Device and method for separating C9 fraction from byproduct of coal-based MTP (methanol-to-propylene) process

A technology of methanol to propylene and separation device, which is applied in distillation purification/separation, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc. The effect of converting added value to coal and extending the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

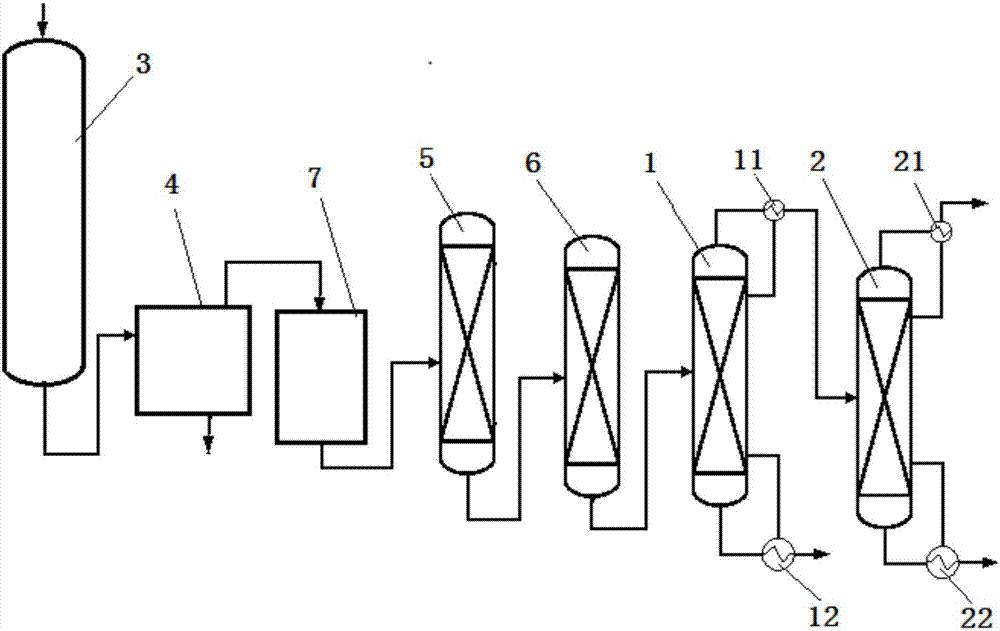

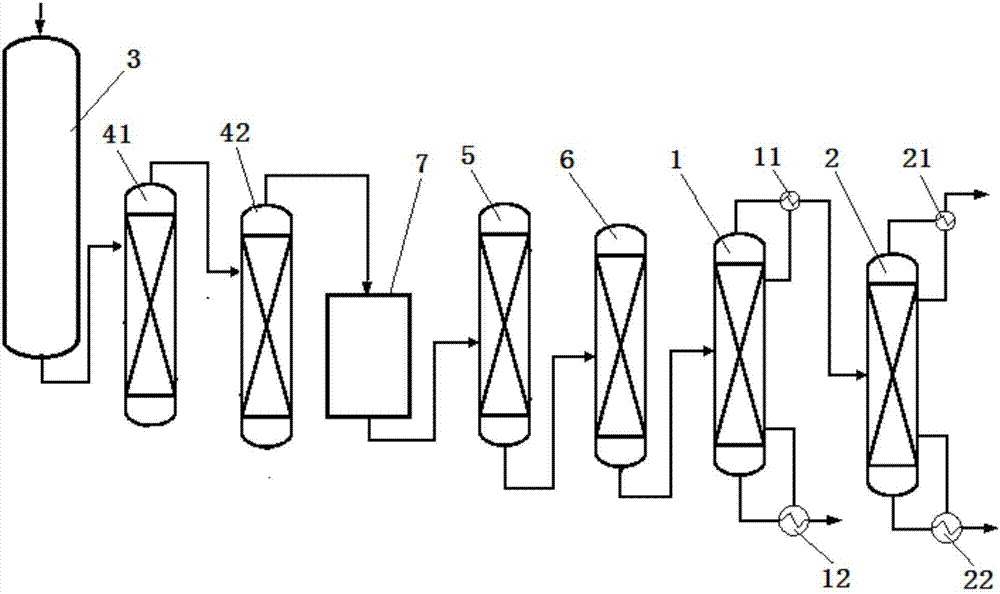

[0065] The separation device and method of the present invention are used to separate the C6+ hydrocarbon mixture in the by-products of the coal-based methanol-to-propylene process. in,

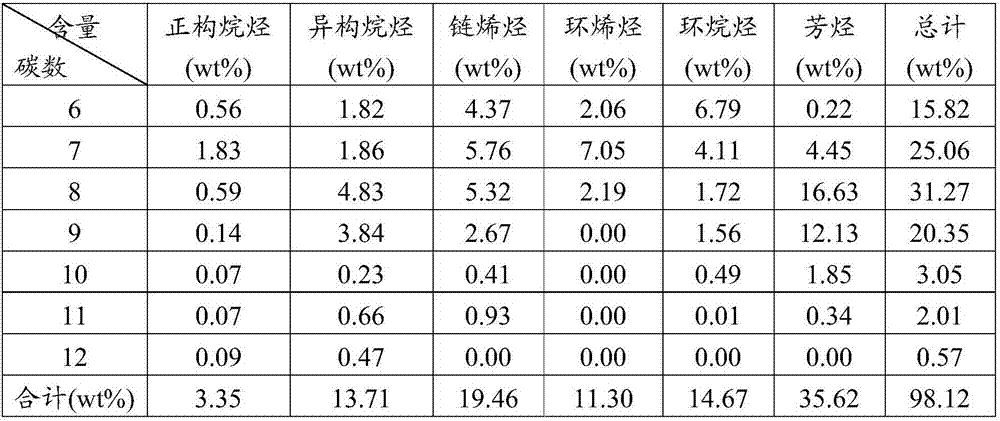

[0066] (1) The C6+ hydrocarbon mixture in the by-product of the coal-based methanol-to-propylene process was prepared under the following operating conditions, and its composition is shown in Table 1.

[0067] Operating conditions:

[0068] The methanol to propylene reactor has an operating temperature of 480°C and an operating pressure of 0.08MPa;

[0069] The operating temperature of the pre-chilling tower in the gas-liquid separation device is 72°C and the operating pressure is 0.019MPa; the operating temperature of the quenching tower in the gas-liquid separation device is 45°C and the operating pressure is 0.008MPa;

[0070] Compression device: the operating temperature is 60°C, and the operating pressure is 1.005Mpa;

[0071] Debutanizer, the operating temperature is 120°C, the opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com