Normal-temperature water-based non-phosphorus rust-proof cleaning agent for heavy oil

A technology of cleaning agent and normal temperature water, applied in the field of cleaning agent, normal temperature water-based phosphorus-free heavy oil anti-rust cleaning agent, can solve the problems of rough quality, operator injury, insufficient washing effect, etc., and achieve high natural degradation and high degreasing Efficiency, the effect of overcoming metal rust easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

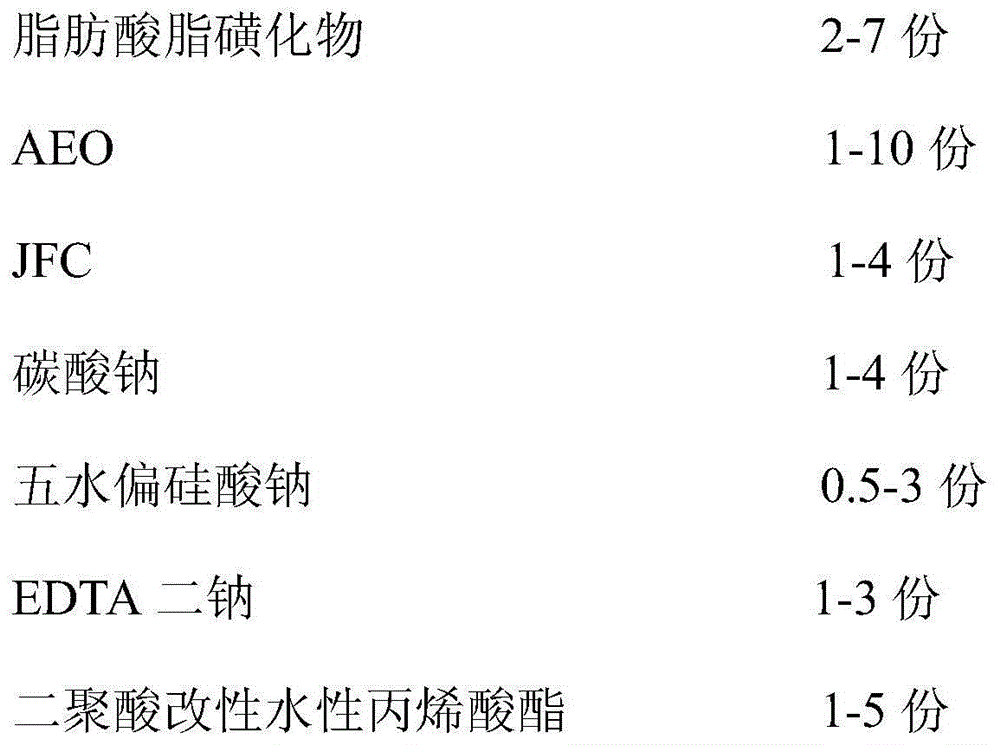

[0023] A normal temperature water-based phosphorus-free heavy oil anti-rust cleaning agent comprises the following components in parts by weight:

[0024]

[0025] Preparation method: First measure a certain amount of tap water, first dissolve disodium EDTA, sodium carbonate, and sodium metasilicate in sequence according to parts by weight to form a homogeneous transparent solution, and then dissolve surfactants and high molecular polymers in sequence to form a homogeneous solution , the two are mixed and stirred evenly.

Embodiment 2

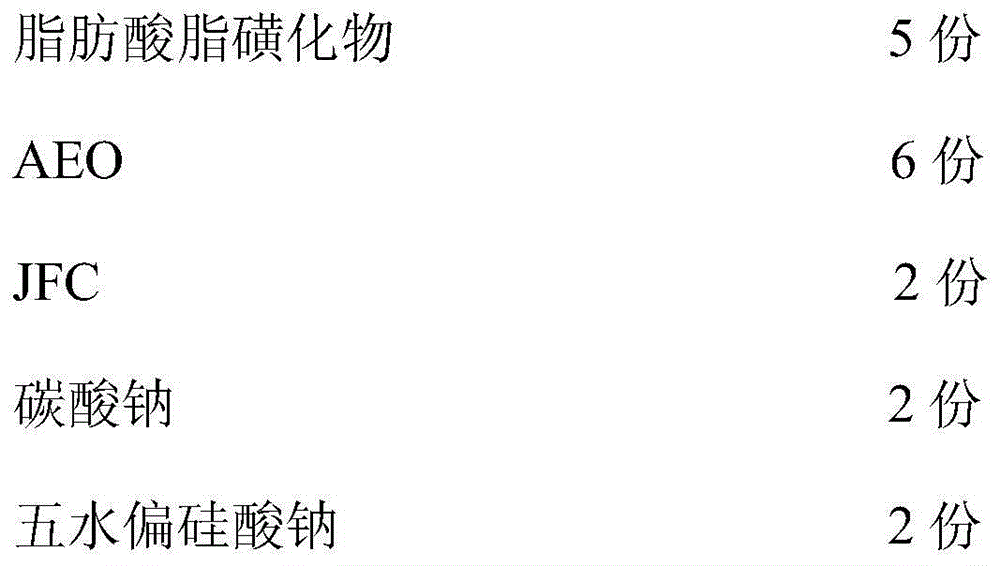

[0027] A normal temperature water-based phosphorus-free heavy oil anti-rust cleaning agent comprises the following components in parts by weight:

[0028]

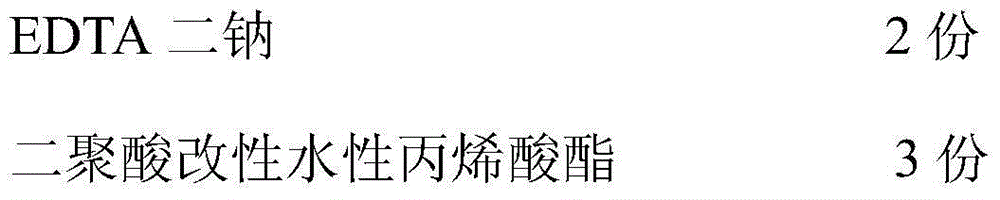

[0029]

[0030] Preparation method: First measure a certain amount of tap water, first dissolve disodium EDTA, sodium carbonate, and sodium metasilicate in sequence according to parts by weight to form a homogeneous transparent solution, and then dissolve surfactants and high molecular polymers in sequence to form a homogeneous solution , the two are mixed and stirred evenly.

Embodiment 3

[0032] A normal temperature water-based phosphorus-free heavy oil anti-rust cleaning agent comprises the following components in parts by weight:

[0033]

[0034] Preparation method: First measure a certain amount of tap water, first dissolve disodium EDTA, sodium carbonate, and sodium metasilicate in sequence according to parts by weight to form a homogeneous transparent solution, and then dissolve surfactants and high molecular polymers in sequence to form a homogeneous solution , the two are mixed and stirred evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com