parts; 7, carrying out concrete backfilling on a side wall foundation gap; 8, carrying out grouting on a base and mortises. The construction method has the advantages that the purpose of winter construction is achieved, and construction of a foundation pit support structure of the subway station, earth excavation, construction of a main structure, earthwork backfilling and road surface recovering can be completed within a year; problems caused by subsurface excavation method construction and open-cut method construction of the station can be fundamentally solved. The assembly type subway station has the advantages of being high in construction speed and small in occupied area and having little influence on the surroundings, the quality can be guaranteed under the on-site construction efficiency, the construction speed of constructing one ring each day is achieved, and therefore the construction method is convenient to widely popularize.

Owner:CHINA RAILWAY 13TH BUREAU GRP 6TH ENG COMPANY +1

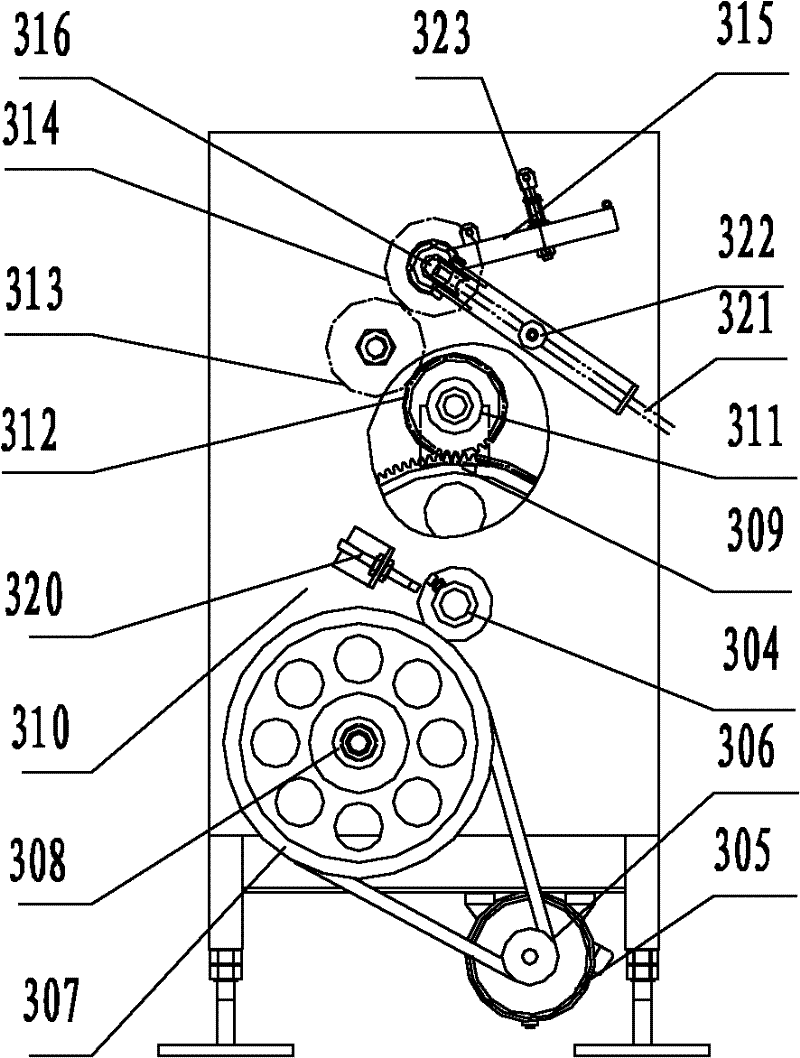

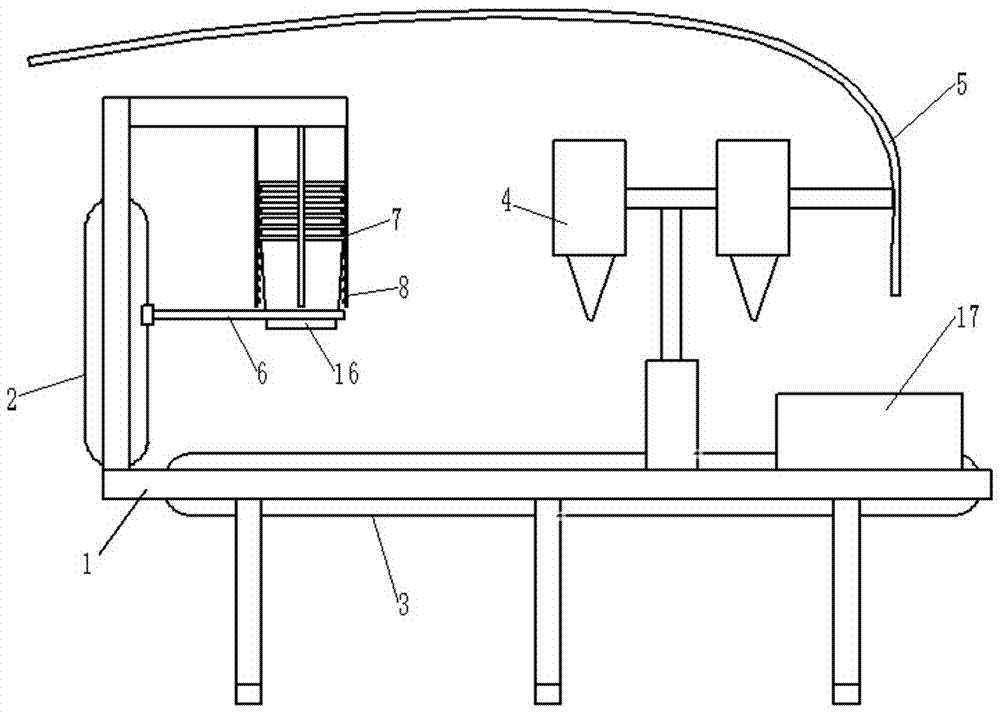

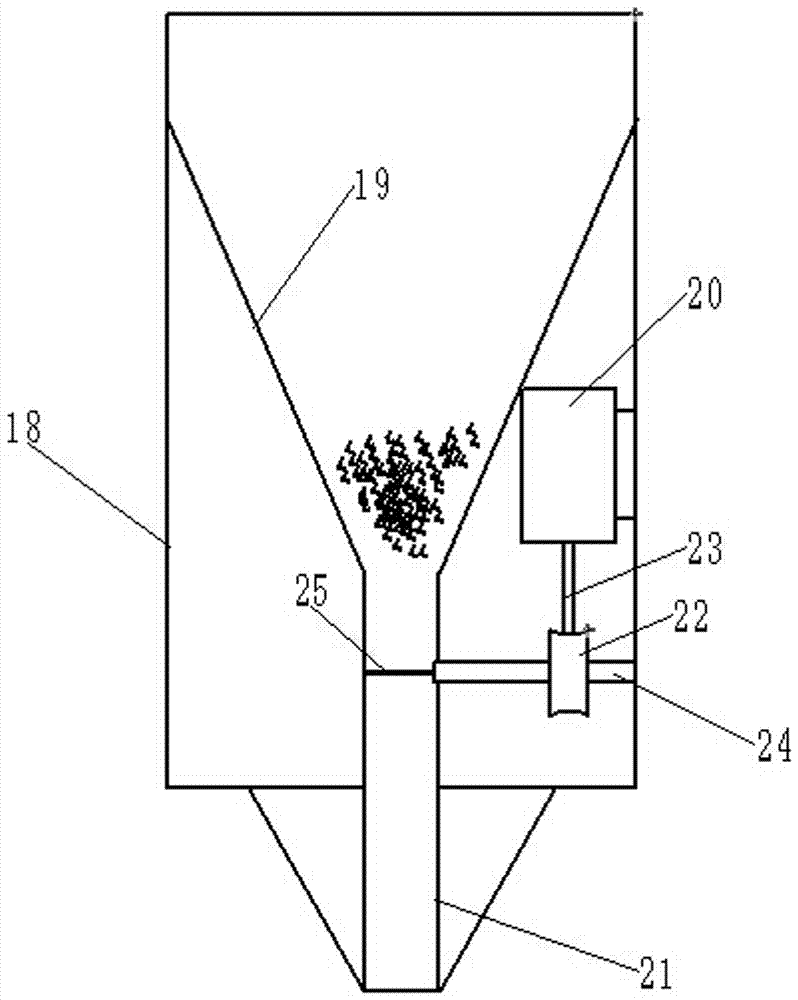

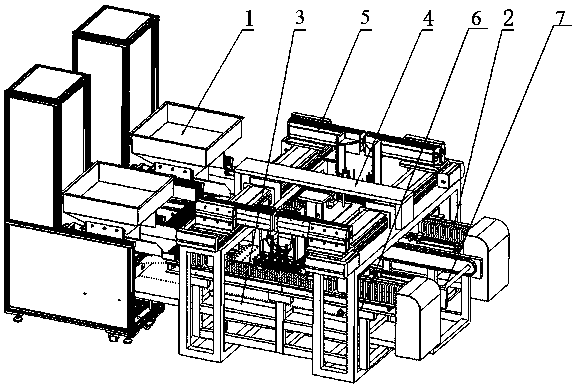

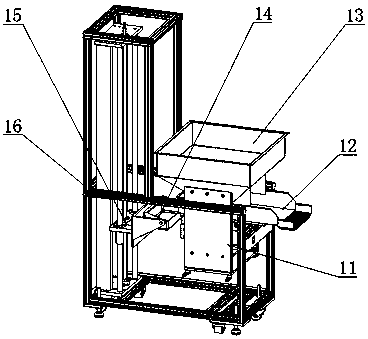

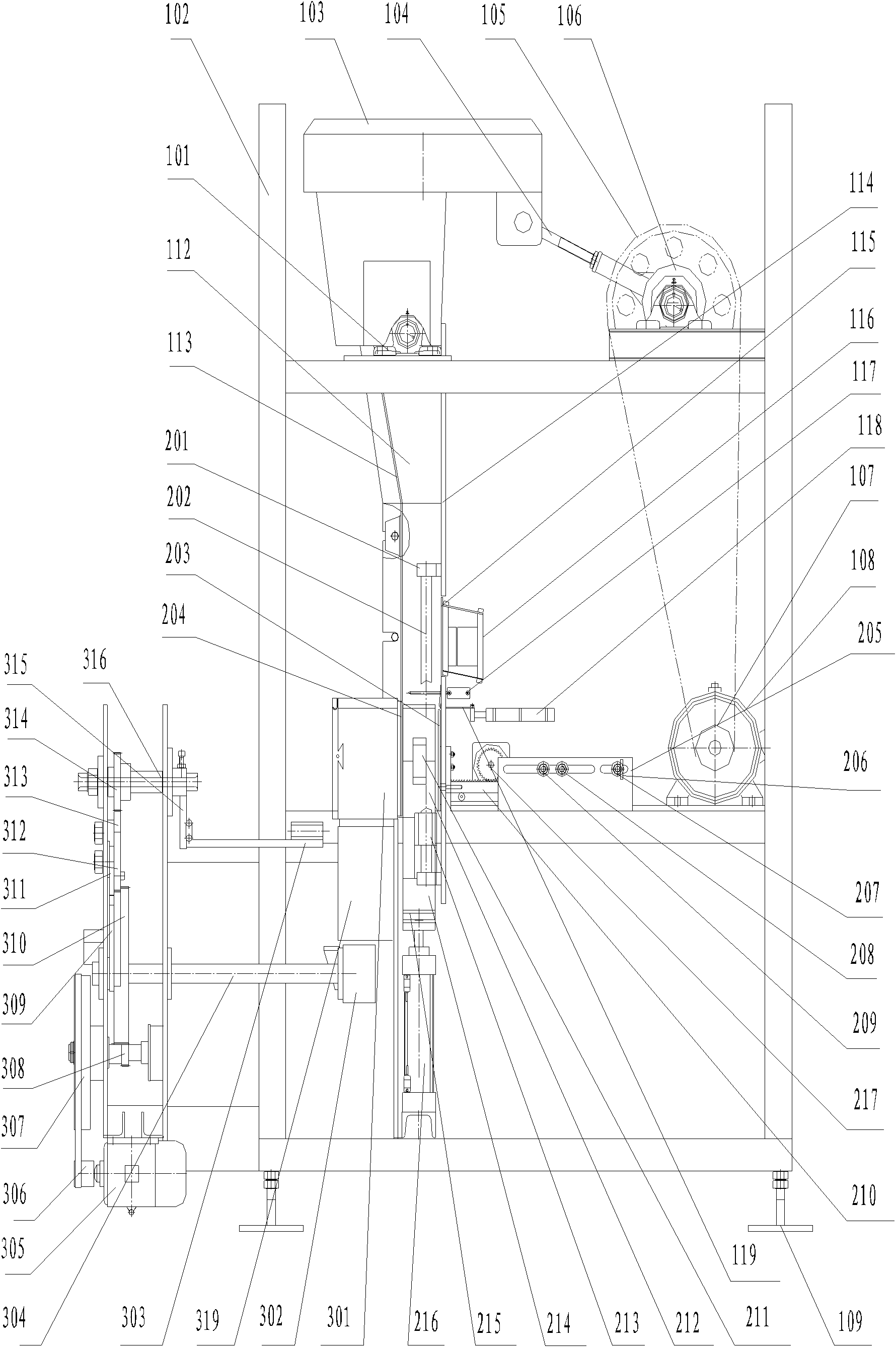

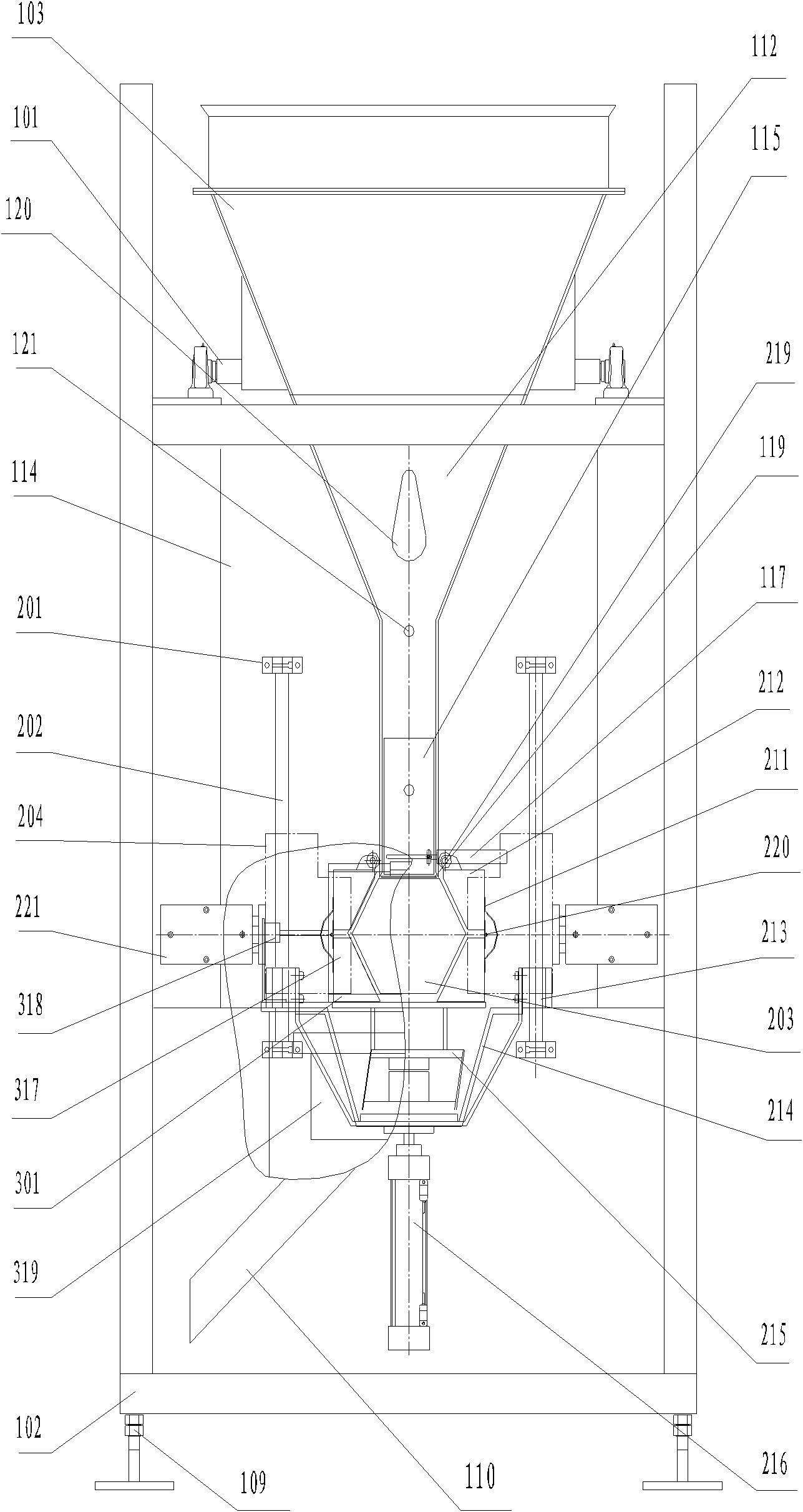

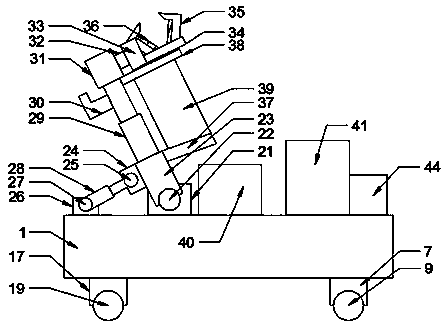

A molding binding device of firecrackers tube cake

The invention discloses a molding binding device of firecrackers tube cake, comprising a vertical feeding system, a loading molding system, a binding system and a control system. The beneficial effects of the molding binding device of firecrackers tube cake are lie in that(1) the arrangement, combination molding and binding of the firecrackers tube cake are completed in full-automation, the molding speed is fast, the binding is tight and the shape of the firecrackers tube cake is regular and beautiful; more than 300 firecrackers tube cakes can be finished per hour, which saves the human resources significantly, improves the work efficiency and solves the problem of labor shortage; (2) each part of the molding binding device is modular designed and installed, the size can be adjusted in accordance with the product, and the operation is convenient and the maintenance is fast; the abrasion of the contact site is low by employing a pneumatic roller structure, so that the device can be used for a long time without worrying about the precision to be effected.

Owner:浏阳市鸿隆综合贸易有限公司

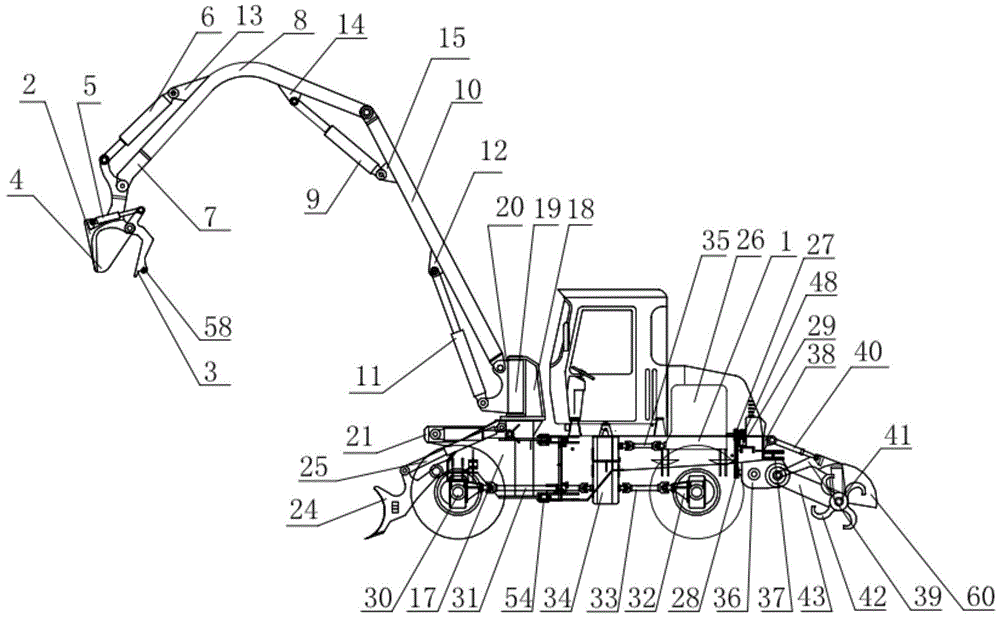

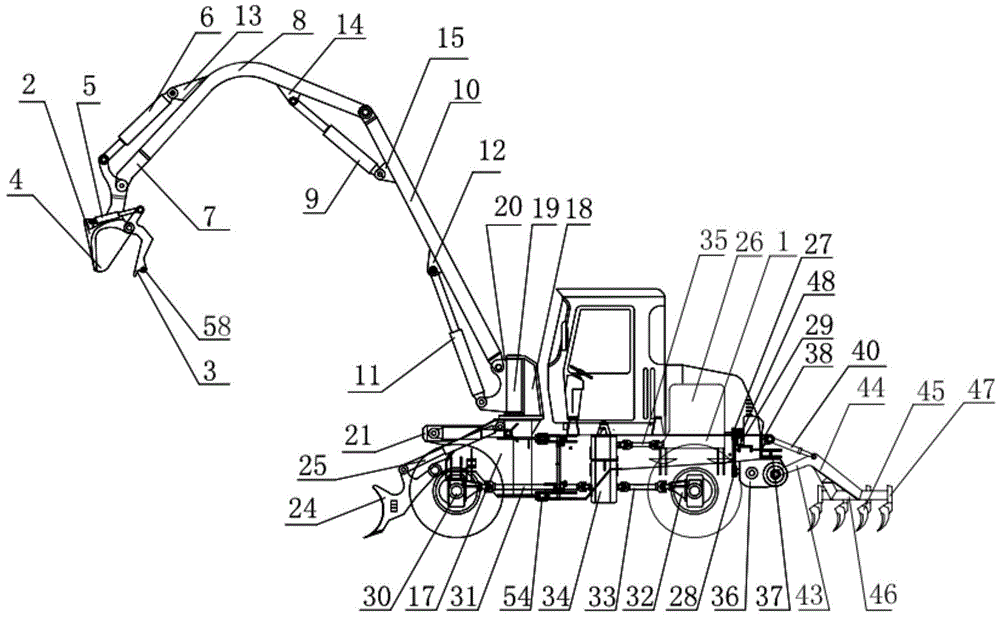

Multipurpose small wheel type excavator

InactiveCN104452843AReduce financial burdenSolve labor shortageMechanical machines/dredgersTilling equipmentsTurn angleDrivetrain

The invention discloses a multipurpose small wheel type excavator. The excavator comprises a frame, a power transmission system, a hydraulic control system connected with the power transmission system, a steering device arranged at the front end of the frame, an excavating device and a push shoveling device respectively connected with the steering device, and a rotary tillage device arranged at the tail of the frame. The multipurpose small wheel type excavator integrates excavation, push shoveling and rotary tillage as a whole; the excavator can work in a turning angle range of 120 degrees under the effect of the hydraulic control system through arranging the steering device, and is combined with the push shoveling device and the rotary tillage device to realize the combination of industrial and agricultural mechanical fields; and the multipurpose small wheel type excavator has such multiple functions as pit digging, grabbing and lifting, rotary tillage, ploughing, ditching, ridging and bulldozing. Therefore, the multipurpose small wheel type excavator relieves the economic burdens of farmers, solves the problem of rural labor shortage, and has wide purposes and great promotion value in national rural areas.

Owner:重庆茂松实业股份有限公司

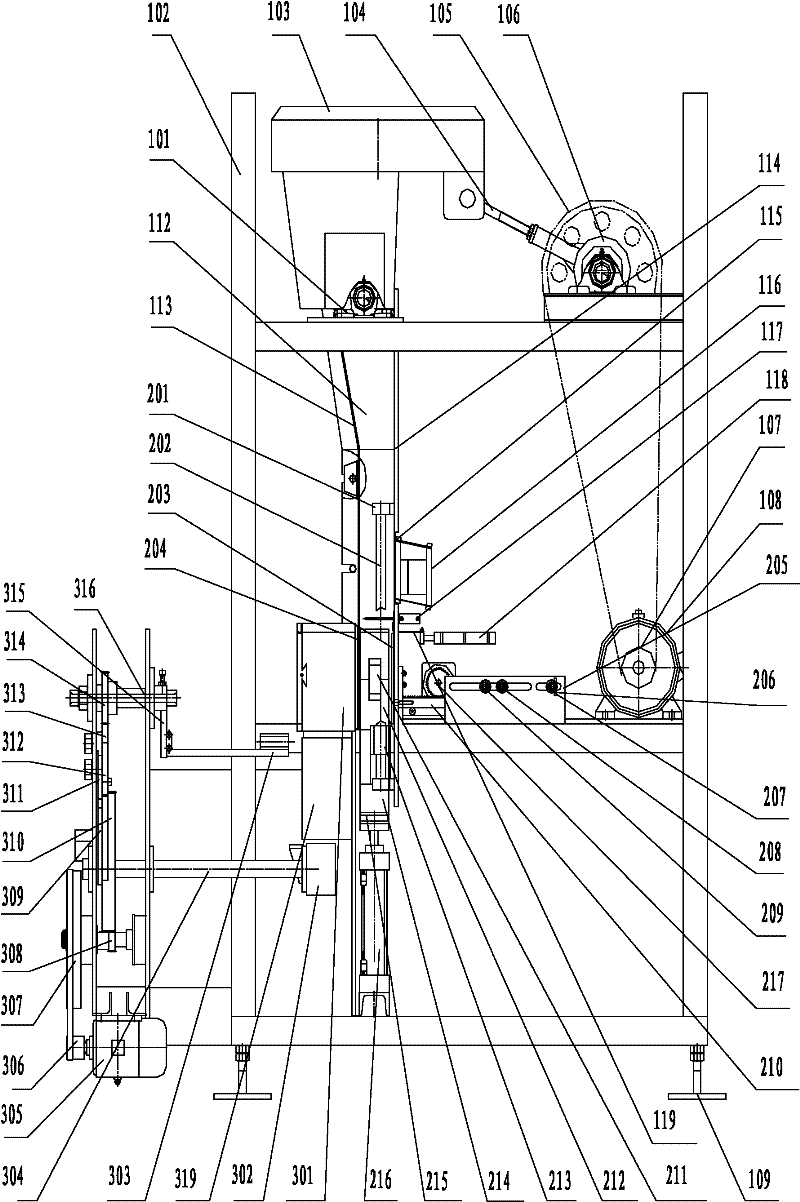

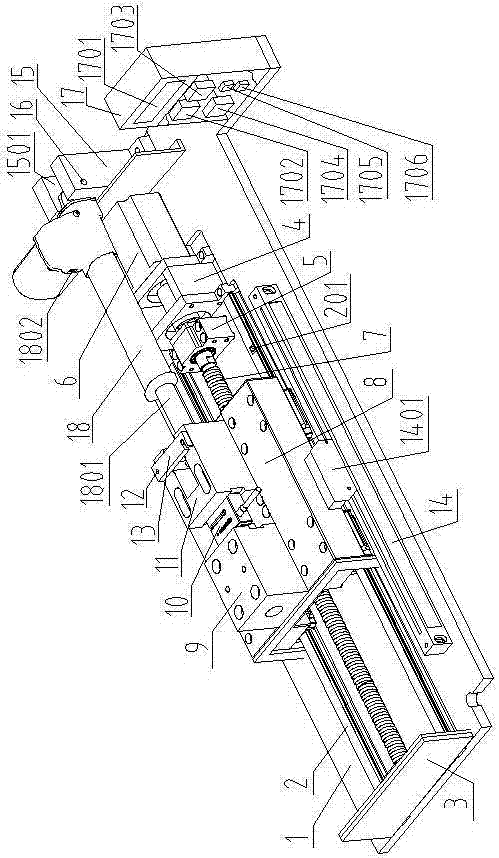

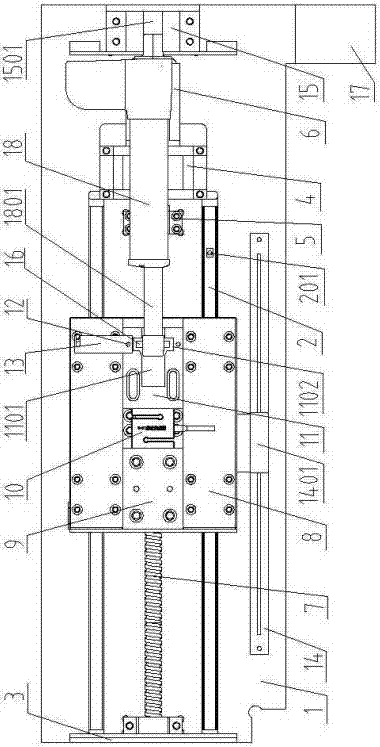

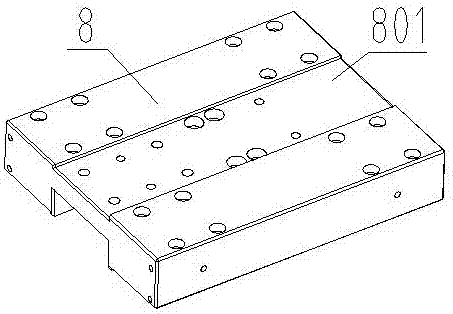

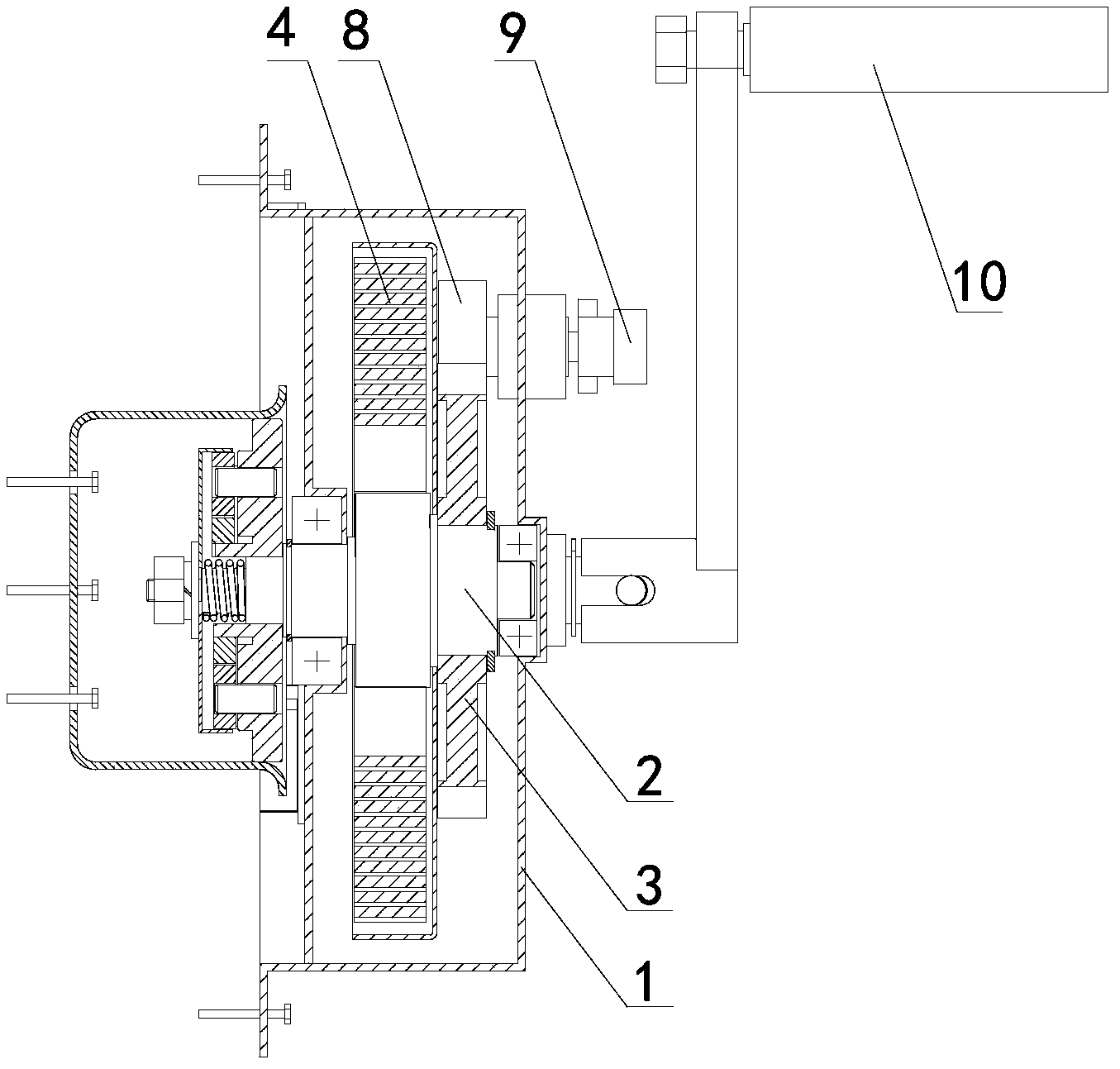

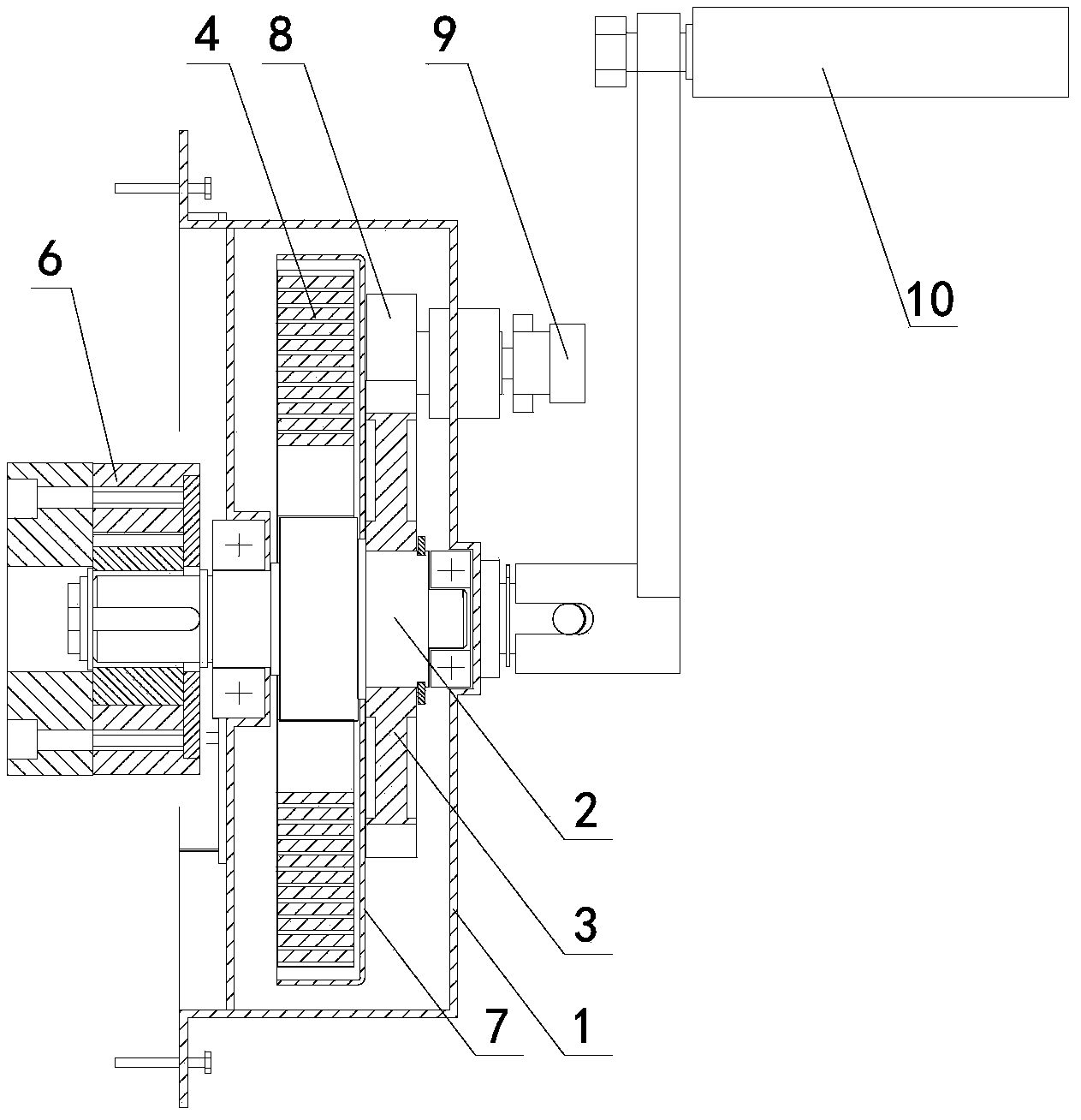

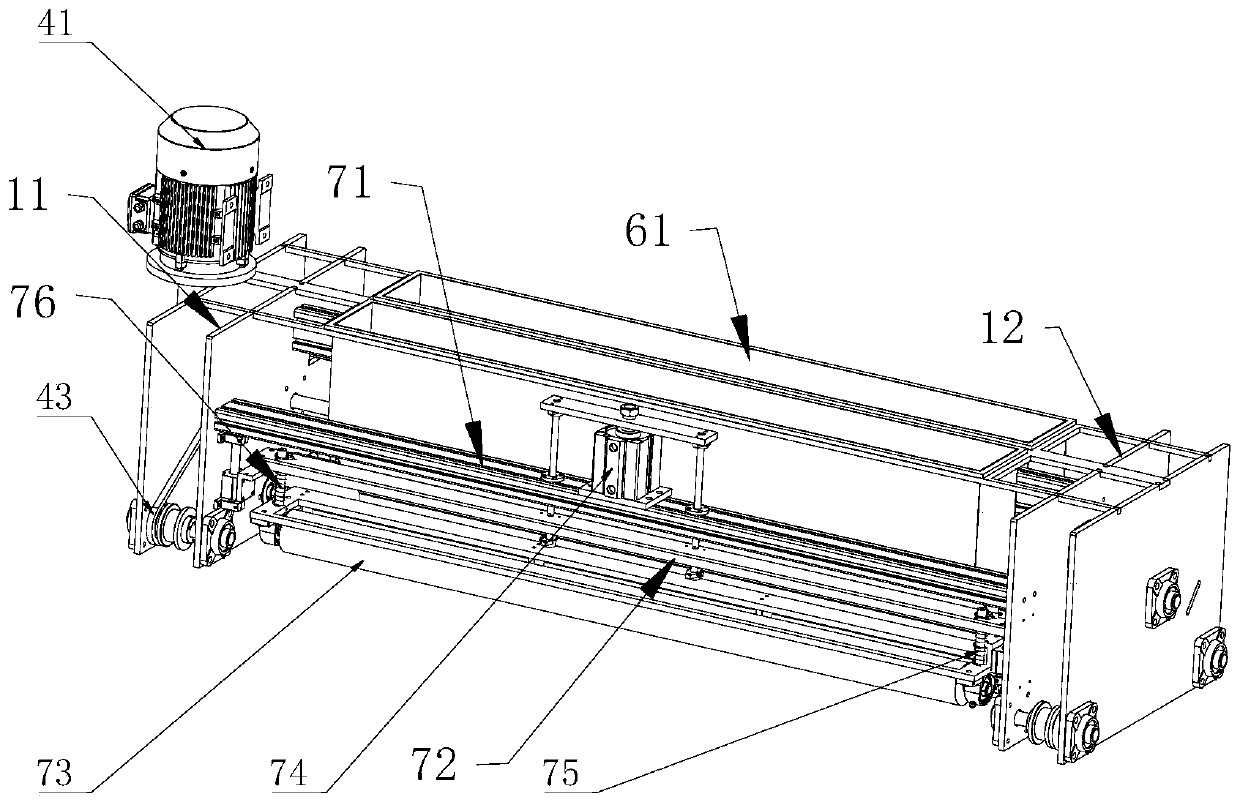

Intelligent testing platform of comprehensive performance of electric push rod and testing method of intelligent testing platform

InactiveCN107340131AImprove test efficiencySimple device structureMachine gearing/transmission testingProgramme control in sequence/logic controllersEngineeringTest platform

The invention discloses an intelligent test platform for the comprehensive performance of an electric push rod, which comprises a bottom plate and a guide rail. Two guide rails are fixedly connected to the bottom plate in parallel, wherein a zero point is set on the right end of one of the guide rails, and a zero point is fixedly connected to the left end of the guide rail. Standing plate, the right end of the guide rail is provided with a servo motor fixing seat, the left side of the servo motor fixing seat is provided with a bearing seat, and a bearing is installed in the bearing seat, and the servo motor fixing seat and the bearing seat are respectively fixedly connected to the base plate , a servo motor is fixedly connected to the right side elevation of the servo motor fixing base, a lead screw is fixedly connected to the power output shaft at the left end of the servo motor, and the lead screw runs through the bearing and the sliding table in the bearing seat, and the left end It is movably connected on the side elevation of the vertical board; the invention also discloses a testing method of an intelligent testing platform for the comprehensive performance of the electric push rod. The invention has high efficiency, multiple functions, low cost, stable performance, good market prospect and is suitable for popularization and use.

Owner:CHANGZHOU COLLEGE OF INFORMATION TECH

Novel tea-water service device

The present invention is a new type of tea service equipment, which includes a frame, a tea conveying assembly, and a paper cup clamping assembly. The tea conveying assembly is connected to the frame. tube; the position of the second conveyor belt is horizontal, the position of the first conveyor belt is vertical, the first conveyor belt is fixedly connected with clamping claws, the tea delivery tube is connected with the frame, and the boiling water filling pipe is connected with the frame; the paper cup clamping assembly Contains at least four vertical rods, the vertical rods are distributed in a circular array, the vertical rods are provided with linearly arranged card slots, and the edges of the paper cups are clamped in the card slots. The beneficial effect is as follows: more people can understand the knowledge of tea culture, and the tea culture can be better inherited. It makes it more convenient for guests to drink tea, does not require the complicated brewing process of the waiter, and solves the problem of the existing labor shortage.

Owner:刘畅

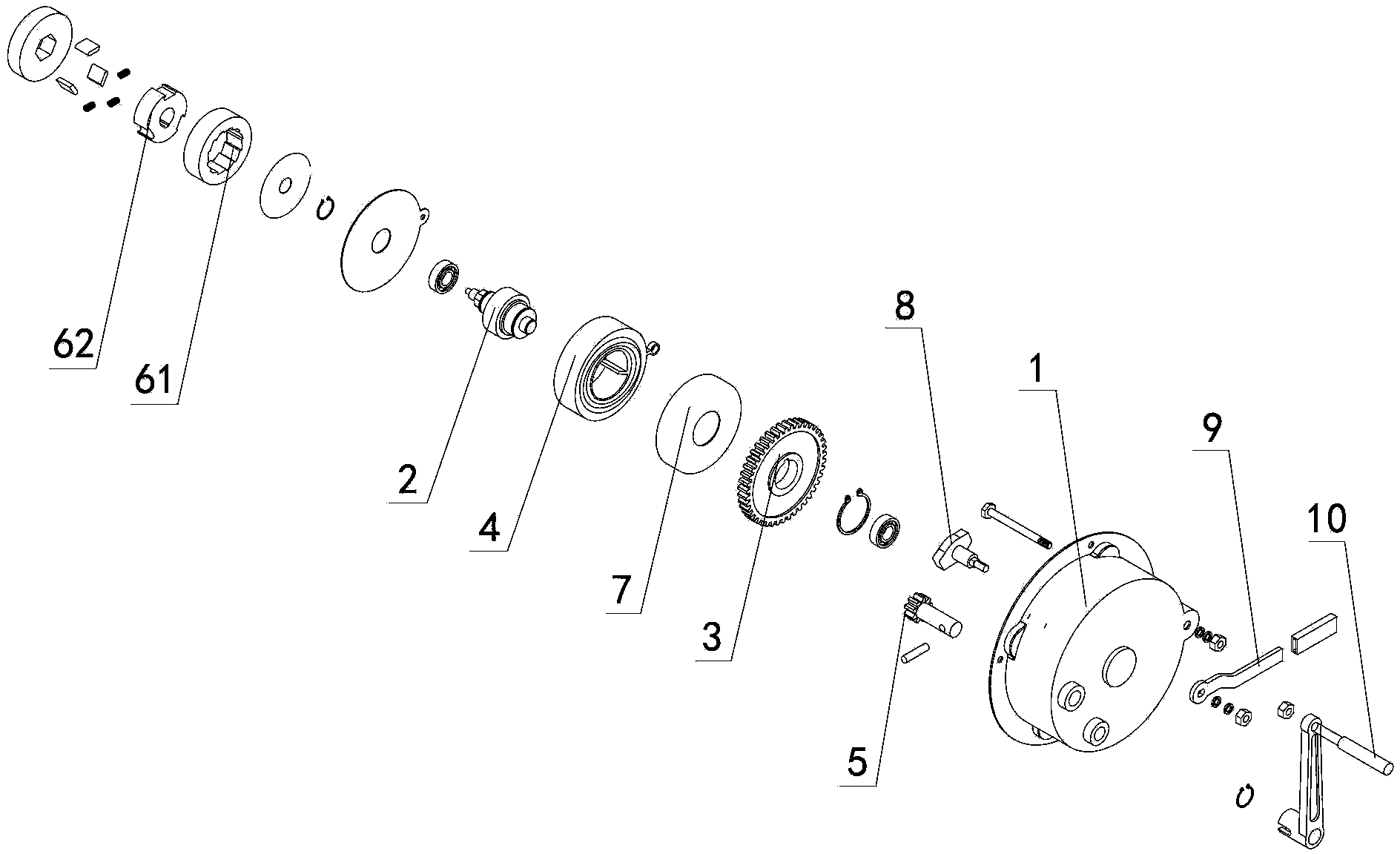

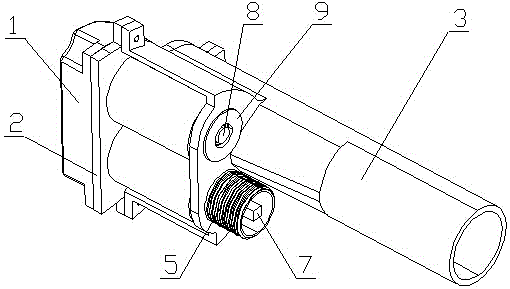

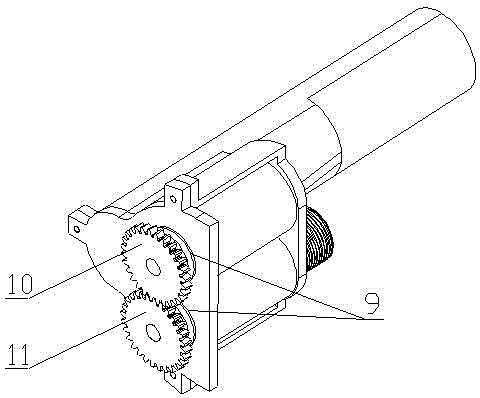

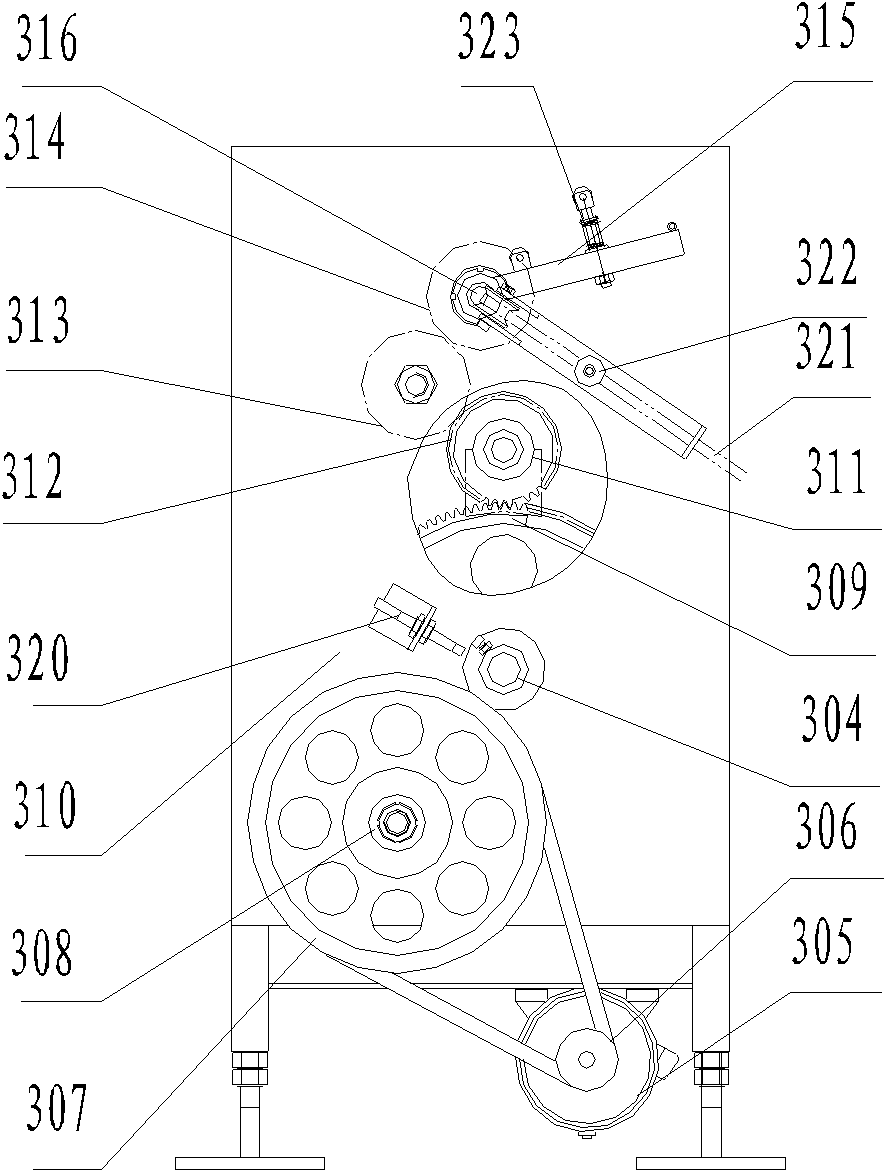

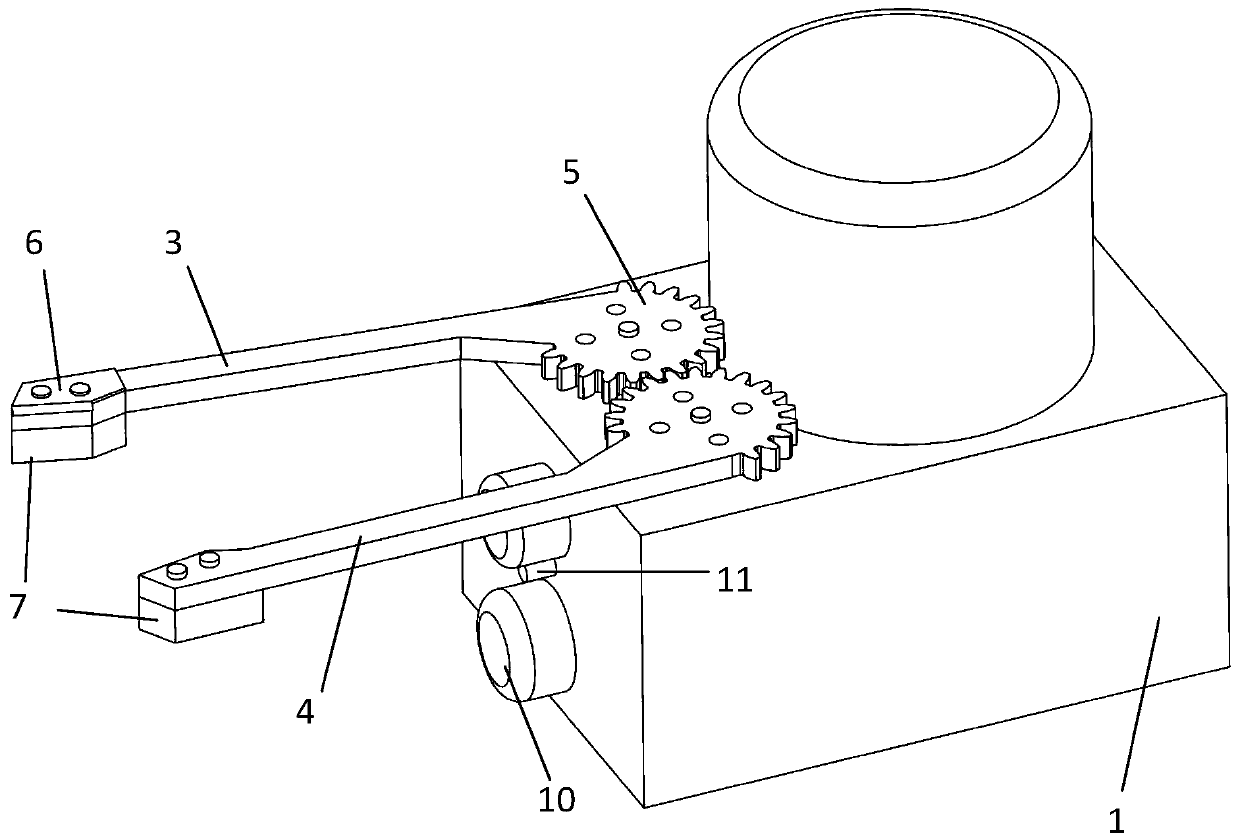

Hand-cranking starter of diesel engine

InactiveCN104279108AStable forceExtended service lifePower operated startersMachines/enginesAgricultural irrigationGear wheel

The invention discloses a hand-cranking starter of a diesel engine, and aims at providing a diesel engine hand-cranking starter which is convenient to use, small in starting impact and long in service life. The hand-cranking starter comprises a machine shell, a rotating shaft, a big gear wheel, a flat spiral spring, a small gear wheel and a shifting fork, wherein one side of the machine shell is detachably connected with a diesel engine shell, the rotating shaft is installed on the two side walls of the machine shell through bearings, the big gear wheel is installed on the side, far away from the diesel engine shell, of the rotating shaft and located in the machine shell, the flat spiral spring is installed on the side, close to the diesel engine shell, of the rotating shaft and located in the machine shell, the small gear wheel is installed on the side, far away from the diesel engine shell, in the machine shell and is meshed with the big gear wheel, and the shifting fork is used for locking the big gear wheel and connected with a handle. The hand-cranking starter is characterized in that the end, close to the diesel engine shell, of the rotating shaft extends out of the machine shell and is provided with a ratchet wheel type overrun clutch which comprises an outer wheel and a core wheel located in the outer wheel, and the core wheel is provided with a plurality of pawls and fixedly connected with the rotating shaft. The hand-cranking starter is suitable for various mini-tillers, agricultural irrigation and drainage devices and other household machines.

Owner:GUIYANG KESHENG MACHINERY

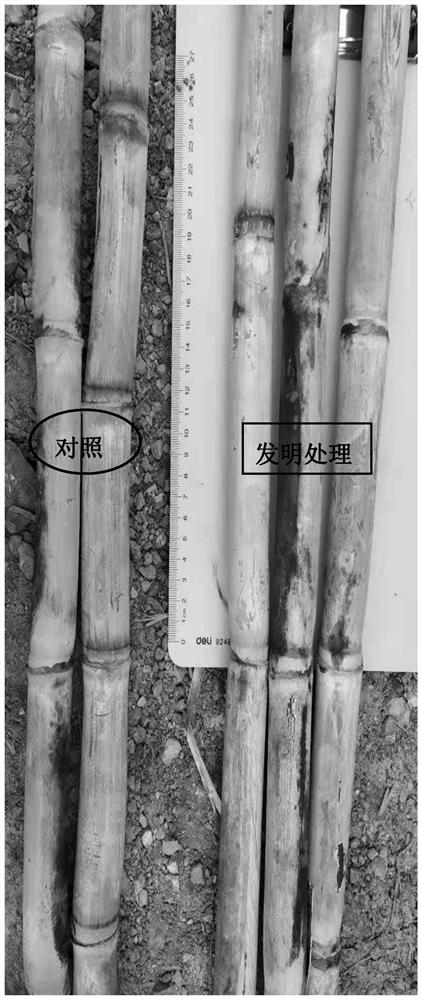

Cultivation method for promoting sugarcane tillering stem formation and internode sugar accumulation under continuous cropping obstacles

ActiveCN113016549AImprove lodging resistanceImprove yield and qualityBiocideSugarcane cultivationContinuous croppingAgricultural engineering

The invention relates to the technical field of sugarcane planting, and discloses a cultivation method for promoting sugarcane tillering stem formation and internode sugar accumulation in advance under continuous cropping obstacles. The cultivation method comprises the steps of (1) soil preparation; (2) base fertilizer combined application and reduced application; (3) factory seed production; (4) planting; (5) sealing ridge (when the land ground is fully covered by crops) and weeding; (6) field management; and (7) timely harvesting. According to the method, healthy sugarcane seed stems are industrially manufactured and coated with a degradable coating film and then planted, seed soaking is not needed, combined application and reduced application of base fertilizer and silicon fertilizer / biochar are combined, a potash fertilizer containing a proper amount of a plant growth regulator is additionally applied in the early tillering stage, and early tillering and rapid tillering and seedling strengthening of the sugarcane can be promoted in advance; the effective tiller seedling number of the sugarcane is ensured, and the lodging resistance of the sugarcane can be improved; and in the initial stage of elongation, an unmanned aerial vehicle is adopted to evenly spray the self-prepared sugarcane sugar-increasing growth promoter, tillering and jointing can be promoted, effective stems can be formed through rapid elongation, rapid accumulation of sugar among stem nodes in advance is further facilitated, and then the sucrose content and the per unit yield are increased.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

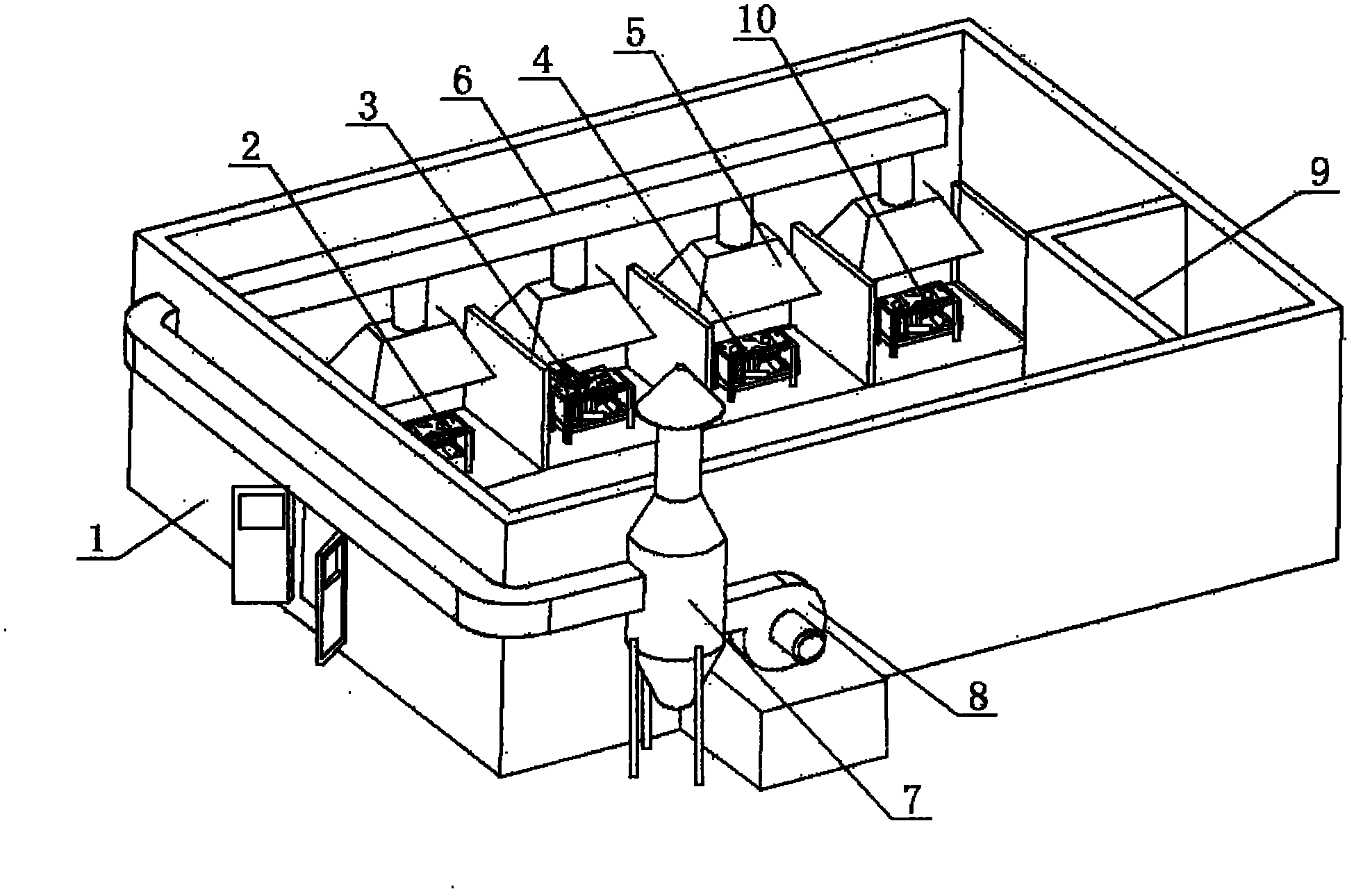

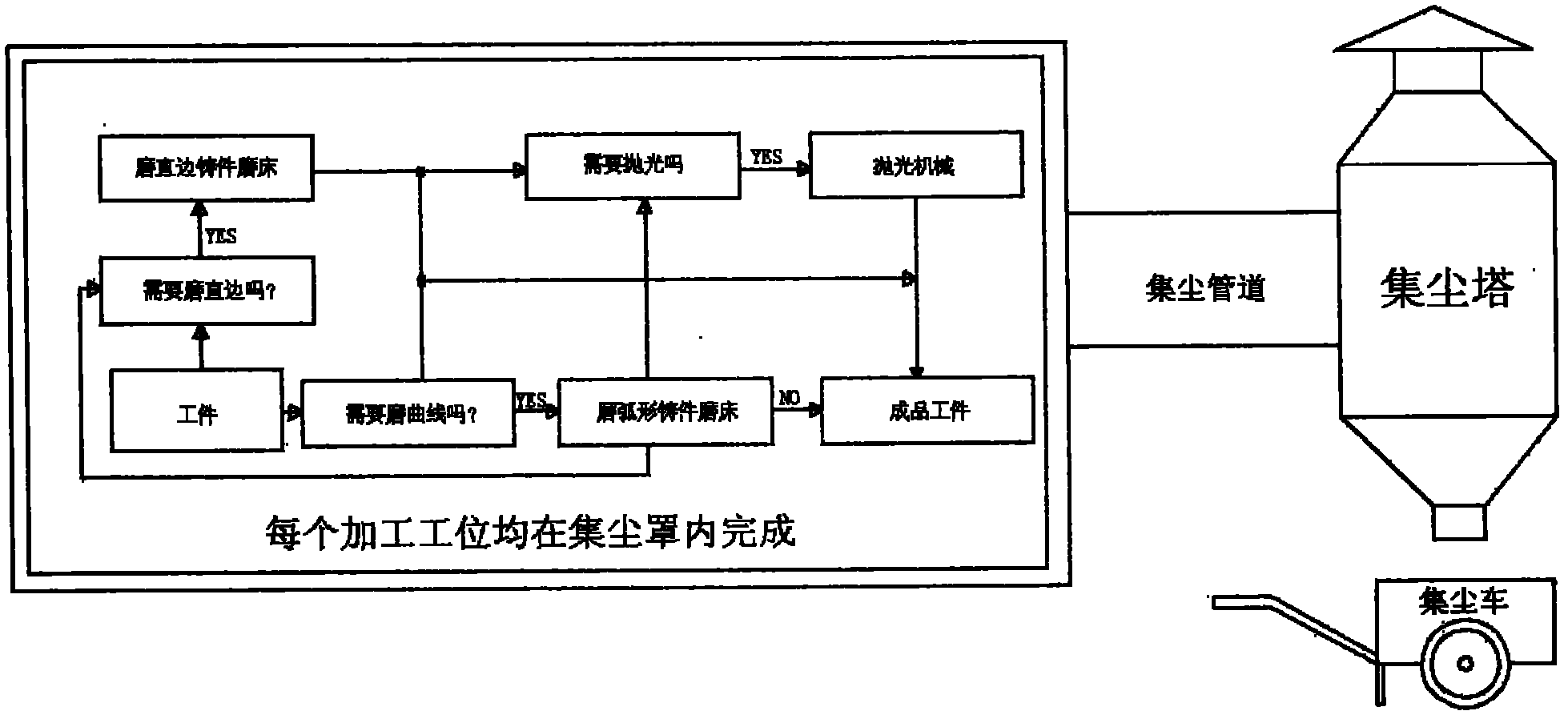

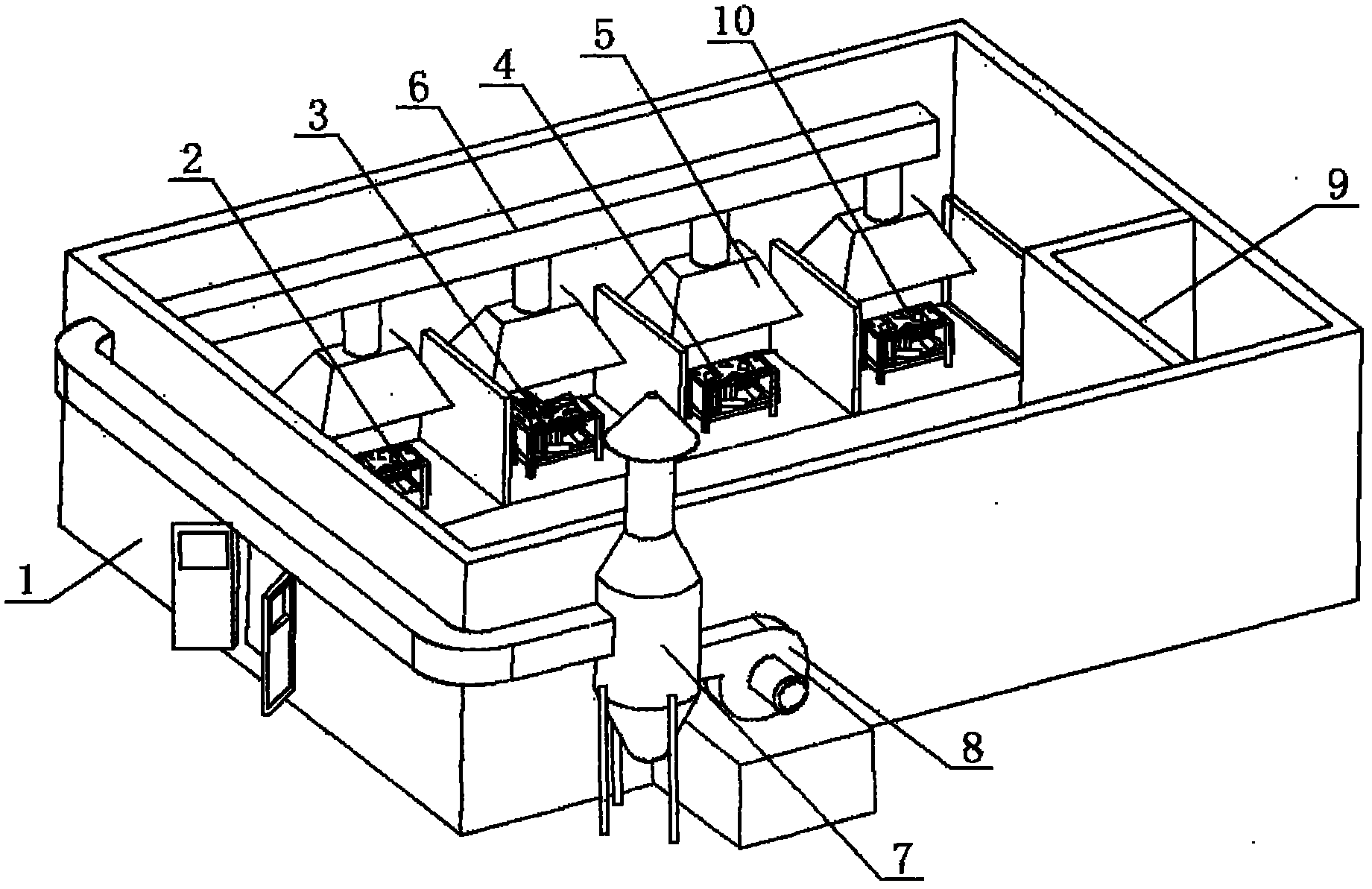

Cast post-processing workshop-level production control system

InactiveCN102328277AImprove working environmentSolve labor shortageGrinding/polishing safety devicesControl systemWorking environment

The invention relates to a cast post-processing workshop-level production control system which comprises a workshop, a plurality of industrial-level cast special grinding machines, a plurality of dust-removing covers, a dust-collecting pipeline and a dust-collecting tower, wherein a plurality of compartments are arranged in the workshop, one industrial-level cast special grinding machine is arranged in each compartment, one dust-removing cover is arranged at the upper end of each compartment, the dust-removing covers are connected with the dust-collecting pipeline, the dust-collecting tower is connected at the tail end of the dust-collecting pipeline and the dust-collecting tower is provided with a dust-collecting fan. In the cast post-processing workshop-level production control system, each process step has an independent operation space, the independent dust-removing covers can effectively remove waste scraps in the operation spaces, and then the waste scraps are collected and recovered by the dust-collecting tower in a centralized manner, thereby keeping air in the workshop clean, effectively improving a working environment of staff, simultaneously timely recovering the waste scraps and also greatly saving non-renewable material resources. The cast post-processing workshop-level production control system adopts the industrial-level cast special grinding machines for performing processing production, thereby effectively improving the production efficiency and saving the labor cost.

Owner:TIANJIN ZHONGYIMING TECH

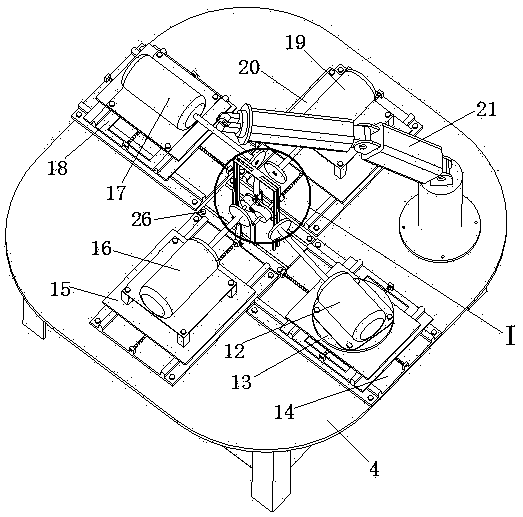

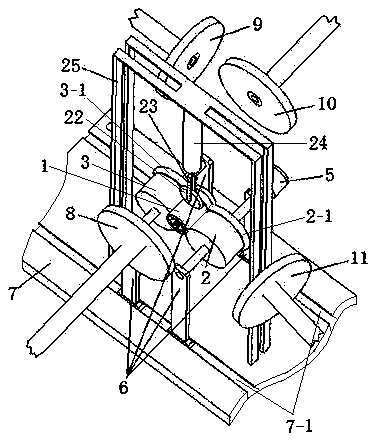

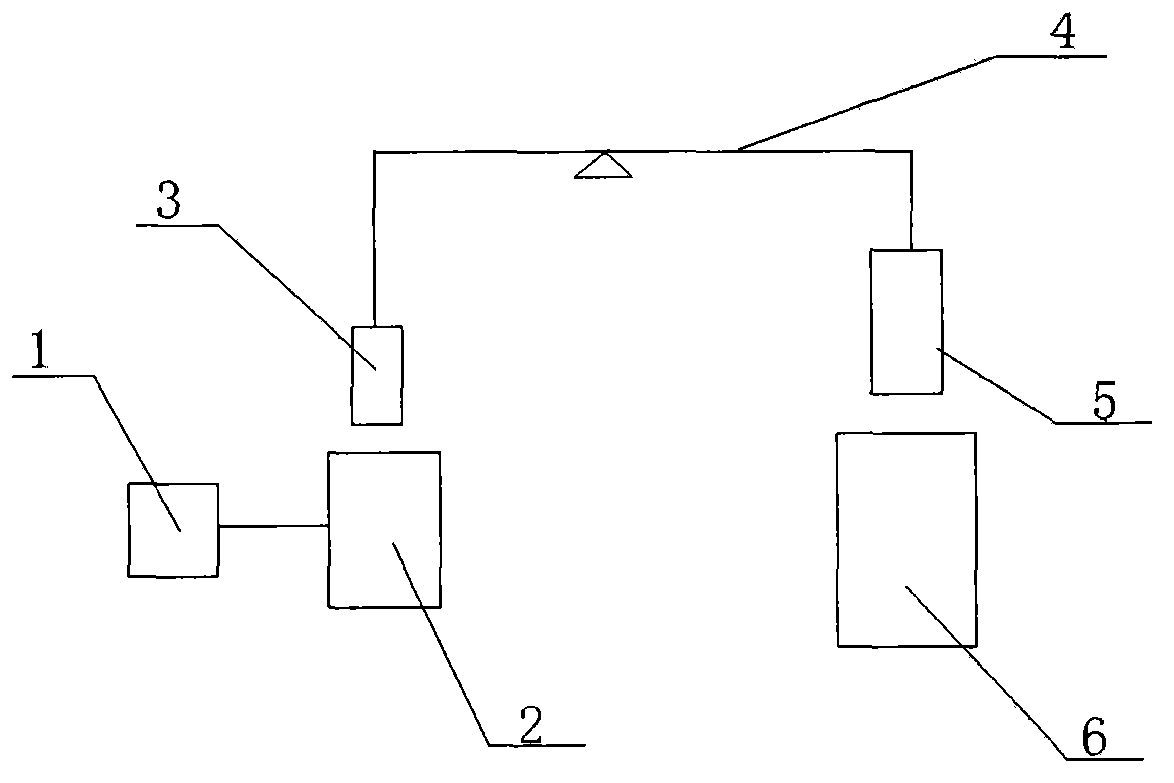

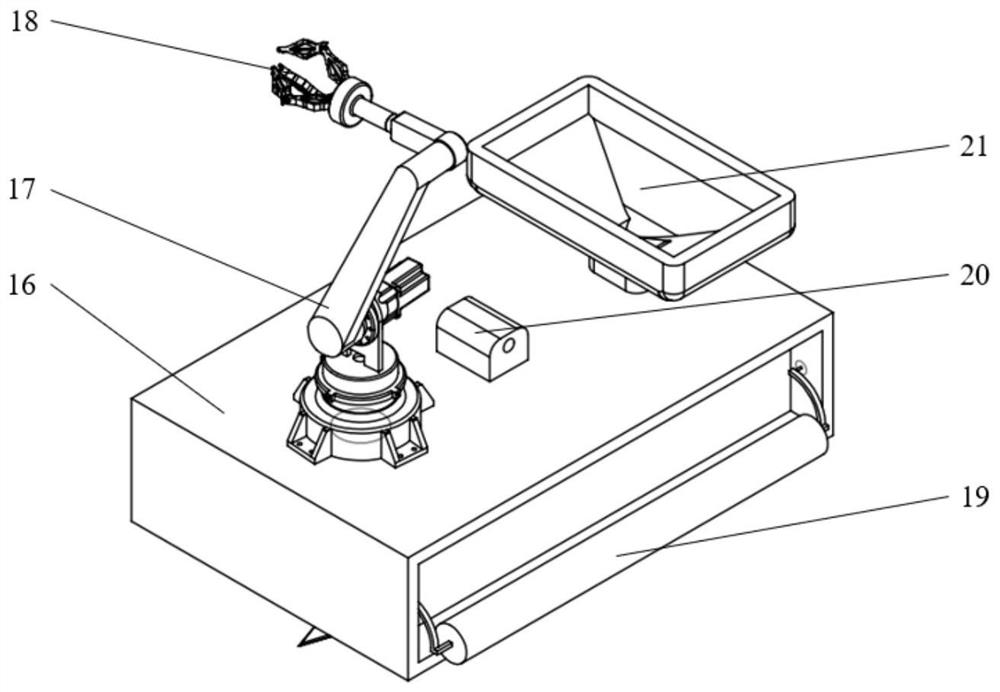

Grape and betel nut dynamic positioning and assembling mechanism and method

ActiveCN108147108AIncrease productivityReduce labor intensityConveyorsControl devices for conveyorsBetel nutsControl system

The invention relates to a grape and betel nut dynamic positioning and assembling mechanism and method. The grape and betel nut dynamic positioning and assembling mechanism comprises a feeding mechanism, a grape arrangement mechanism, a sensor, an intelligent grabbing and placing mechanical arm, a betel nut conveying mechanism, a vision localization module and a control system; the feeding mechanism is connected with the grape arrangement mechanism, the sensor is installed on the grape arrangement mechanism, the vision localization module is located above the betel nut conveying mechanism, andthe sensor, the intelligent grabbing and placing mechanical arm, the betel nut conveying mechanism, the vision localization module and the control system are connected. The invention further relatesto the grape and betel nut dynamic positioning and assembling method. as for the characteristics that coming materials of betel nuts and grapes are uncontrollable, and the shapes of the grapes are large in individual difference, multi-point-to-multi-point betel nut and grape assembling can be achieved through the mechanism and method, the production efficiency can be greatly improved, and the labor intensity and production cost are reduced.

Owner:HUNAN TENYUM INTELLIGENT EQUIP +1

Film forming powder for avoiding apple bagging, and preparation method and using method thereof

The invention discloses a film forming powder for avoiding apple bagging. The film forming powder comprises, by mass, 1.65-1.68% of starch, 3.81-3.85% of carboxymethylcellulose sodium, 6.65-6.75% of gelatin, 0.30-0.34% of sodium lauryl sulfate, 1.32-1.34% of fatty alcohol polyoxyethylene ether, 1.80-1.86% of nanometer titanium dioxide, 0.30-0.34% of boric acid, 0.02-0.03% of salicylic acid, 0.62-0.68% of methyl jasmonate, and the balance of water, and the sum of the mass fractions of the above components is 100%. The film forming powder has a preparation process, is convenient to use, and solves the problems of low bagging efficiency and high labor cost; the film forming powder makes apples sweet, fresh and crisp, and make the fresh-keeping time long; and films formed after spraying of thefilm forming powder onto fruit surfaces can be automatically degraded, and can absorbed by the fruit trees.

Owner:YANAN UNIV

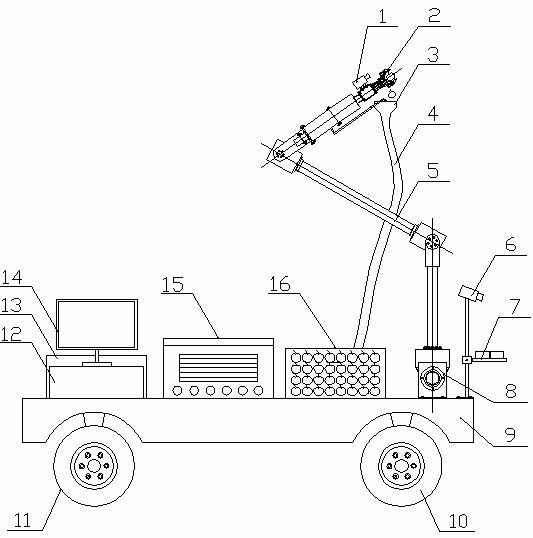

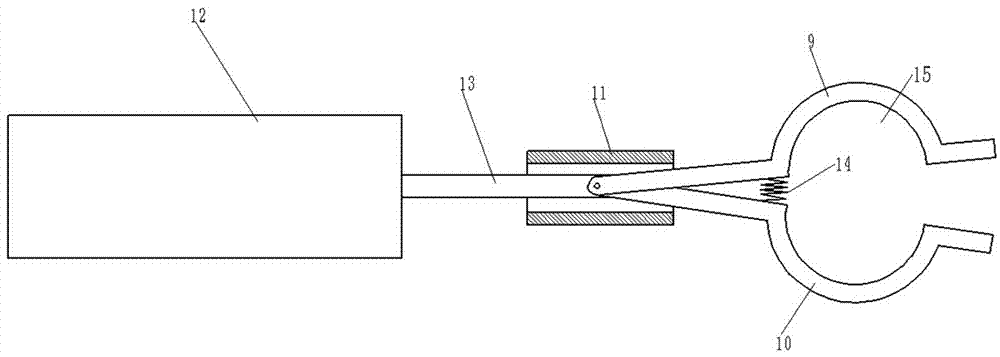

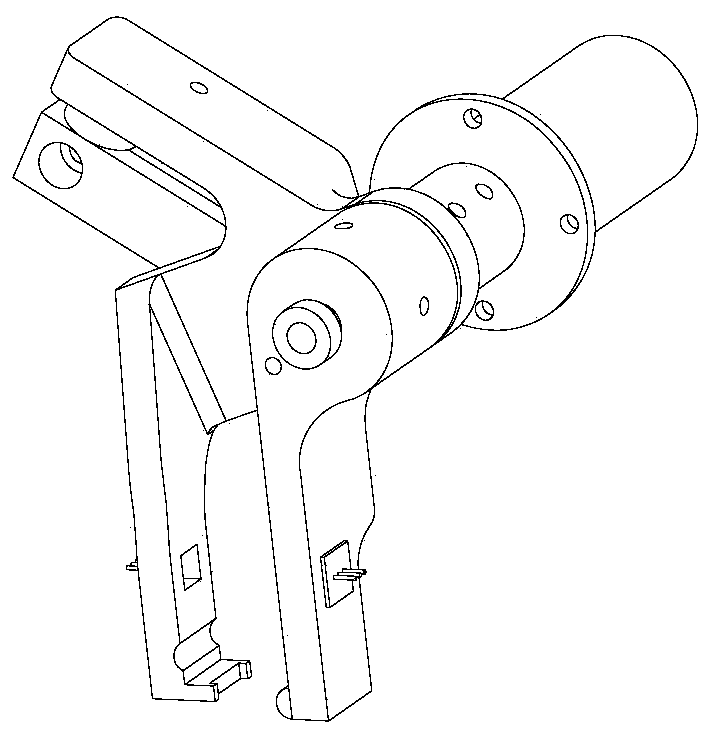

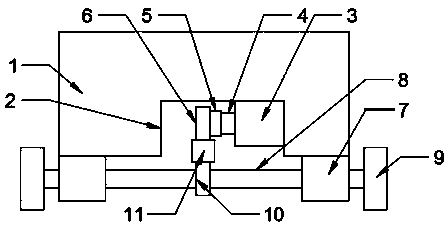

Wheel type mobile fruit picking robot and fruit picking method

InactiveCN102124866BReduce energy consumptionShorten speedProgramme-controlled manipulatorPicking devicesUltrasonic sensorData acquisition

The invention discloses a picking method and picking robot device aiming at fruits which are in size of an apple and is similar to a sphere. The picking robot device comprises a mechanical actuating device, control system hardware and control system software. The mechanical actuating device comprises a picking mechanical arm, an underactuated manipulator, an electric sliding table and an intelligent mobile platform, wherein the control system hardware comprises an IPC (industrial personal computer), a motion control card, a data acquisition card, an AHRS (attitude and heading reference system), a coder, a monocular camera, a binocular camera, a force sensor, a slipping sensor and the like. During operation, the IPC fuses information of the coder, the AHRS, monocular camera components and an ultrasonic sensor to enable the mobile platform to independently navigate and avoid obstacles. A binocular vision system collects images of mature fruits and obstacles and extracts the characteristics of the images so as to realize obstacle avoidance of the mechanical arm and fruit positioning. Finally, the IPC fuses the information of the force sensor, the slipping sensor and the position sensor, thereby further reliably gripping the mature fruits and separating the fruits from fruit branches.

Owner:NANJING AGRICULTURAL UNIVERSITY

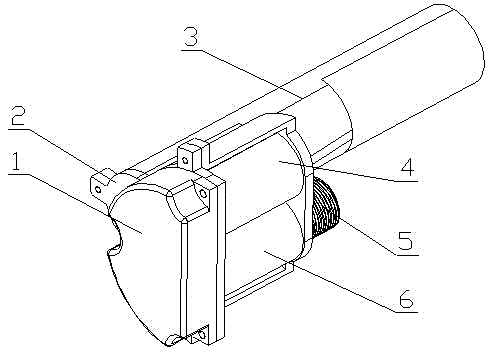

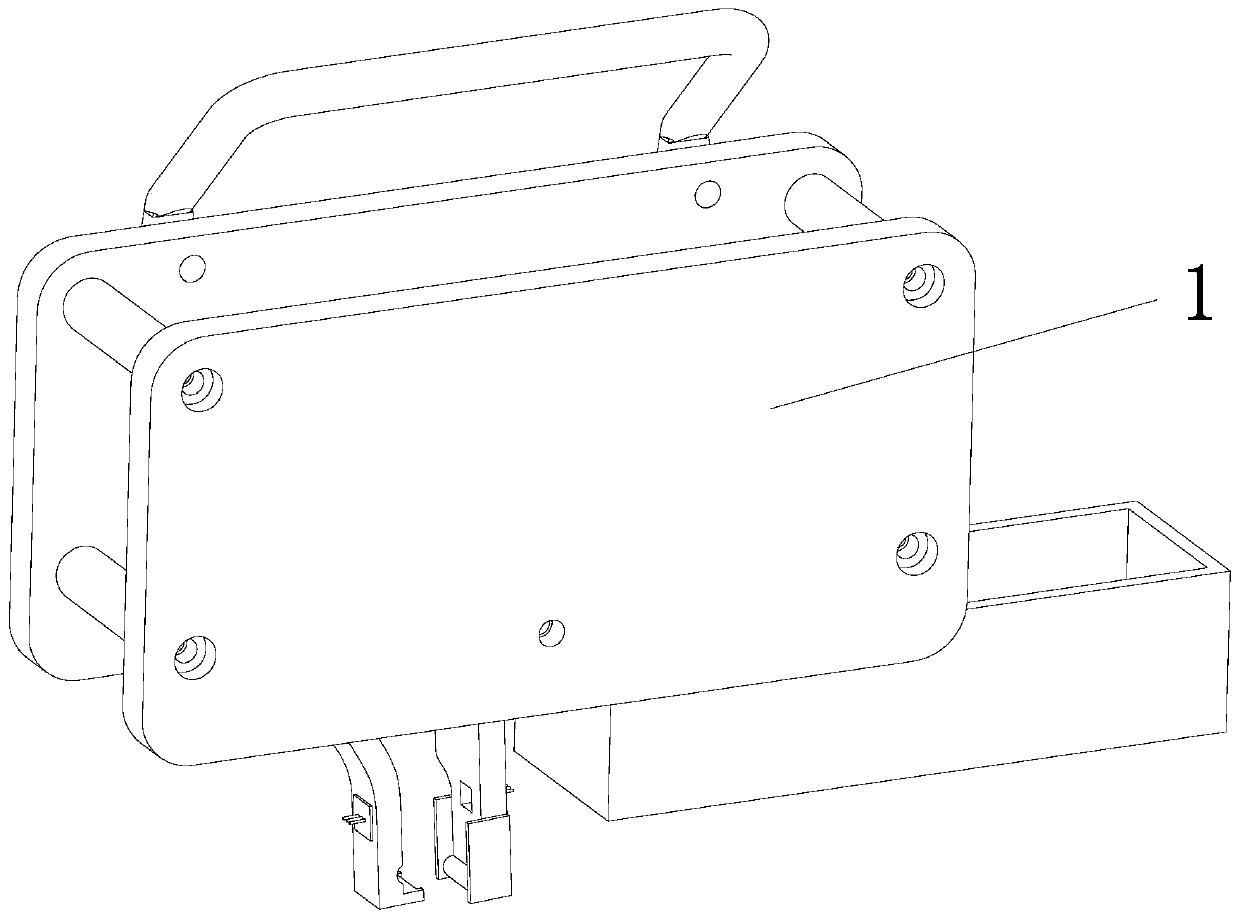

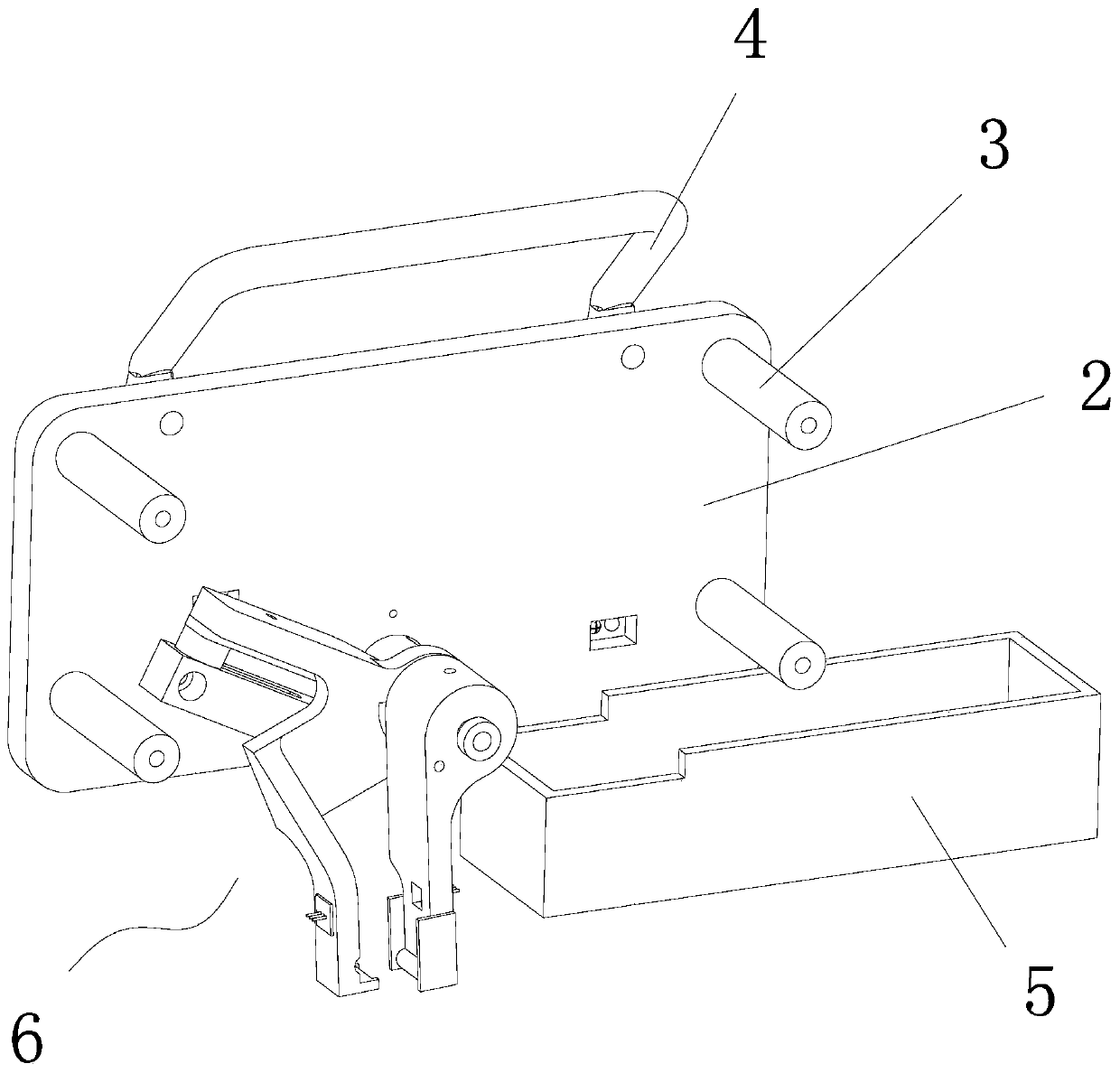

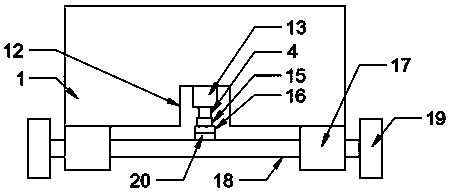

Portable harvesting holding mechanism of carthamus tinctorious harvester

InactiveCN104855043AReduce weightHandy for easy operationPicking devicesEngineeringMechanical engineering

The invention relates to a portable harvesting holding mechanism of a carthamus tinctorious harvester. The portable harvesting holding mechanism of the carthamus tinctorious harvester is characterized in that the mechanism comprises a protective cover, a supporting plate, a handle, a driven rubber roller, a flexible shaft connecting piece, a driving rubber roller, a square transmission shaft, a driven gear shaft, bearing embedded sleeves, a driven gear, a driving gear and bearings; the rear side of the handle is connected with a draught fan of the carthamus tinctorious harvester, the protective cover and the supporting plate are arranged at the front end of the handle, and fastening screws are used for fixing and locking; the square transmission shaft, the driven gear shaft, the bearing embedded sleeves, the driving rubber roller, the driven rubber roller and the flexible shaft connecting piece are sequentially mounted in the handle; the driving rubber roller is mounted on the square transmission shaft, the driven rubber roller is mounted on the driven gear shaft, and the square transmission shaft is connected with a flexible output shaft of the carthamus tinctorious harvester so that power can be supplied to the entire mechanism; the driving gear and the driven gear are mounted at one end of the square transmission shaft and one end of the driven gear shaft respectively, square keys are used for fixing, and the two gears are meshed with each other.

Owner:SHIHEZI UNIVERSITY +1

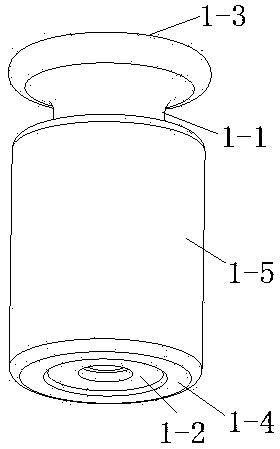

Full-automatic weight polishing device and polishing method

ActiveCN104002224AIncrease productivityRealize fully automatic productionPolishing machinesGrinding work supportsMotor driveEngineering

The invention relates to a full-automatic weight polishing device and polishing method. The polishing device comprises a machine frame, a wheel locating mechanism, a press wheel locating mechanism, a weight top face polishing mechanism, a weight bottom face polishing mechanism and a weight side face polishing mechanism, and all the mechanisms are arranged on the machine frame. A weight is placed on two wheels matched with arc grooves of the weight, the arc grooves are used for axially locating the weight, a press wheel is driven by a cylinder to extend out to press the weight and locate the weight in the radial direction, a motor drives the wheels to rotate, and the weight is driven to rotate through friction force. Four polishing wheels, namely a top face polishing wheel, a bottom face polishing wheel and two side face polishing wheels, are arranged in front of, behind, on the left and on the right of the weight respectively to polish the top face, the bottom face and the side faces of the weight. By means of the polishing device, all surfaces of the weight can be polished on one station, the weight does not need to be taken down in the polishing process, a mechanical hand is used for grabbing materials to achieve feeding and discharging, and continuous, stable and efficient production of weights is achieved.

Owner:PENGLAI HONGMING MECHANICAL & ELECTRIC

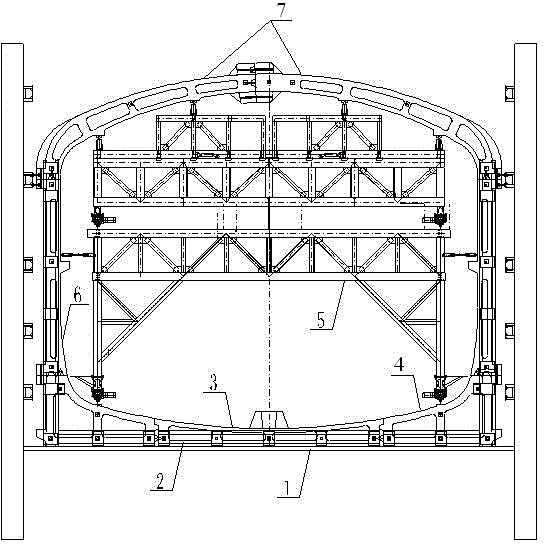

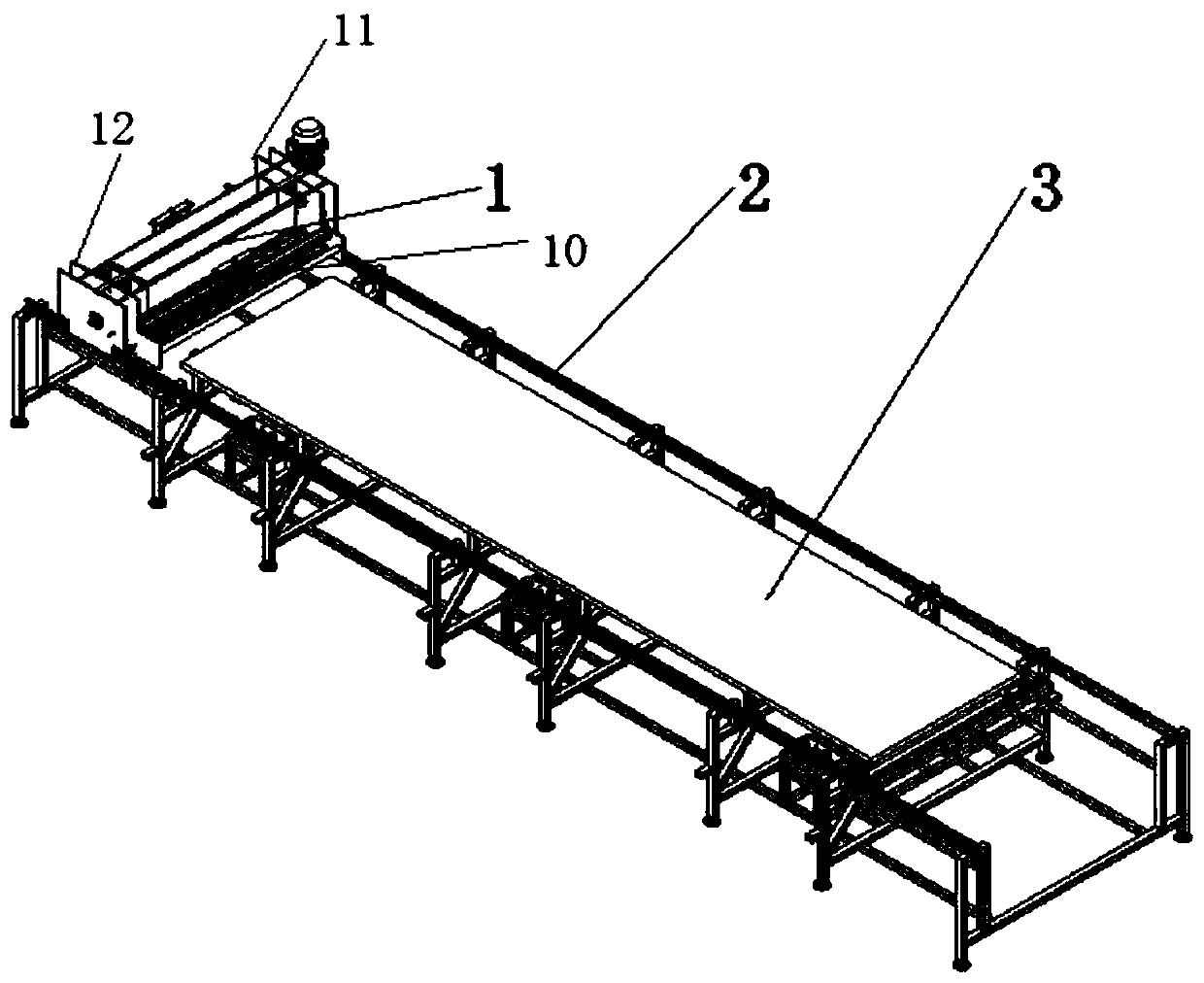

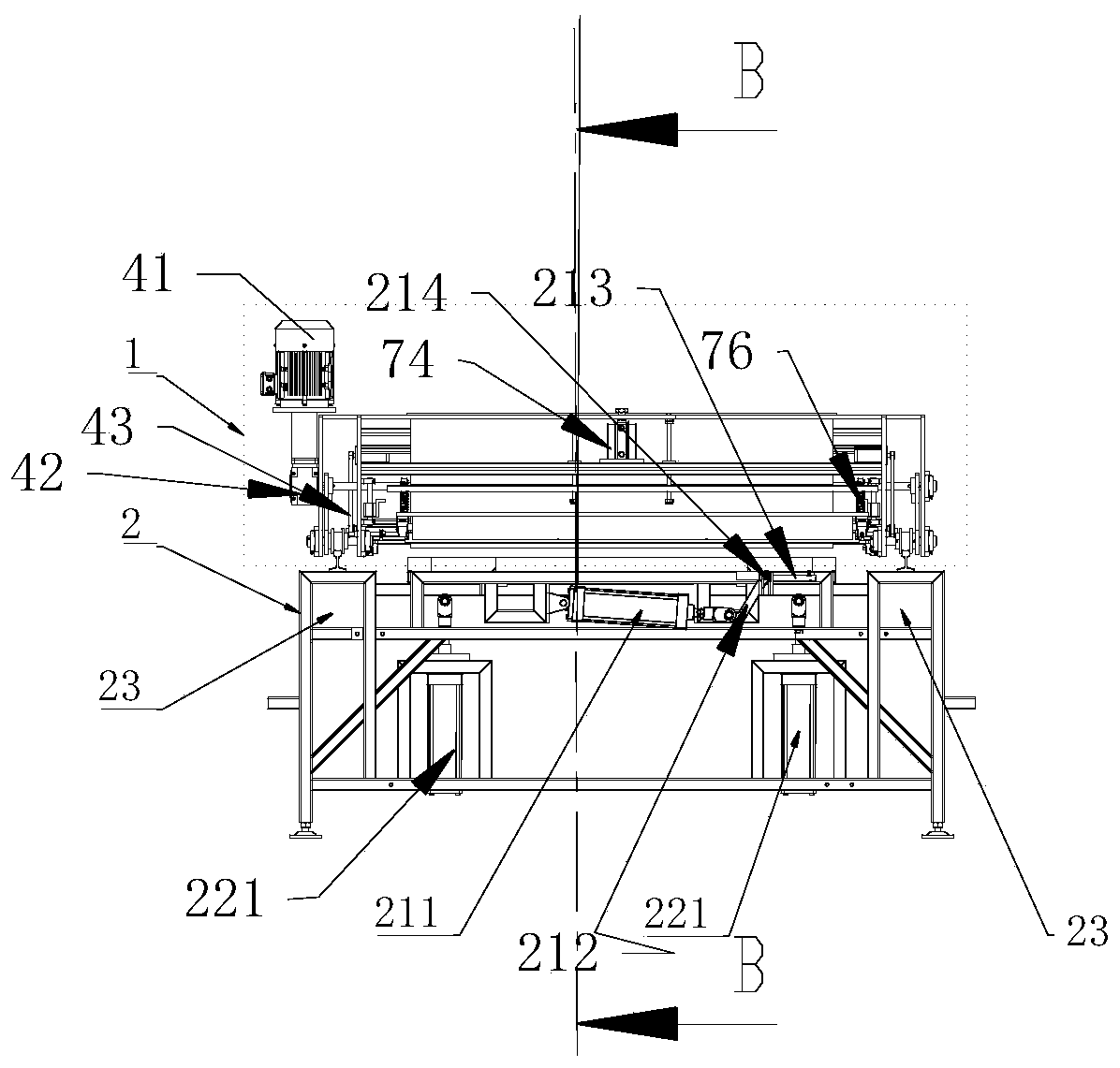

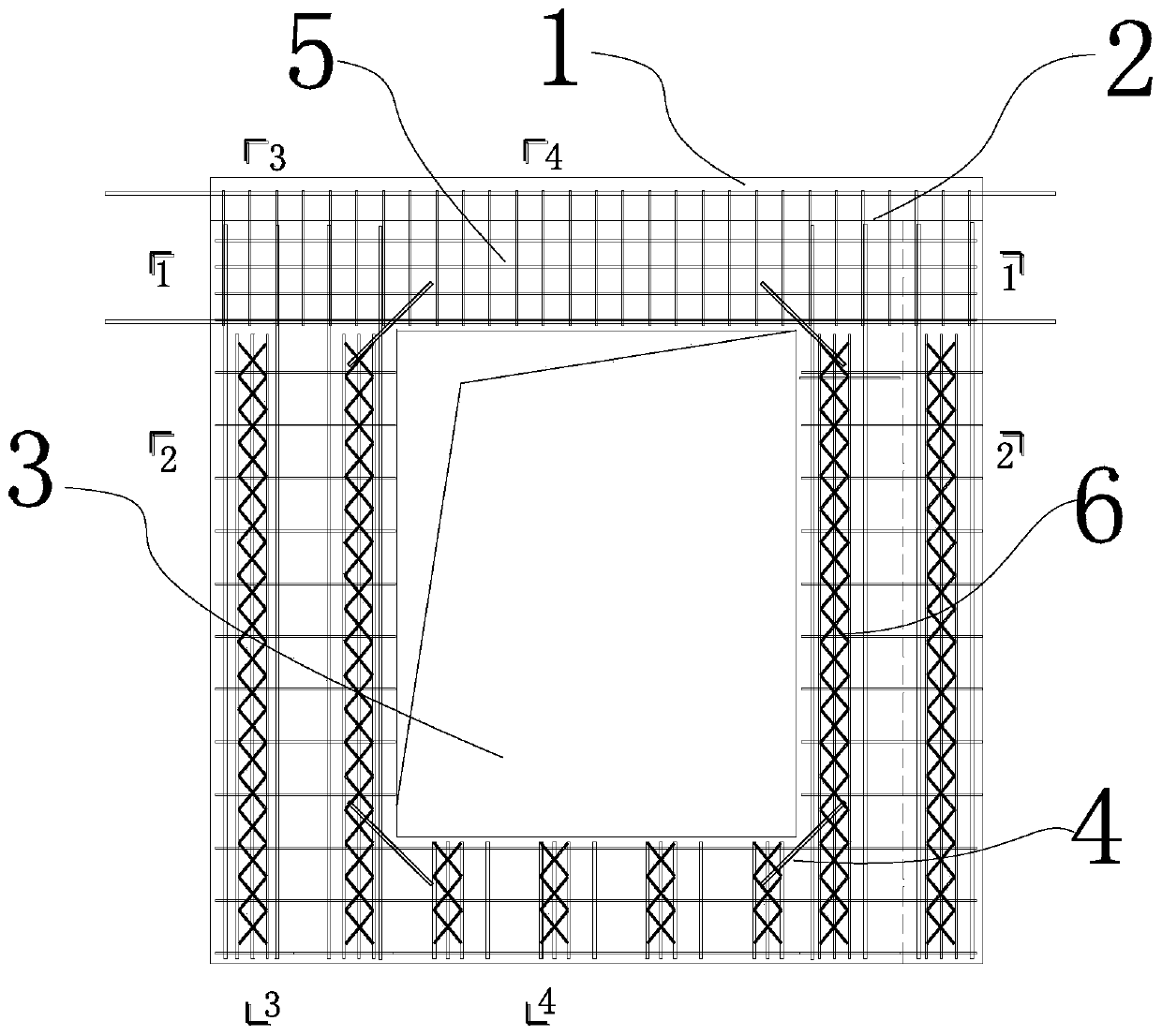

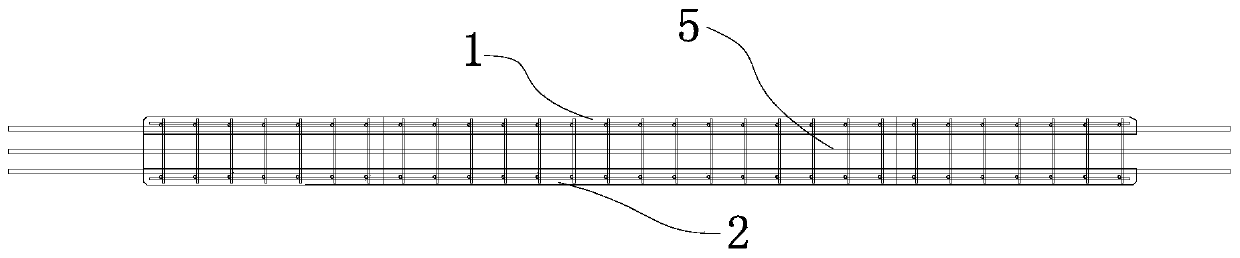

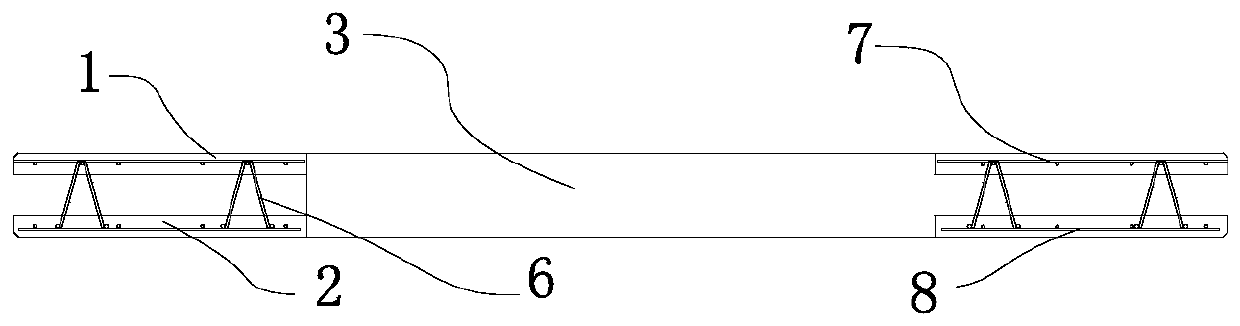

Automatic coating forming device and coating forming method for concentric-square-shaped supporting structural component

ActiveCN111016214ARealize automatic formingSolve labor shortageMechanical engineeringFiber structure

The invention discloses an automatic coating forming device for a concentric-square-shaped supporting structural component. The automatic coating forming device comprises a forming auxiliary frame anda moving support, wherein a wood mold is mounted on the upper surface of the forming auxiliary frame, guide rails are mounted on two sides of the forming auxiliary fame, the moving support is arranged on the guide rails to move in a spanning mode, the two ends of the moving support in the direction of the guide rail are respectively provided with a first mounting plate and a second mounting plate, a first mounting plate and a second mounting plate are mounted at the two ends of the moving support in the direction spanning the guide rails correspondingly, a driving device is mounted on the outer side of the first mounting plate, a pressing roller device, a feeding device and a laying device are sequentially mounted between the first mounting plate and the second mounting plate, so that theraw material laying and compacting are sequentially carried out, a clamping device is mounted on the forming auxiliary frame below the wood mold, ribbons before laying are clamped, after the liquid materials and the ribbons are laid down and completed, a first bending device and a second bending device are sequentially started, and forming of the concentric-square-shaped structure is completed. According to the automatic coating forming device and coating forming method, the complete automatic forming of the concentric-square-shaped fiber structural component can be realized, and the problemof insufficient labor force is fundamentally solved, and a single-direction coating process is adopted, so that a more smooth surface of the structural component is facilitated to be obtained.

Owner:JIANGSU UNIV OF SCI & TECH

Double-faced overlapped wallboard with hole, and production process thereof

The invention provides a double-face overlapped wallboard with a hole, and a production process thereof. The wallboard comprises an outer-vane wallboard and an inner-vane wallboard, wherein the hole is formed in the outer-vane wallboard and the inner-vane wallboard; a steel bar framework for casting a superposed beam in situ is arranged on the upper parts of the outer-vane wallboard and the inner-vane wallboard; and a steel bar truss is fixedly arranged between the outer-vane wallboard and the inner-vane wallboard. The production process comprises the steps of arranging a side formwork of theouter-vane wallboard through an automatic template setting device according to product side formwork data; sequentially arranging steel bar net slice, the steel bar truss and the steel bar framework,and distributing concrete; then placing in a curing kiln for curing; starting arranging a template and distributing concrete for the inner-vane wallboard, then entering a board turnover machine station, turning over and overlapping the cured outer-vane wallboard onto a wet wallboard of the inner-vane wallboard, and feeding into the curing kiln for curing; and finally demoulding through a tipping machine, and placing in a storage rack. According to the double-face overlapped wallboard with the hole provided by the invention, the labor intensity is reduced, the product quality and the productionefficiency are improved, and the enterprise production cost is reduced.

Owner:美好建筑装配科技有限公司

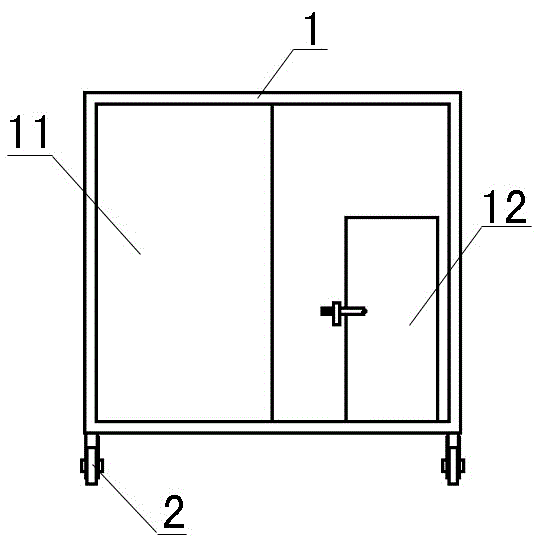

Mobile apricot mushroom growth room

PendingCN106718068ASolution areaSolve labor shortageCultivating equipmentsMushroom cultivationPleurotusGrowth room

A mobile apricot mushroom growth room comprises a box, moving wheels, a culture chamber, a control chamber and a mushroom frame. The mobile apricot mushroom growth room is characterized in that the box is made from a frame, a heat insulating material and an iron sheet; the box is divided into the culture chamber and the control chamber. The mobile apricot mushroom growth room has the advantages that culture of strain and material preparing, bagging, sterilizing, cooling and inoculation operation before inoculation are completed in a factory, hypha growth period and mushroom culture period are performed independently, the apricot mushroom is cultured by the aid of idle and uncultivated lands, farmers' courtyards, roadsides, sand and the like, problems about large occupation of arable land, lack of labor, too large land funds in centralized acquisition and the like are solved, scale production is easy to form, and economic development is mobilized for local farmers.

Owner:SHANXI KINGSHINE FERTILIZER

A molding binding device of firecrackers tube cake

The invention discloses a molding binding device of firecrackers tube cake, comprising a vertical feeding system, a loading molding system, a binding system and a control system. The beneficial effects of the molding binding device of firecrackers tube cake are lie in that(1) the arrangement, combination molding and binding of the firecrackers tube cake are completed in full-automation, the molding speed is fast, the binding is tight and the shape of the firecrackers tube cake is regular and beautiful; more than 300 firecrackers tube cakes can be finished per hour, which saves the human resources significantly, improves the work efficiency and solves the problem of labor shortage; (2) each part of the molding binding device is modular designed and installed, the size can be adjusted in accordance with the product, and the operation is convenient and the maintenance is fast; the abrasion of the contact site is low by employing a pneumatic roller structure, so that the device can be used for a long time without worrying about the precision to be effected.

Owner:浏阳市鸿隆综合贸易有限公司

Hybrid-rice seed production and pollination method by unmanned aerial vehicles

PendingCN108901830ASolve labor shortageSolve productivityAircraft componentsPlant genotype modificationPollinationAgroforestry

The invention discloses a hybrid-rice seed production and pollination method by unmanned aerial vehicles. The flying distance of the unmanned aerial vehicles with plants is 2-3 meters, the flying speed is 4-6 meters per second, and the flight spacing is 1.5-3.5 meters. The method has the advantage that the problems of shortage of labor force in hybrid-rice seed production, high scale and cost in large-scale production, and the like are solved, and the method can be widely applied to production.

Owner:成都大美种业有限责任公司

Lifting type bionic single tea bud picking machine

ActiveCN110839405AAchieve lossless pickingSolve labor shortagePicking devicesRotational axisControl engineering

The invention relates to the field of agricultural machinery. The technical scheme includes that a lifting type bionic single tea bud picking machine is characterized by comprising a supporting frame,a tea collection box and a tea picking mechanism, and the tea collection box is fixed in the supporting frame, and the tea picking mechanism is mounted on the supporting frame and comprises a motor,a rotating shaft, a driven finger, a driving finger, a reset shifting column, a pair of reflection photoelectric sensors, a clamping block and magnetic steel. The driven finger sleeves the rear end ofthe rotating shaft in a clearance sleeve manner and is provided with a metal plate; the driving finger is fixed to the rotating shaft and can be matched with the driven finger; the reset shifting column is fixed to the rear lateral side of the driving finger and inserted into a sector reset groove in the front lateral side of the driven finger; the reflection photoelectric sensors are fixed to left and right ends of a rear supporting plate respectively; the clamping block is fixed to the tail end of the driving finger; the magnetic steel is fixed to the rear supporting plate through a magnetic steel mounting plate and acts on the metal plate. The picking machine is capable of picking by simulating human hand action in single tea bud picking, loss picking of single tea buds is realized, and labor cost in tea picking operation is reduced.

Owner:ZHEJIANG SCI-TECH UNIV

Special weeding method for organic rice field

InactiveCN106212125AAddress labor shortagesEasy to controlPlant protectionRice cultivationOrganic acidGranularity

The invention relates to a special weeding method for an organic rice field. The convenient and effective control of weeds of organic rice is an urgent problem to be solved in the production process of organic rice. The special weeding method comprises the following steps of (1) grinding soybean into soybean meal with granularity less than 1mm; (2) applying 150-180kg of soybean meal per 667m<2> of organic rice field; after the soybean meal is applied, generating strong reduction reaction in water of the organic rice field, consuming a large amount of oxygen in water, enabling the oxidoreduction electric level at the soil surface to suddenly descend, hindering the weed root development and seed germination, and producing a large amount of organic acids to inhibit the weed rooting and bud grouting and damage weed core leaves, so as to reach the weeding effect; (3) timely applying within 3-5 days after rice transplanting, wherein the soybean meal is mainly used for removing the low-age weeds, and shall be timely applied after rice transplanting; in the applying process, the organic rice field shall be reserved with a water layer with thickness more than 5cm, and the water layer shall be maintained for more than 7 days. The special weeding method has the advantages that the technology is simple, and the weeds of organic rice can be conveniently and effectively controlled.

Owner:CHINA NAT RICE RES INST +1

Grinder

InactiveCN104069924AAddress labor shortagesImprove the economic and social efficiency of enterprisesGrain treatmentsTraditional Chinese medicineStart up

The invention discloses a grinder, and belongs to the field of traditional Chinese medicine processing equipment so as to reach the aim of improving the efficiency. The grinder comprises a medicine hammer, a mortar, a power supply, an electromagnet, an armature and a lever. During using, traditional Chinese medicines are put into the mortar; the power supply is started up; the electromagnet generates periodic attraction according to the set frequency; the lever drives the medicine hammer for performing striking by virtue of the armature, so that the traditional Chinese medicines are processed completely. According to the grinder, the problem of shortage of labor in manually grinding the traditional Chinese medicines in the prior art is solved; the number of workers is reduced, and the efficiency is improved, and the economical and social efficiency of enterprises is improved.

Owner:徐美玲

An intelligent production line capable of producing multiple varieties of standard pc components and a production process

ActiveCN108890850BRealize diversified productionReduce manufacturing costDischarging arrangementCeramic shaping plantsInformatizationPalletizer

The invention provides an intelligent production lines capable of producing standard PC components of multiple species and production process. Two intelligent production lines are arranged between anA shaft to a C shaft and between the C shaft to an E shaft respectively, are symmetric relative to the C shaft, and are installed between 1-28 axis of each span; each production line comprises a moldplacing device, a mesh bar processing device, a truss bar processing device, a material distribution machine, a turnover machine, a curing kiln, a stacker and a tipper. According to the production lines, three kinds of standard PC components of laminated slabs, superposed shear walls with no heat preserving function and superposed shear walls with a heat preserving function can be produced simultaneously by a single production line, and an information system is utilized to achieve whole process control of designing, producing and transporting to further reduce labor force. Only eighteen workers are needed to work on the intelligent production line in a working time period, the number of the workers is only one fourth of that of a traditional PC production line, current worker shortage is prevented, the labor intensity is reduced, the product quality and production efficiency are improved, and the production cost of enterprises is reduced.

Owner:美好建筑装配科技有限公司

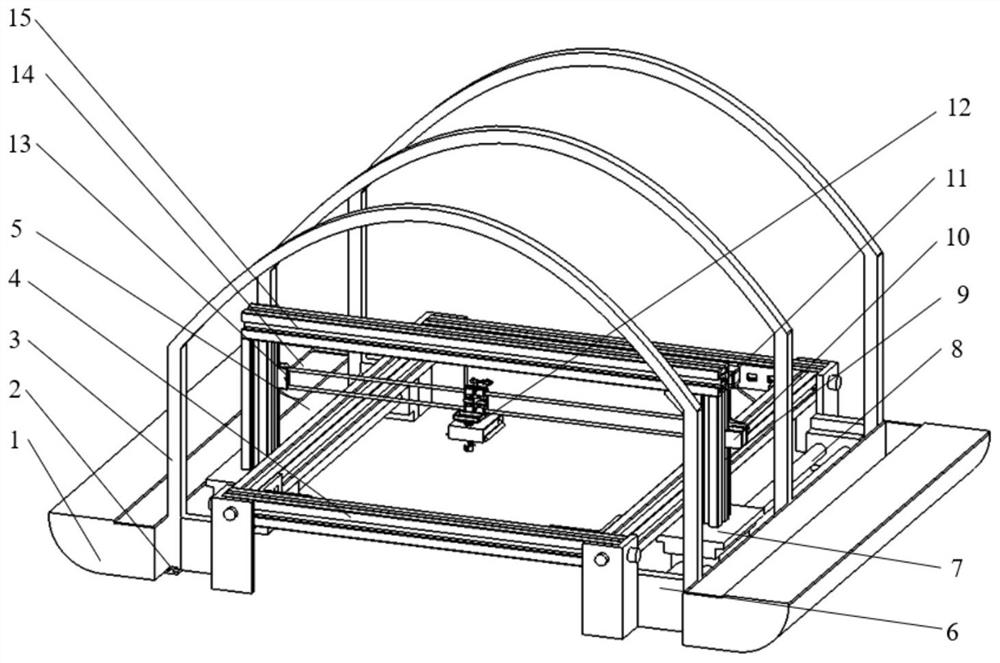

Suspension type omni-dimensional greenhouse operation system

PendingCN112753436ASimple structureStable structureSpadesClimate change adaptationAgricultural scienceGreenhouse

The invention provides a suspension type omni-dimensional greenhouse operation system, and belongs to the technical field of greenhouses. The system comprises a greenhouse, a rainwater collecting device, a ground rail, a square steel pipe, a suspension type guide rail module, an operation system, a control device and a power supply. The suspension type guide rail module comprises three sets of guide rails, three sets of servo motors and a stand column, so that omni-directional movement of the operation system in the space can be achieved, the operation system can achieve operation in any space and place, and damage to plants planted on the ground is reduced. The integrated operation system can achieve the functions of ploughing, sowing, weeding, irrigating, fertilizing, picking and the like, and is compact in structure. The suspension type omni-dimensional greenhouse operation system provided by the invention is reliable in structure, the operation system can move to any direction of the greenhouse, all work from starting of planting to final harvesting can be achieved, manpower constraint is avoided, the automation degree is high, the working efficiency can be improved, and more benefits can be obtained in the planting industry.

Owner:JIANGSU UNIV

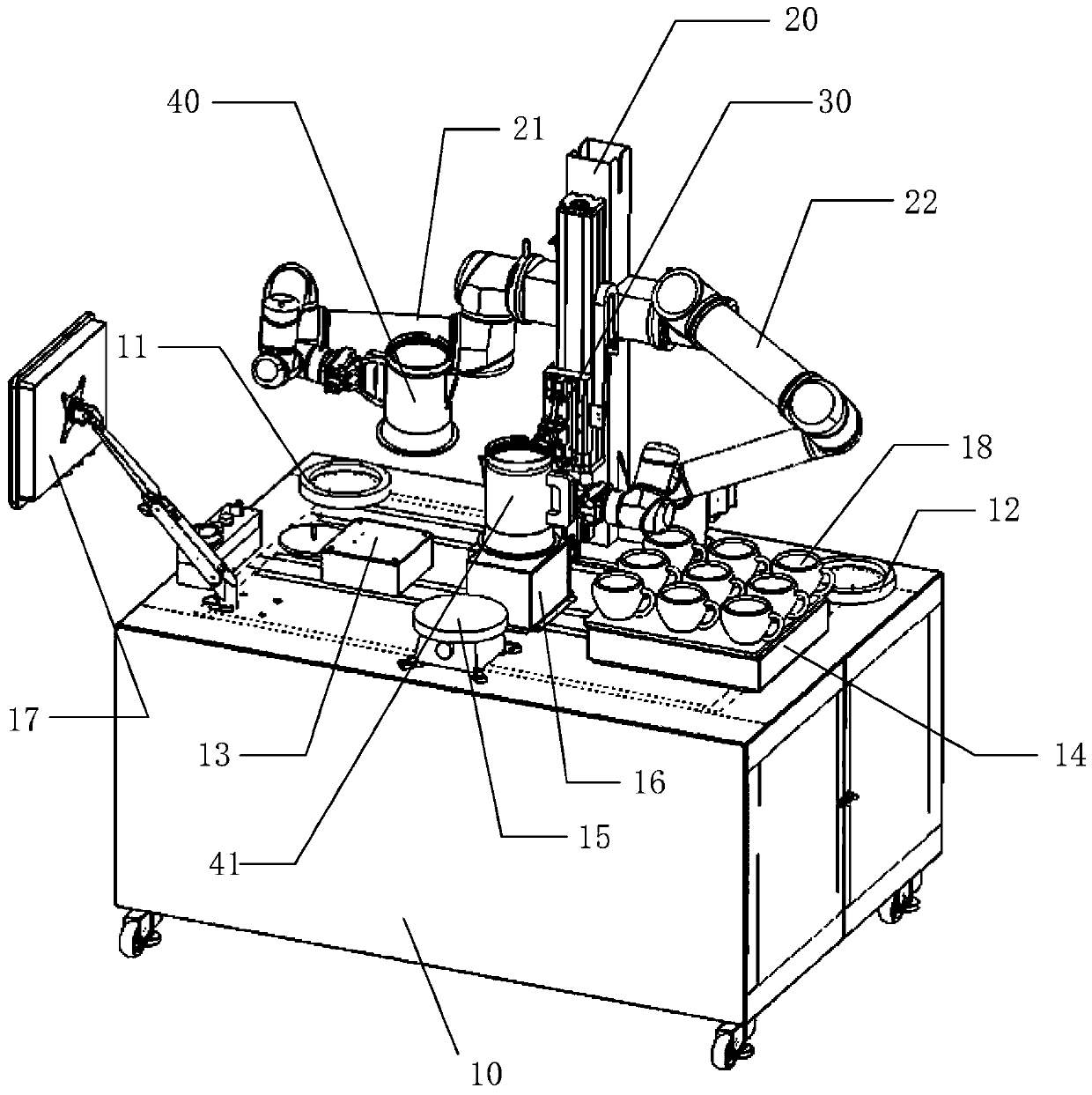

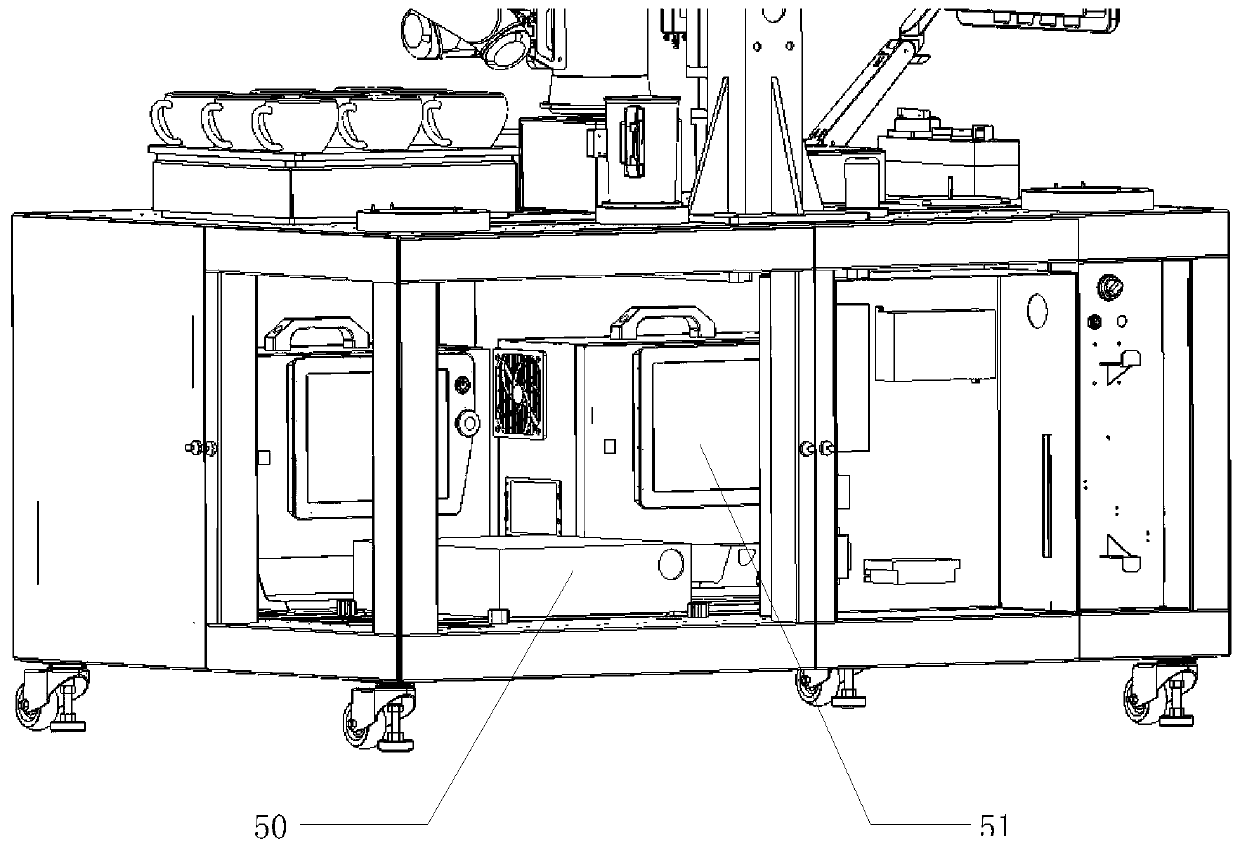

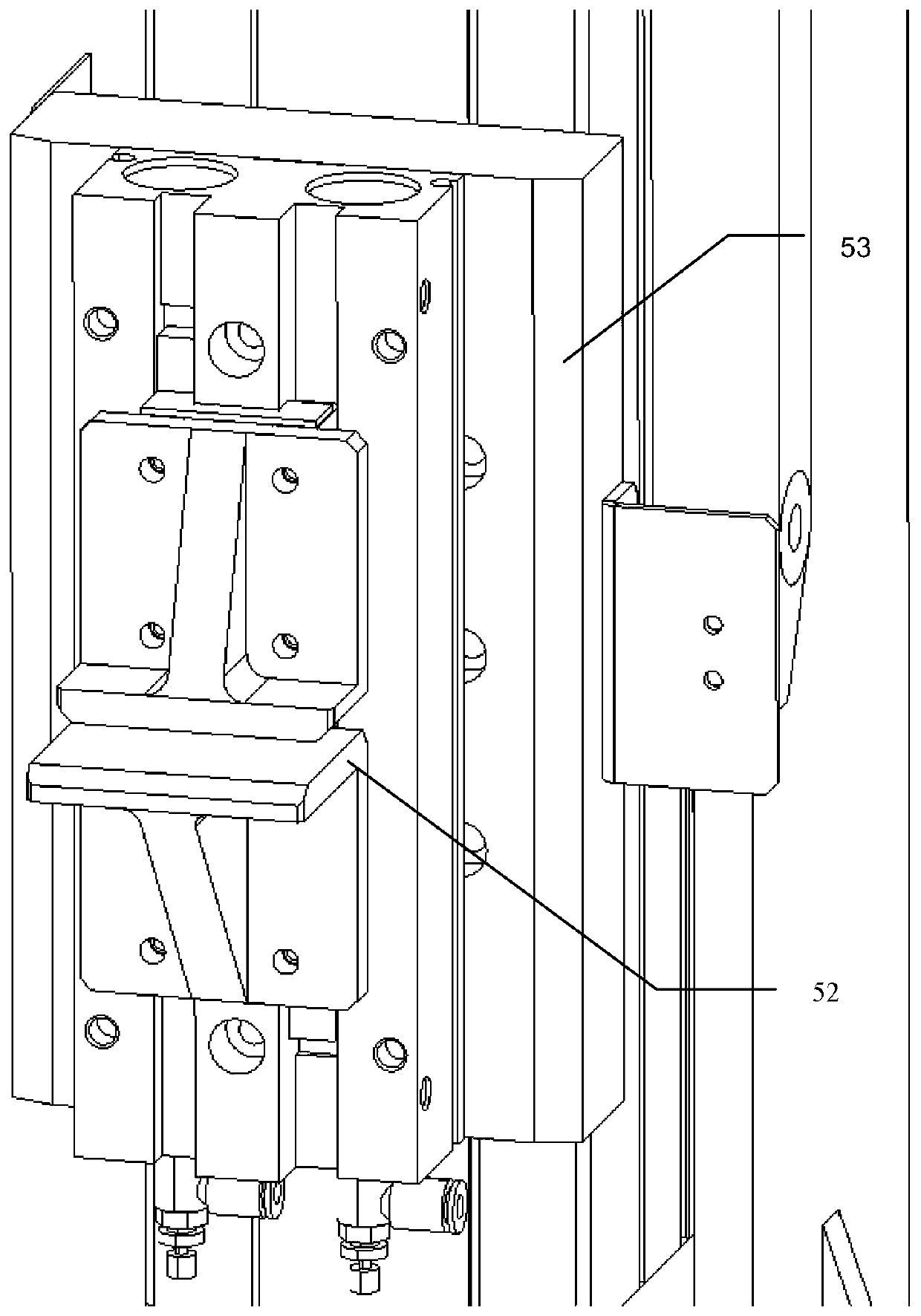

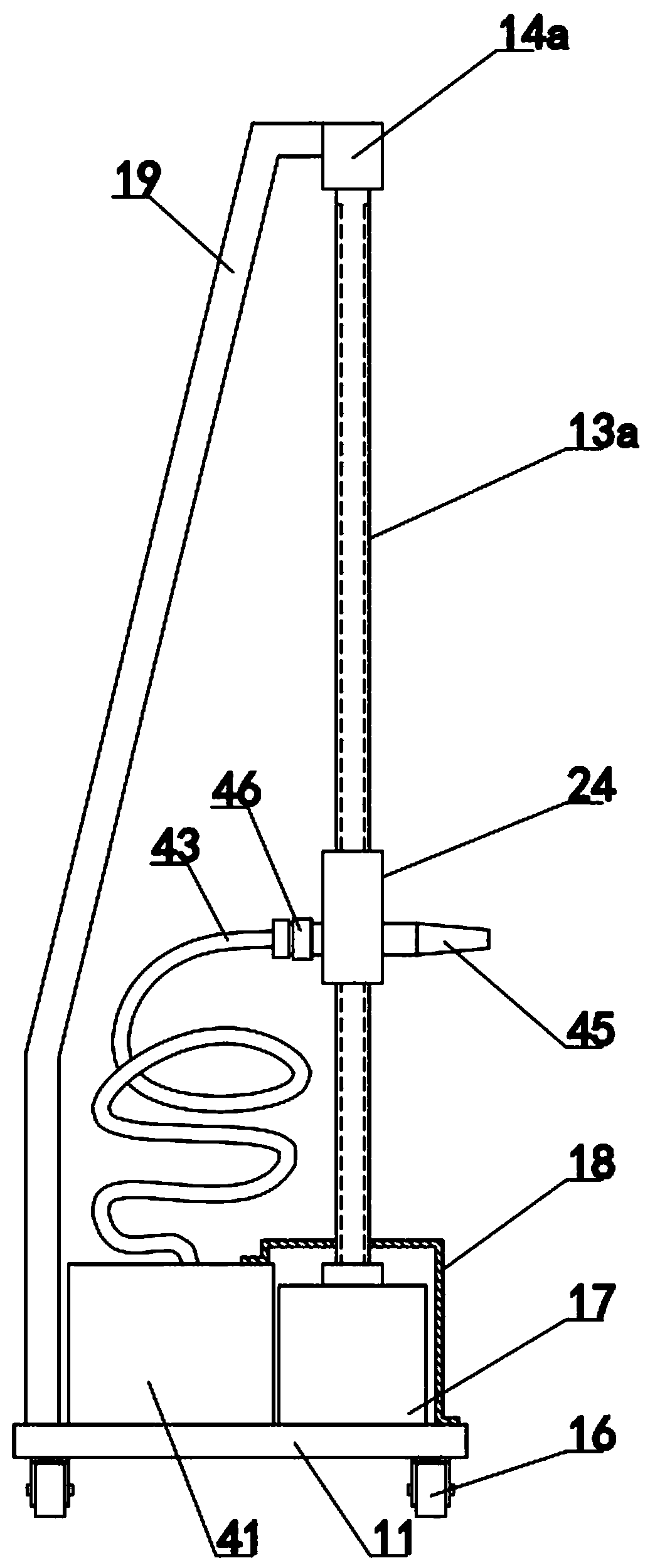

Intelligent robot for making Hong Kong style milk tea

The invention provides an intelligent robot for making Hong Kong style milk tea, which comprises a machine rack, an accommodating space is formed in the machine rack, an operating table is arranged onthe top surface of the machine rack, and the intelligent robot further comprises a bracket arranged on one side of the operating table; a first mechanical arm and a second mechanical arm which are arranged on the bracket; a tea separating mechanism which is arranged on the bracket in a manner of moving up and down; a first teapot and a second teapot which are arranged on the operation table and can be clamped and moved by the first mechanical arm and the second mechanical arm; a first electronic scale which is arranged on the operation table; a second electronic scale which is arranged on theoperation table, wherein at least one teacup is placed on the second electronic scale; an electric heating furnace which is arranged on the operation table; and an operation terminal which is arranged on the operation table, is provided with an operation interface and sends out an operation instruction. Therefore, the problems that the operation of the traditional milk tea preparation process still depends on manual operation and the production period, quality and precision cannot be ensured are solved.

Owner:HONG KONG PRODUCTIVITY COUNCIL +1

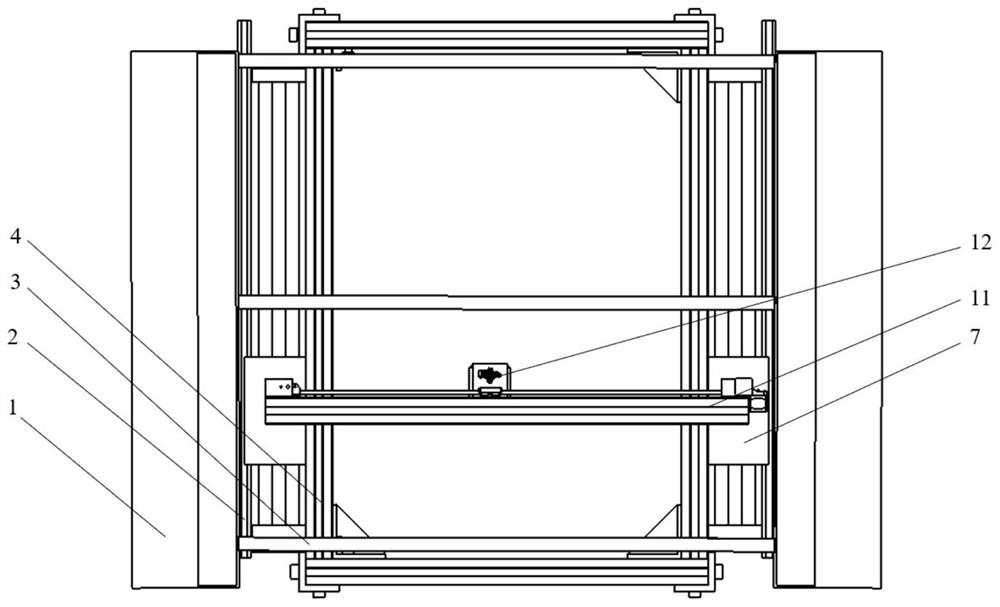

Wall cement mortar spraying machine

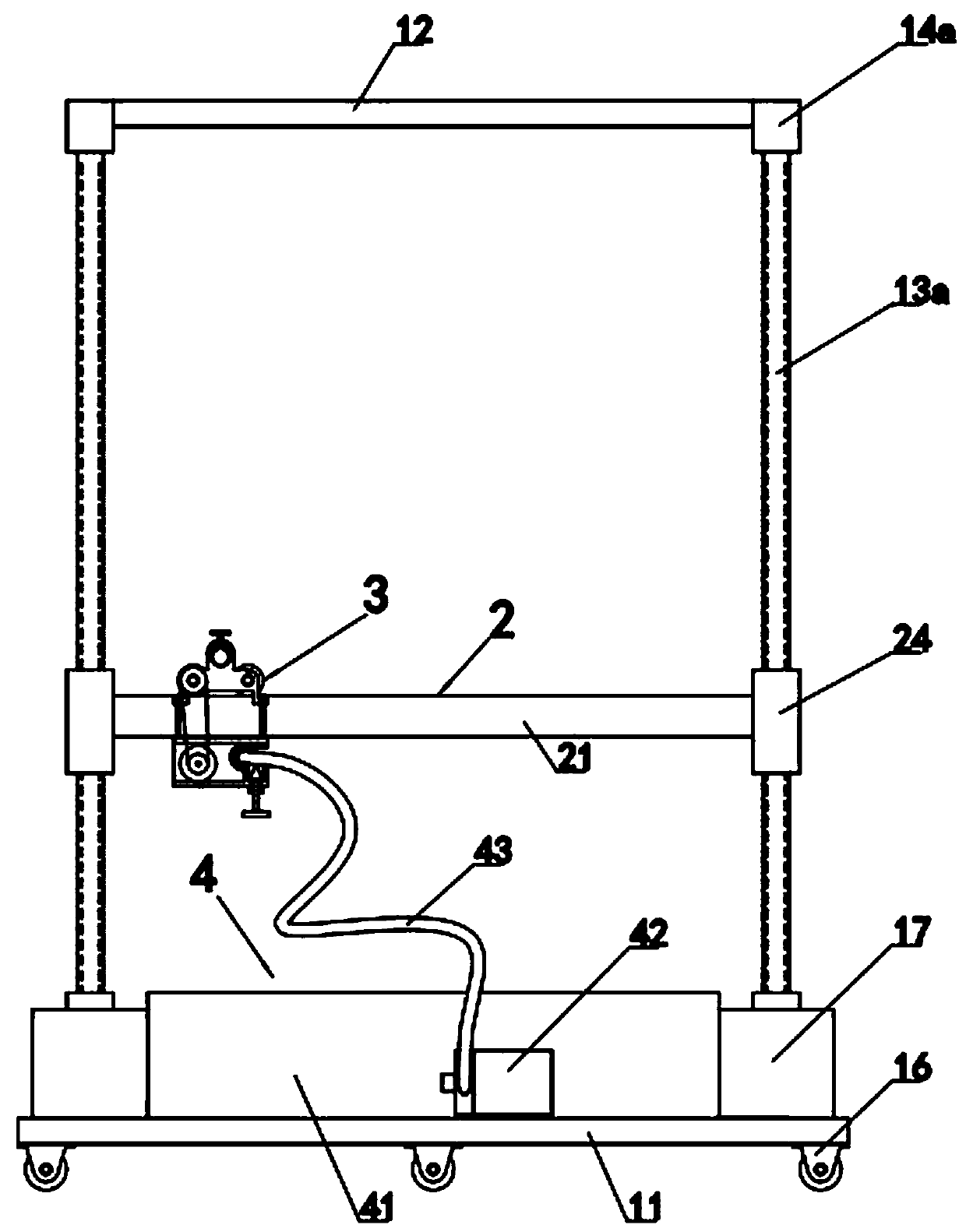

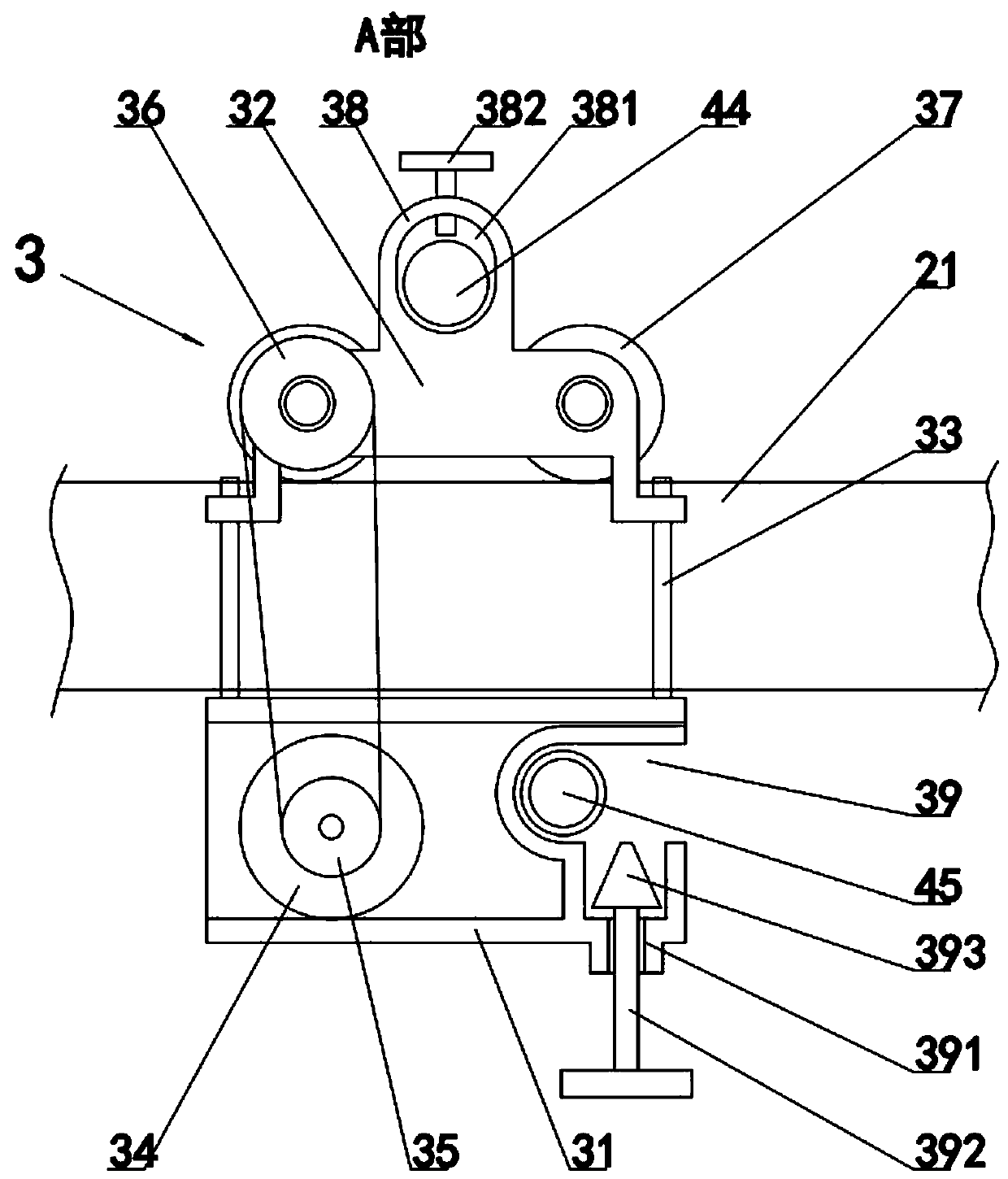

InactiveCN111335598ASolve vertical transportationReduce labor intensityBuilding constructionsCement mortarMechanical engineering

The invention discloses a wall cement mortar spraying machine. The wall cement mortar spraying machine comprises an outer frame, a lifting mechanism, a transversely-moving mechanism and a mortar spraying mechanism. The top ends of vertical screws a1 on the two sides of the outer frame are sleeved with upper rotary seats a2 correspondingly, the upper rotary seats a2 are fixed to the two ends of a top beam correspondingly, and the top ends of fixing rear frames on the two sides and the corresponding upper rotary seats a2 are fixed together. Nuts at the two ends of a cross beam of the lifting mechanism are mounted on the outer sides of the corresponding vertical screws a1 in a threaded manner. Transversely-moving rollers of the transversely-moving mechanism are supported on the upper side ofa sliding cross beam and can transversely walk, and the transversely-moving mechanism is provided with a pipe clamping mechanism. In the wall cement mortar spraying machine, mortar is directly sprayedto the surface of a structure through a pump, the problem about vertical transportation of the mortar is solved, manual mortar transportation and physical labor such as lime spoon lime delivery, supporting plate lime receiving and trowel plastering are removed, thus, the labor intensity of workers is greatly reduced, the working efficiency is improved, and a far-reaching influence is brought to building construction and management.

Owner:郑州宏拓电子技术有限公司

Bumble bee pollination seed production method of hot pepper cytoplasmic male sterile line

InactiveCN102783411ASolve labor shortageSimplify the pollination processPlant genotype modificationHorticultureBiologyPollination

The invention provides a bumble bee pollination seed production method of hot pepper cytoplasmic male sterile line, comprising the steps of raising seedling; preparing soil and paving mulching films; building a net room or shed room; transplanting male parents and female parents to the net room or shed room; putting the bumble bees to the net room or shed room at this time; regulating flower quantity, because the bumble bees are used for pollinating, the male parents produce lots of fruits, the development speed of the fruits is accelerated and then the pollen for the male parents is supplied insufficiently, thus removing the fruits of the male parents in time so as to increase flower quantity of the male parents. The method replaces the artificial pollination with the bumble bee pollination, so that the method solves the contradict between labor intensity and insufficient labor during the seed production of hot pepper male sterile, simplifies pollination process, achieves annual seed production scale of the seed production in the net room, the shed and sunlight greenhouse, enables the hot pepper male sterile seed production to be in large scale production and annual, and has a profound significance in research and development of the seed production technology of the hot pepper cytoplasmic male sterile line in our country.

Owner:BAOJI AGRI TECH PROMOTION SERVICE CENT

Intelligent automatic walking fruit picking device

InactiveCN108966841AReduce labor intensityReduce labor hazardsPicking devicesFixed bearingFixed frame

The invention discloses an intelligent automatic walking fruit picking device which comprises a movable base body. An automatic walking mechanism is arranged on the lower portion of the movable base body, an automatic picking mechanism is arranged on the upper portion of the movable base body, a fruit rolling and placing mechanism is arranged on the upper portion of the automatic picking mechanism, a power supply mechanism is arranged on the right side of the fruit rolling and placing mechanism, a controller is arranged on the upper portion of the movable base body, the automatic walking mechanism comprises a driving mechanism and a steering mechanism, the driving mechanism comprises a first groove, a first small rotating motor, a first coupler, a first fixed bearing, a first belt wheel, afirst roller fixed frame, a first rotating shaft, a first roller, a second belt wheel and a belt, the steering mechanism comprises a second groove, a second small rotating motor, a second coupler, asecond fixed bearing, a first gear, a second roller fixed frame, a second rotating shaft, a second roller and a second gear. The device has the advantages of simple structure and high practicability.

Owner:苏州智多搭智能科技有限公司

Strawberry clamping shear

InactiveCN110999636AAutomated ExtractionPrecision pickingImage analysisCharacter and pattern recognitionBiotechnologyFragaria

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com