Smoke ventilator cleaning compound and preparation method thereof

A technology for cleaning agents and range hoods, which is applied in the directions of detergent compounding agents, detergent compositions, chemical instruments and methods, etc., and can solve the problem of unsatisfactory heavy-duty removal effect, unsatisfactory use safety, skin corrosive damage, etc. It can achieve excellent anti-corrosion protection, inhibit the formation of bacteria, and have strong oil removal ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

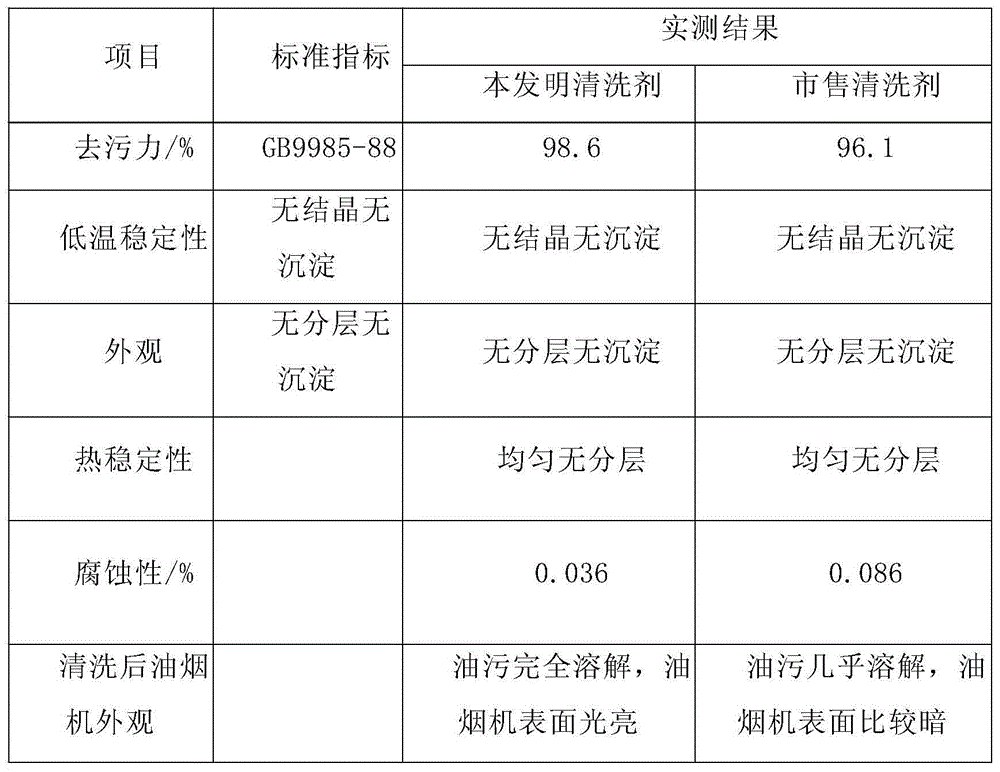

Image

Examples

Embodiment 1

[0012] A cleaning agent for a range hood, comprising the following raw materials in weight percentage: fatty acid sorbitan 5%, fatty acid alcohol polyoxyethylene ether 5%, stearyl alcohol 5%, amylase 0.5%, protease 0.5%, D-limonene 1%, Flavor 0.1%, dispersant 0.1%, anhydrous sodium metasilicate 0.1%, bacteriostatic agent 0.1%, and the balance is deionized water; a preparation method of a range hood cleaning agent includes the following steps: Add deionized water and dispersant to a clean mixer, mix well, then add fatty acid sorbitan, fatty acid alcohol polyoxyethylene ether, stearyl alcohol, and turpentine in sequence at room temperature. Stir evenly. After standing for 10 minutes, the starch Enzyme, protease, flavor, dispersant, anhydrous sodium metasilicate, bacteriostatic agent, stir while adding, and stir evenly. The invention is convenient to use, has mild effect, low cost, strong degreasing ability, high efficiency, safety and no pollution, and mild odor. The addition of ...

Embodiment 2

[0014] A range hood cleaning agent, comprising the following raw materials in weight percentages: fatty acid sorbitan 8%, fatty acid alcohol polyoxyethylene ether 8%, stearylamine 6%, amylase 0.6%, protease 0.6%, D-limonene 3%, Flavor 0.2%, dispersant 0.2%, anhydrous sodium metasilicate 0.2%, bacteriostatic agent 0.2%, and the balance is deionized water; a preparation method of a range hood cleaning agent includes the following steps: Add deionized water and dispersant to a clean mixer, mix well, then add fatty acid sorbitan, fatty acid alcohol polyoxyethylene ether, stearylamine, and turpentine in sequence at room temperature. Stir evenly. After standing for 13 minutes, starch Enzymes, proteases, flavors, dispersants, anhydrous sodium metasilicate, antibacterial agents, add while stirring, and mix well. The invention is convenient to use, mild in action, low cost, strong in degreasing ability, high in efficiency, safe and pollution-free, and mild in smell. The addition of bact...

Embodiment 3

[0016] A cleaning agent for a range hood, comprising the following raw materials in weight percentages: fatty acid sorbitan 10%, fatty acid alcohol polyoxyethylene ether 10%, coco diethanolamine 8%, amylase 0.8%, protease 0.8%, D-limonene 5 %, flavor 0.3%, dispersant 0.3%, anhydrous sodium metasilicate 0.3%, antibacterial agent 0.3%, and the balance is deionized water; a preparation method of a range hood cleaning agent, including the following steps: according to the above weight Add deionized water and dispersant to a clean mixer, mix well, then add fatty acid sorbitan, fatty acid alcohol polyoxyethylene ether, and coco diethanolamine turpentine in sequence at room temperature, mix well, and let stand for 15 minutes Afterwards, add amylase, protease, flavor, dispersant, anhydrous sodium metasilicate, and bacteriostatic agent, and stir while adding, and stir evenly. The invention is convenient to use, has mild effect, low cost, strong degreasing ability, high efficiency, safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com