Intelligent production lines capable of producing standard PC components of multiple species and production process

A production line and multi-variety technology, applied in the direction of wire processing, wire mesh, manufacturing tools, etc., can solve the inability to fully achieve traceability of the production process, report management, remote management, enterprise ERP interactive docking, high energy consumption, and labor intensity major issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

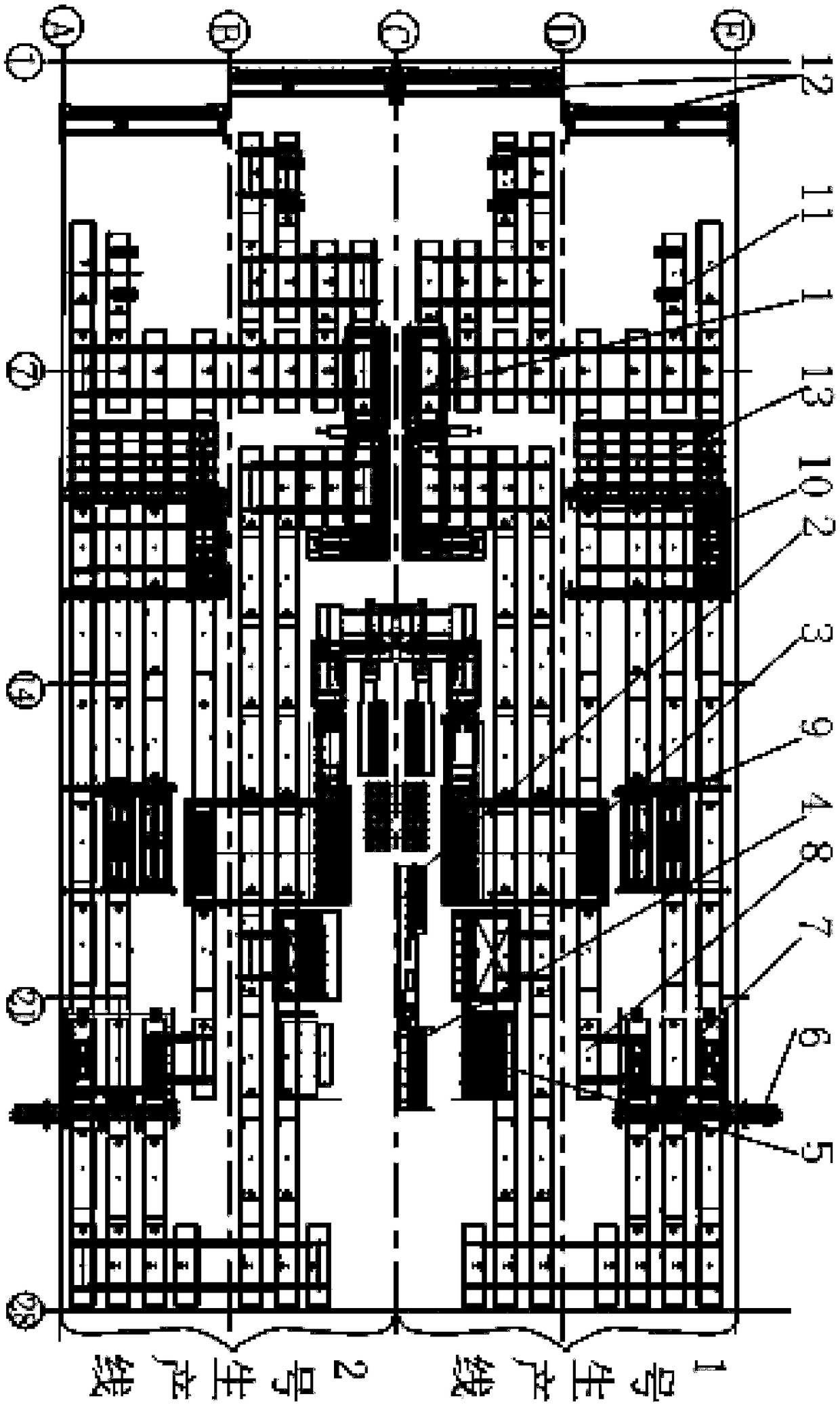

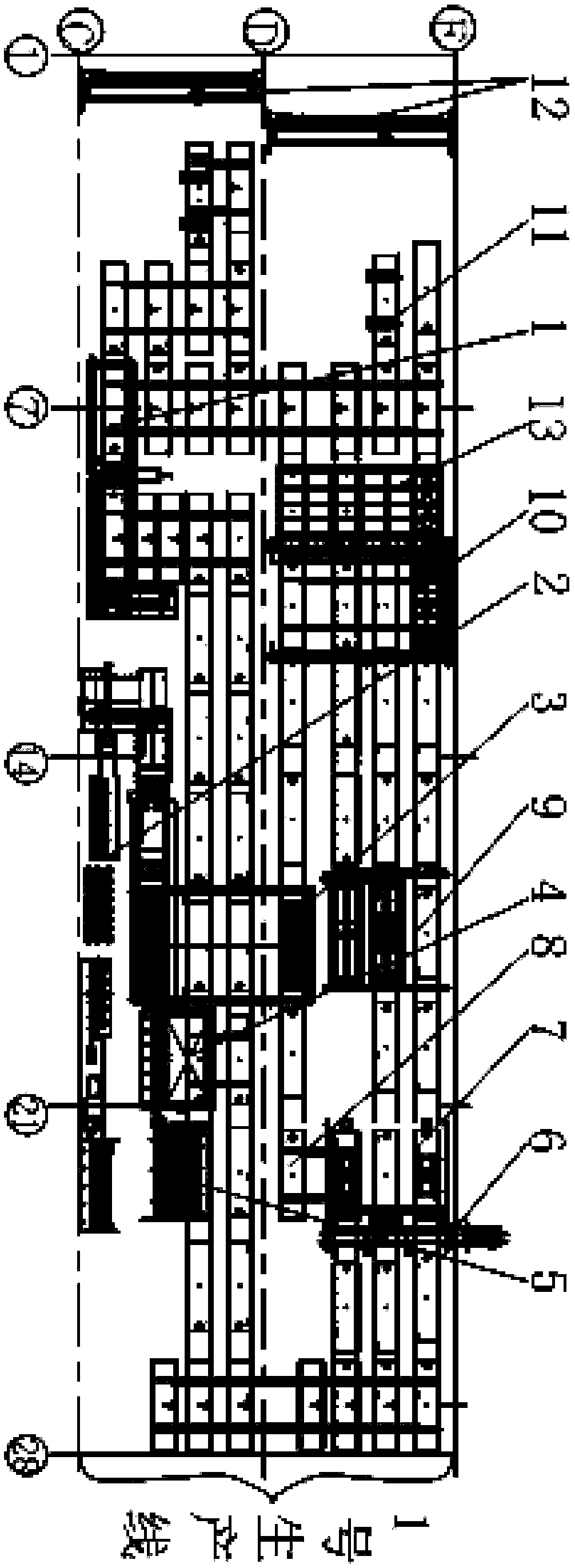

[0118] Embodiment one (laminated floor production):

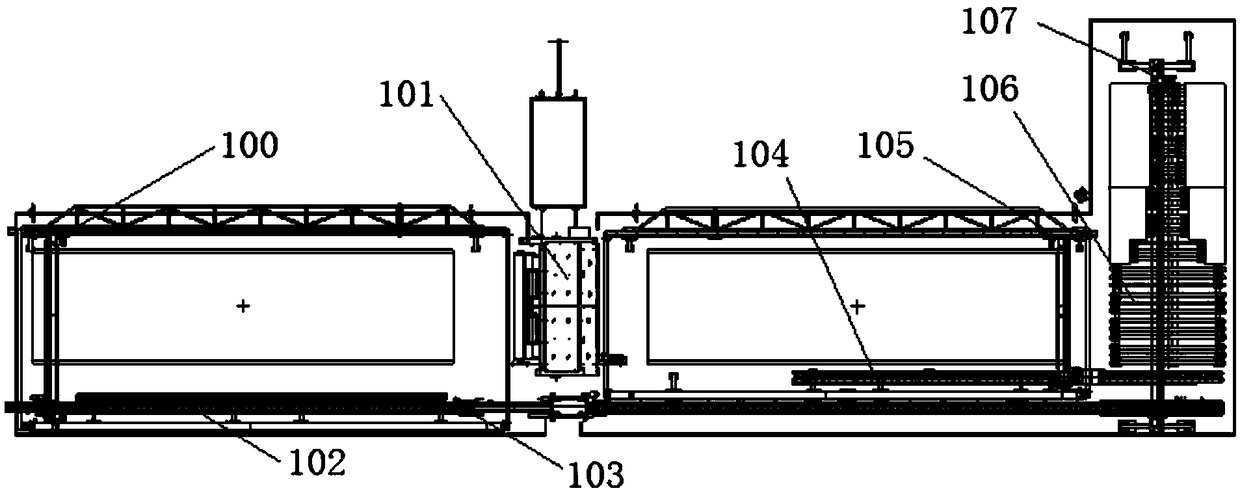

[0119] The empty mold table rotates to the mold setting device station, and the mold removal manipulator 100 automatically recognizes the position of the side mold through the machine vision device, and removes the side mold and transfers it to the side mold transmission track 102. When the side mold transmission track 102 passes through the side mold, it is automatically cleaned When the device 103 is installed, the side mold automatic cleaning device 103 completes the side mold cleaning, and the side mold continues to be transported to the side mold library 106 grabbing area along the side mold transmission track 102. The system automatically finds suitable vacant positions and sorts the side forms into storage. The empty mold table is transferred from the mold table station 1 to the mold table station 2, passing through the mold table automatic cleaning device 101 on the way, automatically completing the mold table clean...

Embodiment 2

[0120] Embodiment two (superimposed shear wall production):

[0121] The empty mold table rotates to the mold setting device station, and the mold removal manipulator 100 automatically recognizes the position of the side mold through the machine vision device, and removes the side mold and transfers it to the side mold transmission track 102. When the side mold transmission track 102 passes through the side mold, it is automatically cleaned When the device 103 is installed, the side mold automatic cleaning device 103 completes the side mold cleaning, and the side mold continues to be transported to the side mold library 106 grabbing area along the side mold transmission track 102. The system automatically finds suitable vacant positions and sorts the side forms into storage. The empty mold table is transferred from the mold table station 1 to the mold table station 2, passing through the mold table automatic cleaning device 101 on the way, automatically completing the mold tab...

Embodiment 3

[0123] Embodiment three (laminate shear wall with insulation board):

[0124] The empty mold table rotates to the mold setting device station, and the mold removal manipulator 100 automatically recognizes the position of the side mold through the machine vision device, and removes the side mold and transfers it to the side mold transmission track 102. When the side mold transmission track 102 passes through the side mold, it is automatically cleaned When the device 103 is installed, the side mold automatic cleaning device 103 completes the side mold cleaning, and the side mold continues to be transported to the side mold library 106 grabbing area along the side mold transmission track 102. The system automatically finds suitable vacant positions and sorts the side forms into storage. The empty mold table is transferred from the mold table station 1 to the mold table station 2, passing through the mold table automatic cleaning device 101 on the way, automatically completing the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com