Method for preparing black rice anthocyanin particles through dry separation

A technology of cyanoside granules and black rice flowers, which is applied in the field of dry separation and preparation of black rice anthocyanin granules, which can solve the problems of loss of active ingredients such as dietary fiber of black rice, loss of active ingredients of black rice husk, and unguaranteed product quality. , to achieve the effect of being rich in phenolic acid and soluble dietary fiber, avoiding microwave heat generation, and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

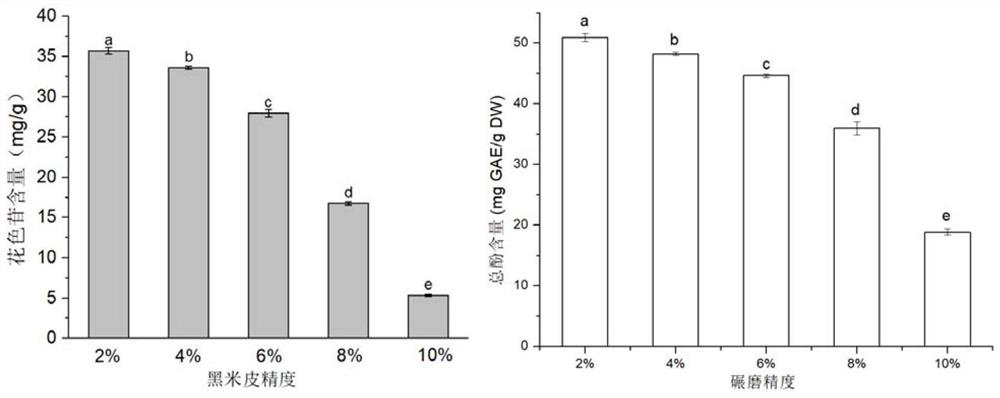

[0048] Example 1 Contents of anthocyanins and phenolic acids in black rice bark with different milling precisions

[0049] Take a certain amount of black rice and brown rice, use a rice polishing machine to grind the black rice skins accounting for 2%, 4%, 6%, 8%, and 10% of the mass of black rice, and pass through a 20-mesh sieve to obtain black rice with different grinding precision skin, the content of anthocyanin and phenolic acid was determined, and the content of phenolic acid monomer was determined by HPLC method.

[0050] The result is as figure 1 It was shown that with the increase of milling precision, the content of anthocyanins and total phenols per gram of black rice bark gradually decreased, especially when the milling precision increased from 6% to 8%, the rate of content decline was greater.

[0051] The content of monomeric phenols is shown in Table 1. Ferulic acid, p-coumaric acid and protocatechuic acid are the main phenolic acids in black rice bark, and th...

Embodiment 2

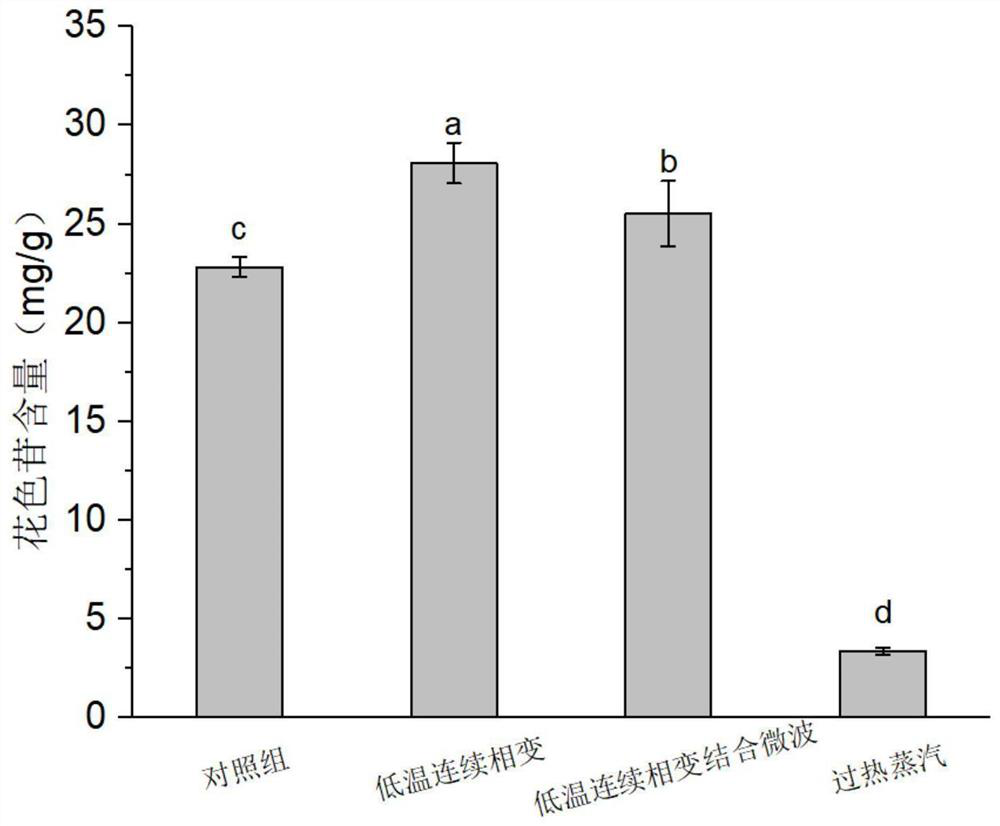

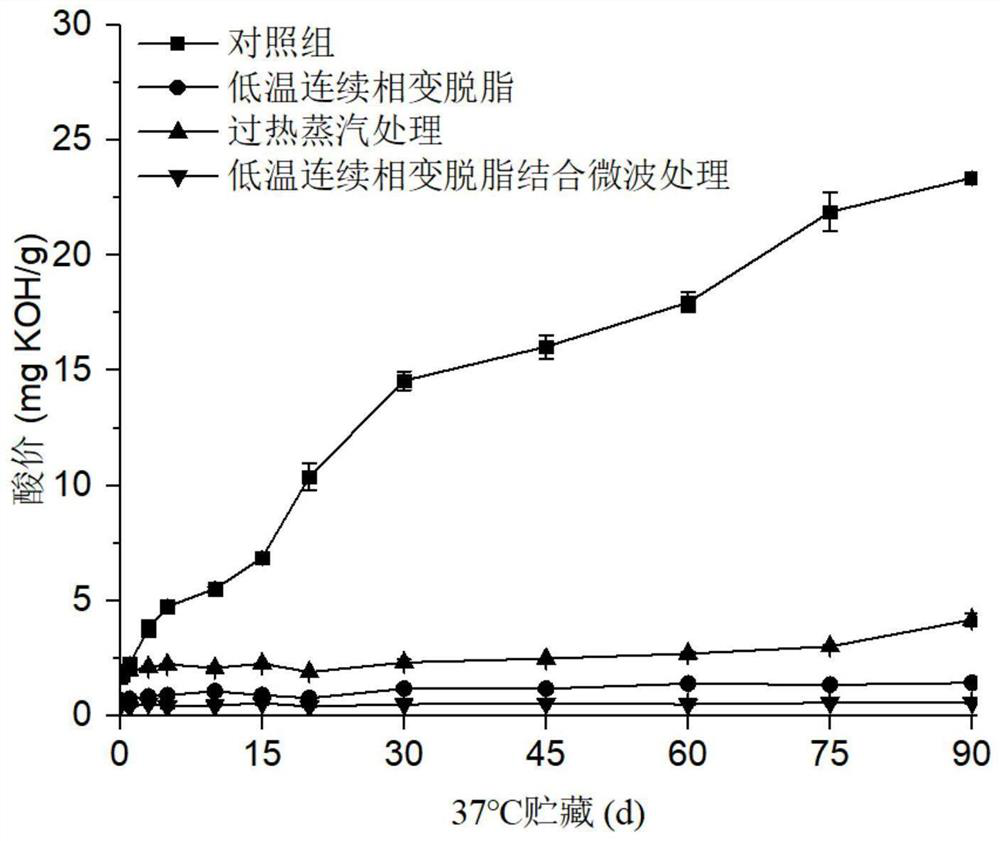

[0054] Example 2 Effects of Different Treatments on Black Rice Bark Acid Value and Anthocyanin Content

[0055] Get a certain amount of black rice and brown rice, use a rice polishing machine to grind black rice skins accounting for 6% of the quality of black rice, and pass through a 20-mesh sieve. The low-temperature continuous phase-change extraction equipment uses n-hexane at 50 °C to extract the defatted black rice skin obtained by degreasing for 1.5 hours; the black rice skin of the superheated steam treatment group is black rice skin, which is treated in an autoclave at 121 °C for 15 minutes, and dried at 50 °C until The moisture content is less than 5%, and the black rice skin has been obtained. The low-temperature continuous phase-change degreasing combined with microwave treatment group black rice skin is the low-temperature continuous phase-change degreasing group black rice skin, which is processed in a microwave oven, and the microwave-treated sample is dried at 50...

Embodiment 3

[0057] Example 3 Effects of different granulation embeddings on the storage stability of black rice bark anthocyanins

[0058] Take the above-mentioned low-temperature continuous phase-change degreasing combined with microwave-treated black rice skin superfine powder, add starch, β-cyclodextrin, citric acid and ascorbic acid to wet mix, sieve, and dry to obtain black rice anthocyanin granules, And the ungranulated black rice bark superfine powder was used as the control group, stored at room temperature for 6 months, and the retention rate of anthocyanins in the granules was determined.

[0059] The results are shown in Table 2, the ungranulated black rice bark has the lowest anthocyanin retention rate, and when any one of β-cyclodextrin, citric acid and ascorbic acid is missing, the anthocyanin retention rate is higher than that of the control group Less, when the addition amount of black rice skin superfine powder, starch, β-cyclodextrin, citric acid and ascorbic acid is 350...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com