Extraction separation tech. of octagonal shickimmi oxalic acid

A separation technology, the technology of shikimic acid, is applied in the separation/purification of carboxylic acid compounds, medical preparations containing active ingredients, plant/algae/fungus/moss components, etc. Production, low utilization of raw materials, etc., to achieve the effect of high product recovery rate, reduced impact, and improved utilization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

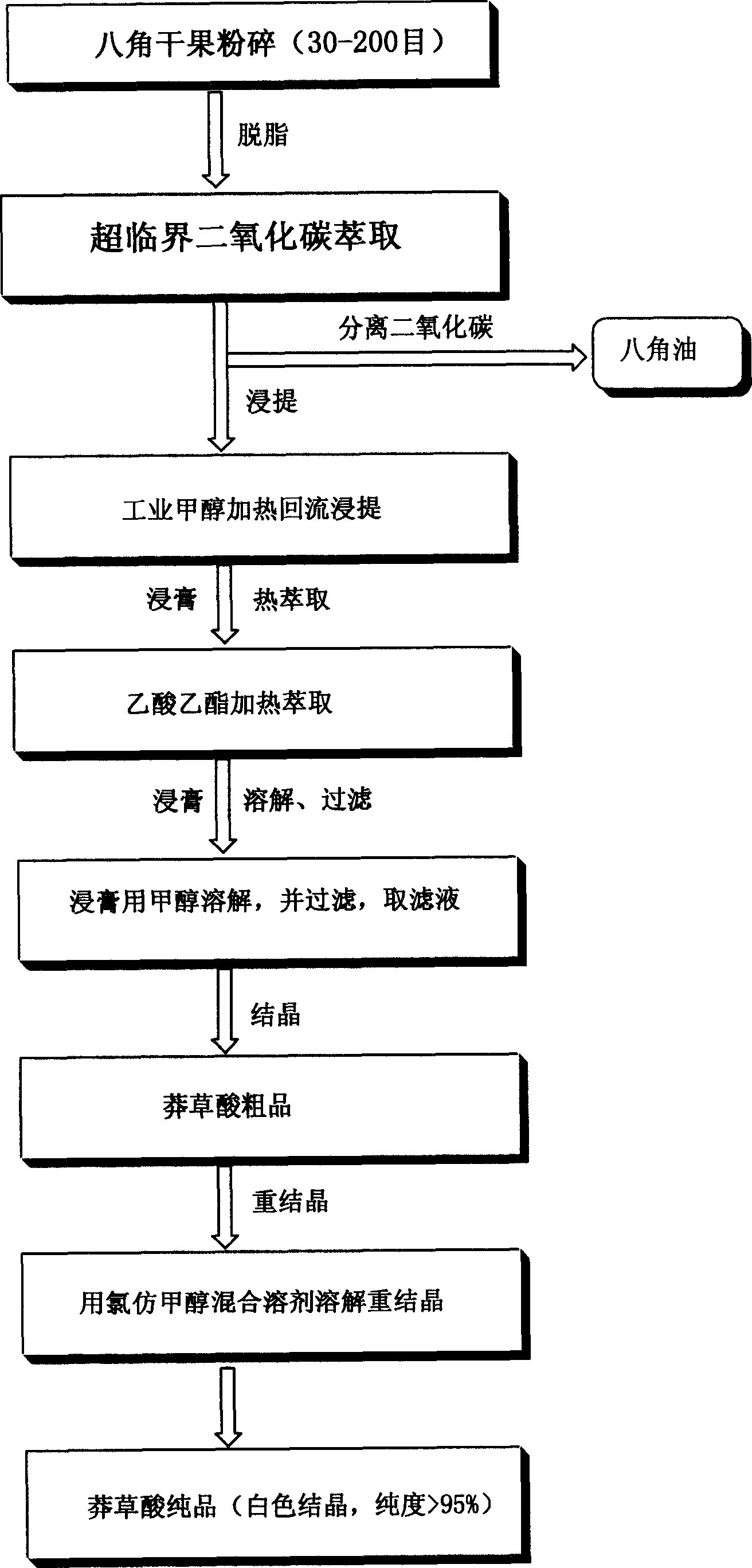

Image

Examples

Embodiment 1

[0020] Use 1 kg of dry star anise produced in Luchun County, Yunnan, crush it to 30 meshes, use a supercritical carbon dioxide extraction device (extraction kettle 10L, separation kettle 10L), under the conditions of 40°C, 25MPa, and a carbon dioxide flow rate of 15kg / h Extract for 1 hour, separate oil and fat under the conditions of 40°C and 12MPa, and obtain 0.16 kg of star anise oil, which can be directly used as food flavoring. The extracted star anise slag was heated and refluxed for 3 times with 3-4 times its volume of commercially pure methanol, the leaching temperature was 50°C, and the reflux time was 3, 2, and 1 h respectively. The three extracts were combined, and the methanol was recovered to obtain leaching Paste 0.15kg. The extract was heated and extracted with 0.3L ethyl acetate, the extraction temperature was 50°C, the extraction times were 2 times, the extracts were combined, and the ethyl acetate was recovered. Heat and stir the extract with 0.5L of methanol...

Embodiment 2

[0022] 5 kg of star anise raw material, crushed to 150 mesh, using a supercritical carbon dioxide extraction device, extracted at 43°C, 30MPa, and a carbon dioxide flow rate of 17kg / h for 1.5h, separated oil and fat at 43°C, 14MPa, and obtained 0.95kg of star anise oil . The extracted star anise slag is heated and refluxed for 3 times with industrially pure methanol 3 to 4 times its volume. The leaching temperature is 55°C, and the reflux time is 3, 2, and 1 h respectively. The three extracts are combined, and the methanol is recovered to obtain leaching Cream 0.7kg. The extract is heated and extracted with ethyl acetate 2 to 4 times its volume, the extraction temperature is 53°C, the extraction times are 3 times, the extracts are combined, and the ethyl acetate is recovered. Heat and stir the extract with 3L of methanol at 55°C to dissolve, filter while hot, let the filtrate stand naturally, cool and crystallize to obtain 205g of crude shikimic acid. The crude product of sh...

Embodiment 3

[0024] 5 kg of star anise raw material was crushed into 200 meshes, extracted by supercritical carbon dioxide extraction device at 45°C, 35MPa, and carbon dioxide flow rate of 20kg / h for 2 hours, and oil was separated at 45°C and 14MPa to obtain 0.96kg of star anise oil. The extracted star anise slag is heated and refluxed for 3 times with industrially pure methanol 3 to 4 times its volume. The leaching temperature is 55°C, and the reflux time is 3, 2, and 1 h respectively. The three extracts are combined, and the methanol is recovered to obtain leaching Cream 0.7kg. The extract is heated and extracted with ethyl acetate 2 to 4 times its volume, the extraction temperature is 53°C, the extraction times are 3 times, the extracts are combined, and the ethyl acetate is recovered. Heat and stir the extract with 3L of methanol at 55°C to dissolve, filter while hot, let the filtrate stand naturally, cool and crystallize to obtain 207g of crude shikimic acid. The crude product of shi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com