Cast post-processing workshop-level production control system

A technology of production control and post-processing, which is applied in the direction of manufacturing tools, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of technical bottlenecks that cannot be effectively improved, imported 3D manipulators are expensive, and processing products are single. , to achieve the effect of solving simplification, saving labor costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings.

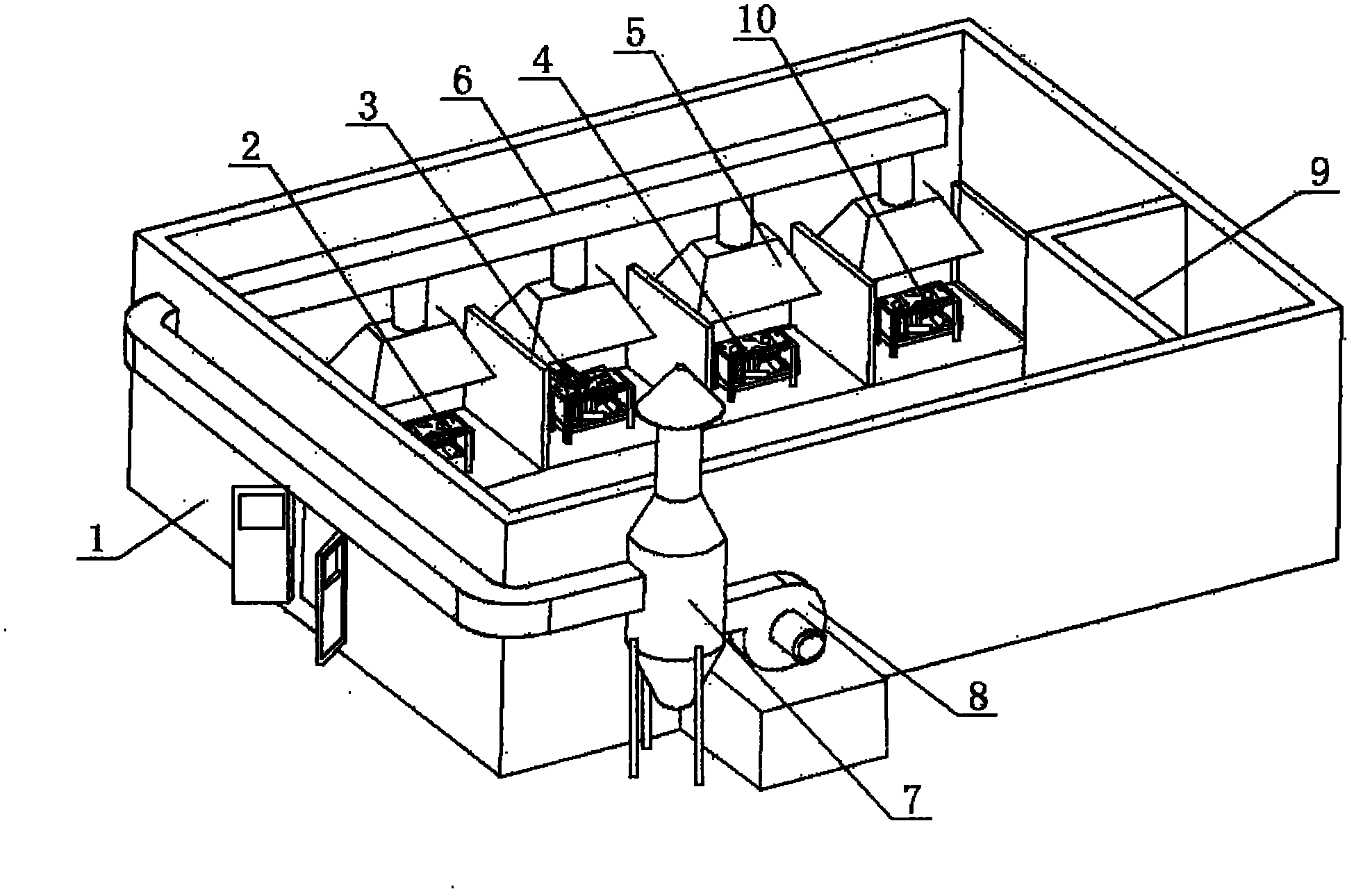

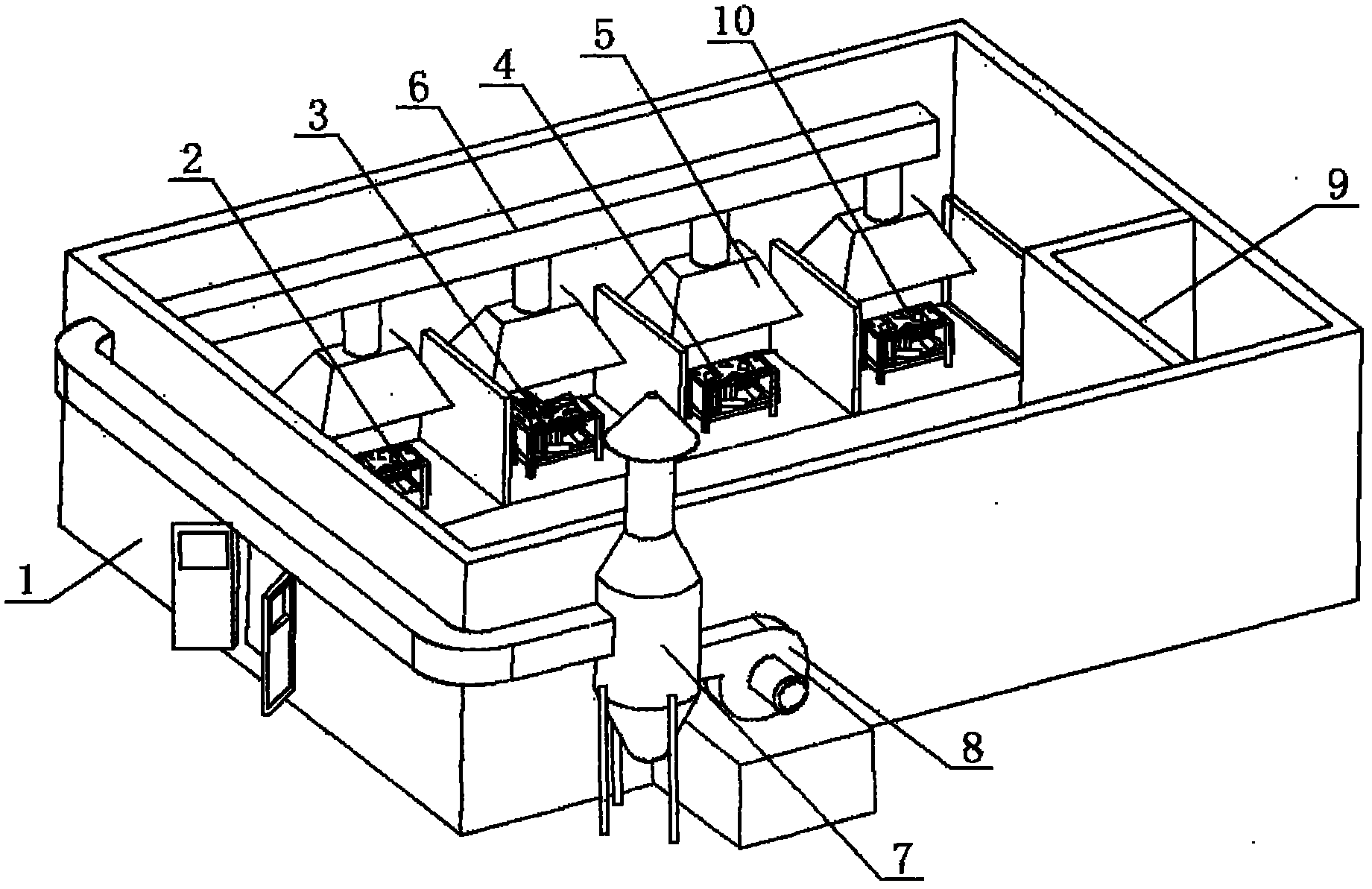

[0014] Such as figure 1 As shown, a level 1 production control system for post-processing workshop of castings, including workshop 1, multiple special grinding machines for industrial grade castings, multiple dust removal covers 5, dust collection pipes 6 and dust collection towers 7, and workshop 1 is equipped with multiple Each compartment is equipped with an industrial-grade casting special grinder, and the upper end of each compartment is equipped with a dust removal cover 5, the dust removal cover 5 is connected to the dust collection pipe 6, and the dust collection tower 7 is connected to the dust collection At the end of the pipeline 6, the dust collection tower 7 is provided with a dust collection fan 8.

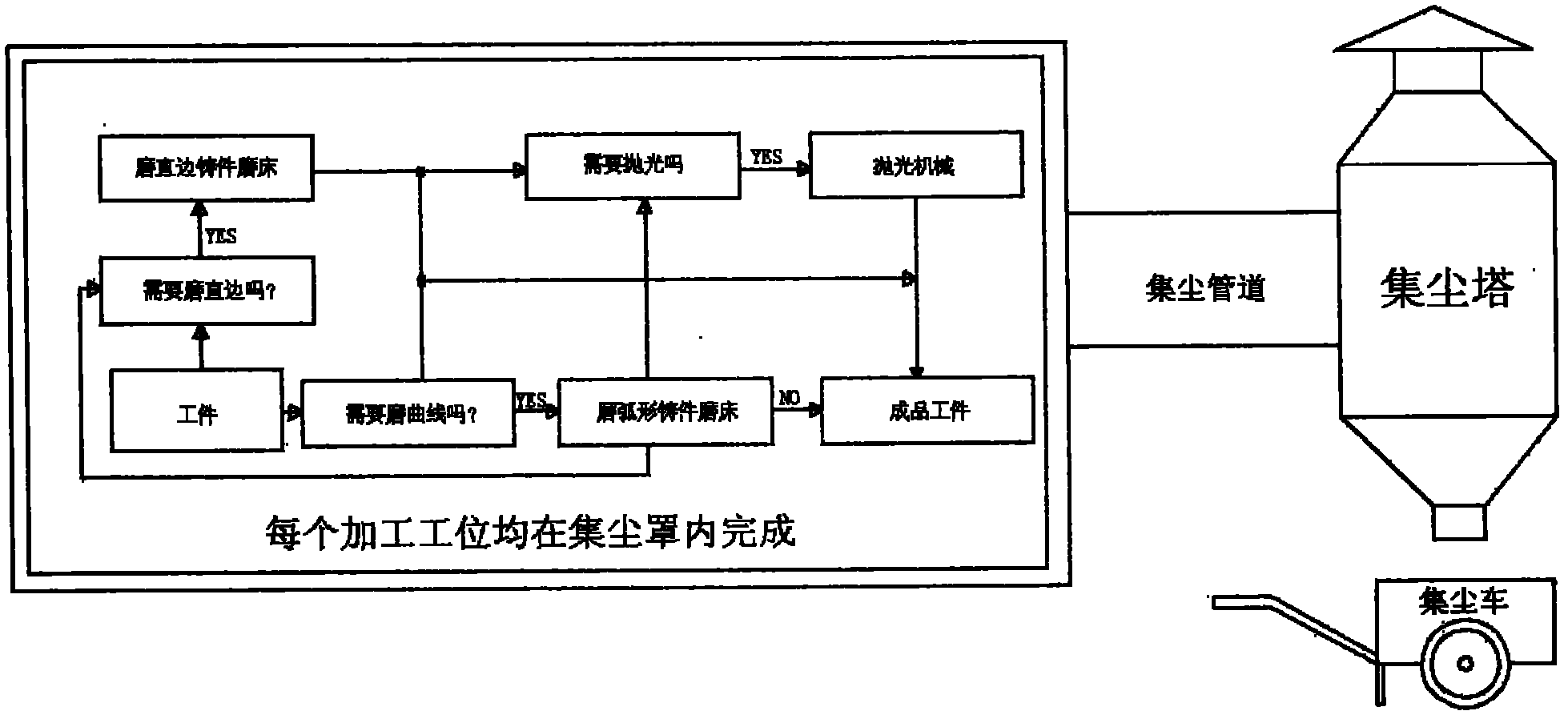

[0015] Among them, the special grinding machine for industrial-grade castings is the grinding machine 2 for grinding straight edge castings, the grinding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com