Comprehensive treatment method for oily sewage and comprehensive treatment system

A comprehensive treatment and sewage technology, applied in water/sewage treatment, multi-stage water/sewage treatment, biological water/sewage treatment, etc., can solve problems such as ineffective disposal of odor, great impact on air quality, and single treatment technology. Achieve the effects of avoiding the loss of biological bacteria, facilitating operation and management, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

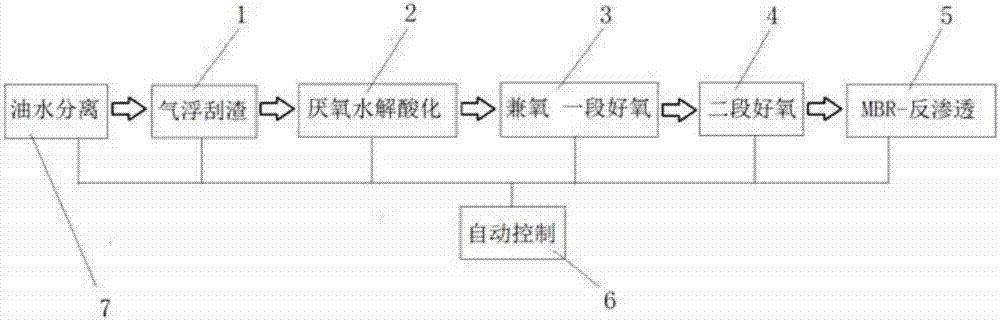

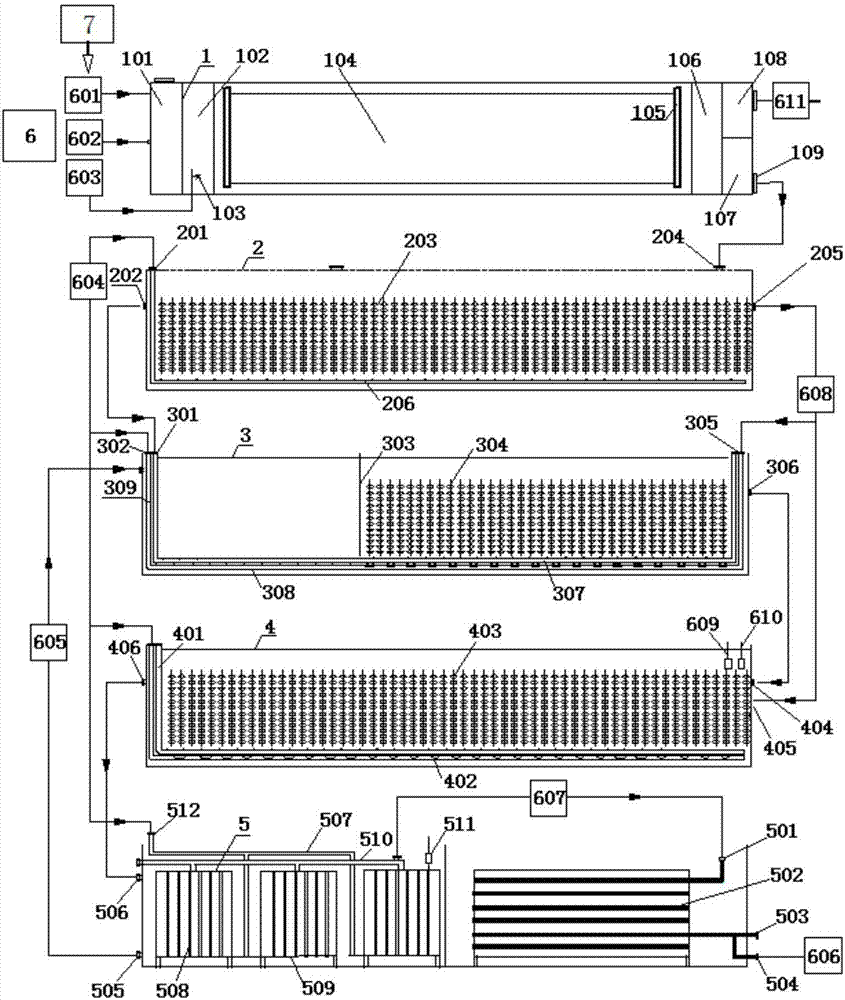

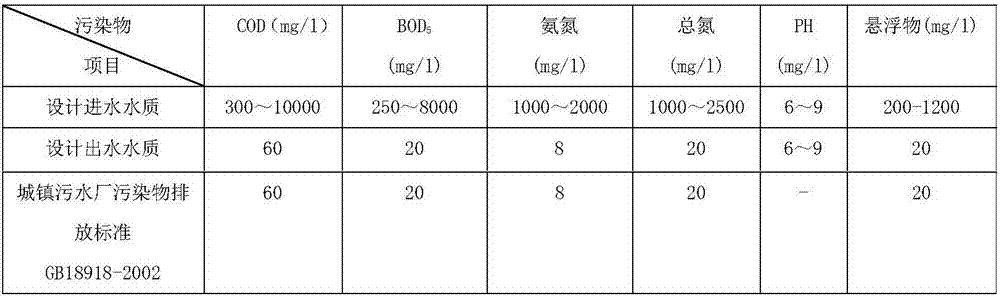

[0050] In order to achieve the above goals, the present invention provides oil-water separation system, air flotation and slag scraping system, anaerobic hydrolysis acidification system, facultative oxygen system, biological contact oxidation system, MBR membrane bioreactor / reverse osmosis process system and automatic control equipment system, etc. The highly modular and integrated mobile closed sewage comprehensive treatment process is a new type of sewage treatment system that transports the odor generated by the anaerobic hydrolysis acidification system to the biological contact oxidation system and uses activated sludge for odor treatment.

[0051] Among the above systems, oil-water separation system, air flotation and slag scraping system, anaerobic hydrolysis and acidification system, aerobic system, one-stage aerobic system, two-stage aerobic system, and MBR membrane bioreactor / reverse osmosis system are composed of 6 modules, which are respectively centralized Packed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com