Vacuum degreasing sintering furnace

A vacuum degreasing and sintering furnace technology, applied in the field of vacuum heat treatment equipment, can solve the problems of low degreasing rate, complicated operation and low processing efficiency at one time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

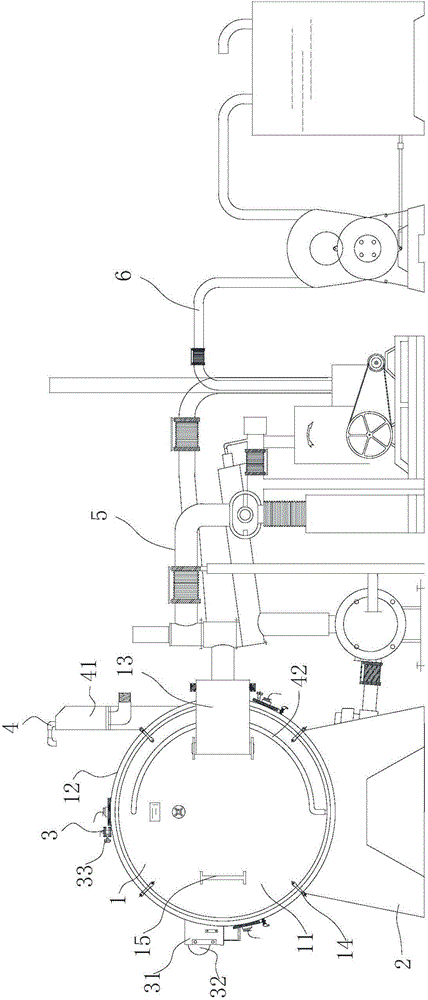

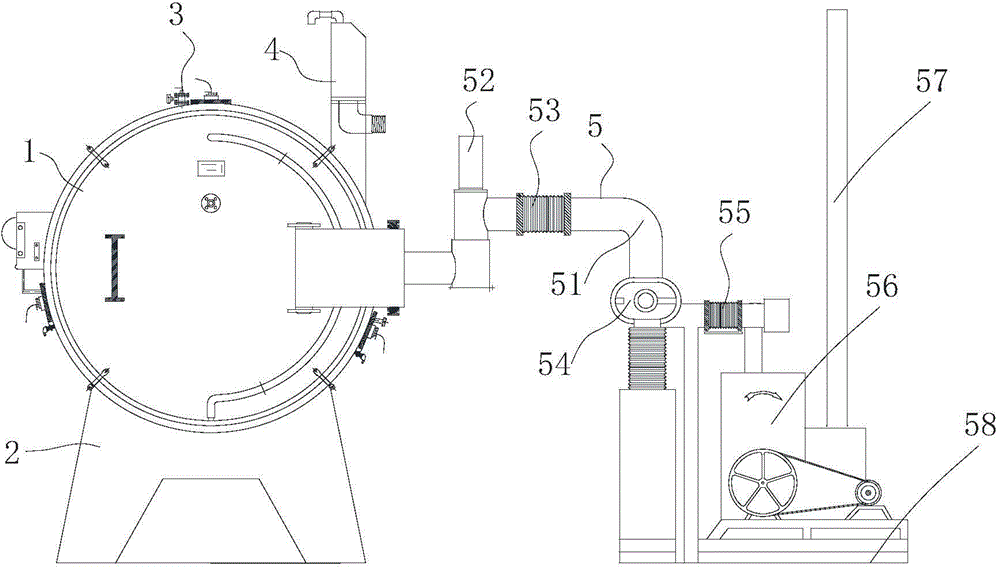

[0014] Combine below Figure 1-4 A detailed description will be made to the specific embodiment of the present invention.

[0015] Such as Figure 1-4 The shown vacuum degreasing sintering furnace includes a furnace base 2, a sintering furnace 1 fixed on the furnace base, an inflating device 3 connected to the sintering furnace, a water cooling device 4, a vacuuming device 5 and a degreasing device 6.

[0016] The sintering furnace 1 includes a furnace door 11 and a furnace body 12, the furnace door 11 and the furnace body 12 are connected by a hinge 13, a handle 15 is provided on the furnace door 11, and multiple sets of furnace door locks are arranged along the edges of the furnace door 11 and the furnace body 12. piece 14.

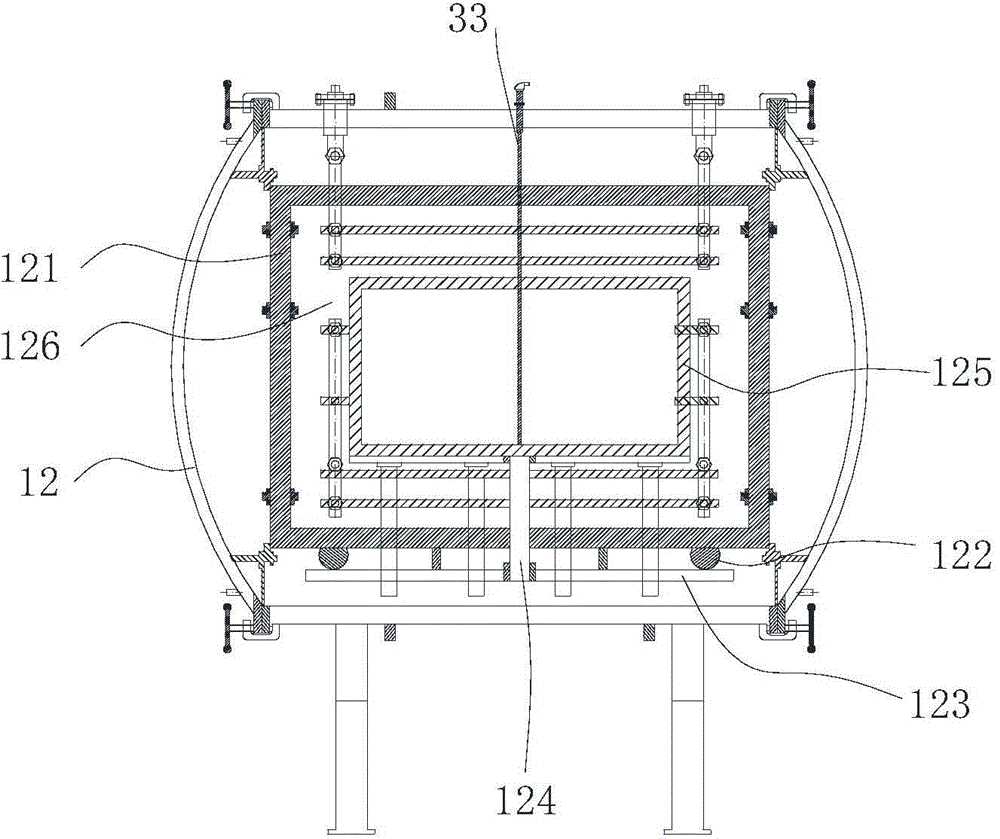

[0017] The body of the furnace is provided with an inner insulating door 121, a graphite storage box 125, a pulley 122, a bracket 123 and an outlet pipe 124. The inner insulating door 121 seals the middle part of the hearth 126 in the body of furnace ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com