Grape and betel nut dynamic positioning and assembling mechanism and method

A technology of dynamic positioning and assembling mechanism, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of pungent smell, different sizes, shapes and uncontrollable incoming materials in the production workshop, so as to solve the problem of labor force. The effect of shortage, lower production cost, lower labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

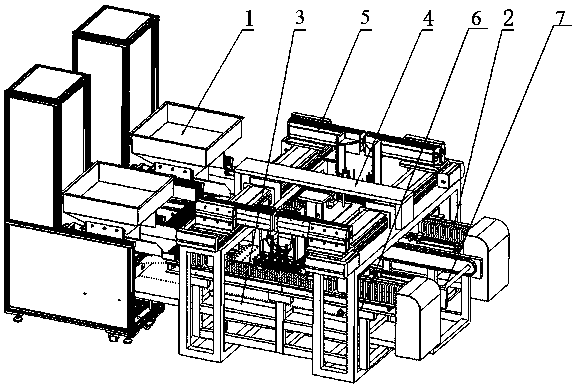

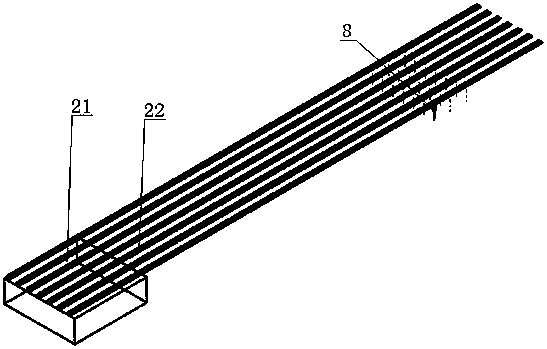

[0027] refer to figure 1 , a dynamic positioning and assembly mechanism for grapes and betel nuts, including a feeding mechanism 1, a grape arrangement mechanism 2, an optical fiber sensor 8, an intelligent pick-and-place manipulator 5, a betel nut transport mechanism 7, a visual positioning module 4 and a control system; The mechanism 1 is connected to the grape arrangement mechanism 2, the optical fiber sensor 8 is installed on the grape arrangement mechanism 2, the visual positioning module 4 is located above the betel nut delivery mechanism 7, the optical fiber sensor 8, the intelligent pick-and-place manipulator 5, the betel nut delivery mechanism 7. The visual positioning module 4 is connected with the control system.

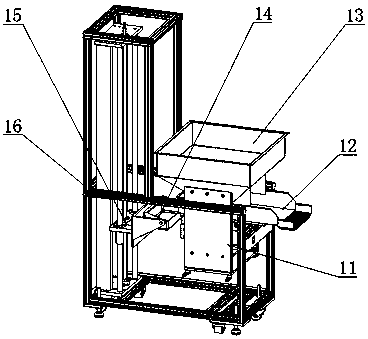

[0028] refer to figure 2 , the feeding mechanism 1 is a vibrating feeding mechanism, including a vibrator 11, a hopper 13, a surplus material collector 14, a lifting mechanism 15 and a support 16, and the vibrator 11, the hopper 13, and the lifting mech...

Embodiment 2

[0039] The difference between the dynamic positioning and assembly mechanism of grapes and betel nuts in this embodiment and the first embodiment is that a second visual positioning module is installed instead of the optical fiber sensor to carry out visual positioning and grasping of grapes.

[0040] The difference between the dynamic positioning and assembling method of grapes and betel nuts in this embodiment and that of Embodiment 1 is that the second visual positioning module is used to visually locate the grapes to complete the grabbing of the grapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com