Patents

Literature

156results about How to "High degreasing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

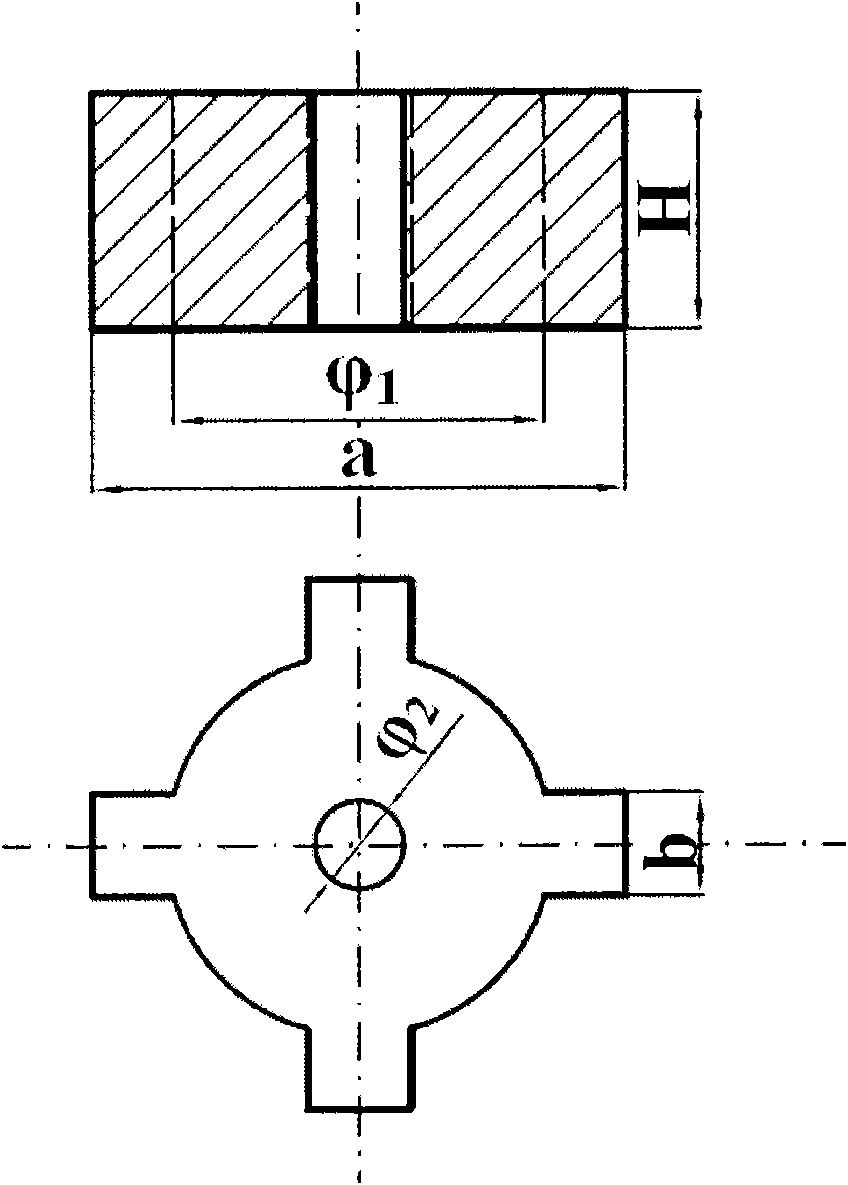

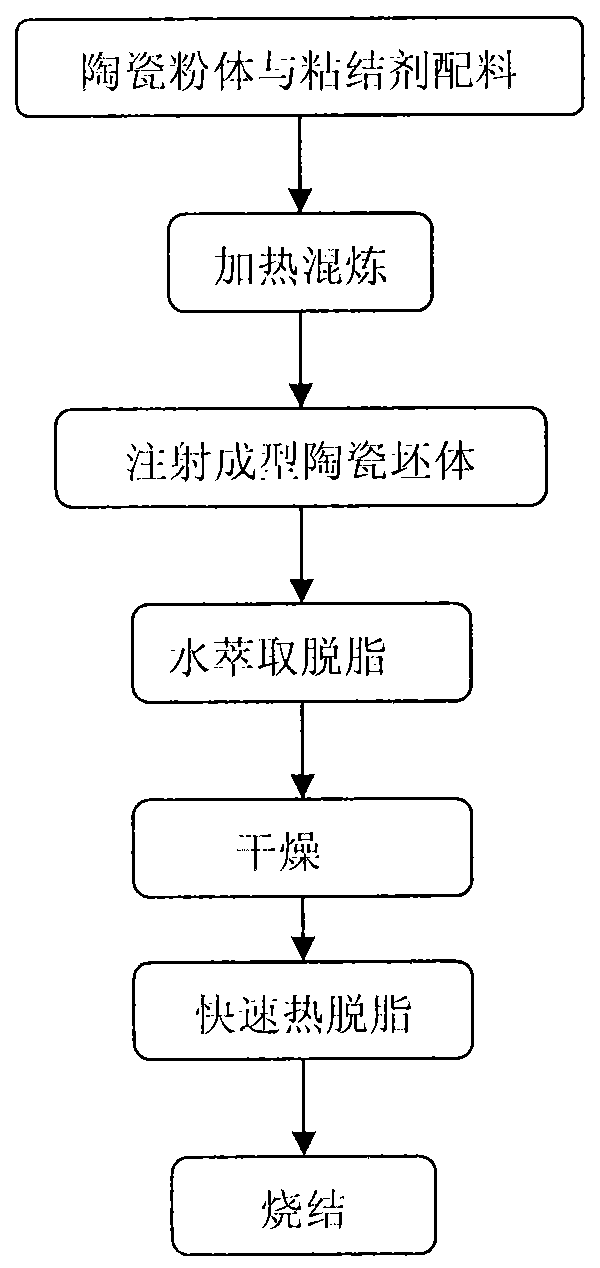

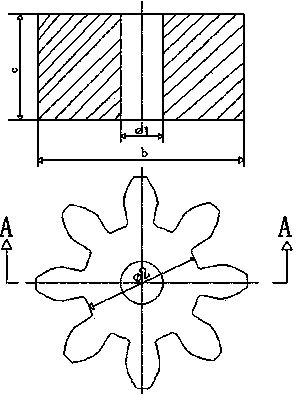

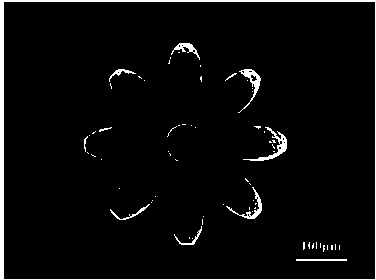

Method for manufacturing dentate special-shaped ceramic components by injection molding

InactiveCN101643360AEfficient preparationHigh precision manufacturingCeramic shaping apparatusSurface finishHigh dimensional

The invention discloses a method for manufacturing dentate special-shaped ceramic components by injection molding, belonging to the technical field of high-performance ceramic preparation. The methodcomprises the following steps: evenly mixing 81wt% to 90wt% of ceramic powder and 10wt% to 19wt% of organic binders by weight percentage to obtain an injection-molding mixture, injection-molding the injection-molding mixture on an injection-molding machine with the injection temperature being 175 to 195 DEG C, to obtain a green body, and de-molding within 2 minutes after the injection, so as to obtain a molded green body; and then, subjecting the molded green body to water-extraction degreasing and thermal degreasing, sintering the degreased green body at 1,350 to 1,550 DEG C, holding for 1 to4 hours and furnace-cooling to obtain the ceramic components. The invention has the advantages of high automation degree, high molding and degreasing efficiencies, even green body, high dimensional accuracy and surface smoothness of sintered products, and environment-friendly and energy-saving manufacture.

Owner:TSINGHUA UNIV +1

Powder injection molding feedstock preparing method and powder injection molding method

Disclosed are a powder injection molding feedstock preparing method and a powder injection molding method. The powder injection molding feedstock preparing method includes: stirring and heating 80% to 94%, preferably 85% to 94%, by percent, of forming powder in an internal mixer, adding 6% to 20%, preferably 6% to 15%, by percent, of binder component when the forming powder is heated to 180 DEG C to 200 DEG C, and continuing stirring for 60min to 120min according to the mixing temperature 175 DEG C to 195 DEG C, preferably at the mixer speed 10rpm to 30rpm, thus obtaining evenly mixed feedstock. The powder injection molding method includes performing injection molding and degreasing sintering with the feedstock. The powder injection molding feedstock preparing method and the powder injection molding method have the advantages that degreasing efficiency is high, the process is simple and easy to control, blank quality is good and the methods are sanitary and environment friendly.

Owner:DONGGUAN HUAJING POWDER METALLURGY

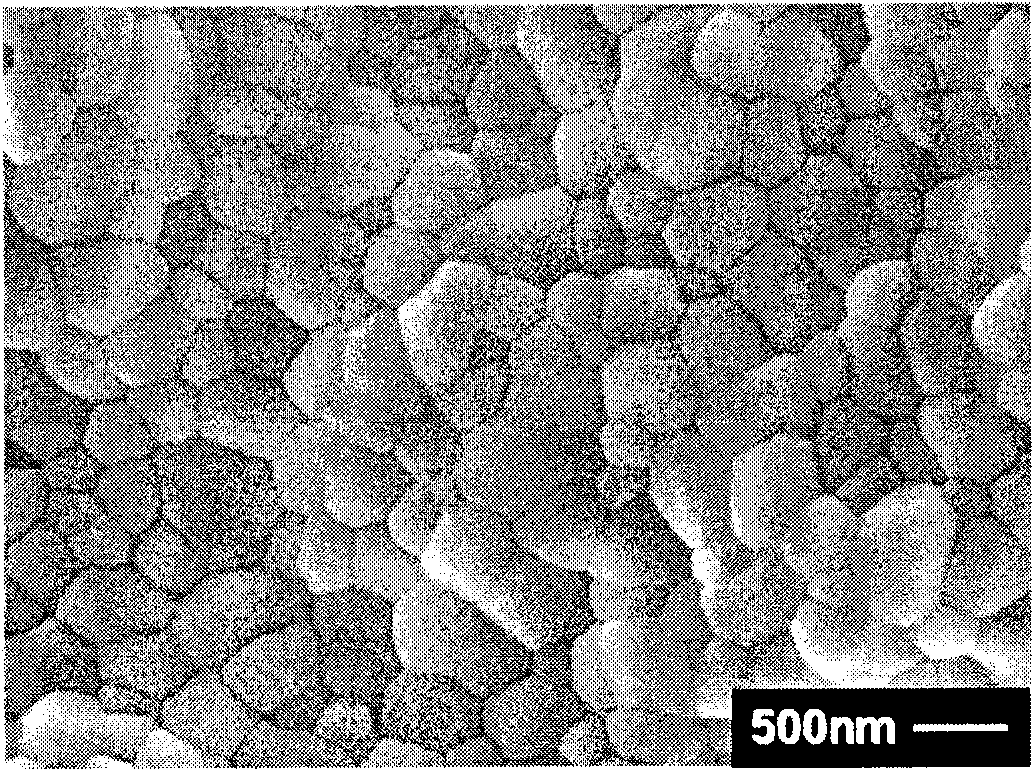

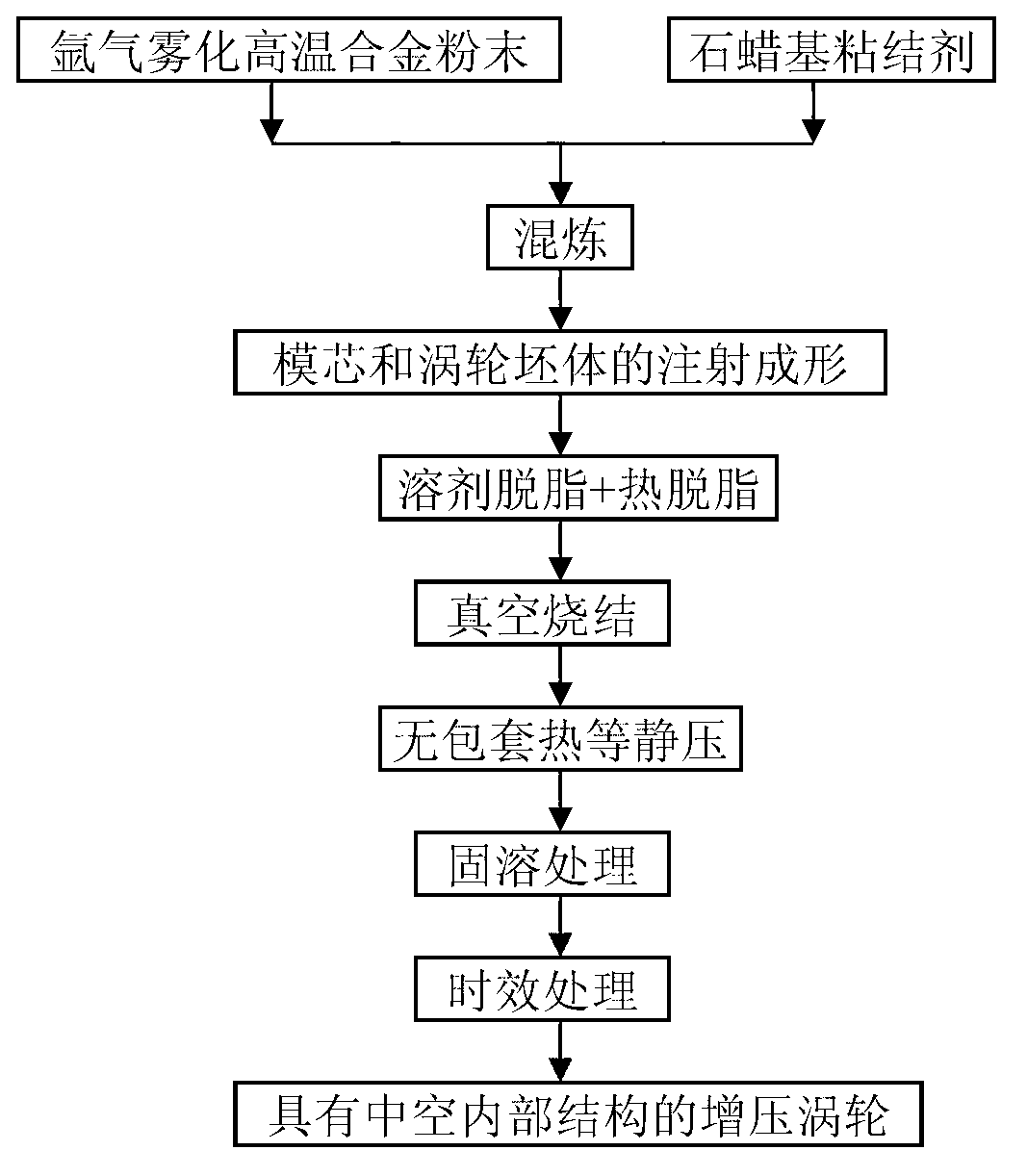

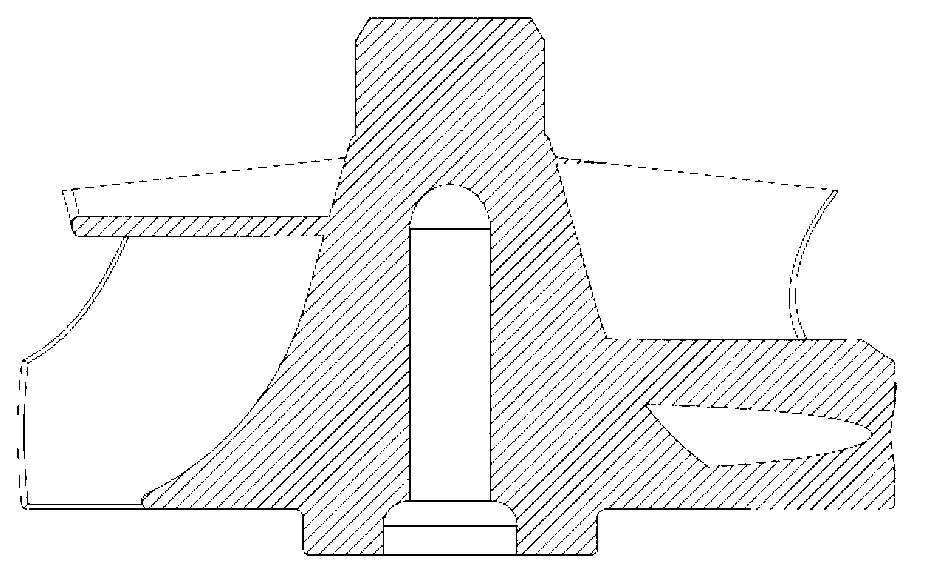

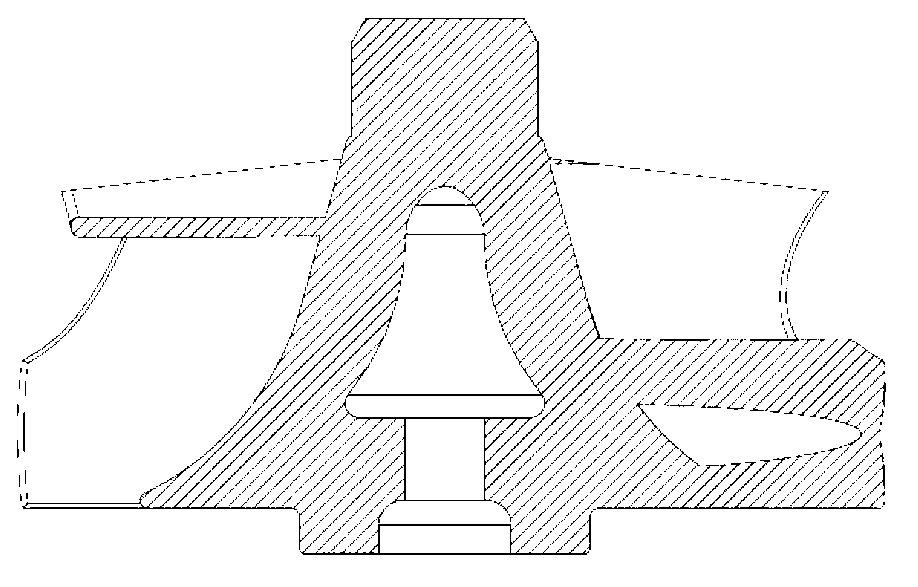

Near-net shaping method for charging turbine with hollow internal structure

ActiveCN103240418AHigh degreasing efficiencyReduce skimming defectsHot isostatic pressingEngineering

Disclosed is a near-net shaping method for a charging turbine with a hollow internal structure. Atomized high-temperature alloy powder and paraffin base binders are mixed to manufacture feedstock with a uniform rheological performance. As for a turbine with a simple hollow internal structure, the feedstock is directly formed on an injection forming machine to obtain a turbine blank with the hollow structure. As for as a turbine with a complicated hollow internal structure, firstly, polystyrene is formed into a mold core by injection, the shape of the mold core is as same as that of the internal structure, secondly, the mold core is embedded into a mold, a turbine blank with the mold core is obtained after injection forming, and thirdly, the mold core is completely dissolved after the turbine blank with the mold core is soaked in trichloroethane to obtain the turbine blank with the hollow structure. The turbine blank is sintered in vacuum after solvent degreasing and hot degreasing, the sintered blank is compacted by the aid of unjacketed hot isostatic pressure, and finally, the charging turbine with the hollow structure is obtained by the aid of solid solution and aging treatment. The problem of difficulty in near-net shaping of a charging turbine in a complicated shape is solved, the obtained turbine is almost fully compact and uniform in structure, and the comprehensive mechanical property of the turbine is superior to that of a cast turbine.

Owner:UNIV OF SCI & TECH BEIJING

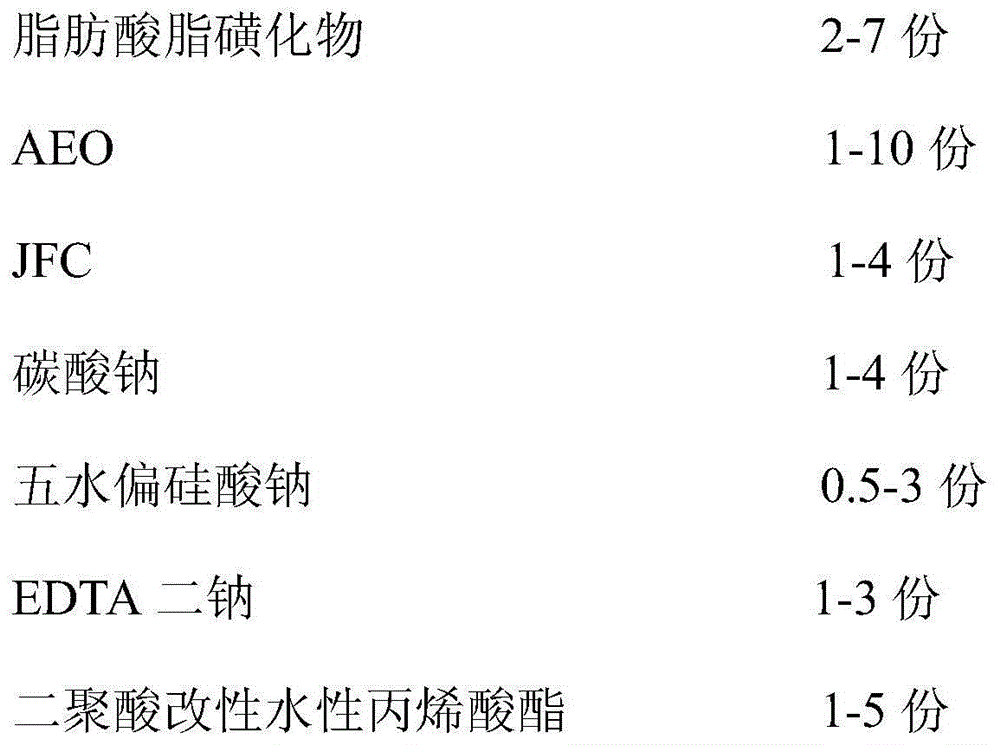

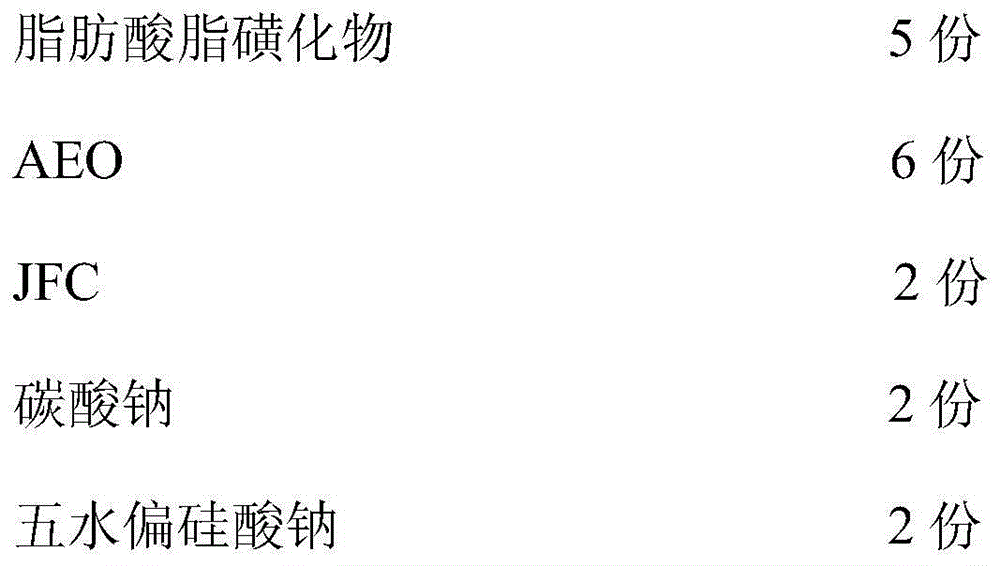

Normal-temperature water-based non-phosphorus rust-proof cleaning agent for heavy oil

InactiveCN104313622AHigh degreasing efficiencyImprove natural degradation performanceWater basedSodium metasilicate

The invention discloses a normal temperature water-based non-phosphorus rust-proof cleaning agent for heavy oil. The rust-proof cleaning agent comprises an anionic surfactant, a nonionic surfactant and auxiliaries, wherein the mass ratio of the anionic surfactant to the nonionic surfactant to the auxiliaries is (1.5-4): (1.5-4): 1. The cleaning agent comprises the following components in parts by weight: 5 parts of sulfonated fatty acid ester, 6 parts of AEO (alcohol ethoxylate), 2 parts of JFC, 2 parts of sodium carbonate, 2 parts of sodium metasilicate pentahydrate, 2 parts of EDTA (ethylene diamine tetraacetic acid) disodium and 3 parts of dimer acid-modified water-based acrylate. The cleaning agent disclosed by the invention has a relatively high natural degradation effect and overcomes the defect that common cleaning agent has the cleaning function only at a medium temperature or relatively high temperature and the cleaning agent disclosed by the invention has a relatively high cleaning effect at normal temperature. In addition, the cleaning agent disclosed by the invention further overcomes the defect that the existing cleaning agent is poor in anti-rust performance.

Owner:HEFEI QIANFENG LUBRICATION TECH

Plastic-based binder for injection molding of copper and copper alloys and method of injection molding for copper and copper alloy parts

InactiveCN106552942AHigh degreasing efficiencySmall total footprintTransportation and packagingMetal-working apparatusPolyoxymethyleneAntioxidant

The present invention discloses a plastic-based binder for injection molding of copper and copper alloys. The plastic-based binder is obtained by blending polyoxymethylene (POM), high-density polyethylene (HDPE), ethylene-vinyl acetate copolymer (EVA), stearic acid (SA), and an antioxidant together in a certain ratio. The present invention also discloses a method of injection molding for copper and copper alloy parts using a plastic-based binder, which comprises: preparing of the plastic-based binder, mixing and granulating, injection molding, and debinding using an oxalic acid catalyst, thermal debinding, and sintering. Using the plastic-based binder provided by the present invention for injection molding of copper and copper alloy parts, the debinding efficiency can be improved, while the production cost can be reduced. Therefore, the plastic-based binder is suitable for preparation of high-precision complicated copper and copper alloy parts.

Owner:深圳市卡德姆科技有限公司

Extrusion forming agent and preparation and use thereof

The invention discloses an extrusion forming agent, and preparation and use thereof, in particular to a forming agent for a tungsten-based alloy or hard alloy or ceramic powder extrusion forming process, and preparation and use thereof. The forming agent comprises 60 to 80 percent of solid and liquid paraffin wax, 3 to 8 percent of carnauba wax, 10 to 20 percent of high density polyethylene and ethylene-vinylacetate copolymer, 1 to 8 percent of plasticizer, 1 to 5 percent of stearic acid and the balance of modifier. In the invention, the drawbacks of long degreasing time, low degreasing conformality and more degreasing defects of extrusion blanks, particularly large-size extrusion blanks, are overcome, the raw materials are cheap and easy to purchase, the component compatibility of the prepared forming agent is high, the forming agent is used in a powder extrusion forming process, the micro structure of the forming agent is uniform, the forming agent has strong interaction force with powder, the formability is high, the quick and flawless degreasing of blanks with a thickness of 40 millimeters can be realize, the production efficiency is improved, and the development of extrusion forming industry is promoted greatly.

Owner:CENT SOUTH UNIV

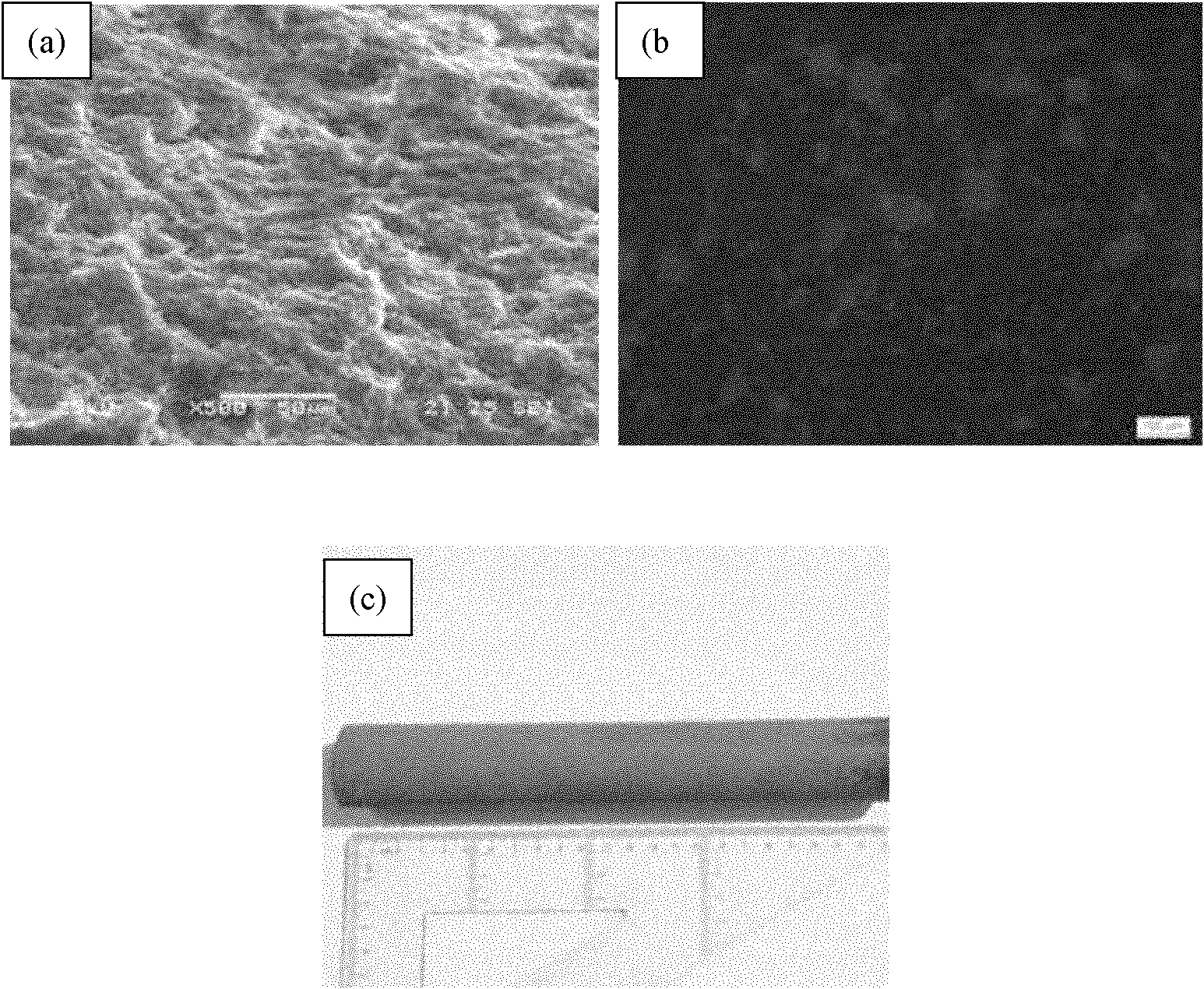

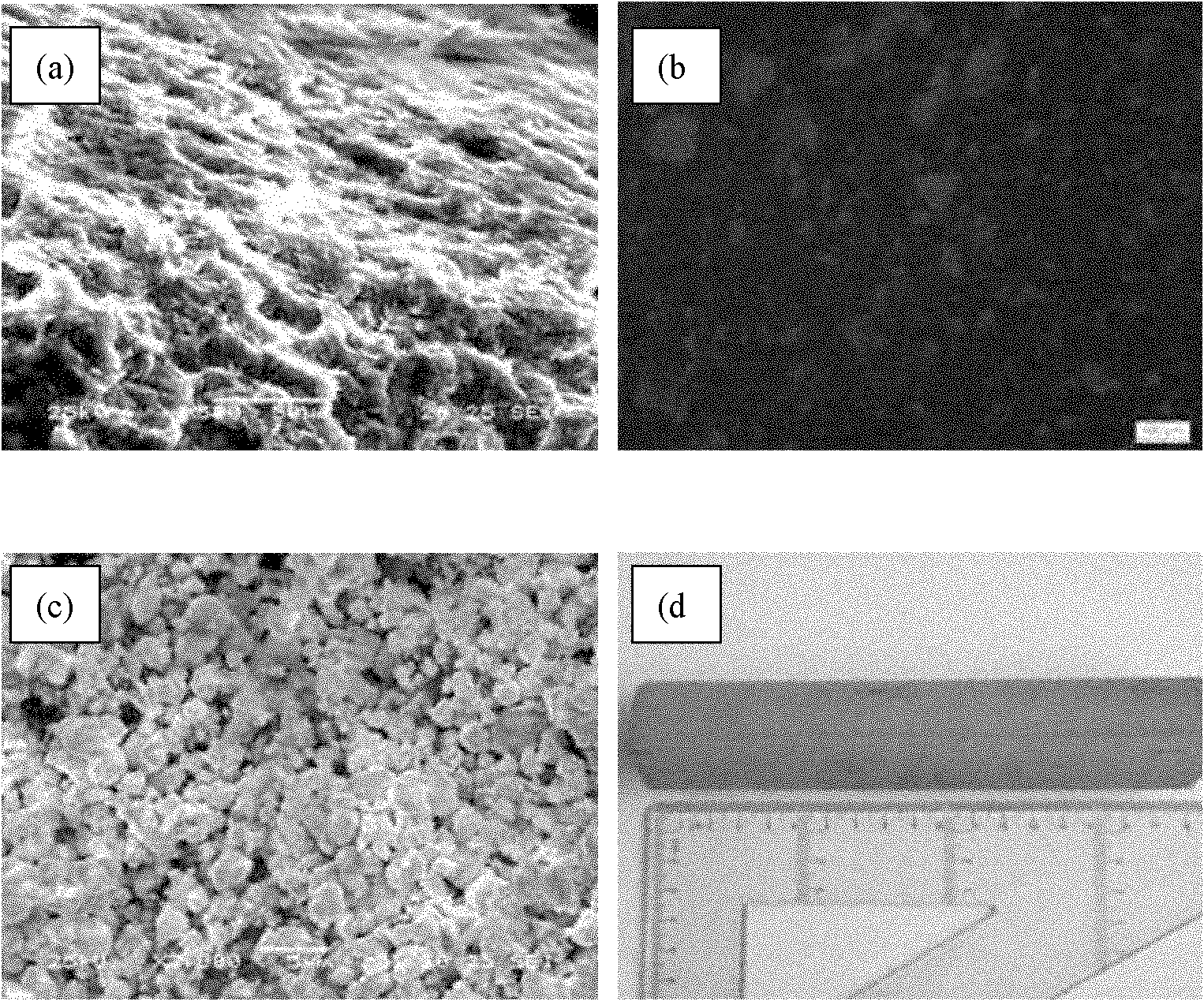

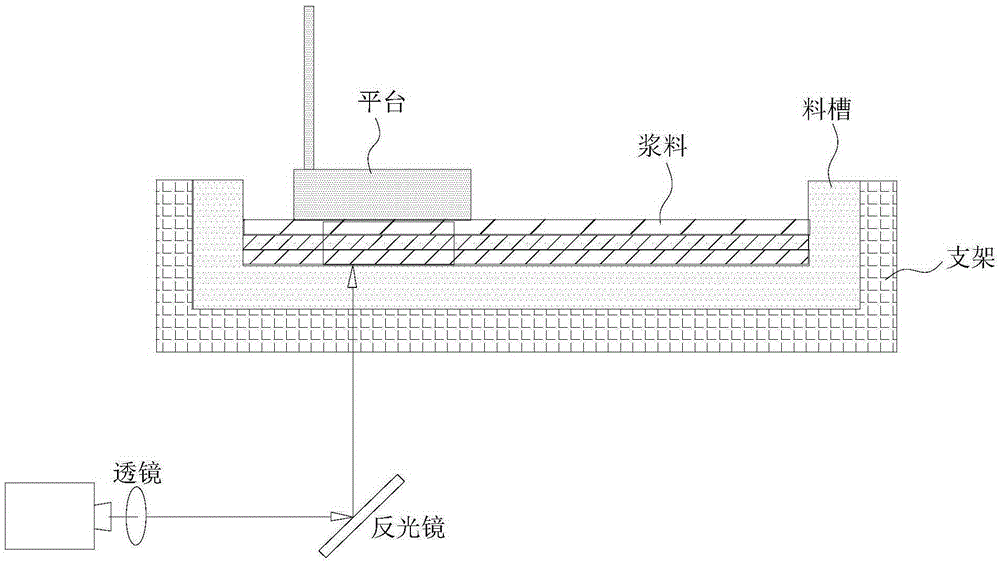

Manufacturing method of laminated ceramics

The invention relates to the technical field of ceramic manufacturing, in particular to a manufacturing method of laminated ceramics. Slurry can be applicable to a DLP photo-curing face forming method to manufacture laminated ceramic bodies by optimizing the composition and proportioning of the slurry, the forming efficiency is high, ceramic particles in the bodies can be dispersed evenly, and the shape and size accuracy of the bodies is high; then the bodies cannot deform and crack in the manufacturing process by controlling process parameters in degreasing and sintering steps, the laminated ceramics with micron-scale thickness can be manufactured and are uniform in compactness, good in surface smoothness, high in accuracy and excellent in performance, and manufactured ceramic products are high in reliability. The manufacturing method adopts a two-step degreasing method integrating vacuum / atmosphere protection degreasing and air degreasing, can remarkably improve the degreasing efficiency, enables the degreasing time to be shortened from 48-60 hours required by an existing method to 8-20 hours and can also decrease the defects including deformation, cracking, blistering and the like of the bodies due to the too high one-step degreasing and heating rate or the too high pyrolysis rate of organic matter in the bodies.

Owner:广东金瓷三维技术有限公司

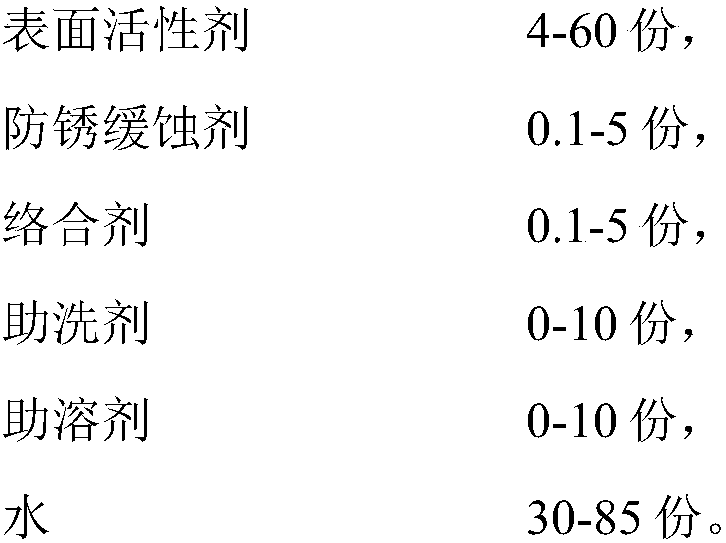

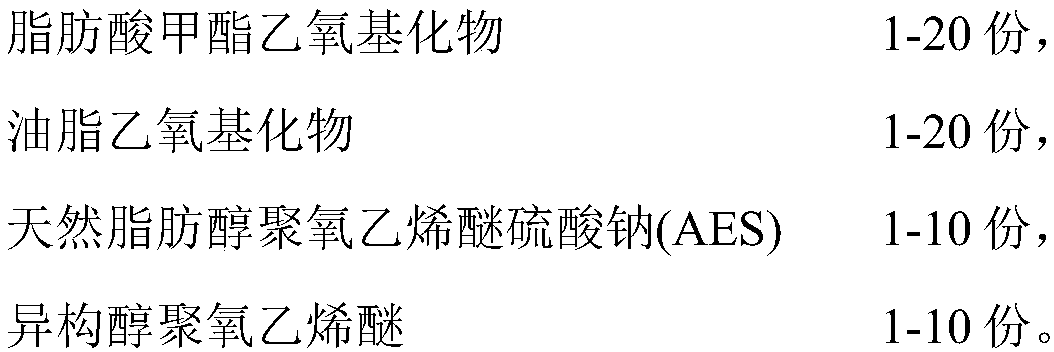

Biodegradable water-based type metal cleaner, as well as preparation method and application thereof

The invention discloses a biodegradable water-based type metal cleaner which is prepared from the following components in parts by weight: 4 to 60 parts of surface active agent, 0.1 to 5 parts of rust-proof corrosion inhibitor, 0.1 to 5 parts of complexing agent, 0 to 10 parts of detergent assistant, 0 to 10 parts of cosolvent, and 30 to 85 parts of water. The surface active agent is prepared fromthe following components in parts by weight: 1 to 20 parts of fatty acid methyl ester ethoxylates, 1 to 20 parts of grease ethoxylate, 1 to 10 parts of natural fatty alcohol polyoxyethylene ether sodium sulfate, and 1 to 10 parts of alcohol alkoxylate. Compared with a conventional surface active agent, the biodegradable water-based type metal cleaner provided by the invention is easy to biodegradable, has high permeability and cleaning capacity, has an outstanding solubilization effect on oily dirt, has high degreasing efficiency on metal without corroding the metal surface, has excellent biodegradability, and is capable of effectively reducing the pollution of degreaser waste water on the environment.

Owner:中轻日化科技有限公司

Light-yellow odourless degreasing silkworm pupa protein power and preparation method thereof

InactiveCN105124131ALow degreasing temperatureShort degreasing timeProtein composition from waste materialsProtein composition from vegetable materialsPROTEIN S HEERLENBiology

The invention relates to light-yellow odourless degreasing silkworm pupa protein power and a preparation method thereof. According to the technical scheme, silk reeling silkworm pupae of which the skin and the gland are removed are selected as the raw material, silkworm pupa pretreatment is conducted, and coarse silkworm pupa powder is obtained; the coarse silkworm pupa powder is evenly mixed in degreasing solvent, ultrasonic degreasing treatment is conducted, centrifugal separation is conducted, and degreasing fluid and degreasing coarse pupa protein are obtained; drying and smashing are conducted on the degreasing coarse pupa protein, and the degreasing coarse pupa protein power is obtained; the degreasing coarse pupa protein power is evenly mixed in a sodium hydroxide solution, a silkworm pupa protein extracting solution is obtained, ultrasonic extraction treatment is conducted, macroporous resin is added into the silkworm pupa protein extracting solution, adsorption treatment is conducted, solid-liquid separation is conducted, resin and protein fluid are obtained, the protein fluid pH is adjusted, protein precipitation is collected, and wet silkworm pupa protein is obtained; vacuum drying and smashing are conducted on the wet silkworm pupa protein, and the light-yellow odourless degreasing silkworm pupa protein power is obtained. The light-yellow odourless degreasing silkworm pupa protein power and the preparation method thereof have the advantages that the technology is simple, the degreasing efficiency is high, effects of deodorization and decolorization are good, the treatment is low in temperature and short in time, the cost is low, the green and environmental protection is achieved, and the light-yellow odourless degreasing silkworm pupa protein power and the preparation method thereof can be used for industrial production.

Owner:WUHAN UNIV OF SCI & TECH

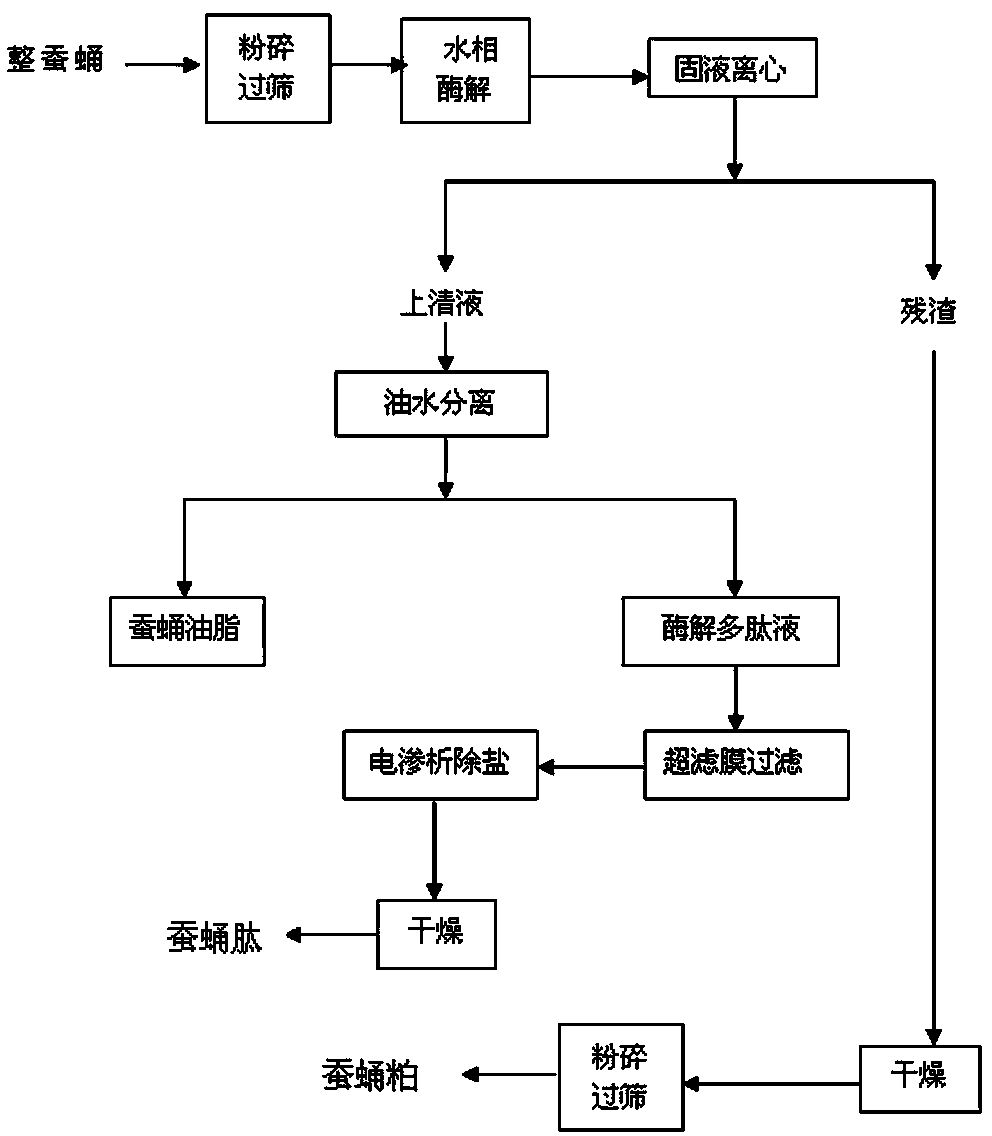

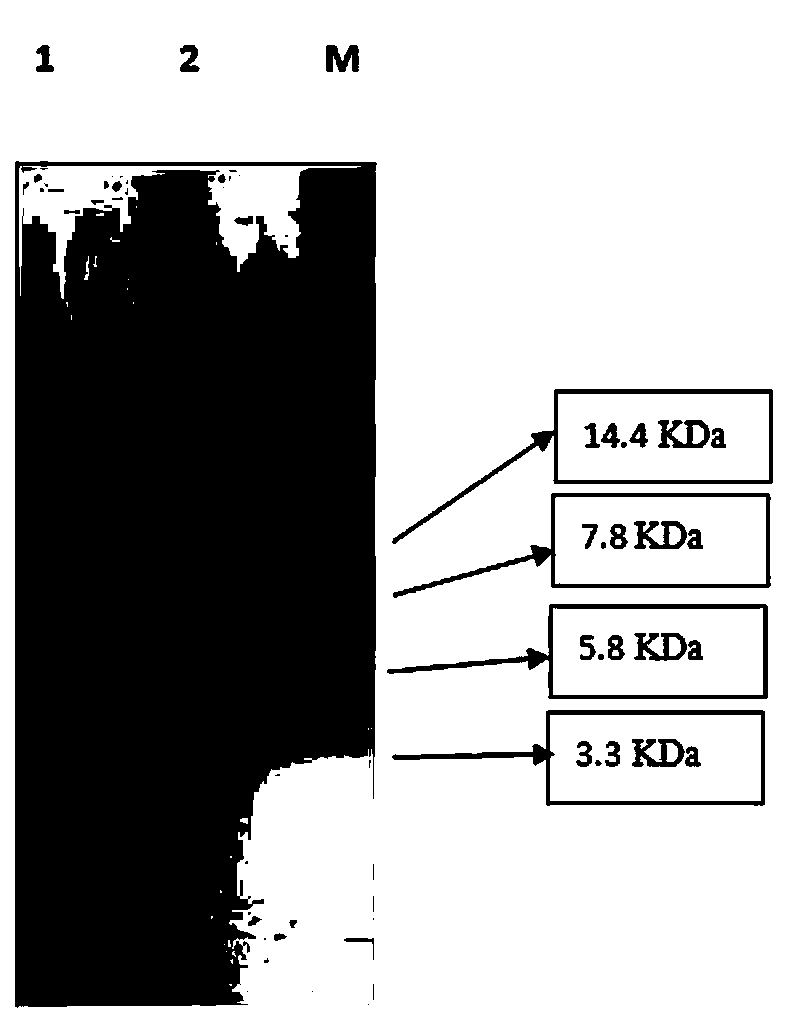

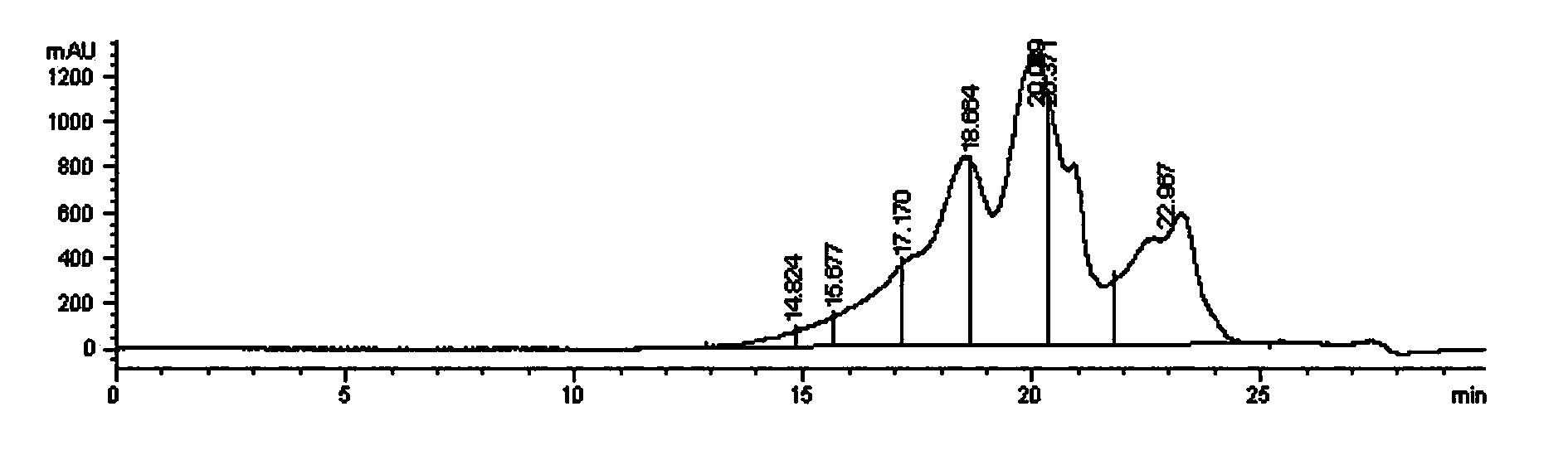

Method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by aqueous biological enzyme method

ActiveCN103540639AImprove qualityGood effectAnimal feeding stuffPeptide preparation methodsBiotechnologyUltrafiltration

The invention relates to a method for producing silkworm chrysalis peptide powder and silkworm chrysalis meal by an aqueous biological enzyme method. According to the method, silkworm chrysalises serve as raw materials, an enzymolysis solution is obtained through drying, crushing and carrying out aqueous-phase enzymolysis, a supernatant and residues are obtained through carrying out centrifugation on the enzymolysis solution, the silkworm chrysalis meal is obtained through drying and crushing the residues, and the silkworm chrysalis peptide powder is obtained through carrying out oil-water separation, ultrafiltration-membrane ultrafiltration and desalination on the supernatant and then drying and crushing. The method specifically comprises the following steps of (1) drying and crushing; (2) carrying out aqueous-phase enzymolysis; (3) carrying out centrifugation and oil-water separation; (4) carrying out ultrafiltration-membrane filtration; (5) carrying out desalination; (6) drying and crushing, thereby obtaining the silkworm chrysalis peptide powder. According to the method, the aqueous biological enzyme method is applied to insect cells-silkworm chrysalis cells for the first time; the method has the advantages that the process is simple, safe and environmental-friendly, the cost is low, the quality of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is high, and the like; the method disclosed by the invention has the characteristics that the oil and fat removal efficiency is high, the residual fat content of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is low, the oligopeptide content of the obtained silkworm chrysalis peptide powder and silkworm chrysalis meal is high, and the like.

Owner:ZHEJIANG ESIGMA BIOTECH CO LTD +1

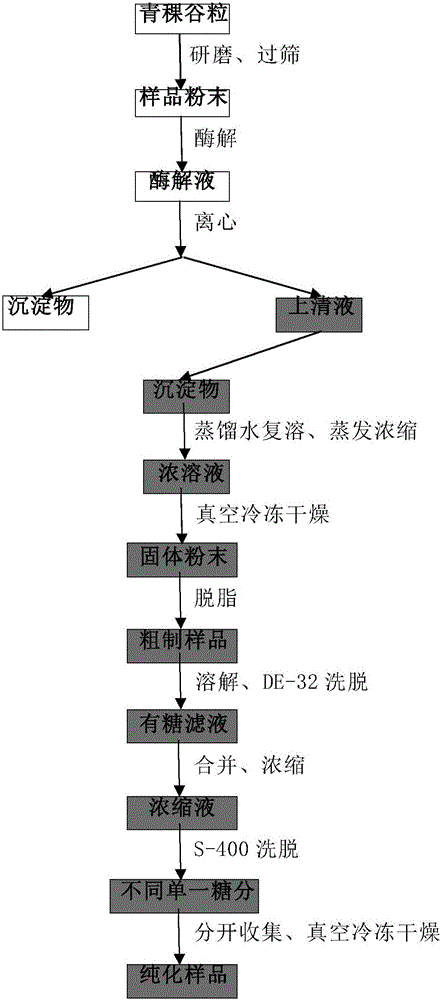

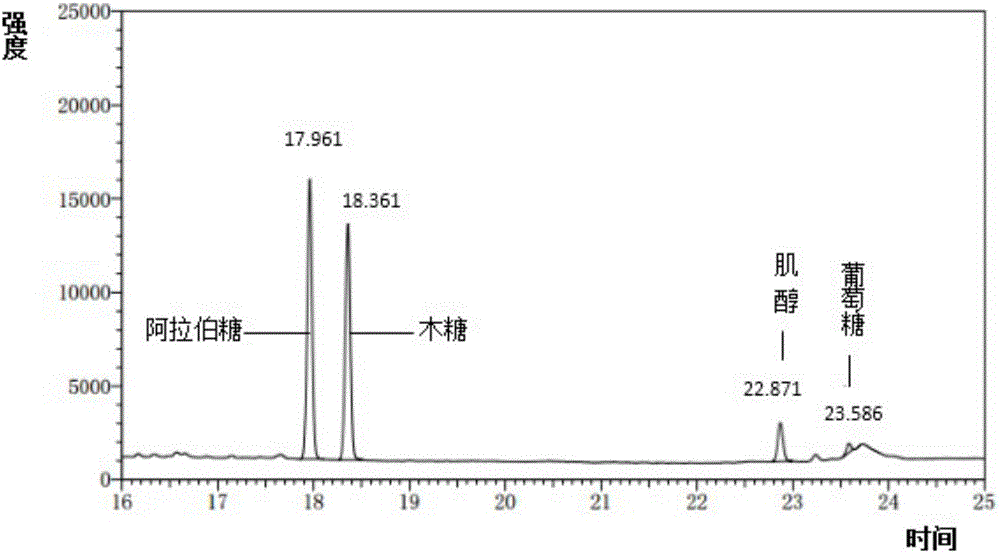

Method for extracting and purifying beta-glucan from highland barley grains

The invention discloses a method for extracting and purifying beta-glucan from highland barley grains. The method comprises the following steps: taking the highland barley grains as raw materials; grinding, sieving, carrying out enzymolysis, carrying out alcohol precipitation, carrying out vacuum freeze drying and degreasing to obtain a coarse sample; and after dissolving the coarse sample, eluting with packing cellulose DE-32 and S-400 successively to obtain a purified sample. By the method, the high-purity beta-glucan can be effectively separated from the highland barley grains, the extraction rate of the beta-glucan in the coarse sample can reach 31.1%, and the purity can reach 98.86%.

Owner:SHANGHAI JIAO TONG UNIV

Method for manufacturing microarray through powder microinjection molding

The invention discloses a method for manufacturing a microarray through powder microinjection molding, belongs to the field of powder microinjection molding, and discloses a preparation method of the microarray through the powder microinjection molding by using a water debinding characteristic adhesive feed. The feed is prepared by using a metal / ceramic powder and an adhesive, a preform is prepared by using a powder microinjection molding technology, and then the microarray is prepared through debinding and sintering. The method comprises the following specific preparation steps: uniformly mixing selected metal / ceramic powder and a water soluble adhesive in a mixer or a screw extruder according a proportion for 1-2 hours; pelletizing and then forming the preform through injection molding; performing water debinding and thermal debinding; placing a debinding ring in a tubular sintering furnace to sinter to obtain a compact metal / ceramic microarray. The preparation method has the advantages of high water debinding speed, environmental friendliness, capability of forming the micron-sized metal / ceramic microarray, no deformation and high dimensional accuracy.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

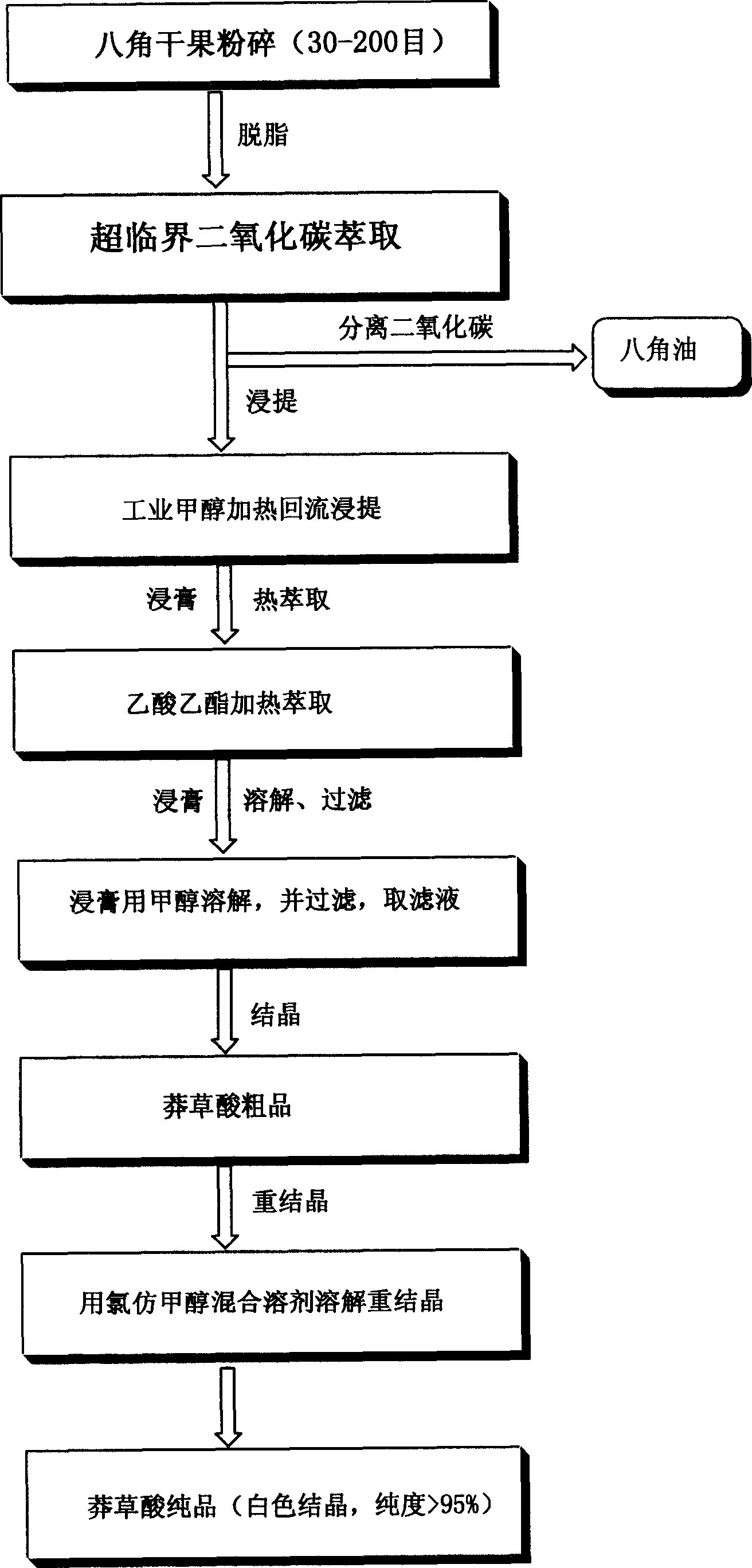

Extraction separation tech. of octagonal shickimmi oxalic acid

InactiveCN100999461AImprove the level of comprehensive utilizationAvoid the disadvantage of extracting inedibleBulk chemical productionCarboxylic compound separation/purificationFiltrationSeparation technology

This invention relates to an extraction and separation technology of anise tree shikimic acid. The main steps are : Using supercritical carbon dioxide to defat the crushed dry anise tree at 40 ~ 45 deg C, 25 ~ 35MPa to gain food spices; then heating back with methanol at 50 ~ 60 deg C to leach extract; under 50-55 deg C using acetic ether to extract, filtration and separation to remove acetic ether, remaining solid extract; methanol will be used in 50 ~ 60 deg C to heat and stir with extract until dissolved, by hot filtration, liquid natural still, cooling crystallization, then gain crude shikimic acid; chloroform and methanol mixed solvent used under 45 ~ 50 deg C to dissolve crude shikimic acid, through natural still, cooling and crystallization , and recrystallization to gain purified product, with purity greater than 95% pure. This invention use supercritical carbon dioxide to extract and degrease. The product spices can be directly consumed, non-toxic and harmless to humans.

Owner:HONGHE COLLEGE

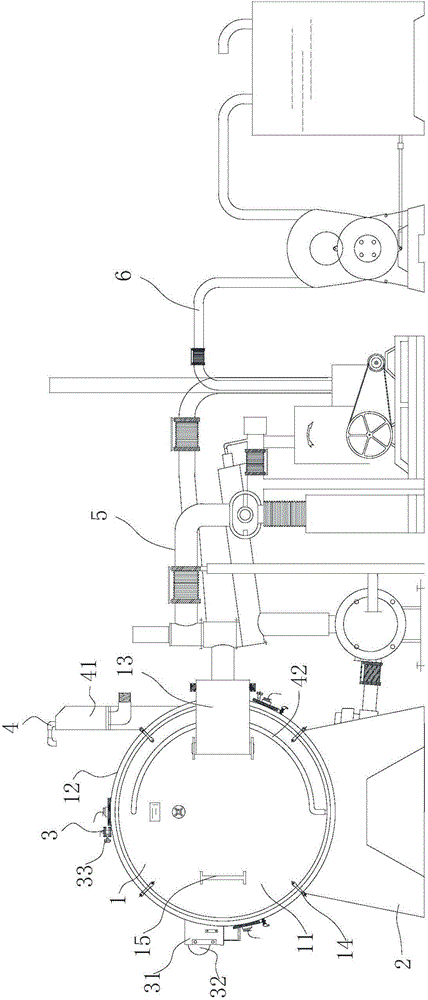

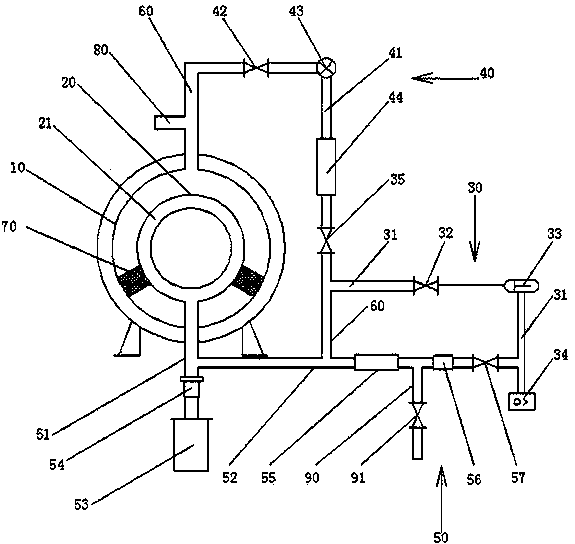

Vacuum degreasing sintering furnace

The invention relates to a method for metal powder vacuum sintering forming. The method for metal powder vacuum sintering forming comprises the following steps in sequence: (1) material loading: putting a metal powder product to be processed in a hearth of a vacuum degreasing sintering furnace; (2) vacuumizing: carrying out vacuumizing treatment on the hearth of the vacuum degreasing sintering furnace; (3) degreasing: clearing a forming agent in the metal powder product; (4) high temperature sintering. The method for metal powder vacuum sintering forming has the advantages of novel technology, convenient degreasing and high primary degreasing rate.

Owner:宁波优戈新材料科技有限公司

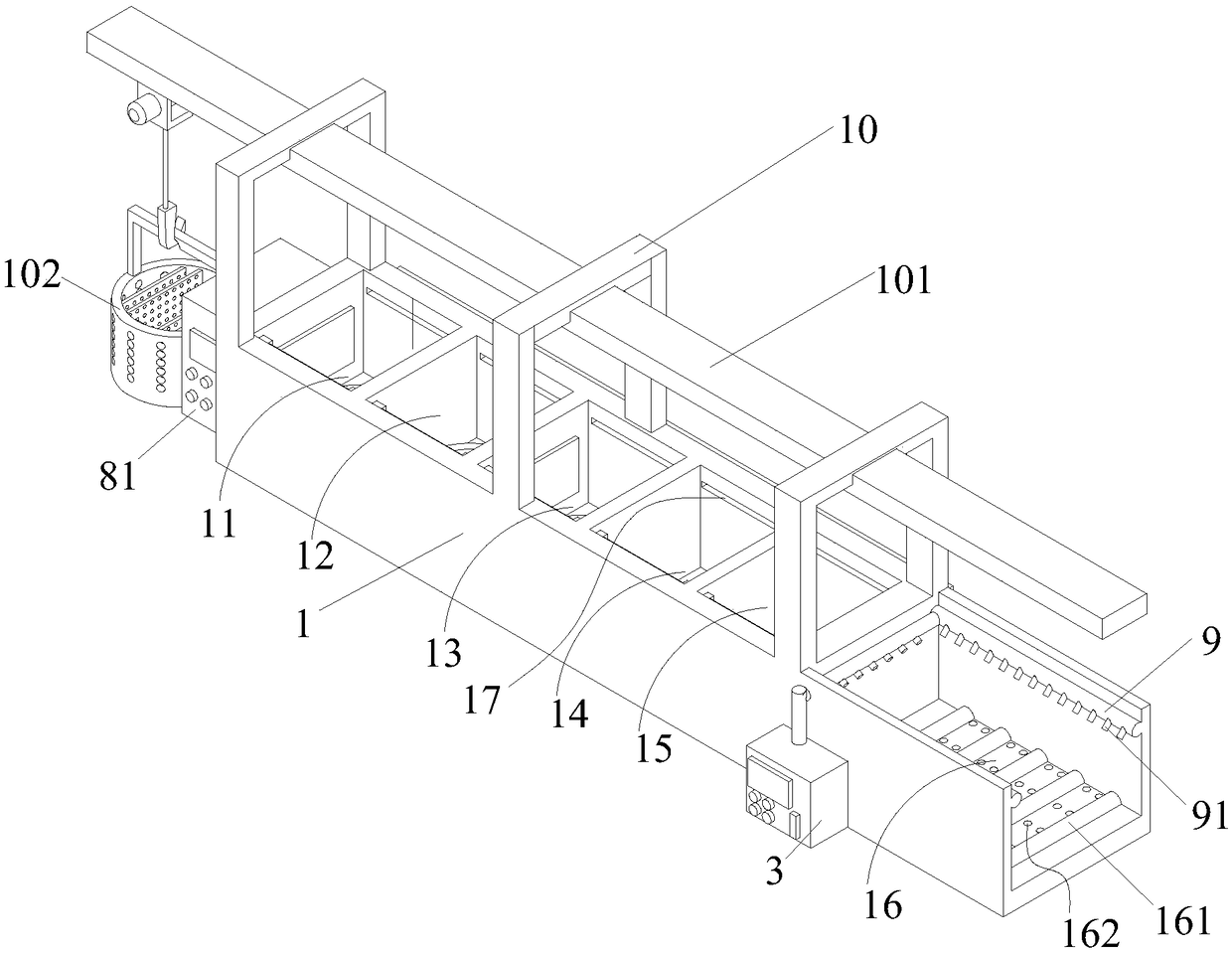

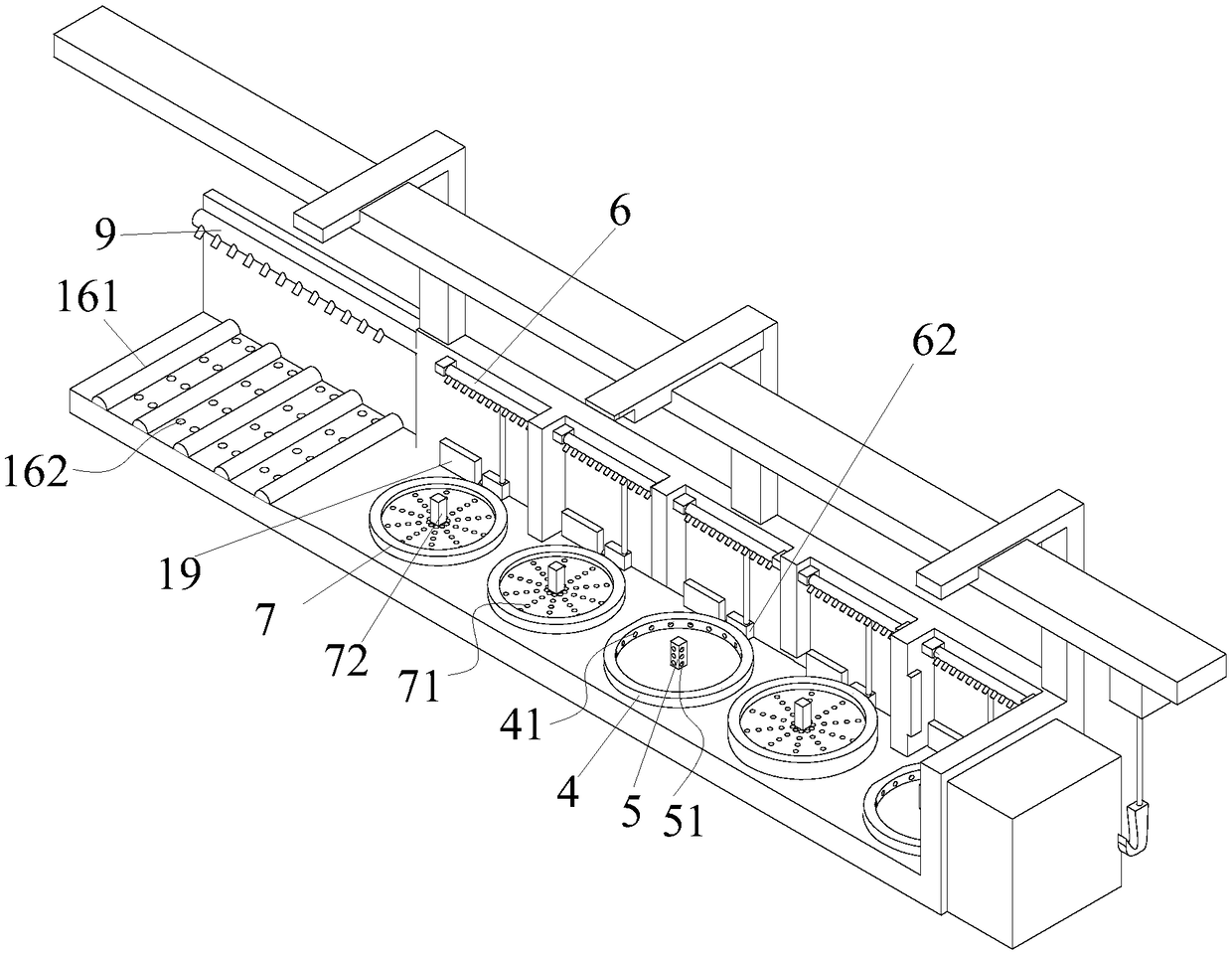

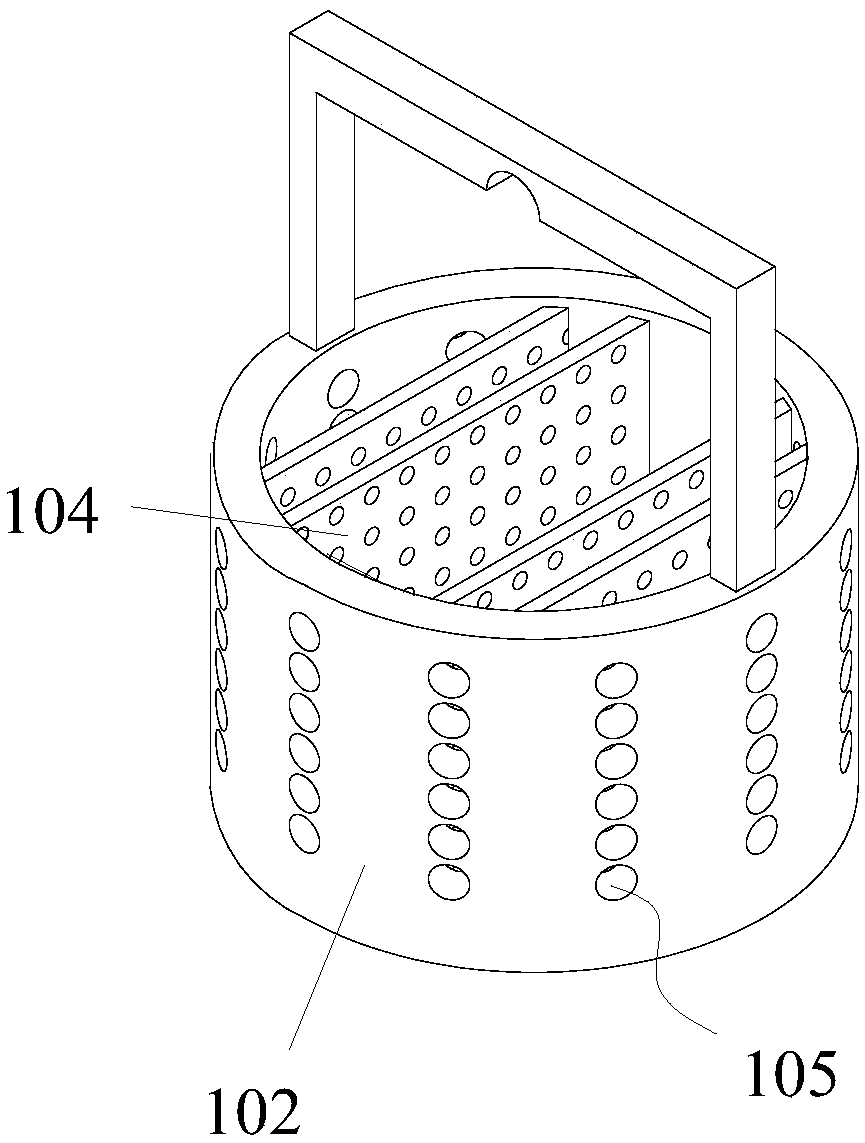

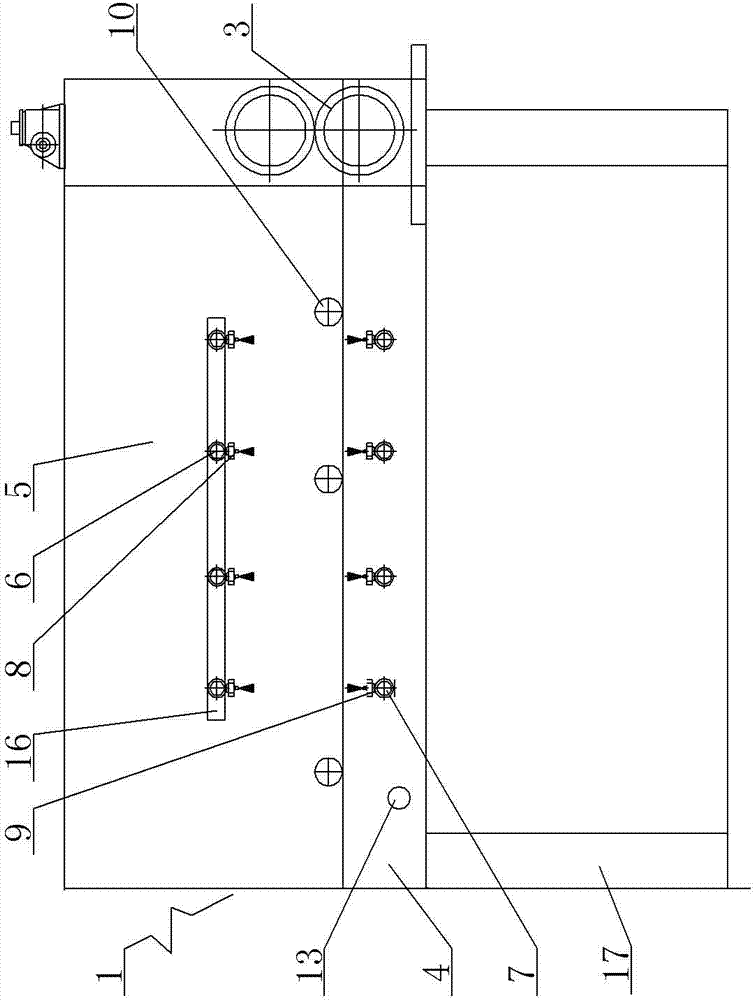

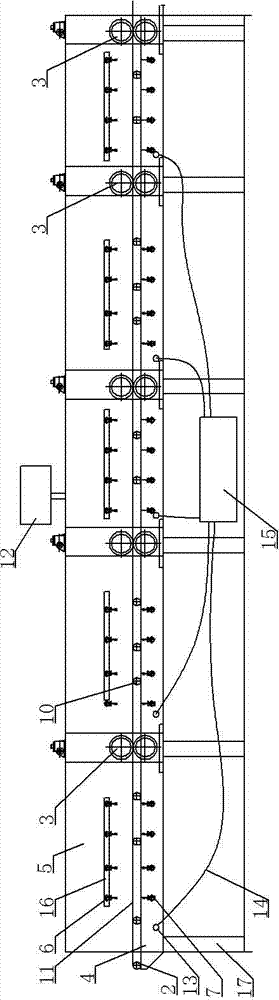

Device for deoiling surface of metal part

ActiveCN109201575ANo secondary pollutionSolve the poor effect of manual degreasing and degreasingCleaning using liquidsEngineeringSewage

The invention discloses a device for deoiling the surface of a metal part and a process of the device, and relates to the technical field of metal treatment devices. The device comprises a workbench.A first degreasing tank, a first pure water tank, a second degreasing tank, a second pure water tank, a third pure water tank and a water cutting box are sequentially arranged on the workbench, a sewage hopper and a draught fan are fixedly mounted on the side wall of the workbench, mounting frames are arranged on the workbench, a crane is fixedly mounted on the mounting frames, the crane is located over the workbench, and a storage basket is arranged on the crane. The multiple degreasing tanks and pure water tanks are arranged, the metal part is degreased and washed with ultrasound, a pre-degreasing agent, a main degreasing agent and pure water multiple times, the metal part is completely washed, generated oil dirt is discharged in time, it is guaranteed that the metal part is not secondarily contaminated, the deoiling quality and efficiency are improved, and the problems that the existing metal part manual deoiling and degreasing effect is poor, time and labor are wasted, and the production efficiency is low are solved.

Owner:安徽新合富力科技有限公司

Steel strip degreasing process

The invention discloses a steel strip degreasing process. The steel strip degreasing process comprises the steps of: steel strip precleaning, chemical degreasing, spray brushing, electrolytic degreasing, cleaning section and hot air drying. The steel strip degreasing process has the following advantages and beneficial effects: as steel strip degreasing production line and process are improved, the viscosity of oil stains on a steel strip is reduced, the infiltration capacity with alkaline liquid is improved, the oil stain removing efficiency is promoted,the whole degreasing efficiency is improved, the practicability is strong, and the operability is excellent; and the process is simple and feasible, is convenient to realize, is obvious in product quality promoting effect, and is high in improvement and transformation investment benefits.

Owner:TIANJIN FUREN STRIP

Extraction method and use method of naringin

ActiveCN104817602AHigh purityEasy to operateSugar derivativesTobacco treatmentReflux extractionNaringin

The invention discloses an extraction method and a use method of naringin. The extraction method comprises stripping yellow outer pericarp of shaddock peel as a raw material to obtain white spongy shaddock peel, carrying out crushing and sieving to obtain shaddock peel powder, carrying out degreasing by an alkane solvent such as petroleum ether with weak polarity, carrying out filtration, drying the filter residue, adding ethanol into the filter residue, carrying out reflux extraction, carrying out pumping filtration, collecting the filtrate, carrying out reduced pressure condensation and carrying out recrystallization to obtain naringin. The extraction method has simple processes and a low cost. The naringin added into cigarette cut tobacco so that cigarette fragrant characteristics are improved and cigarette sensory quality is improved.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Preparation method and application of coix seed extract

InactiveCN109170532AInhibit blood sugar riseImprove starch removal rate and degreasing rateOther chemical processesCombustible gas purificationIonic strengthEmulsion

The invention relates to a preparation method of a coix seed extract. The method comprises the steps as follows: S1, drying and crushing coix seeds to obtain coix seed flour; S2, removing starch and fat in the coix seed flour through acid treatment and addition of a degreasing agent; S3, performing dynamic superhigh-pressure microfluidization treatment on coix seed pulp to promote dissolution extraction of polysaccharide and protein in the coix seed pulp; S4, adjusting the mass concentration of the coix seed pulp, adding an ionic strength regulator to regulate the ionic strength of the coix seed pulp, and adjusting the pH of the coix seed pulp; S5, adding an organic polymer adsorbent to the coix seed pulp to adsorb protein and polysaccharide agglomerates; S6, performing standing and filtration, collecting a filtered-out organic polymer adsorbent, and sequentially eluting polysaccharide and protein; and S7, removing starch and grease again through low-temperature settlement and centrifugal degreasing to finally prepare a coix seed emulsion containing polysaccharide and protein. The prepared coix seed emulsion is compounded into instant compound coix seed flour.

Owner:福建拓天生物科技有限公司

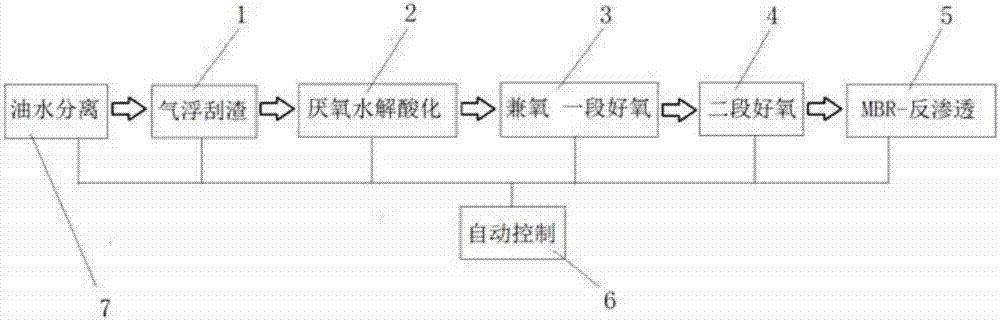

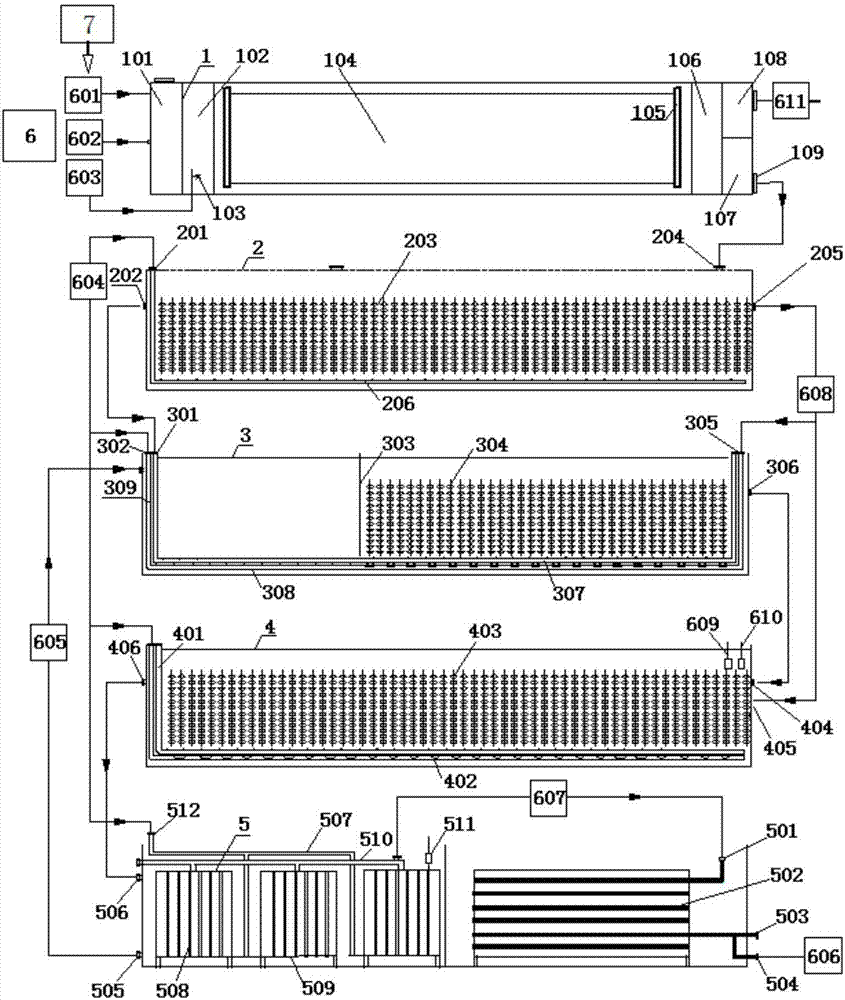

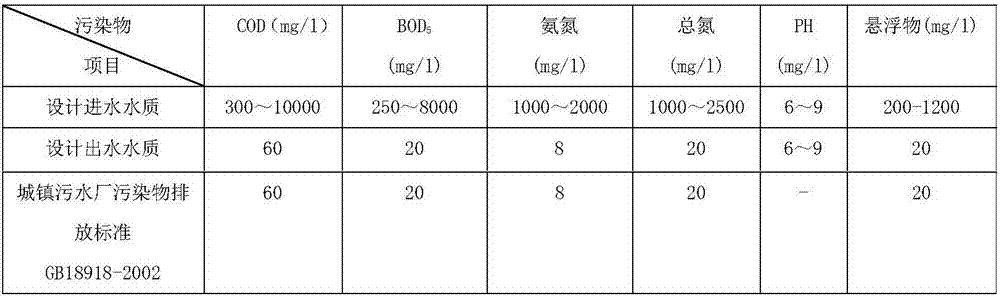

Comprehensive treatment method for oily sewage and comprehensive treatment system

InactiveCN107244787AReduce pollutionHigh degreasing efficiencyWaste water treatment from quariesWater/sewage treatment by centrifugal separationAutomatic controlProcess systems

The invention belongs to the technical field of sewage disposal and relates to a comprehensive treatment method for oily sewage and a comprehensive treatment system. According to the novel sewage treatment system provided by the invention, an oil-water separation system, a floatation scum scraping system, an anaerobic hydrolytic acidification system, a facultative system, a biological contact oxidation system, an MBR (Membrane Bioreactor) / reverse osmosis process system, an automatic control equipment system and the like are integrated into a mobile closed integrated sewage treatment process in a high modularized manner, odors generated by the anaerobic hydrolytic acidification system are conveyed to the biological contact oxidation system, and odor treatment is carried out by using activated sludge. The method and the system have the advantages of simplicity, small investment, low operating cost, convenience in maintenance management, good effect and the like, the treated sewage is discharged after reaching standards, and generated odors are subjected to organized disposal and are discharged after reaching standards, so that the requirements of national environment-friendly policies at present and in future are completely met.

Owner:PANJIN NINGTAI ENERGY TECH

Preparation method of dried salted large yellow croakers

InactiveCN108739968AIncrease contact surfaceFully infiltratedMeat/fish preservation by heatingFood ultrasonic treatmentUltrasonic assistedCold storage

The present invention provides a preparation method of dried salted large yellow croakers. The dried salted large yellow croakers are prepared by pre-treating, fish flesh perforating, ultrasonic assisted pickling, low-temperature dehydrating, quantifying, vacuum packaging and mild sterilizing. The prepared instant dried salted large yellow croakers can also be preserved for a long term; the quality of the product is improved; and the dried salted large yellow croakers have a shelf life of 30-60 days at a normal temperature and a shelf life of 300-360 days at a cold storage, and overcome problems that the processed dried salted large yellow croakers by using the prior art are high in oil content, need cold storage, are hard in texture, poor in mouthfeel, short in time, etc.

Owner:NINGDE CITY YUEHAI AQUATIC PROD

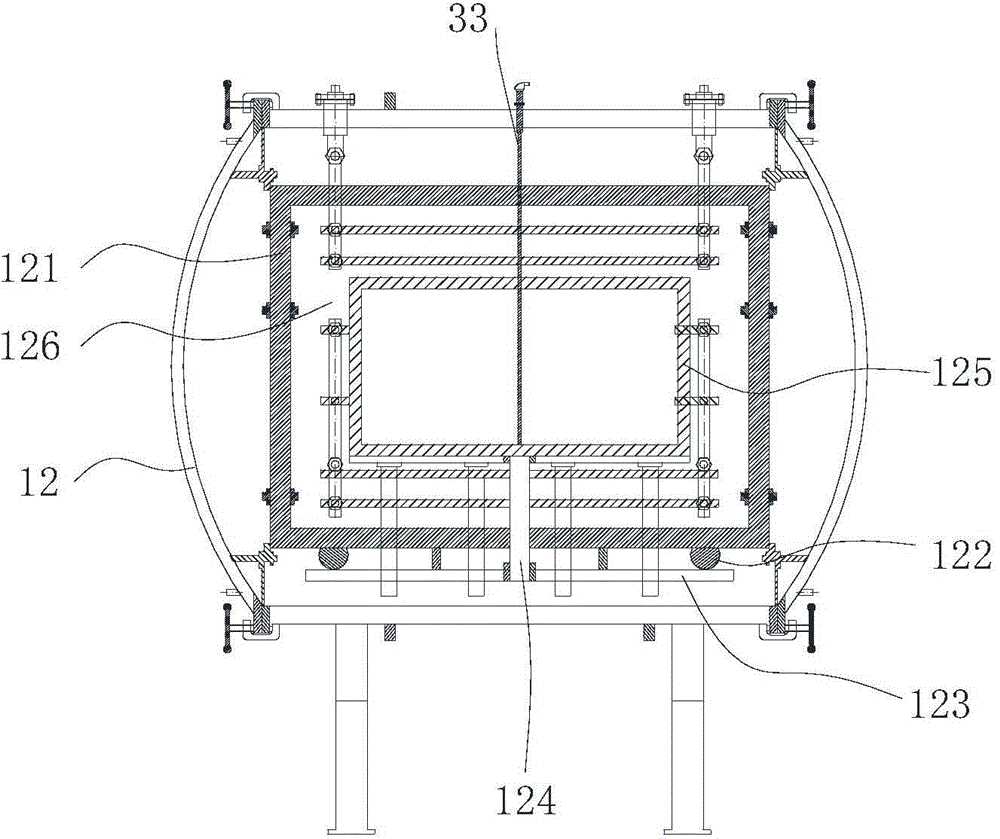

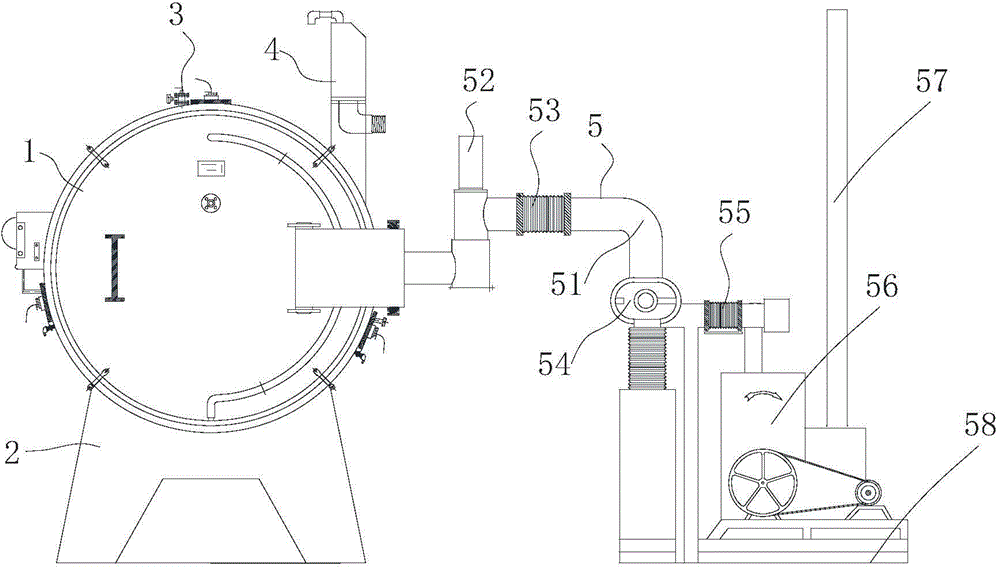

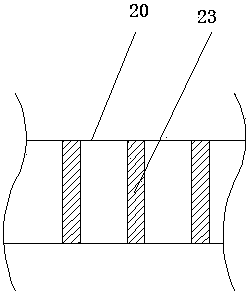

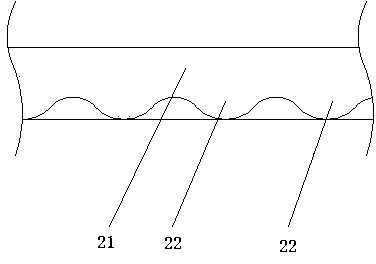

Vacuum degreasing furnace

The invention relates to a vacuum degreasing furnace which comprises a furnace shell with an internal degreasing furnace body. A vacuum device, a circulating cooling device and a degreasing device which are connected through a pipeline are arranged on the outer side of the furnace shell. The degreasing furnace body is a seal cavity with a round section, guide grooves are formed in the inner wall of the seal cavity, and reinforcing rib rings are hooped on the outer wall of the seal cavity. The vacuum degreasing furnace is simple in structure, no grease accumulation dead space exists inside the degreasing furnace body, full degreasing effect is achieved, and degreasing effect is greatly improved; deformation-resisting capability of the degreasing furnace body is improved, and service life of the degreasing furnace body is prolonged; in addition, the external circulating cooling device is utilized, so that cooling time is greatly shortened, and degreasing efficiency is improved.

Owner:SUZHOU MIMO METAL SCI & TECH

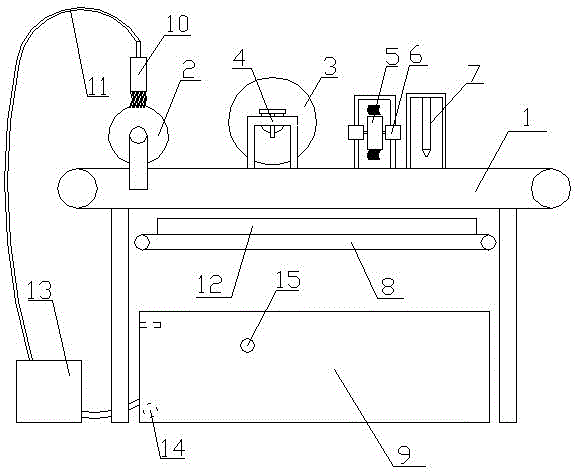

Storage battery plate plaster brushing device

InactiveCN104485447AIncrease usageSave production materialsLead-acid accumulator electrodesWaste accumulators reclaimingBrush deviceEngineering

The invention provides a storage battery plate plaster brushing device which comprises a transfer rail, wherein a plaster coating roller is arranged on the transfer rail and is full of lead plaster; a compaction roller is arranged on the right side of the plaster coating roller and is arranged on two sides of the transfer rail by virtue of a height adjusting device on two sides; a residual plaster brush is arranged on the right side of the compaction roller and rotates by virtue of rotating motors on two sides; an air faucet is arranged on the right side of the residual plaster brush and is flush with the position of the residual plaster brush; the middle of the transfer rail is hollow; a recovery rail is arranged on the lower part of the transfer rail and is opposite to the direction of the transfer rail; and a residual plaster collection box is arranged at the bottom at the leftmost end of the recovery rail. The residual plaster cleaned by the residual plaster brush and the air faucet is recovered into the residual plaster collection box by virtue of the recovery rail and is recycled, the utilization rate of the lead plaster is improved, the production materials are saved, the cost is reduced, the plaster is removed by virtue of a form of combining the air faucet and the residual plaster brush, and the plaster removal efficiency is improved.

Owner:TIANNENG BATTERY WUHU

Environment-friendly microorganism degreasing agent

The invention discloses an environment-friendly microorganism degreasing agent, and belongs to the technical field of chemical industry. The microorganism degreasing agent consists of two ingredients A and B, wherein the ingredients A comprise the following ingredients in parts by weight: 20 to 30 parts of sodium carbonate, 0.2 to 1.6 parts of sodium alkyl benzene sulfonate, 0.1 to 0.5 parts of nonylphenol polyoxyethylene ether, 10 to 15 parts of isopropanol, 1 to 10 parts of organic silicon defoamer and 20 to 30 parts of water, and the ingredients B comprise the following ingredients in parts by weight: 3 to 15 parts of peptone, 4 to 9 parts of glucose, 15 to 20 parts of microbial strains, 5 to 10 parts of biological enzyme, 10 to 15 parts of soluble starch and 30 to 40 parts of water. A preparation method comprises the steps that after the ingredients B are uniformly mixed, the culture is carried out for 1 to 3 days at 30 to 40 DEG C, seed solution is obtained, the seed solution and the ingredient A are mixed and stirred uniformly, and the microorganism degreasing agent is obtained. The microorganism degreasing agent has the characteristics that a glass or plastic surface is not damaged, the degreasing speed is high, the degreasing efficiency is high, safety and environment protection are realized, and the like.

Owner:张锦碧

Degreasing-sintering integrated production method of ITO target

The invention discloses a degreasing-sintering integrated production method of an ITO target. The production method comprises the following steps: 1) mixing ITO powder, a dispersing agent and water, performing ball milling, adding a binder, and performing ultrasonic and vacuum defoaming to obtain slurry; 2) injecting the slurry into a mold, molding to obtain a target blank, demolding, and drying the target blank; and 3) placing the target blank on a load bearing board in a degreasing-sintering integrated furnace, and carrying out programmed heating and programmed cooling, so as to obtain the ITO target. In the process of densification of the target blank, the target billet is directly heated from the highest temperature of degreasing to perform sintering at a higher temperature, and a process of cooling, transferring and reheating the target blank after degreasing is omitted, so that the efficiency of degreasing and sintering is remarkably improved, the cracking caused by the transferof the target blank between a degreasing furnace and a sintering furnace is eliminated, the production effectiveness is improved, and the mass production of ITO targets is facilitated.

Owner:GUANGDONG KAISHENG PV TTECH RES INST +1

Formula of biological compound type degreasing agent

The invention discloses a formula of a biological compound type degreasing agent, which relates to the technical field of surface degreasing of metal materials. According to the formula, the degreasing agent consists of a microorganism component and a chemical component, wherein each liter of microorganism component comprises 2.5 to 3mL of zoogloea sp., 4 to 5mL of Mohave bacillus, 2 to 2.5mL of bacillus subtilis and 3 to 4mL of Serratia marcescens; and each liter of chemical component comprises 2g of polyethyleneglycol fatty alcohol ether sulfonate, 5g of nonylphenol polyoxyethylene ether, 4g of fatty alcohol polyurethane alkyl ether, 2.5g of fatty alcohol polyoxyethylene ether, 2g of nonylphenol polyoxyethylene ether sodium sulfate, 2.5g of sodium metasilicate, 3g of isopropyl alcohol, 0.1g of ethylene diamine tetraacetic acid and the balance of water. By the formula, greasy dirt on a metal surface can be treated in advance, and then the emulsified greasy dirt in water is decomposed on the basis of the microorganism component, so that the metal surface has an efficient, economic and environment-friendly degreasing process; and the degreasing agent has a wide degreasing range, high degreasing efficiency and a simple preparation method, is biologically degradable and is convenient to use.

Owner:BENGBU YUCHENG NEW MATERIAL TECH

Degreasing cleaning spraying tank

The invention provides a degreasing cleaning spraying tank, and the tank helps to shorten degreasing length, reduce land cost and improve degreasing efficiency, and further helps to improve the production efficiency of a whole production line. The tank comprises five oil-removing cleaning boxes; the front end of the first-segment oil-removing cleaning box is provided with a guide roller structure, and the last-segment oil-removing cleaning box segment is provided with a guide pressure-roller structure; a support is arranged at the bottom of each oil-removing cleaning box, a hot-water accumulation tank is arranged at the central part of each oil-removing cleaning box, and two baffle plates are arranged at two sides of the upper part of each oil-removing cleaning box; a guide pressure-roller structure is arranged between each two adjacent oil-removing cleaning boxes; uniformly-distributed upper water pipes are installed in a clamping groove between two baffle plates at the upper part of each oil-removing cleaning box in a clamping manner; uniformly-distributed lower water pipes are arranged at two side walls of the hot-water accumulation tank at the central part of each oil-removing cleaning box; and the lower end face of each upper water pipe is uniformly provided with upper nozzles, and the upper end face of each lower water pipe is uniformly provided with lower nozzles.

Owner:WUXI XINJIAYUAN METALLURGY MACHINERY MFG

Process of utilizing sturgeon raw material to extract collagen

PendingCN110128530AReduce in quantityEasy extractionConnective tissue peptidesPeptide preparation methodsYeastSturgeon

The invention discloses a process of utilizing a sturgeon raw material to extract collagen. The process includes following steps: 1), selecting sturgeon skin and / or swim bladder which is washed cleanas a raw material, slicing, adding into 5-10wt% sodium hydroxide solution for soaking for 5-10h, filtering, and washing the material clean; 2), adding a material obtained in the step 1) into a defatting mixed solution for defatting for 1-2h, performing ultrasonic treatment during defatting, and washing clean after ultrasonic treatment is completed; 3), adding a material obtained in the step 2) into acid for swelling, homogenizing, using a sodium hydroxide solution to adjust pH to 4.0-5.5, adding protease for enzymolysis, adding yeast powder after enzymolysis is completed, controlling temperature at 30-35 DEG C, stirring for reaction for 2h, and performing enzyme deactivation; 4), discoloring enzymolysis liquid obtained after enzyme deactivation in the step 3), centrifuging, purifying, concentrating, and spray-drying to obtain collagen powder. The process can quickly extract collagen, and the collagen extracted by the process is high in purity, small in molecular weight and easy to absorb.

Owner:湖北清江鲟龙渔业有限公司

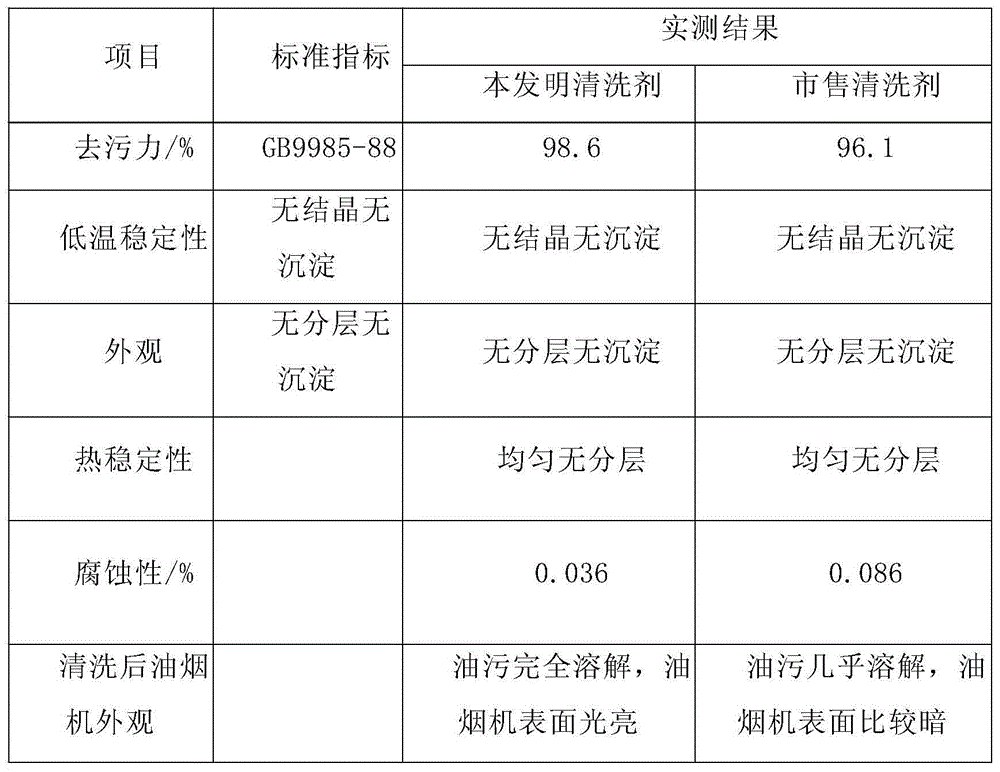

Smoke ventilator cleaning compound and preparation method thereof

InactiveCN103911226ASuppress generationEasy to useOrganic detergent compounding agentsSurface-active detergent compositionsAmylaseSodium metasilicate

The invention relates to the technical field for removing oil stain, and discloses a smoke ventilator cleaning compound and a preparation method. The smoke ventilator cleaning compound comprises the following raw materials by weight percentage: 5-20% of fatty acid sorbitan, 5-20% of behenyl alcohol polyoxyethylene ether, 5-10% of cosurfactant, 0.5-1.5% of amylase, 0.5-1.5% of protease, 1-15% of turpentine, 0.1-1% of essence, 0.1-1% of dispersant, 0.1-1% of anhydrous sodium metasilicate, 0.1-1% of bacterial depressant and the balance of deionized water. The smoke ventilator cleaning compound has the advantages of convenient usage, mild effect, low cost, strong oil stain removal capability, high efficiency, safety, no pollution and mild smell. The addition of the bacterial depressant can effectively inhibit the generation of bacteria, the addition of antirust antiseptic can provide excellent anticorrosion and protection effect. The smoke ventilator cleaning compound adds amylase and protease, so that oil stain removal efficiency is increased, and the oil stain removal time can be shortened.

Owner:王素贞

Novel catgut degreasing technological method

InactiveCN106310354AHigh degreasing efficiencyHigh tensile strengthSuture equipmentsTime rangeFreeze-drying

The invention belongs to the field of biological suture lines and particularly relates to a novel catgut degreasing technological method. The novel catgut degreasing technological method includes the following steps of 1, cleaning, wherein a fresh sheep intestine and a cattle casing are selected, blood-containing water on the surface of the casing is washed away with clean water, and then mucosa, serosa and mesentery in the casing are removed; 2, freezing, wherein the cleaned casing is placed in a refrigeration house after surface water of the casing is removed, the temperature of the refrigeration house is below -60 DEG C, and the refrigeration time ranges from 20 h to 24 h; 3, freeze-drying, wherein freeze-drying is carried out for 48 hours at the temperature of -40 DEG C to -45 DEG C, the casing is wrapped by filter paper, and the casing is put in an extractor; 4, degreasing, wherein the freeze-dried casing is put in alkali liquor at the temperature of 18 DEG C to be treated for 8-12 h, and then a degreasing agent is added for treatment for 12 h. Degreasing efficiency is improved, the degreasing rate reaches 98%, no fat white dot exists on the appearance of a catgut body, and anti-tensile strength is enhanced by 20%.

Owner:程庭润

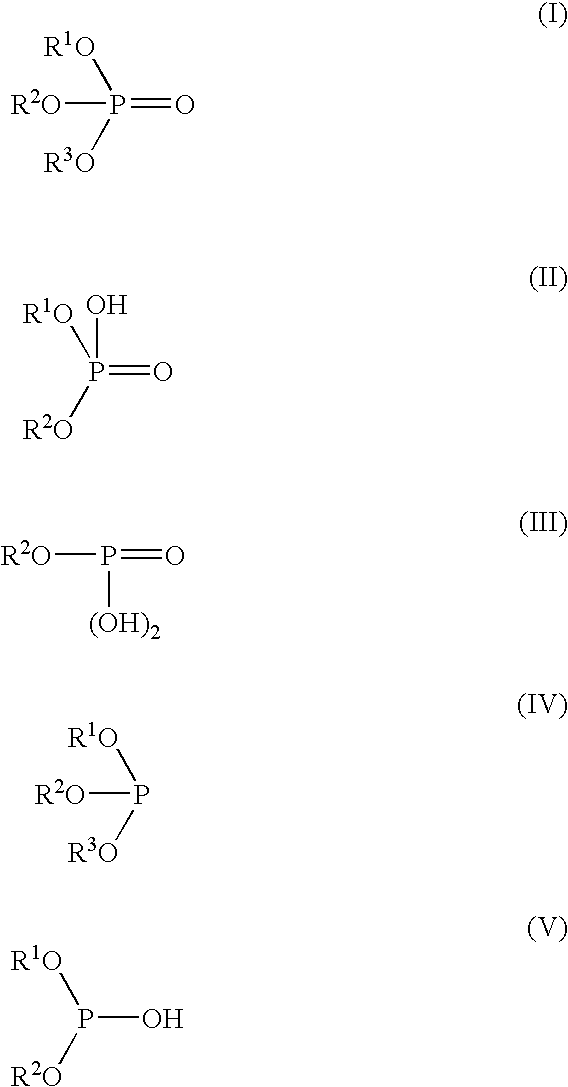

Lubricating oil composition for working using sizing press

InactiveUS20070149416A1Good compatibilityHigh degreasing efficiencyBearing componentsAdditivesViscositySizing

Provided is a lubricating oil composition for sizing which is excellent in machinability and degreasing efficiency and which is excellent in compatibility with an impregnating oil and a sintered metal of oil impregnated bearings. A lubricating oil composition for sizing, including (A) a lubricating base oil having a kinematic viscosity of 0.5 to 100 mm2 / s at 40° C. and compounded therein (B) an extreme-pressure agent in an amount of 0.1 to 10% by mass, and (C) a metal deactivator in an amount of 0.01 to 5% by mass, each based on a total amount of the composition.

Owner:IDEMITSU KOSAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com