Extraction method and use method of naringin

An extraction method and naringin technology are applied in the application and preparation field of naringin, which can solve the problems of low target substance content, complicated operation and high cost, and achieve the effects of high degreasing efficiency, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] ① Wash the white spongy mesocarp obtained after peeling off the yellow exocarp of the mature fresh pomelo peel, dry, crush and sieve to 30 mesh;

[0030] ② Reflux degreasing with petroleum ether, filter, and dry the filter residue at 40°C;

[0031] ③Add 60% ethanol to the filter residue, the volume of the added ethanol is 15 times of the quality of the degreased pomelo peel filter residue, heat and stir at 60°C, and reflux for 1.5h;

[0032] ④ suction filtration, collecting the filtrate, concentrating the filtrate under reduced pressure to 1 / 3 of the original volume of the filtrate, to obtain crude naringin;

[0033] ⑤ Add a small amount of water to the crude naringin, dissolve it at 60°C, cool it at 4°C for 24 hours, remove the supernatant, filter and collect the precipitate;

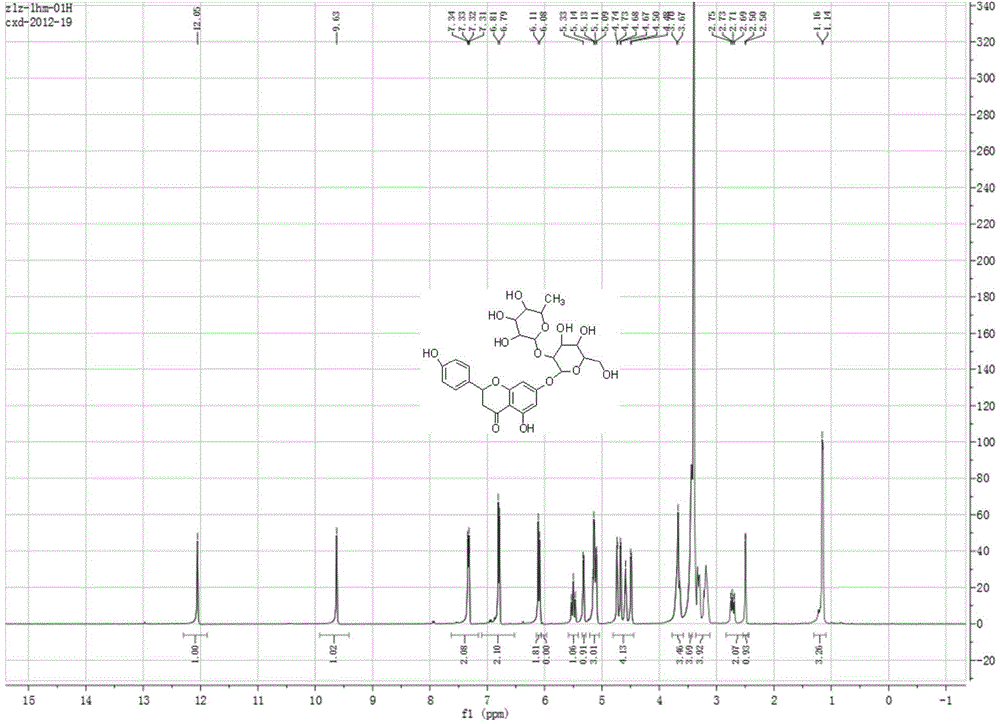

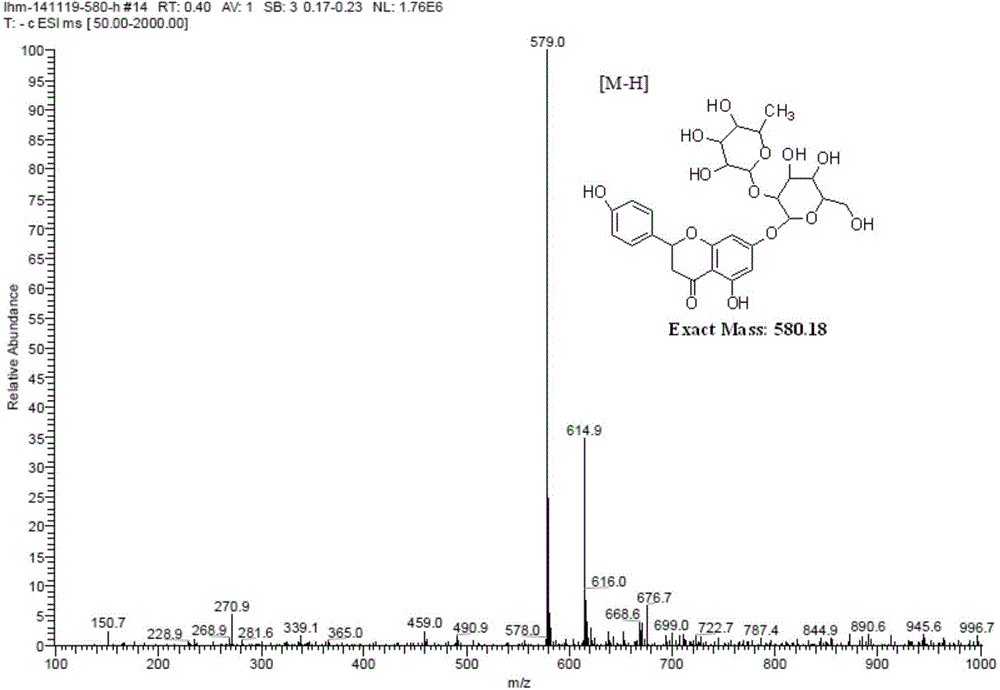

[0034] ⑥Under the same conditions, repeated recrystallization twice to obtain naringin, the purity of naringin was 81.2%. Experimentally measured the prepared naringin 1 See attached for HNMR...

Embodiment 2

[0036] ① Wash the white spongy mesocarp obtained after peeling off the yellow exocarp of mature fresh pomelo peel, dry, crush and sieve to 30 mesh;

[0037] ② Reflux degreasing with petroleum ether, filter, and dry the filter residue at 40°C;

[0038]③Add 70% ethanol to the filter residue, the volume of the added ethanol is 20 times of the quality of the degreased pomelo peel filter residue, heat and stir at 60°C, and reflux for 2h;

[0039] ④ suction filtration, collecting the filtrate, concentrating the filtrate under reduced pressure to 1 / 3 of the original volume of the filtrate, to obtain crude naringin;

[0040] ⑤ Add a small amount of water to the crude naringin, dissolve it at 60°C, cool it at 4°C for 24 hours, remove the supernatant, filter and collect the precipitate;

[0041] ⑥Under the same conditions, repeated recrystallization twice to obtain naringin, the purity of naringin was 83.7%.

Embodiment 3

[0043] ① Wash the white spongy mesocarp obtained after peeling off the yellow exocarp of the mature fresh pomelo peel, dry, crush and sieve to 30 mesh;

[0044] ② Reflux degreasing with petroleum ether, filter, and dry the filter residue at 40°C;

[0045] ③Add 80% ethanol to the filter residue, the volume of the added ethanol is 25 times of the quality of the degreased pomelo peel filter residue, heat and stir at 60°C, and reflux for 2.5h;

[0046] ④ suction filtration, collecting the filtrate, concentrating the filtrate under reduced pressure to 1 / 3 of the original volume of the filtrate, to obtain crude naringin;

[0047] ⑤ Add a small amount of water to the crude naringin, dissolve it at 60°C, cool it at 4°C for 24 hours, remove the supernatant, filter and collect the precipitate;

[0048] ⑥Under the same conditions, repeat the recrystallization twice to obtain naringin, the purity of naringin is 85.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com