Patents

Literature

260results about How to "Save production materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

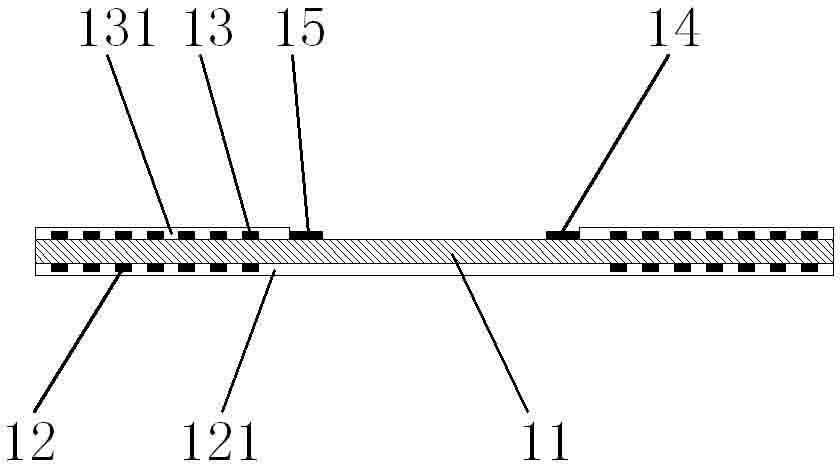

Flexible display device

ActiveCN107464512AImprove the detection rateSave production materialsStatic indicating devicesInput/output processes for data processingEngineeringFlexible display

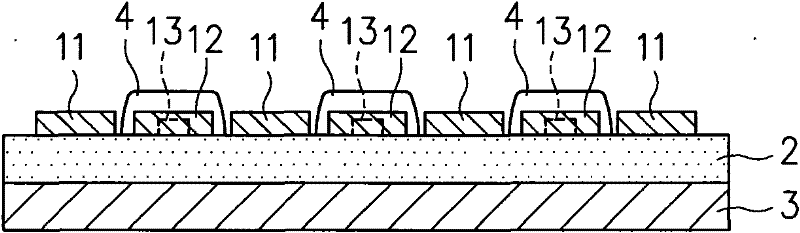

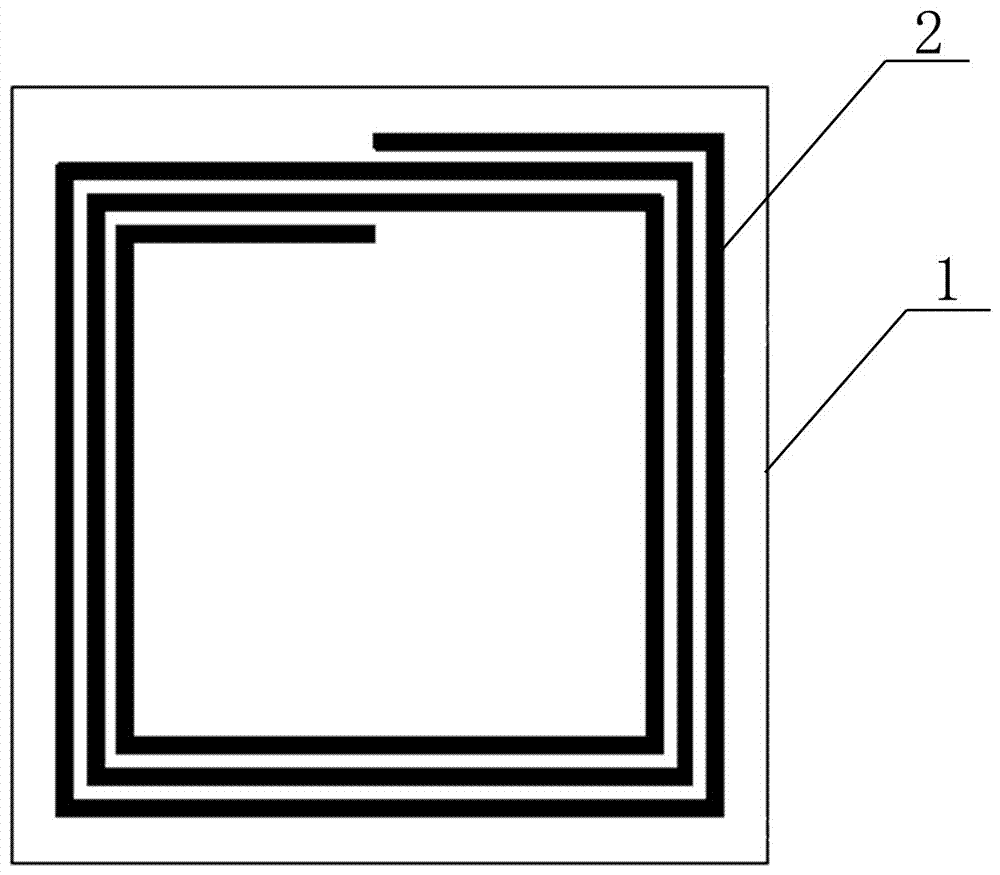

The invention discloses a flexible display device which comprises a display area and a non-display area encircling the display area, a first flexible substrate, an inorganic layer arranged on the first flexible substrate, and grounding wires arranged on the inorganic layer, wherein the grounding wires are arranged in the non-display area and form a detection circuit; at least two grounding wires are arranged in the non-display area on the same side of the display area at least; the at least two grounding wires comprise at least one first grounding wire and at least one second grounding wire; the inorganic layer is provided with a groove; the first grounding wire is arranged in the groove; the second grounding wire is arranged on the surface of the inorganic layer. According to the flexible display device disclosed by the invention, crack positions can be judged by the detection circuit, whether the cracks exist on the inorganic layer and on the first flexible substrate can be judged, and the detection rate of risk products is improved; meanwhile, since the first grounding wire is positioned in the groove, and the second grounding wire is positioned on the surface of the inorganic layer, the horizontal distance among the various grounding wires can be reduced, and the narrow bezel design of the flexible display device is promoted.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

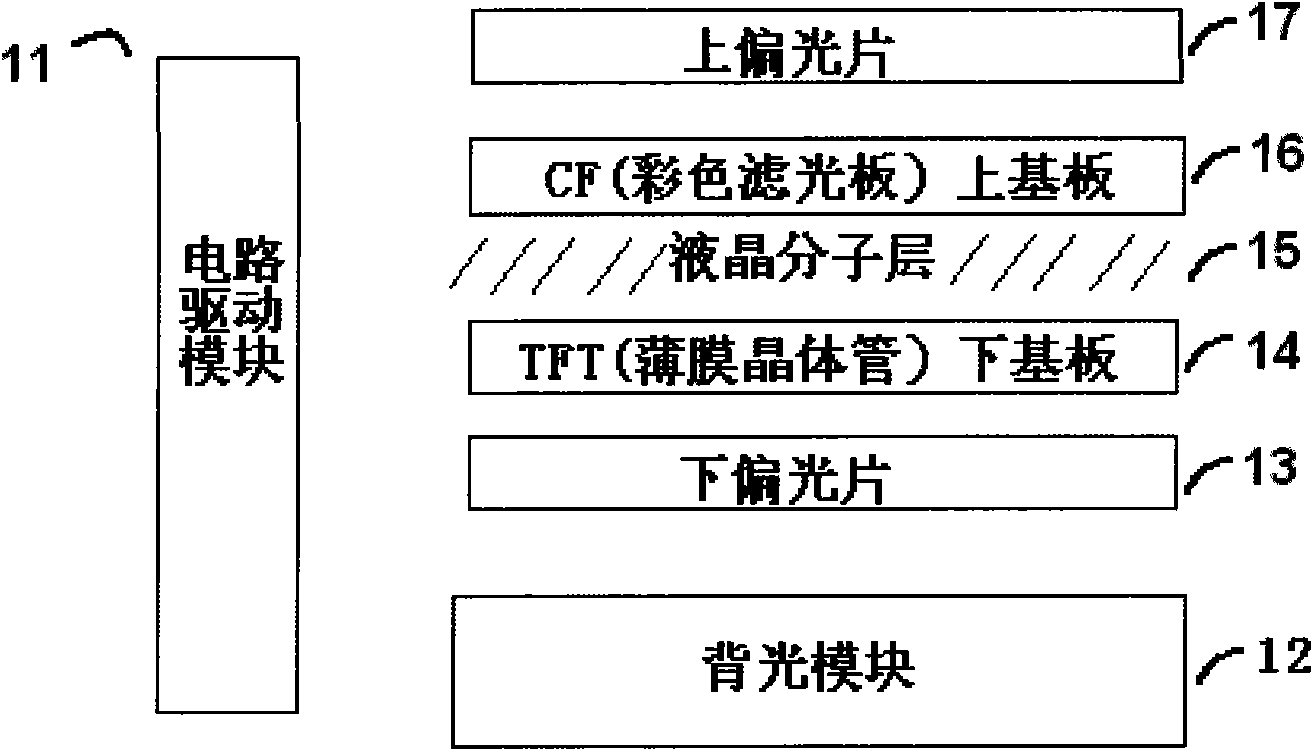

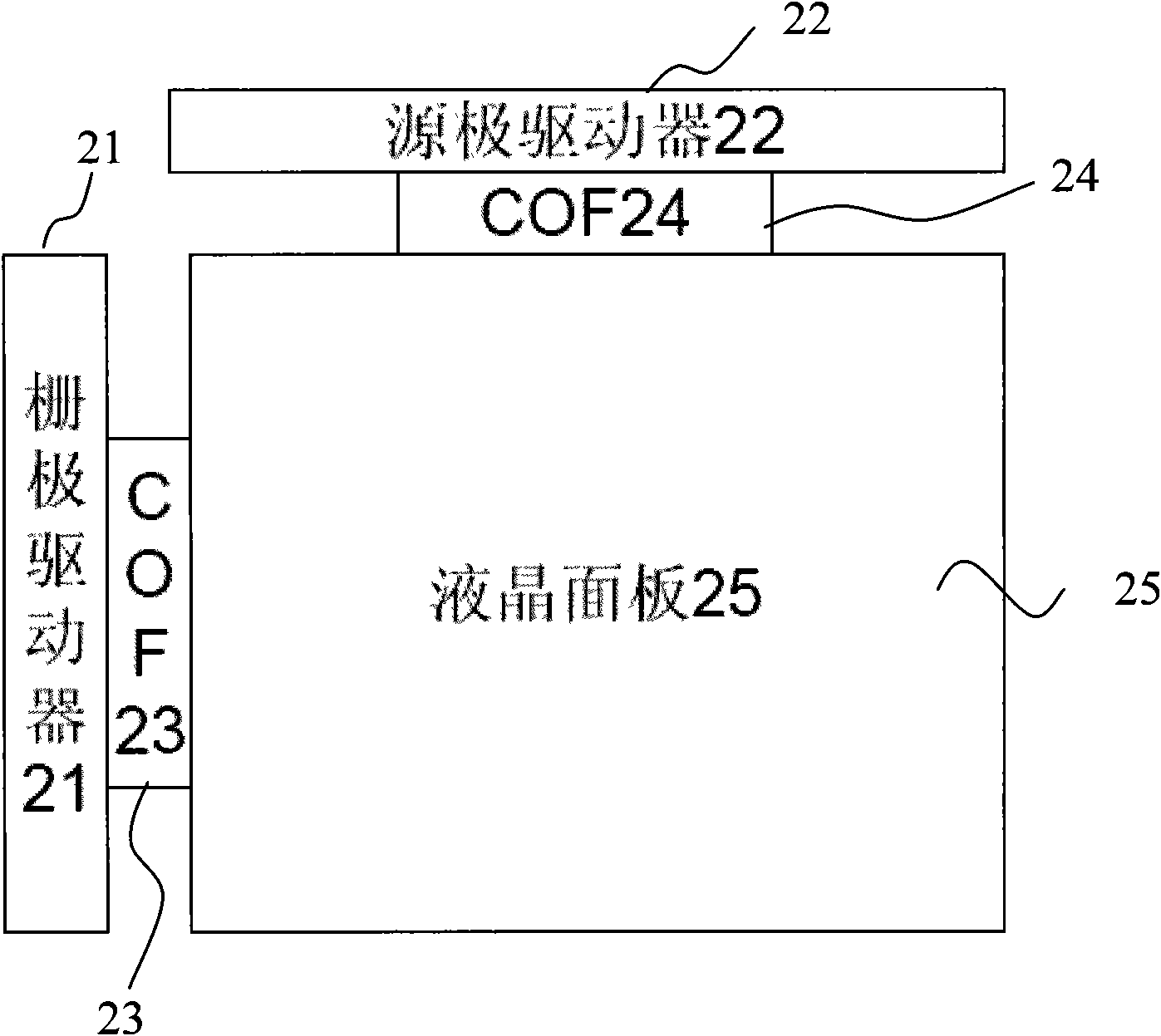

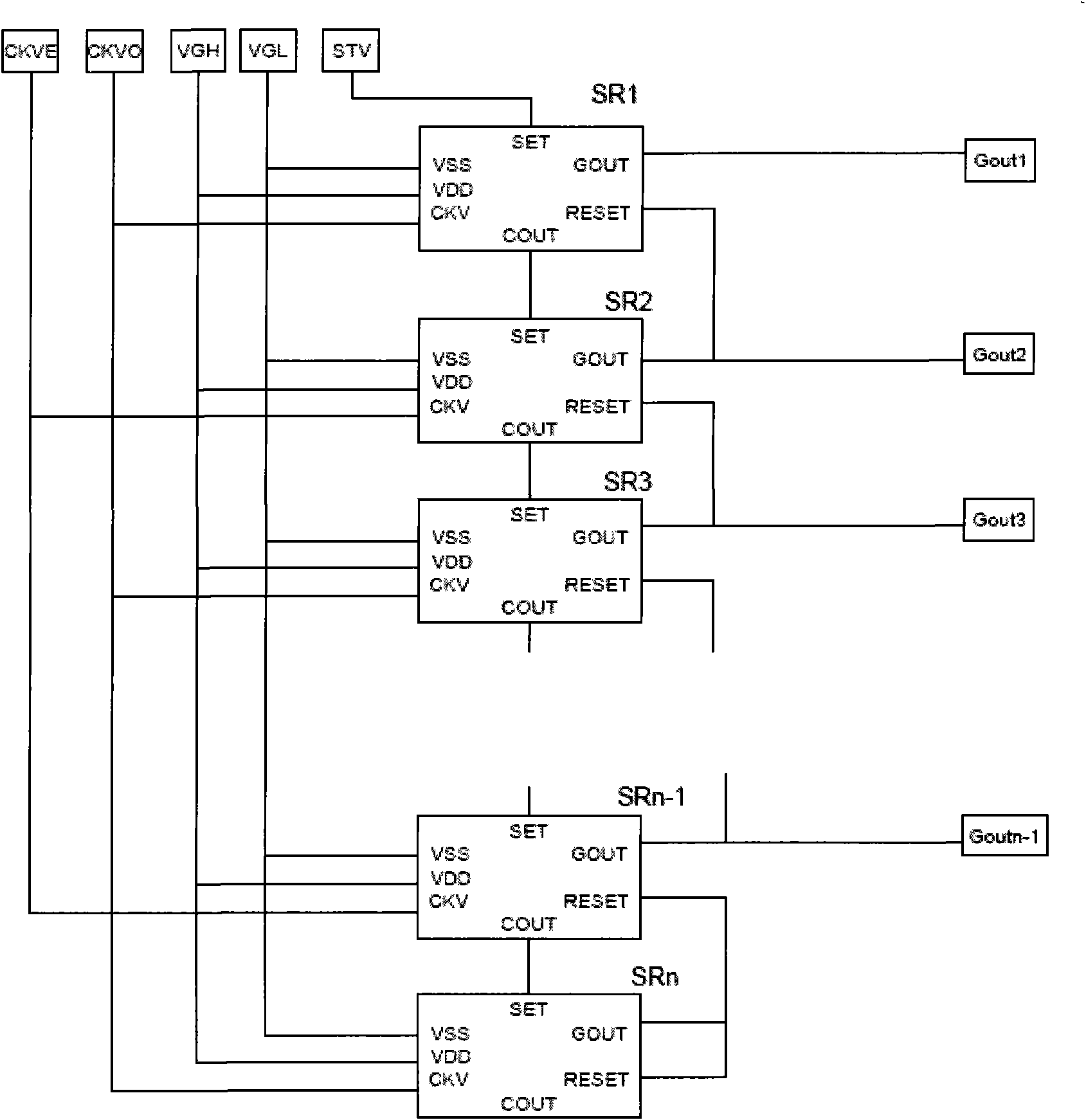

GIP type liquid crystal display panel and detecting method thereof

InactiveCN101567160AImprove the phenomenon of inspectionAvoid enteringElectronic circuit testingStatic indicating devicesShift registerLiquid-crystal display

The invention relates to a GIP type liquid crystal display panel and a detecting method thereof. The liquid crystal display panel is integrated with a grid driver; the grid driver comprises a plurality of cascaded displacement registers; each displacement register comprises a setting input terminal, a clock signal input terminal, a level input terminal, a carry output terminal and a grid wire output terminal; wherein the first displacement register is provided with a setting input terminal lead, a clock signal input terminal lead and a level input terminal lead; each displacement register is provided a grid wire output terminal lead; the grid wire output terminal lead is connected with a TFT switch; the grid of the TFT switch is connected with a drive testing point CP; and a source electrode is connected with an output testing point TP. The GIP type liquid crystal display panel and the detecting method thereof check and test the GIP drive unit in an array engineering, thus avoiding a GIP drive unit with defects from entering a box forming engineering.

Owner:NANJING CEC PANDA LCD TECH

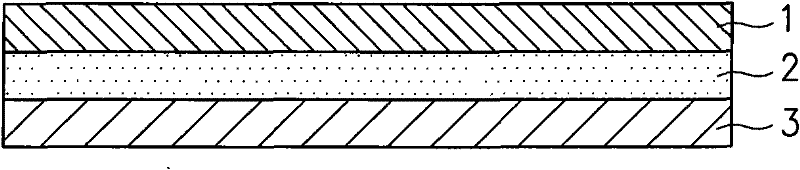

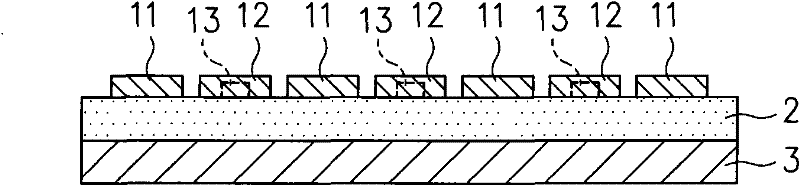

Touch control panel structure and manufacture method thereof

InactiveCN102207784ASimplify the fitting processSave production materialsInput/output processes for data processingInsulation layerElectrical conductor

The invention provides a touch control panel structure and a manufacture method thereof. In the invention, a conductive structure layer is formed on at least one adhesive layer; the conductive structure layer comprises at least one first conductor and at least one second conductor; and an insulation layer is arranged between the first conductor and the second conductor so that the first conductoris insulated from the second conductor. The purposes of saving production materials, reducing cost, improving product good rate, simplifying panel laminating procedure, attaching the touch control panel to object surfaces of arbitrary curved surfaces or plane surfaces, and facilitating design of thinned products and the like are achieved.

Owner:WINTEK CORP +1

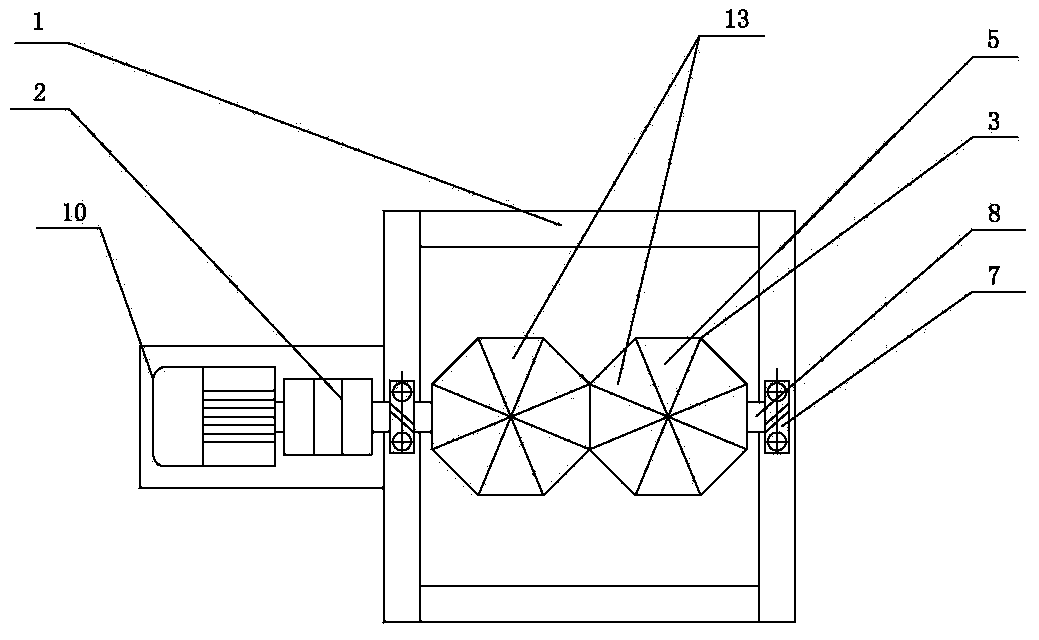

Device for cleaning and recycling waste wood for building

InactiveCN106807661ASave production materialsReduce manufacturing costCleaning using toolsCleaning using liquidsWastewaterWater collection

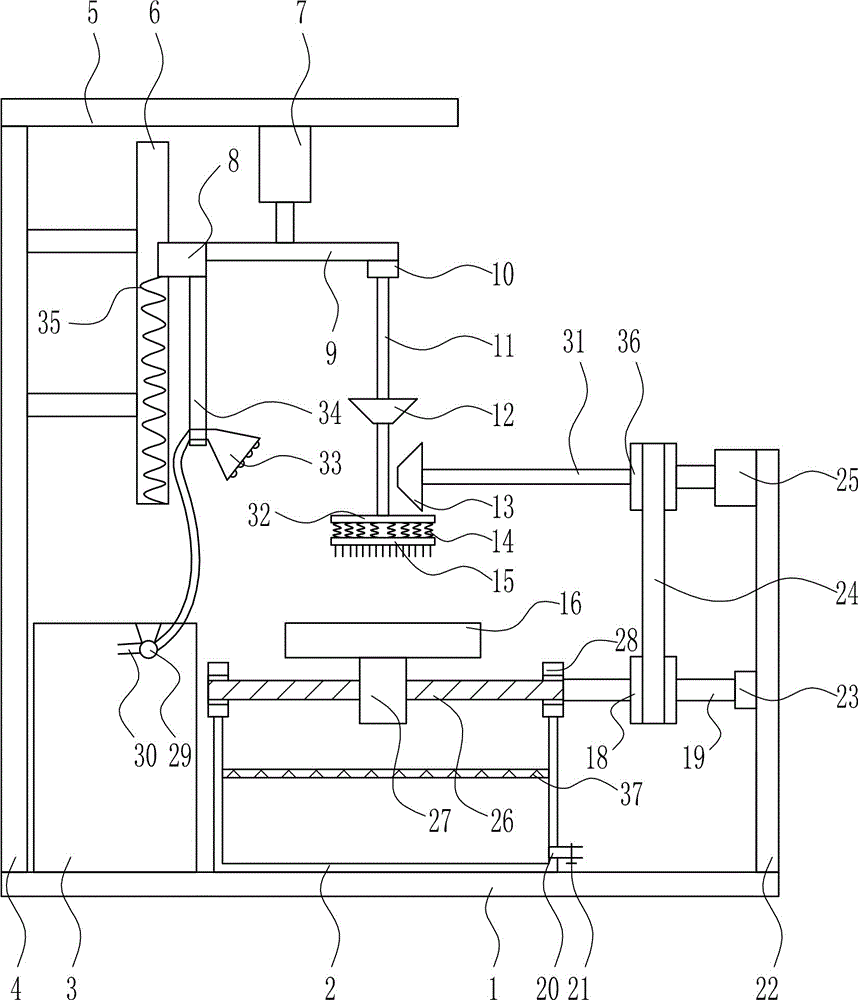

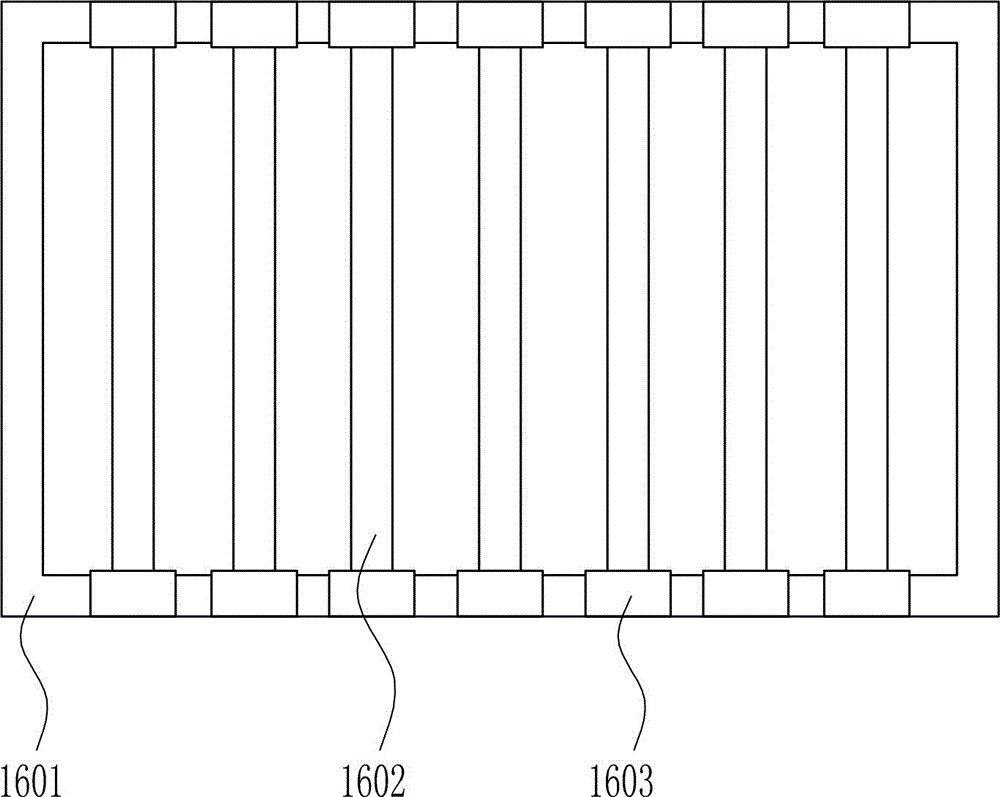

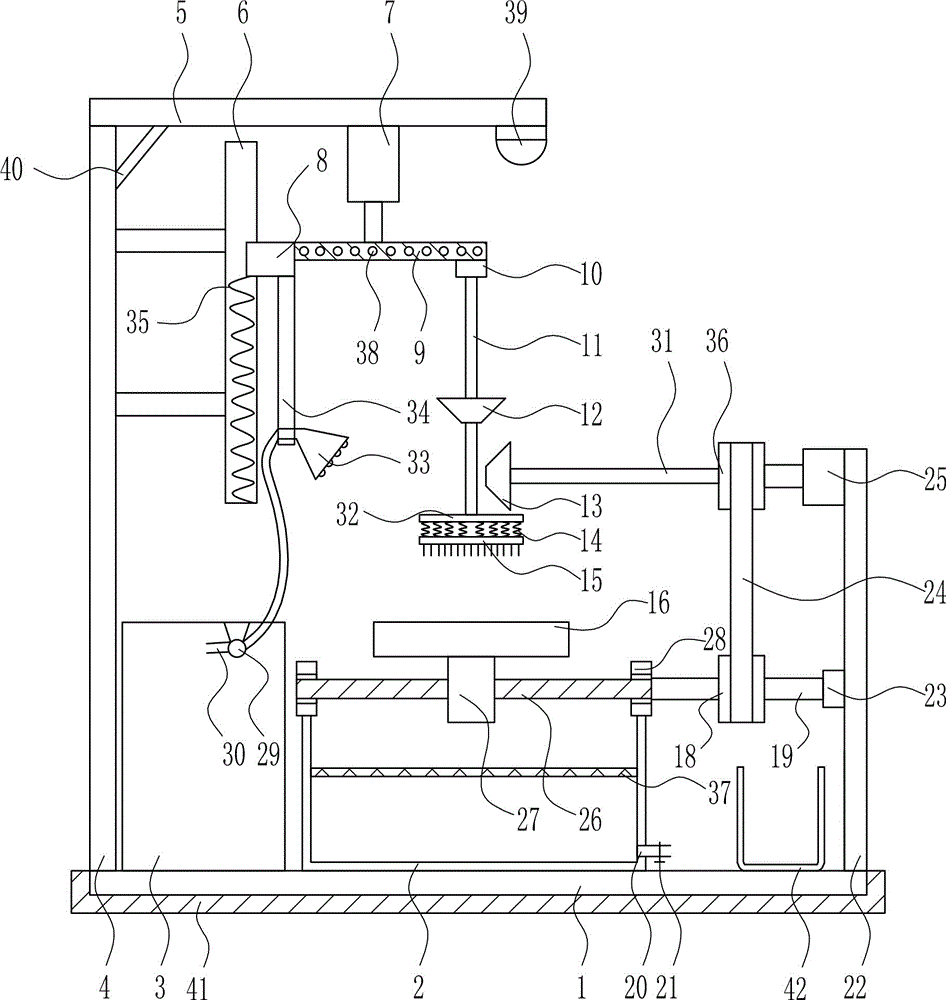

The invention relates to a recycling device, in particular to a device for cleaning and recycling waste wood for building. The device for cleaning and recycling the waste wood for building aims at achieving the technical effect that cleaning efficiency is high. The device for cleaning and recycling the waste wood for building comprises a base plate, a waste water collection tank, a water tank, a left support, a top plate, a slide rail, an air cylinder, a slide block, a fixing rod, a first bearing seat, a first rotating shaft, a first bevel gear and the like. The top plate is arranged at the top end of the left support. The air cylinder is arranged at the bottom of the top plate. The fixing rod is arranged at the bottom end of the air cylinder. The first bearing seat is arranged at the right side of the bottom of the fixing rod. The first rotating shaft is mounted on the first bearing seat. By means of the device for cleaning and recycling the waste wood for building, the effect that cleaning efficiency is high is achieved.

Owner:河南正华置地建工集团有限公司

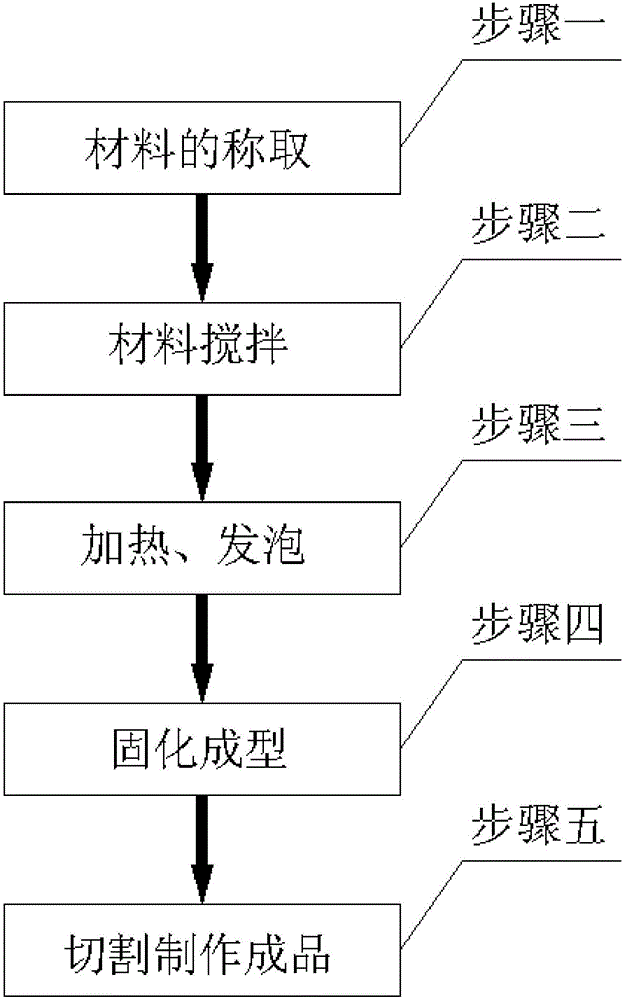

Low-density high-bearing sponge and manufacturing process

The invention relates to a low-density high-bearing sponge. The low-density high-bearing sponge comprises the following materials in parts by weight: 0-50 parts of polyether polyol, 0-50 parts of polymer polyol, 0-15 parts of a flame adhesive, 0-0.5 part of a catalyst, 0-2 parts of silicon oil, 0-10 parts of a foaming gent and 45-56 parts of toluene diisocyanate. The foaming density of the sponge is reduced, while the sponge with the same size is produced, required production materials are greatly reduced, and therefore, production cost is reduced; and the relation between the bearing capacity of the sponge and the density of the sponge is relatively direct, under general conditions, the bearing capacity of the sponge can be reduced along with reduction of the density of the sponge, and once the bearing capacity of the sponge is reduced excessively, the material cannot be used; and by using appropriate polyether, the hardness of the sponge can be controlled, and meanwhile, the shortcomings that the bearing force is difficult to control and the sponge deforms easily due to over-low density are avoided.

Owner:上海馨源新材料科技有限公司

Novel ultrathin battery and preparation method thereof

ActiveCN104779402AReduce thicknessIncrease capacitySecondary cells manufactureCell component detailsBattery capacityMetal

The invention discloses a novel ultrathin battery and a preparation method thereof. The novel ultrathin battery comprises a battery cathode substrate, a battery anode substrate, a cathode metal mesh, an anode metal mesh, a cathode particle material, an anode particle material and a barrier, wherein the cathode tab and the anode tab of the battery are formed by extending from the cathode metal mesh and the anode metal mesh, respectively; the cathode metal mesh and the anode metal mesh are bonded to the battery cathode substrate and the battery anode substrate, respectively; the cathode particle material and the anode particle material cover the battery cathode substrate and the cathode metal mesh, and the battery anode substrate and the anode metal mesh, respectively; the barrier is arranged between the battery cathode substrate and the battery anode substrate, and the barrier is capable of blocking the battery cathode substrate and the battery anode substrate from each other; the battery is covered with a flexible insulating sealing layer. The novel ultrathin battery and the preparation method thereof have the advantages of simplified production process, low battery production cost, large battery capacity, convenience for application and the like.

Owner:HIGHPOWER TECH HUIZHOU +3

Method for preparing immersion gold printed circuit board

InactiveCN103763869AThe method is simple and controllableReduce stepsPrinted element electric connection formationPrinting inkEngineering

The invention discloses a method for preparing an immersion gold printed circuit board. The method includes the steps that an outer layer circuit diagram is provided and manufactured, and a PCB with plug holes and an aluminum sheet with guide holes are prepared, wherein the aluminum sheet is used for plugging printing ink into drill holes of the PCB through the aluminum sheet guide holes corresponding to the drill holes in the PCB; the printing ink is plugged into the drill holes of the PCB through the aluminum sheet; solder resisting is conducted on the PCB with the drill holes into which printing ink is plugged; exposure is conducted on the PCB, wherein in the exposure process, Favrini negative films are utilized to block light for the faces of the drill holes in which semi-plug holes need to be formed; the PCB on which exposure is conducted is developed, wherein in the developing process, printing ink of 20% to 80% of the depth of the drill holes is rinsed out through developing potions; immersion gold processing is conducted on the developed PCB. The method for preparing the semi-plug holes of the immersion gold board is easy to control, operation steps and production materials are reduced, production cost is greatly saved, and production efficiency can be rapidly improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

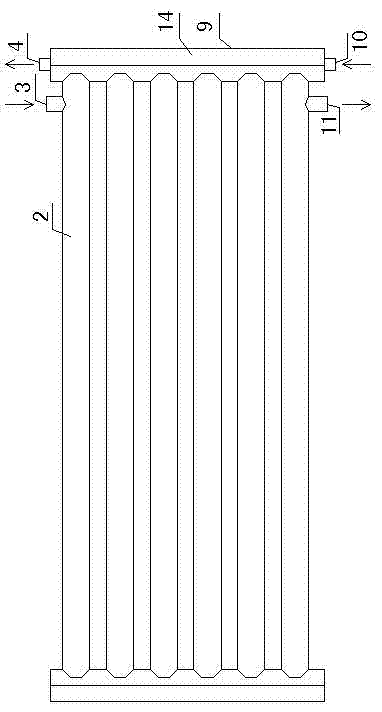

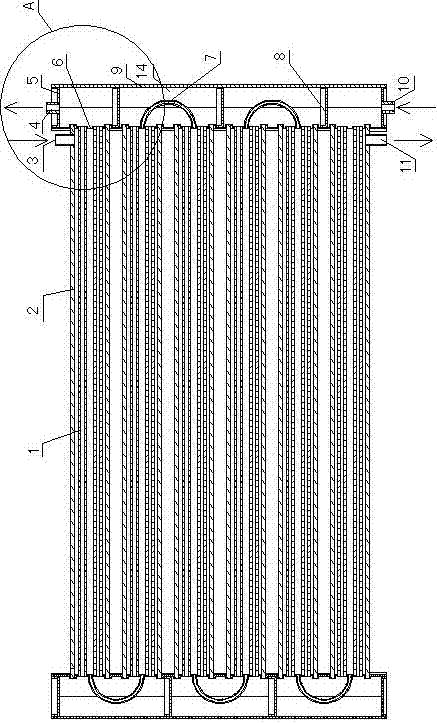

Header cold water pipe open communication heat absorption heat exchanger and manufacturing process thereof

ActiveCN102927604AReduce cloggingReduce heat lossLighting and heating apparatusSpace heating and ventilation detailsWater channelMetallic materials

The invention discloses a header cold water pipe open communication heat absorption heat exchanger and a manufacturing process of the header cold water pipe open communication heat absorption heat exchanger. The header cold water pipe open communication heat absorption heat exchanger at least comprises two heat supply pipes, wherein two ends of the heat supply heats are respectively welded with a header, at least one cold water channel is arranged inside a heat supply pipe cavity, ports at two ends of the cold water pipe channel are communicated in open cavity mode, and deposited scales in a cold water pipe can be conveniently cleaned by poured acid liquor. The cold water pipe stores water and absorbs heat, effective heat sources can be fully utilized, the heat is quickly absorbed through multiple dividing walls, the heat is transmitted in step mode, a heat absorption area is enlarged, and due to the fact that water is stored in the headers, the length of flow path of cold liquor is increased, the time of heat exchange is prolonged, heat loss is reduced, and heat exchange efficiency is improved. Longitudinal or transverse flexible installation is achieved by reasonable utilization of space, requirements of users can be met, materials are saved, and production cost is reduced. Product quality is stable and reliable, and service life is prolonged. The same kind of metal material is adopted, the weight is light, transportation is convenient, and logistics transportation cost is saved.

Owner:ZAOZHUANG LINENG WATER HEATER FACTORY

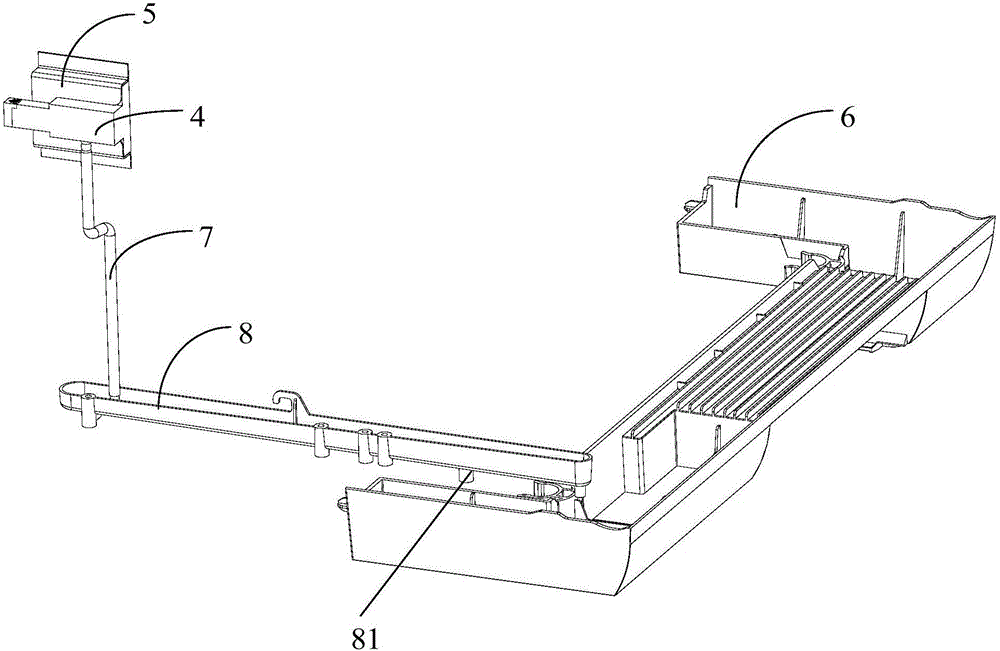

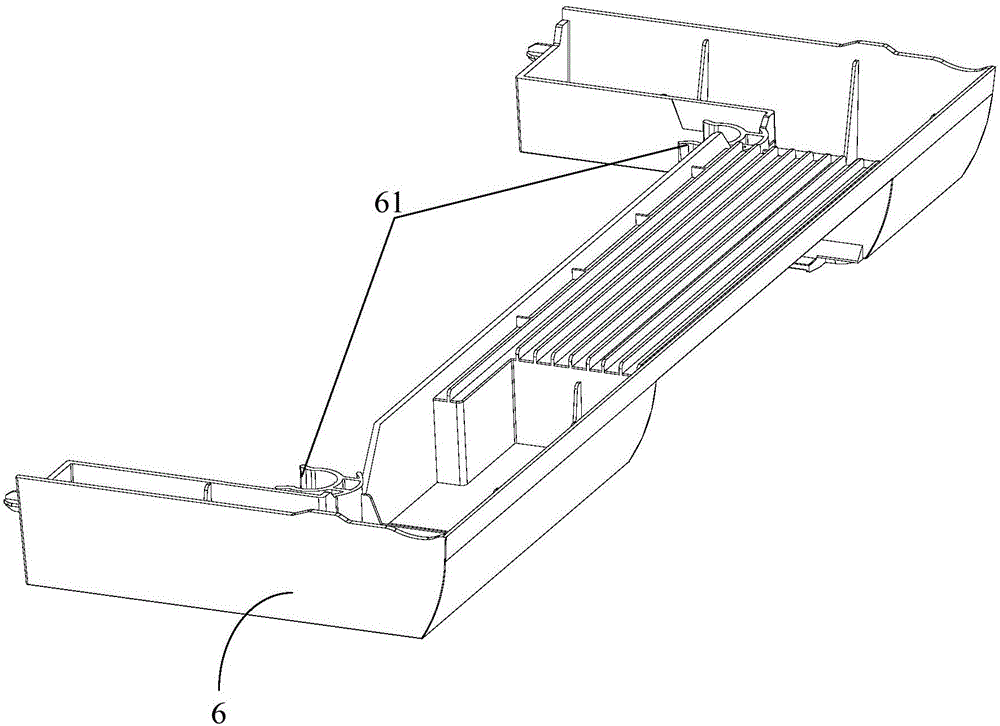

Steam exhausting system and steam cooking device

The invention provides a steam exhausting system and a steam cooking device. The steam cooking device comprises an outer shell and a cooking chamber arranged in the outer shell, wherein steam exhaust ports are formedina chamber wall of the cooking chamber. The steam exhausting system comprises a steam exhausting box, wherein the steam exhausting box is fixedly mounted on an outer wall of the cooking chamber and is in sealing connection with the chamber wall of the cooking chamber; a through hole is formedinthe outer shell; the steam exhausting box locally penetrates through the through hole and extends out of the outer shell; a steam channel is arranged in the steam exhausting box; a steam inlet of the steam channel is communicated with the steam exhaust ports; and a steam outlet of the steam channel is located on the part of the steam exhausting box extending out of the outer shell. The steam exhausting system provided by the invention has the advantages that the structure is simple, the cost is low, the mounting is convenient, the production efficiency of the steam cooking device product is promoted and the production cost of the product is lowered. Besides, according to the invention, the steam outlet is formed on the part of the steam exhausting box extending out of the outer shell, so that the user can easily scrub the steam outlet part and the problem of difficulty in cleaning and even incapability of cleaning the steam outlet of the present steam cooking device product can be solved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

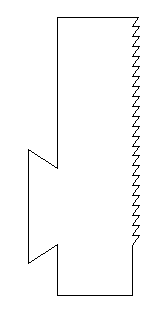

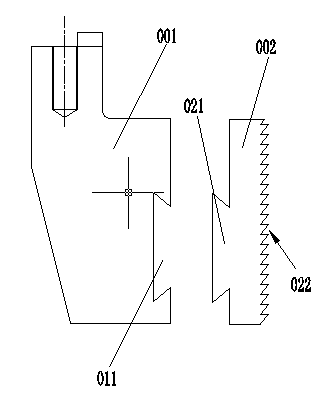

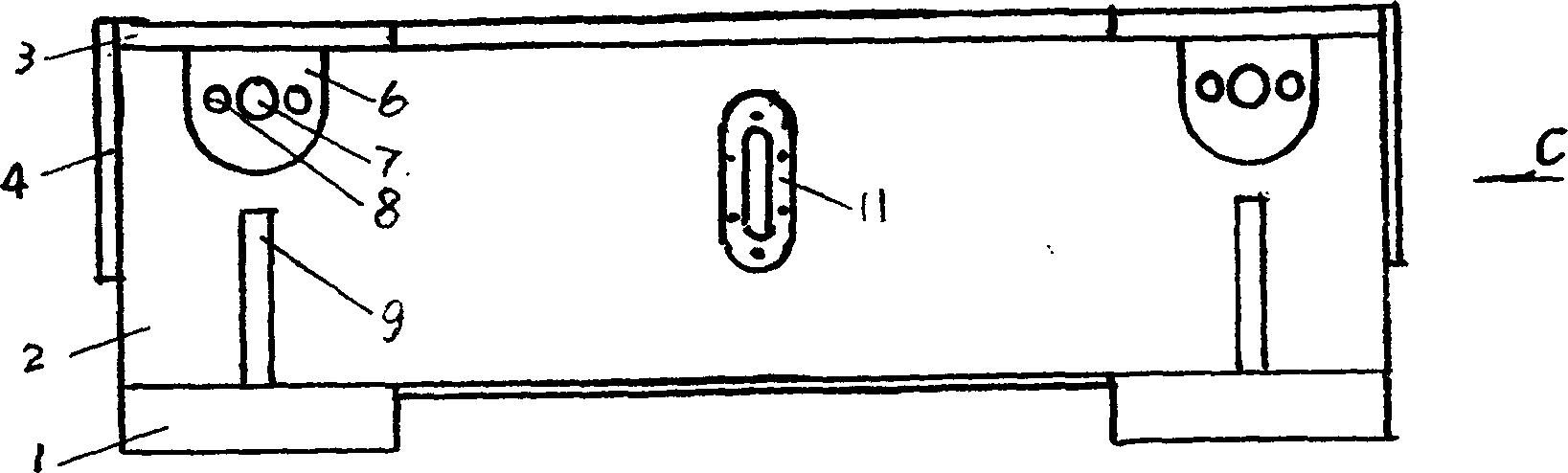

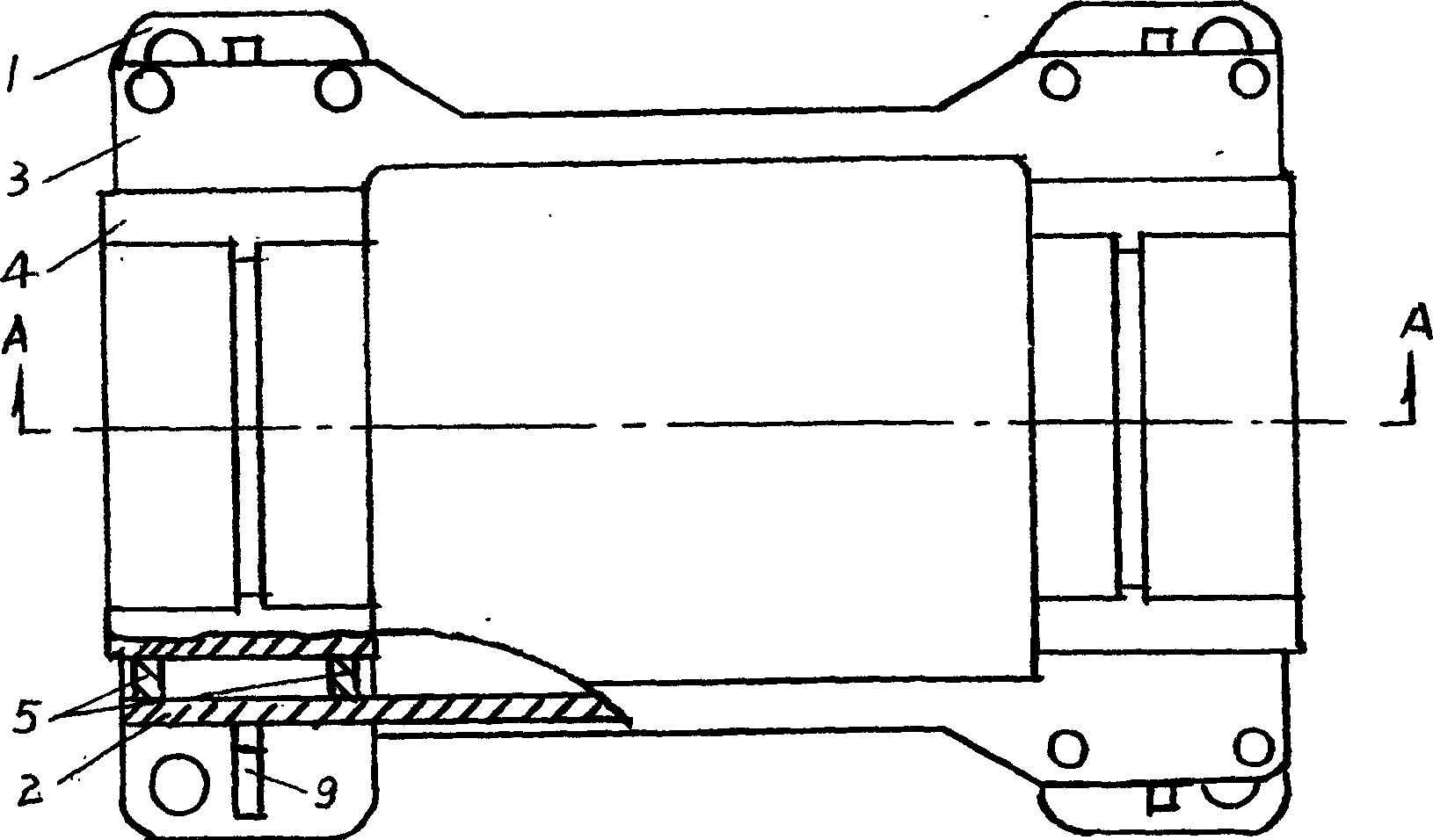

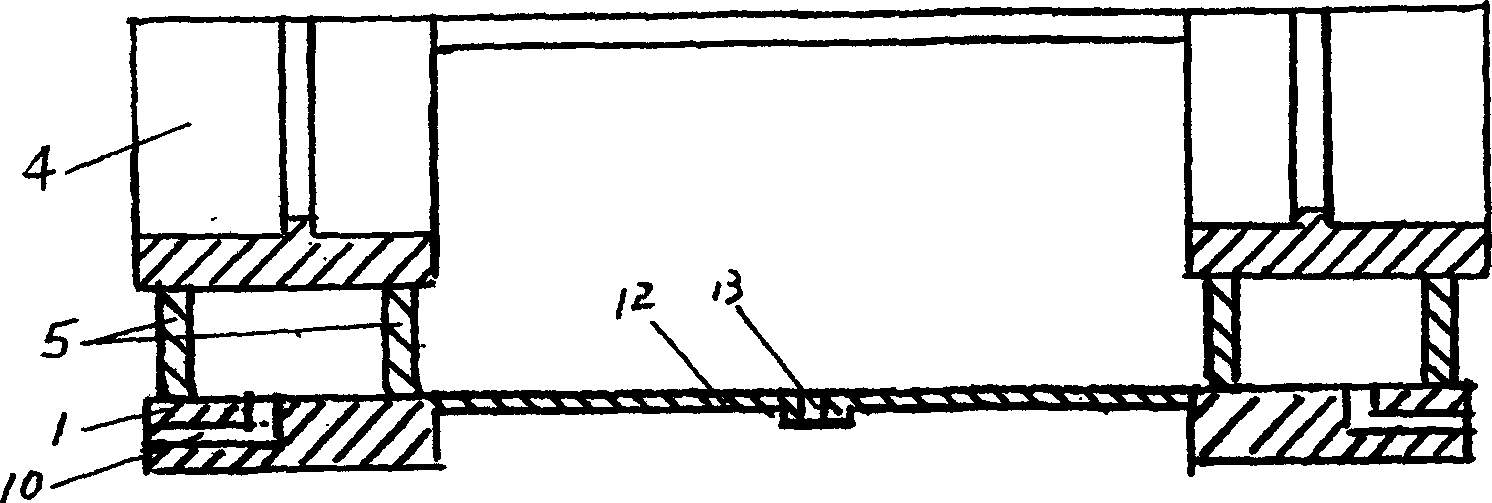

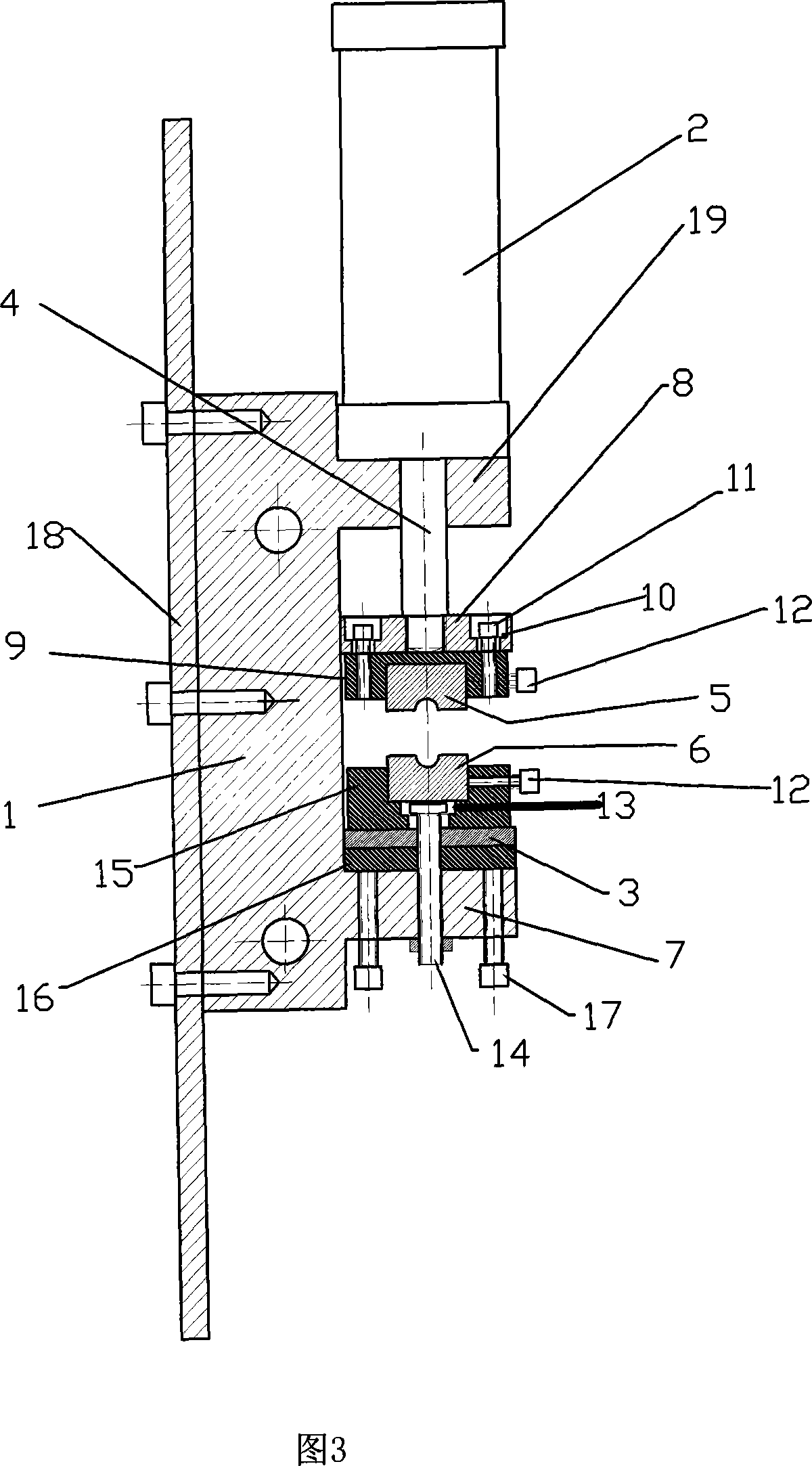

Combined hydraulic drawbench jaw plate

The invention relates to a combined hydraulic drawbench jaw plate, which comprises a clamping part and a jaw working part clamped and embedded in the clamping part. The clamping part is a square matrix. The sidewall center at one end of the matrix is provided with a horizontally perforating dovetail rabbet. One end of the jaw working part is provided with a dovetail shaped bulge matching the dovetail rabbet, and the surface of the other end is set in a jagged shape.

Owner:宜兴市创天管业有限公司

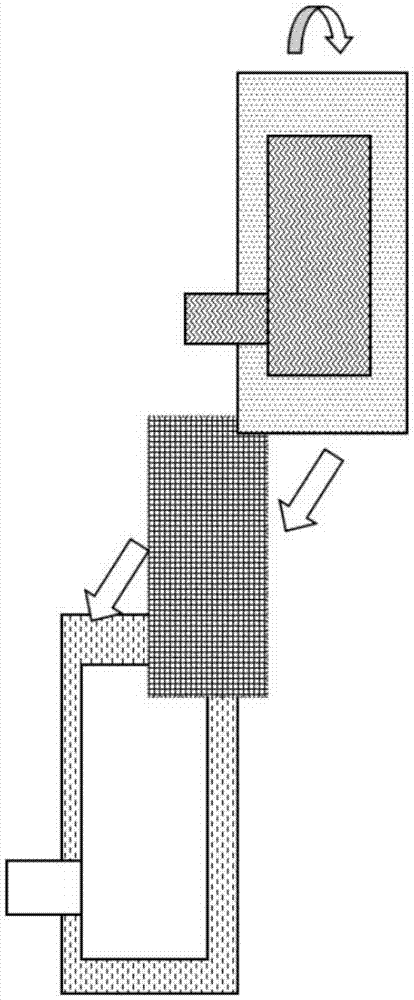

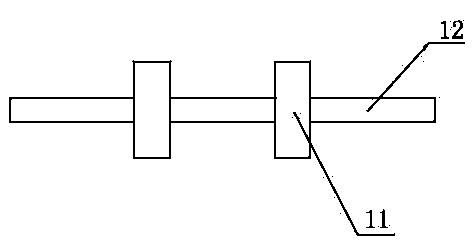

Double-bag overturning device

The invention discloses a double-bag overturning device which comprises a support. The double-bag overturning device further comprises a material overturning hopper composed of two frames, the inner sides of the two frames are connected together, the two sides of the material overturning hopper are supported on the support through rotating shafts and bearings, and the rotating shaft on one side extends out to be connected with a gear motor through a coupler; each frame is formed by connecting an octagonal upper opening edge, an octagonal lower opening edge and a sliding way between the octagonal upper opening edge and the octagonal lower opening edge, and self-locking doors are arranged on the outer sides of an upper opening and a lower opening respectively; a sliding chassis capable of vertically sliding through the sliding way is arranged in each frame. The double-bag overturning device has the advantages that material hitting automation is achieved; the labor strength of a worker is reduced, and the operation environment of the worker is improved; the using efficiency of a crown block is improved; two bags can be overturned at the same time, continuous bag overturning is achieved, and the labor efficiency of an operator is improved in a multiplied mode; the good conditions of the bags can be kept after bag overturning, and the bags can be recycled and repeatedly used; the sliding chassis is used, and discharging space is saved; meanwhile, manufacturing materials are greatly saved, and the manufacturing cost is reduced.

Owner:FUSHUN ALUMINUM

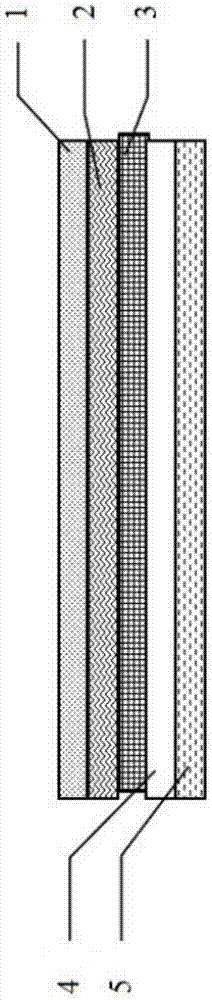

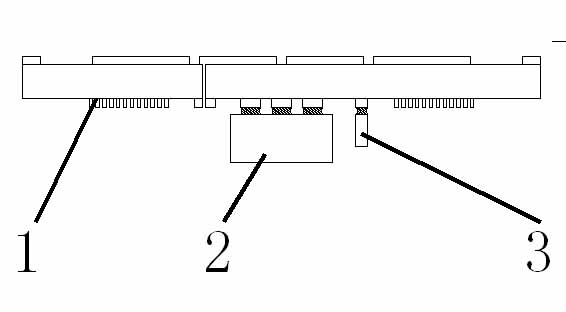

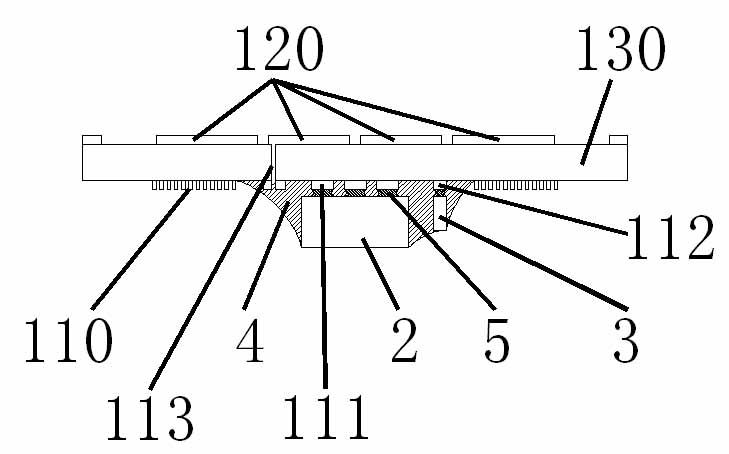

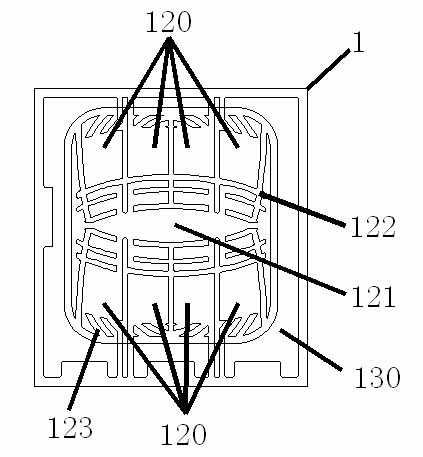

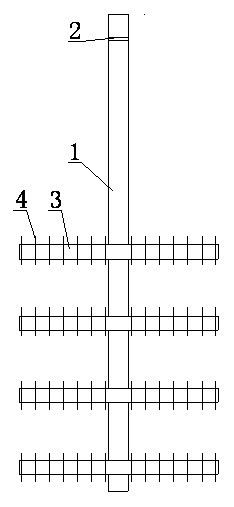

Novel double-interface intelligent card

ActiveCN102663480ALow costReduce manufacturing costRecord carriers used with machinesCouplingSmart card

The invention discloses a novel double-interface intelligent card. The card is formed by a card base (1), a double-interface intelligent card module (2) and a coupling amplification antenna (3). The card base is formed through laminating and pressing 2-6 layers of thin type insulating material. The coupling amplification antenna is a double-sided film circuit board and is formed by a group of radio frequency antennas and a group of plate condensers. The double-interface intelligent card module is formed by a carrier tape which is integrated with the radio frequency antennas and contacts, a double-interface intelligent card chip and a matching circuit. The coupling amplification antenna is arranged in an interlayer of an inner layer of the card base and simultaneously is laminated. The double-interface intelligent card module is arranged in a stepped groove of one side of the card base. The double-interface intelligent card of the invention simultaneously possesses a contact intelligent card function and a non-contact intelligent card function. Product performance can be increased and simultaneously most of production equipment and technology can be used so that production cost can be reduced and a production period can be shortened.

Owner:SHANGHAI CHANGFENG SMART CARD

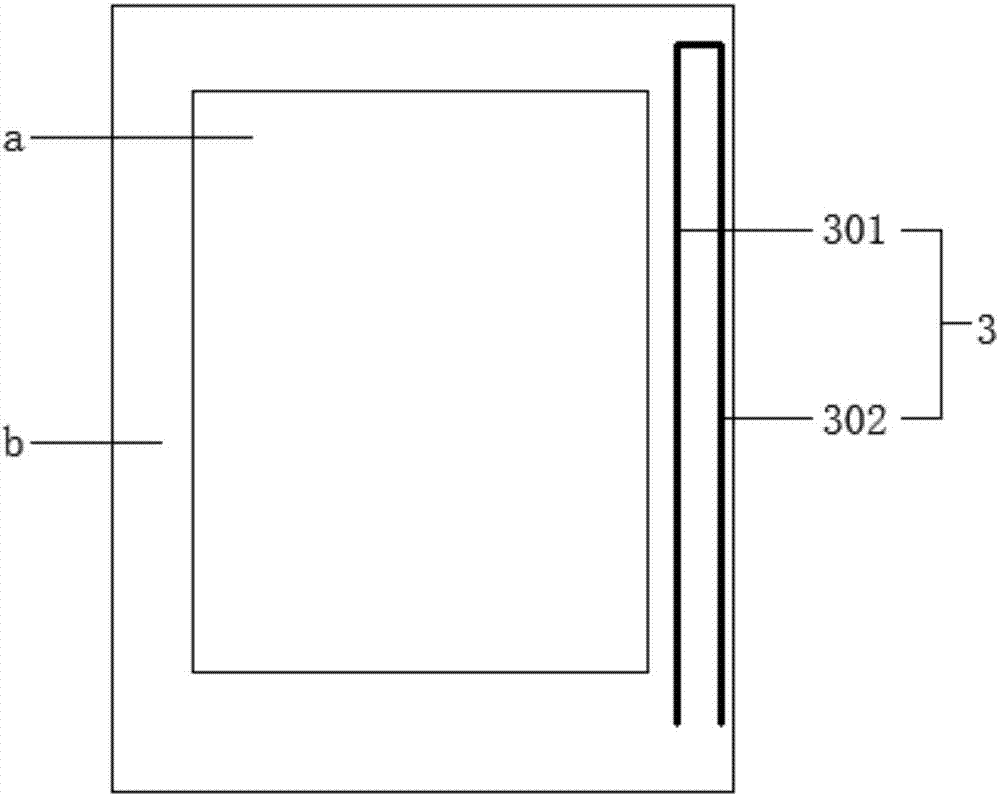

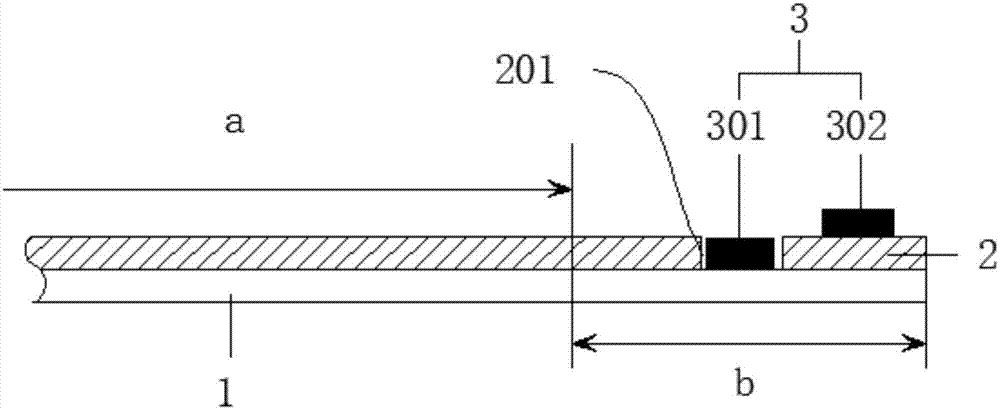

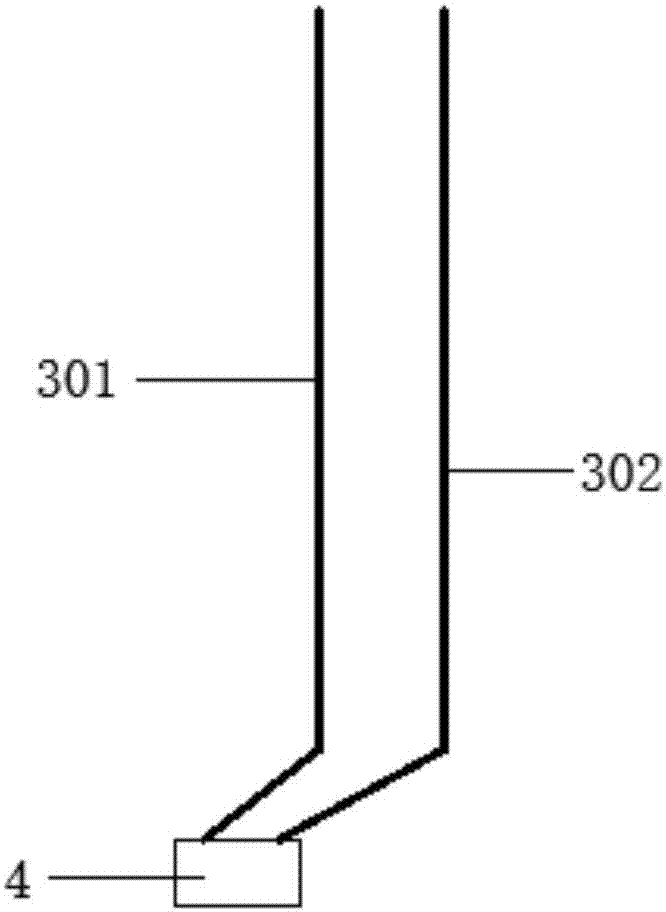

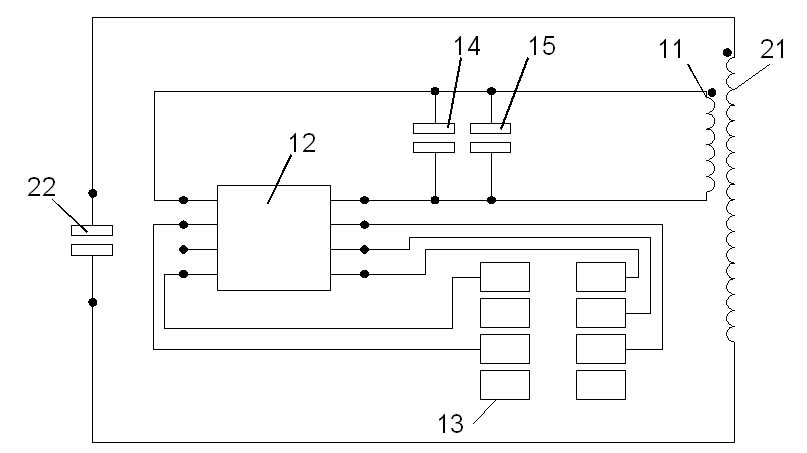

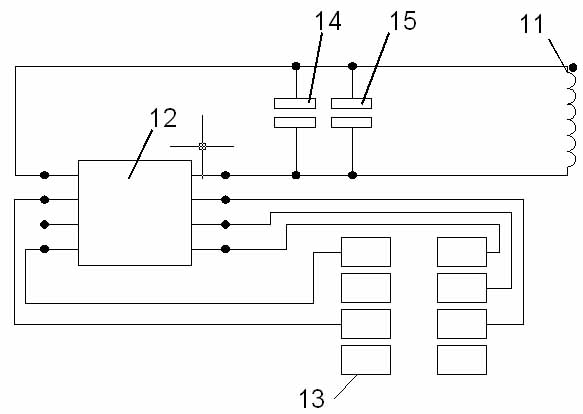

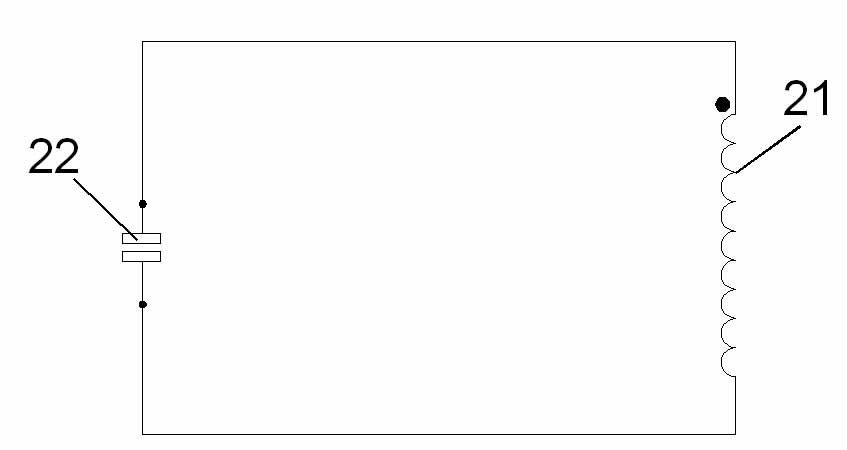

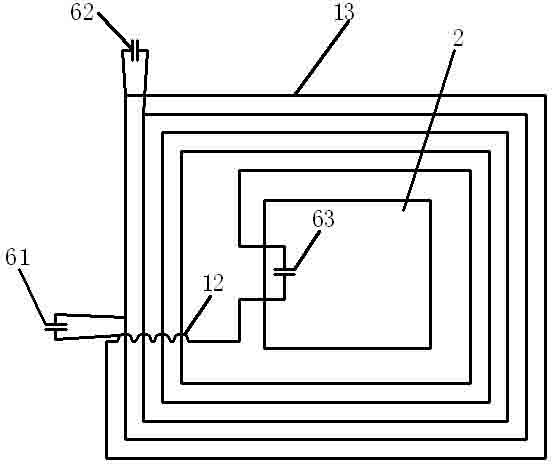

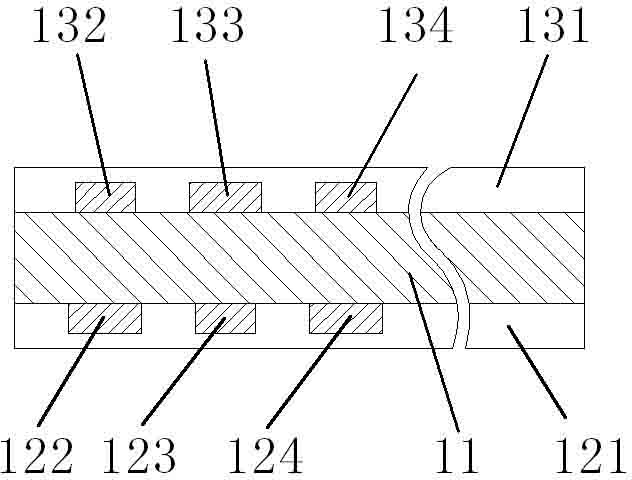

Novel double-interface intelligent card module

InactiveCN102663481ASave production materialsReduce manufacturing costRecord carriers used with machinesResonanceSurface mounting

The invention discloses a novel double-interface intelligent card module which is formed by a carrier tape (1), a double-interface intelligent card chip (2) and a matching circuit (3). A solder side of the carrier tape is provided with multi-circle surrounded radio frequency antennas and a part welding plate. The welding plate and a corresponding contact surface carry out electrical connection through a blind hole. The contact surface of the carrier tape is provided with eight conductive contacts which are mutually electrically independent with each other. The size of the contact accords with a dimension requirement ruled by ISO7816. The double-interface intelligent card chip is performed on a packaging processing and is suitable for a surface mounting technology to carry out welding. The matching circuit is a resonance matching circuit formed by one or two miniature surface mounting capacitors. The chip and the capacitor adopt the surface mounting technology so as to achieve once welded forming. The intelligent card produced by using the double-interface intelligent card module of the invention is directly used in a contact environment and a non-contact environment. Product performance can be increased and simultaneously most of production equipment and technology can be used so that production cost can be reduced and a production period can be shortened.

Owner:上海祯显电子科技有限公司

All welded steel structured bearing seat of blower fan water-cooling type in large-scale power station, and manufacturing method thereof

InactiveCN1687600AStress reliefMeet the design requirementsPump componentsPumpsPower stationWater channel

The invention discloses a fan water-cooled bearing base of the large power station with full steel welded structure and its manufacturing method. It is characterized in that it adopts the Q235A swage with good welding capability to process the separating parts and assembly the parts, adopts CO2 to protectively weld to form the upper cover and the base of the bearing base. The bearing base has cooling water channel, the lubrication oil tank and the temperature detecting channel; the raw metal roughing after the annealing, and anneal again after the roughing, metal refine and the cooling water channel and the lubricating oil channel detect the water pressure.

Owner:SICHUAN ENG TECHN COLLEGE

Preparation method for hollow mold core having high temperature deformability and removability

ActiveCN102896278ASolve crackingSolve the problem of difficult core removalFoundry mouldsFoundry coresThermal insulationMaterials science

The present invention relates to the technical field of mold core preparation, specifically to a preparation method for a hollow mold core having high temperature deformability and removability. According to the preparation method, a hollow mold core blank is pressed, wherein a mold is adopted to press a hollow mold core blank with a large outlet on one end and a small outlet on the other end; the hollow mold core blank is sintered, wherein the large outlet end surface of the pressed-molded hollow mold core blank is upwardly, a final firing temperature is 1000-1160 DEG C, and a thermal insulation time is 1-6 hours at every stage; a cavity of the hollow mold core is filled; and finally the hollow mold core is strengthened to obtain the final product. With the method, the problem of hollow casting cracks or difficult core removing is effectively solved, shrinkage depression easily generated during thick large mold core pressing and other defects are avoided, mold core production qualification rate is improved, production materials are saved, the method can be widely used in aerospace or civilian product production, casting qualification rate is significant improved, and production cost is reduced.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

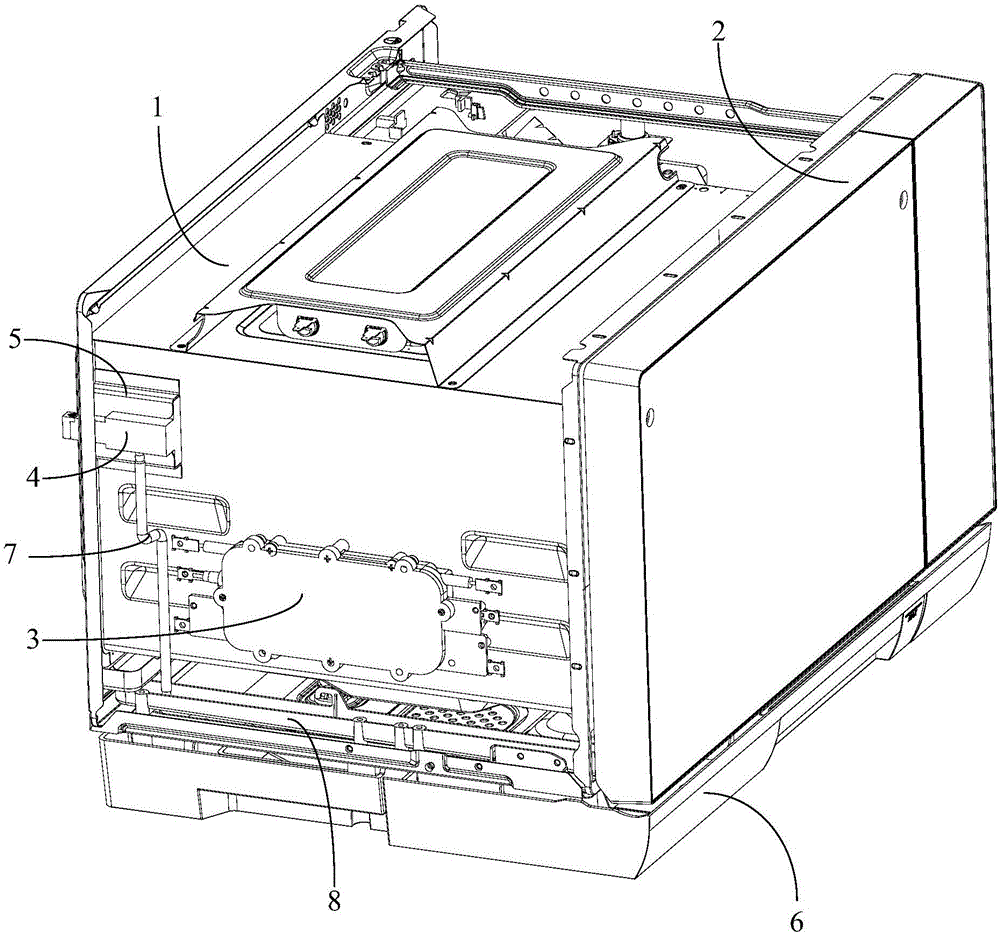

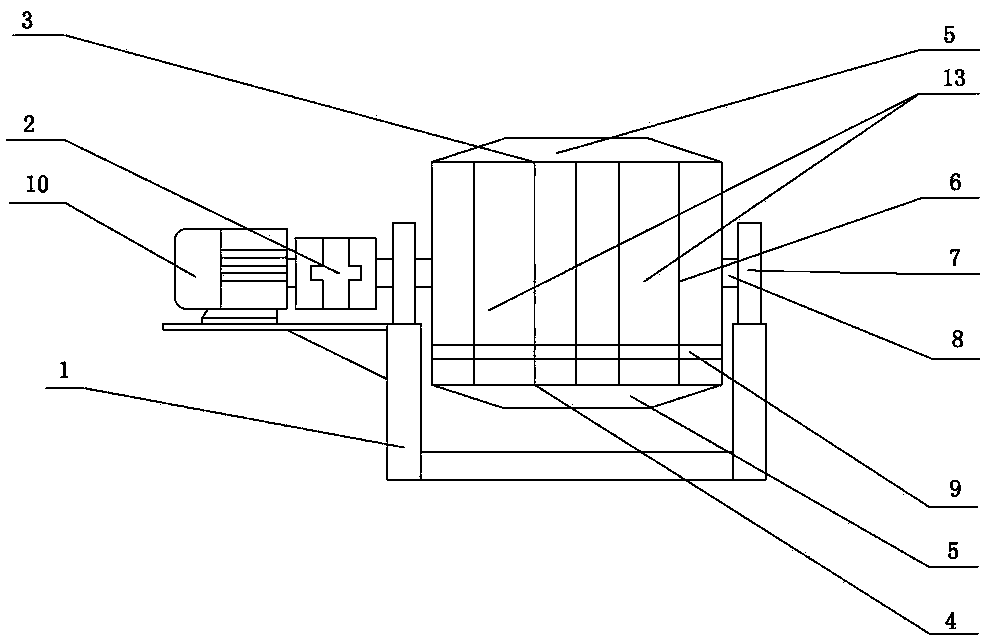

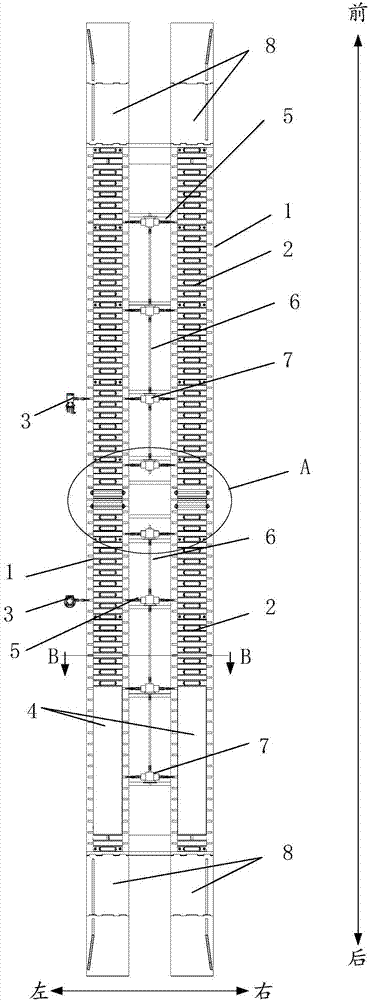

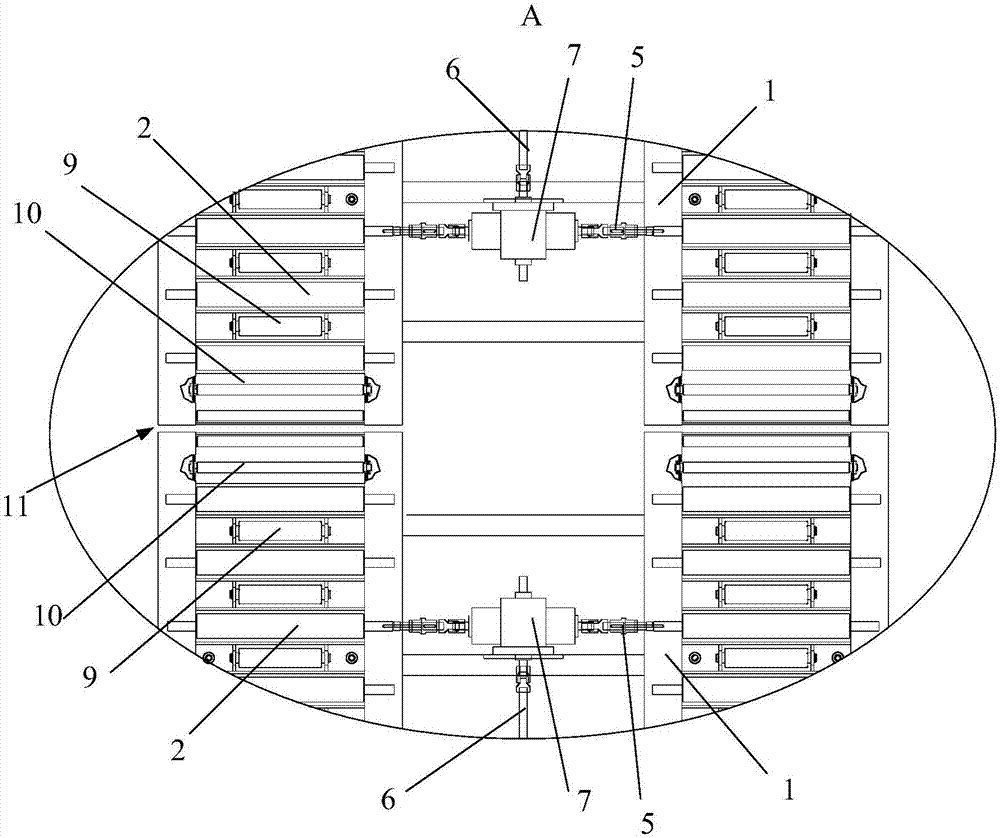

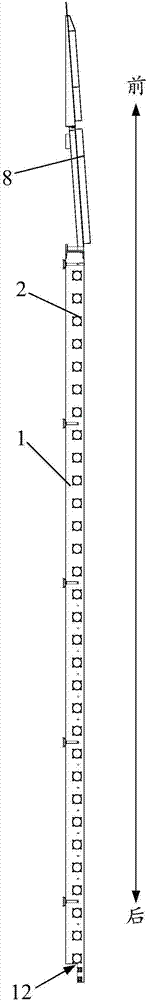

Vehicle conveying device and vehicle radiometric scanning check system

PendingCN106904394AReduce widthEasy to drive toMaterial analysis using wave/particle radiationConveyorsReciprocating motionWorkload

The invention provides a vehicle conveying device and a vehicle radiometric scanning check system. The vehicle conveying device comprises a rail bracket, a conveying roller group, a drive device and a car carrying board, wherein the conveying roller group comprises a plurality of drive rollers and a transmission mechanism connected to the drive rollers; the drive rollers can be driven by the transmission mechanism to synchronously move; the drive device is connected with the transmission mechanism or at least one drive roller; the drive device can drive the drive rollers to positively rotate or negatively rotate; and the car carrying board can be driven by the drive rollers to move back and forth along the rail bracket. The vehicle conveying device provided by the technical scheme adopts a conveying mode that a single row of rollers drives the car carrying board to horizontally move, is small in dimension in the height direction, does not need to trench on ground during mounting, and can be directly mounted on ground, so that mounting workload of the conveying device is reduced, and the construction period can be shortened; and moreover, the mounting device is not affected by facilities such as underground cables and pipelines, so that universality of the vehicle conveying device is improved.

Owner:BEIJING HUALIXING SCI TECH DEV

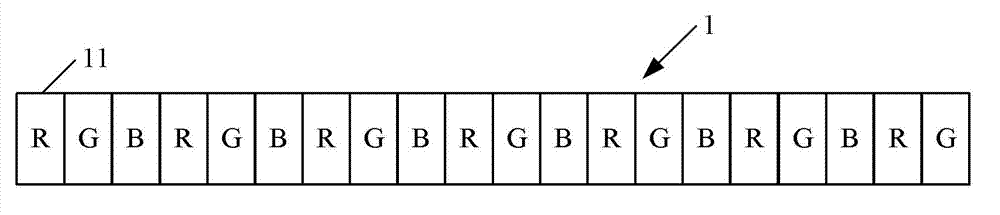

Display device and display method thereof

InactiveCN102890897ASave production materialsReduce manufacturing costStatic indicating devicesIdentification meansComputer graphics (images)Display device

The invention discloses a display device and a display method of the display device. The display device comprises at least one display unit, wherein each display unit comprises at least one pixel region; and shapes of the display units are predetermined, and the display units move along preset tracks at a preset frequency to form display regions in which pictures are displayed through the pixel region. The display device provided by the invention is formed by the display units which move along the preset tracks at the preset frequency, and the shapes of the display units are predetermined, thus sizes of the display units can be less than those of the display regions. Therefore, compared with traditional display devices, the production materials are saved and the production cost is reduced.

Owner:BOE TECH GRP CO LTD +1

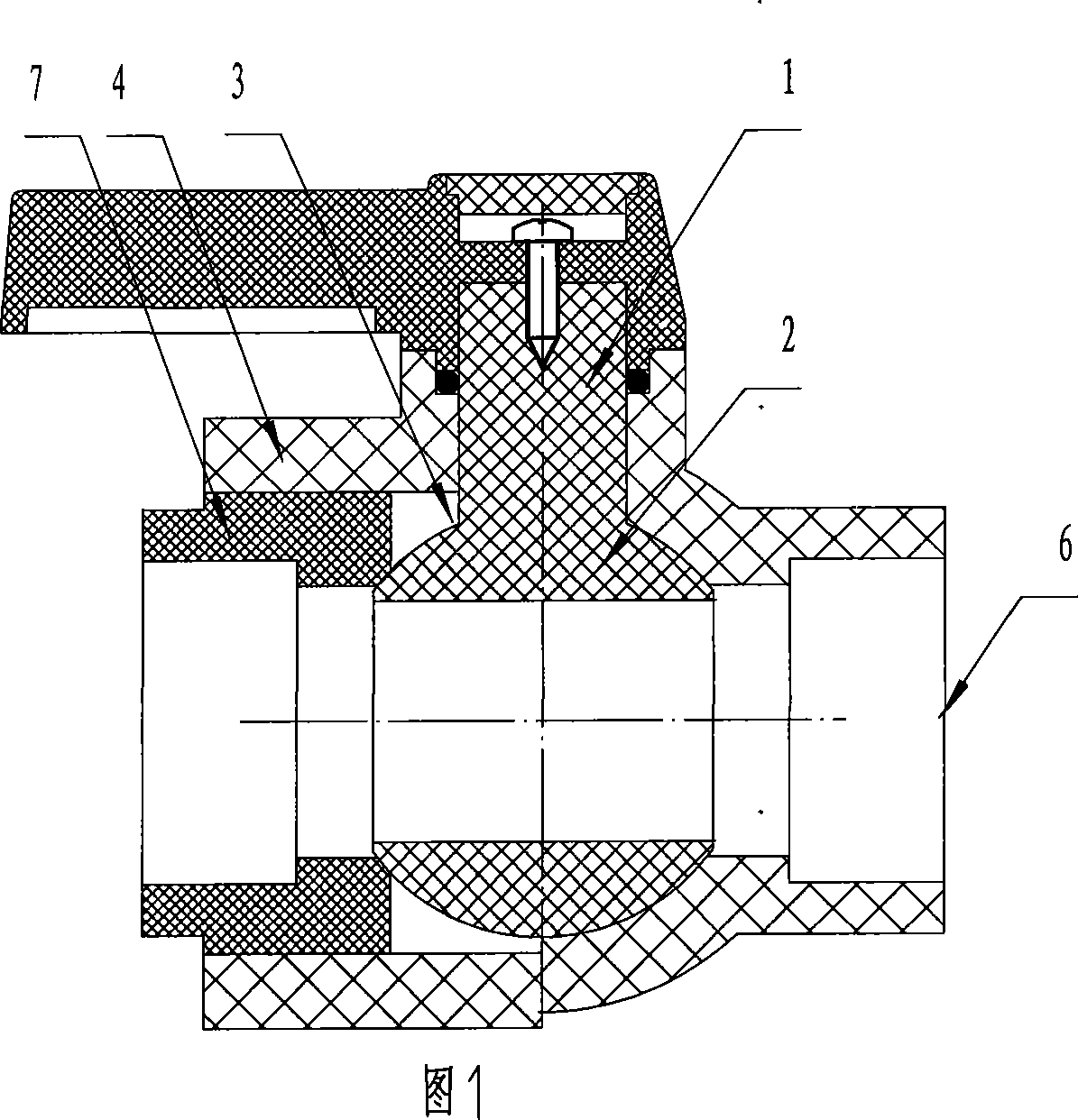

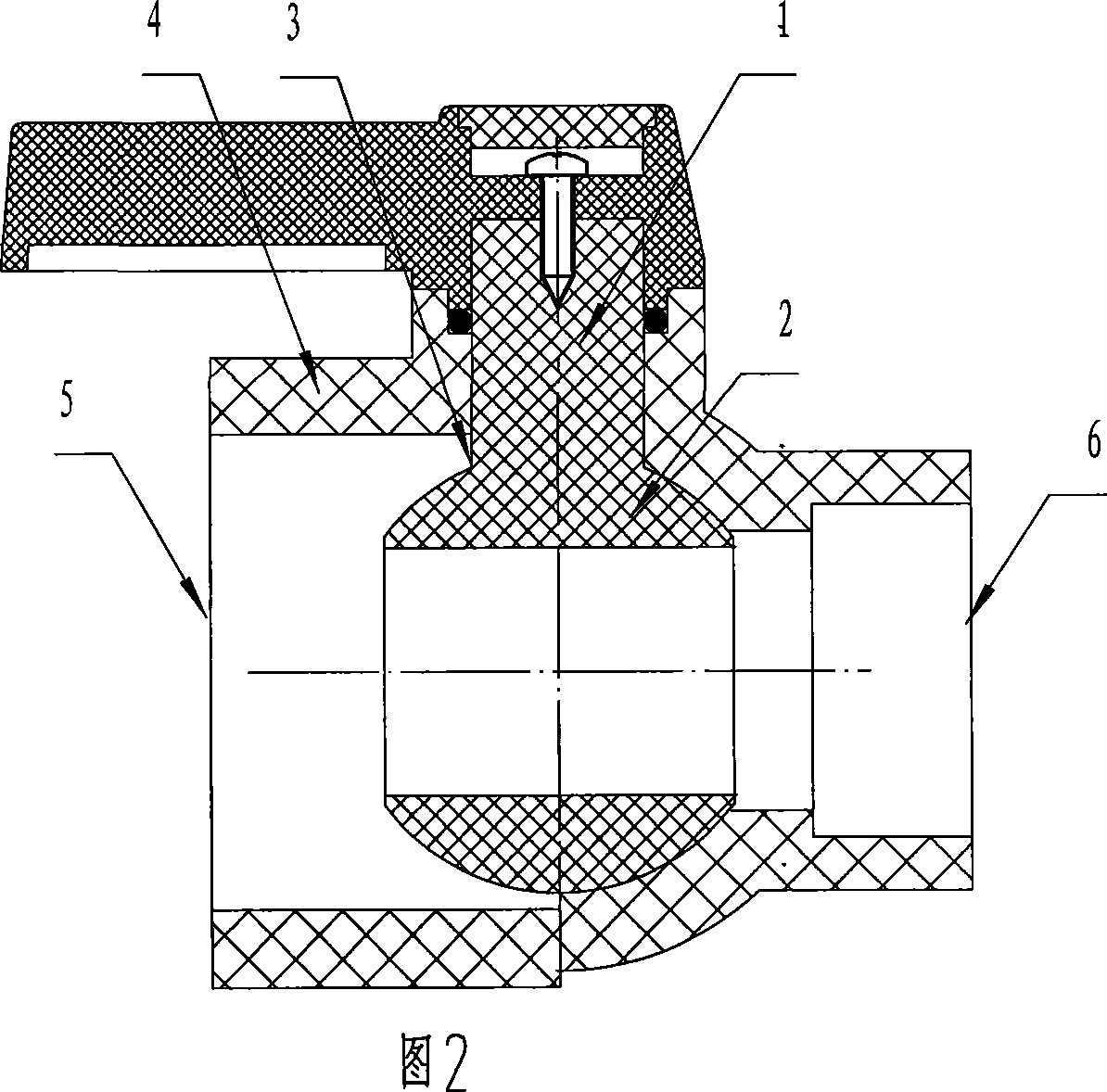

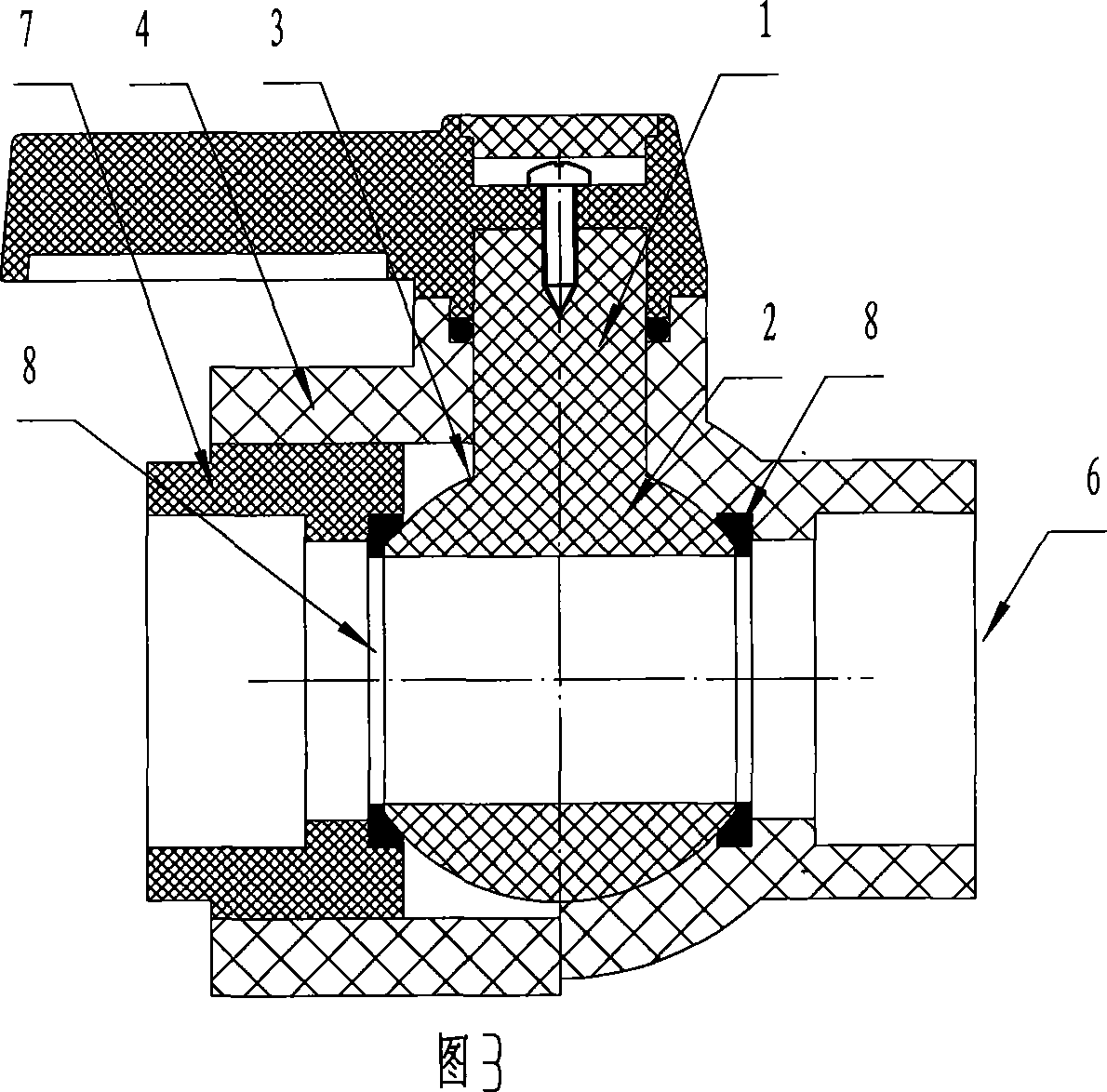

Method for producing plastic ball valve

InactiveCN101059177AAvoid the risk of sheddingReduce contact areaPlug valvesValve housingsPlastic materialsBall valve

The present invention relates to a manufacturing method of plastic ball valve, it is characterized by producing as the following steps: a. producing integrated spool which fixes and connects the valve bar and the valve ball into one unit; b, laying the valve ball of said integrated spool and the valve bar position connected with the valve ball in the die used for producing the plastic ball valve body; c. injecting the plastic material into the die used for producing the plastic ball valve body after the plastic material is heated and melted, cooling the plastic material in the die and modeling into plastic ball valve body, and the valve ball of integrated spool and the valve bar position connected with the valve ball is completely limited in the plastic ball valve body and can not be pulled out after the plastic ball valve body is cooled and shaped; d. connecting a plastic valve cover with through-hole on at least one open position of two side openings of plastic ball valve body, and linking the through-hole of plastic valve cover with the flow way in the plastic ball valve body. The invention is benefit for raising the products quality and extending the use life of products, and is facilitated the production of valve body.

Owner:罗荣森

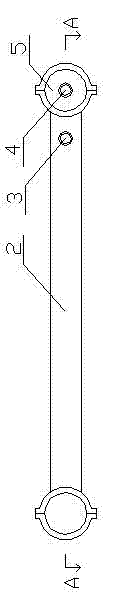

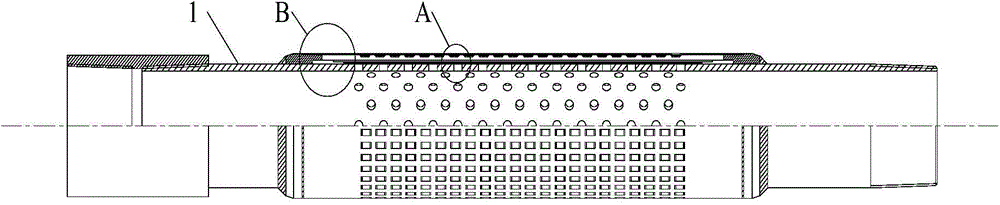

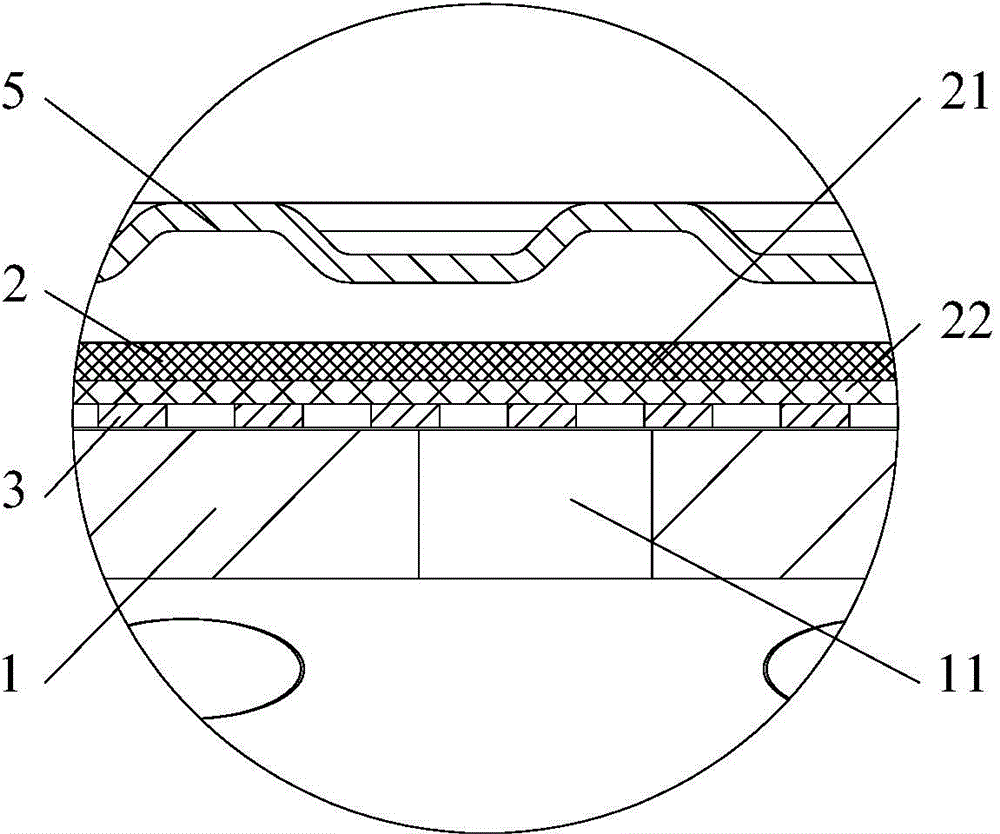

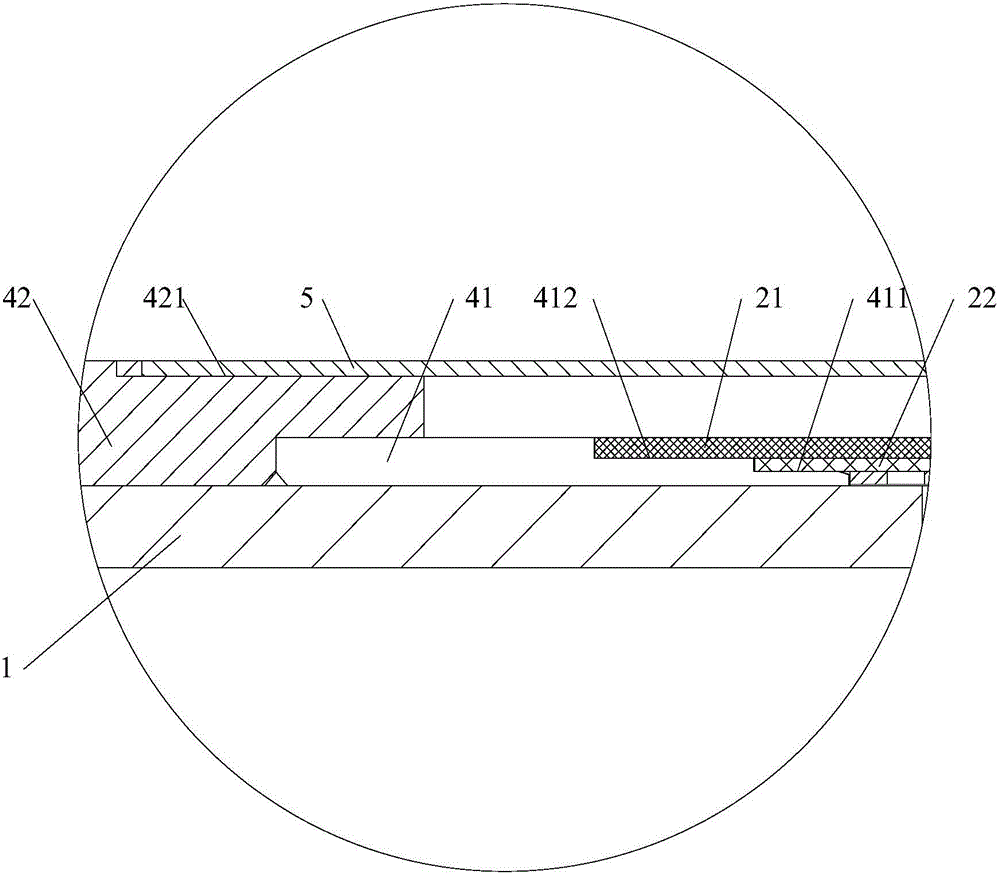

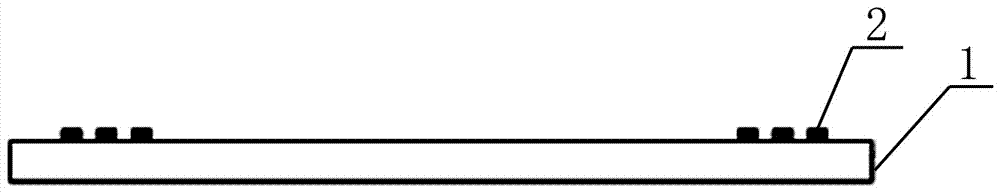

Sand control sieve pipe and manufacturing method of sand control sieve pipe

InactiveCN104675369ASmall apertureNo loss of sand control performanceFluid removalWelding apparatus% diameter reductionPetroleum

The invention provides a sand control sieve pipe and a manufacturing method of the sand control sieve pipe, relates to the field of petroleum equipment and mainly aims at reducing the pipe diameter of the sand control sieve pipe. The sand control sieve pipe comprises a base pipe and a filtering component, wherein a through hole is formed in the pipe wall of the base pipe, the filtering component comprises a layer of filtering screen, the filtering screen is provided with an open hole with the first dimension hole diameter, the first side edge of the filtering screen and the second side edge of the filtering screen are welded through a welding process for forming a first sleeve structure, and the first sleeve structure is arranged on the outer side of the base pipe in a sleeving way for forming a first filtering layer of the base pipe. The hole diameter dimension of an open hole formed by welding the open hole formed in the first side edge part of the filtering screen with the open hole formed in the second side edge part of the filtering screen is smaller than or equal to the first dimension. Compared with a structural mode of winding 2 to 5 coils of metal screens on the periphery of the base pipe in the prior art, the sand control sieve pipe and the manufacturing method have the advantages that the pipe diameter of the sand control sieve pipe can be reduced, the sand control sieve pipe after the pipe diameter reduction can be put into an oil gas well hole. In addition, the seepage rate and the anti-blocking capability of the sand control sieve pipe can also be improved.

Owner:ANTON OILFIELD SERVICES (GRP) LTD

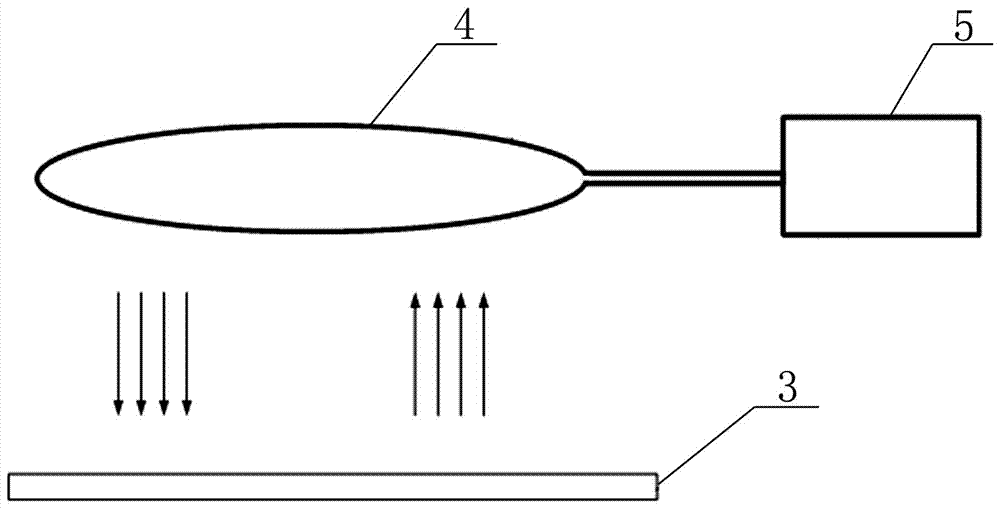

Ultra-high temperature passive thin-film temperature sensor and manufacturing method thereof

ActiveCN107421654AExpand the scope of testingSimple structureThermometers using electric/magnetic elementsUsing electrical meansPlatinumPlanar spiral inductors

The invention belongs to the technical field of temperature sensors and in order to address failure of current temperature sensors to accurately measure the temperature parameter under ultra-high temperature environment, provides an ultra-high temperature passive thin-film temperature sensor and a manufacturing method thereof. The ultra-high temperature passive thin-film temperature sensor herein includes a medium substrate and a planar spiral inductor. The planar spiral inductor is disposed on one side of the medium substrate and is provided with a stray capacitor. The planar spiral inductor and the stray capacitor constitute a LC resonance circuit. According to the invention, the sensor herein uses the LC resonance theory to obtain a signal in a wireless manner and prints a platinum to a high purity aluminum oxide ceramic substrate, and greatly expands the range of tests at high temperature. According to the invention, the sensor herein obviates the need for extra power supplies, can remote measure and read signals in a non-contact manner from long distance, can measure temperature in high-temperature and bad environment and enclosed environment. Further, according to the invention, the sensor herein has the characteristic of simple structure, easy preparation, and lower manufacturing cost compared with traditional sensor structures.

Owner:ZHONGBEI UNIV

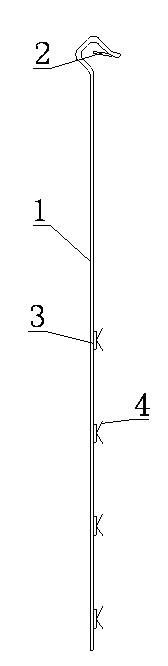

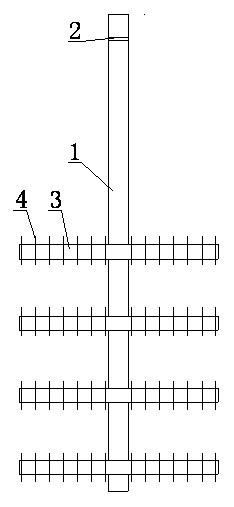

Anode special for oxidation of deep hole aluminum piece hard anode and oxidation method of deep hole aluminum piece hard anode

The invention discloses an anode special for oxidation of a deep hole aluminum piece hard anode and an oxidation method of the deep hole aluminum piece hard anode. According to a machining method of the special anode, a titanium material TA2 with both better conductivity and strength is adopted, so that good conductivity, corrosion resistance and convenience for clamping are guaranteed, and the requirements for oxidation of the deep hole piece hard anode are met. Since the oxidation of the deep hole hard anode is special, the selection of a material which has good selectivity and that a clamp can be soaked into sulfuric acid solution for long time without being easily dissolved or oxidized is particularly important. The treatment of the special clamp is that: a TA2 titanium plate or titanium wire is subjected to treatment such as welding and then used for the deep hole piece hard anode oxidation clamp. The conduction mode is that power is supplied by the anode. The anode provided by the invention is used for oxidation; the qualification rate of products at one time can be increased by over 98 percent; and the consumption and the production cost of the clamp are greatly reduced while the product quality is guaranteed.

Owner:CHONGQING JIANSHE IND GRP

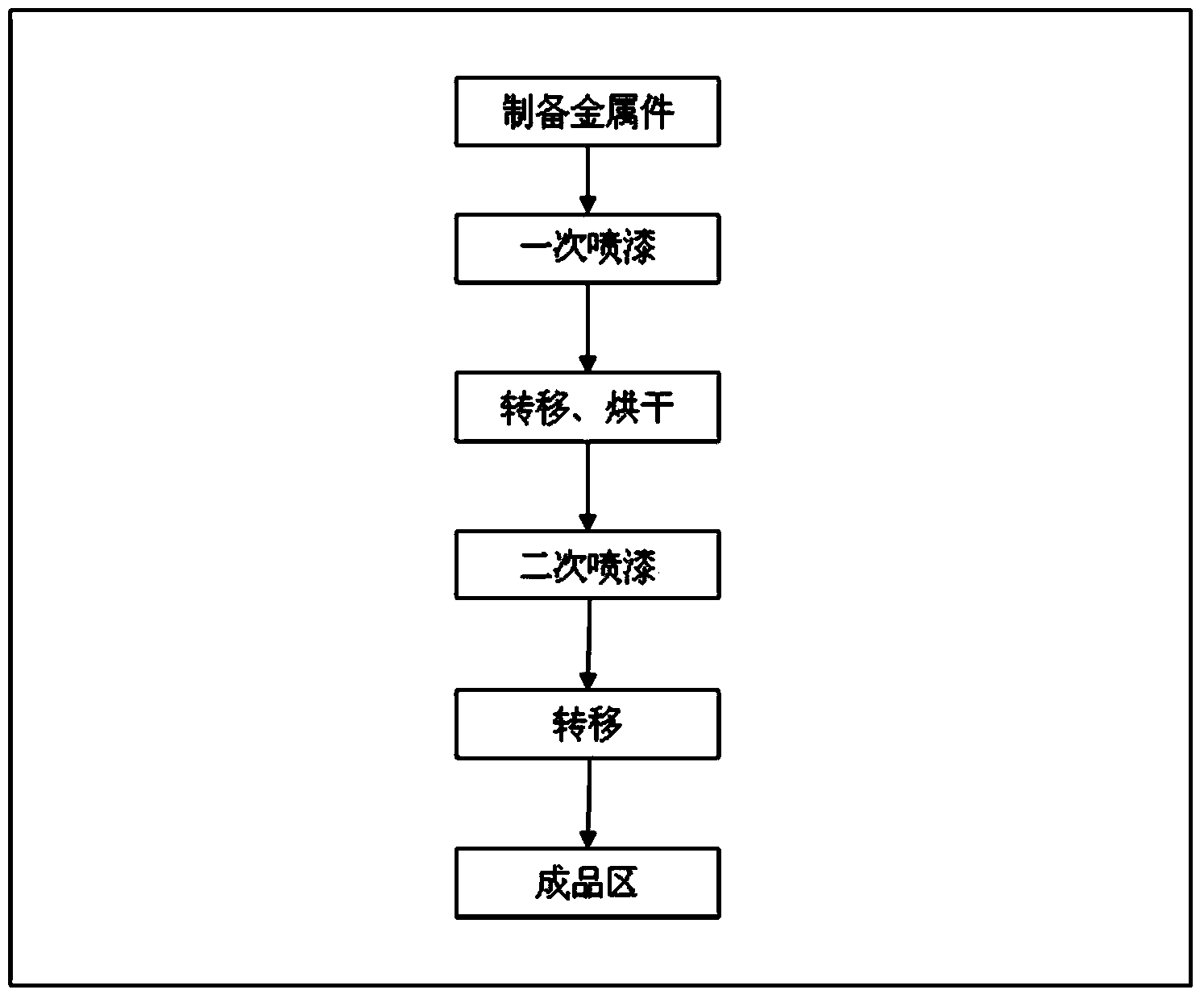

Multi-station multicolor hardware product spray coating method and equipment

ActiveCN103801499AReduce usageHigh degree of automationPretreated surfacesCoatingsControl systemSpray coating

The invention discloses a multi-station multicolor hardware product spray coating method. The method includes the following steps that a spray coating chamber is arranged; a plurality of electrostatic automatic spray coating machines are arranged in the spray coating chamber, and a uniform spray coating layer is formed on a hardware body through spray guns of the electrostatic automatic spray coating machines; a control system connected with the multiple electrostatic automatic spray coating machines is arranged and controls the working states of the multiple electrostatic automatic spray coating machines; a conveying track which is connected with and controlled by the control system is arranged, wherein the conveying track is used for conveying the hardware body to a required preset position; a plurality of mechanical arms which are connected with and controlled by the control system are arranged, wherein the mechanical arms are used for taking out or placing the hardware body. The invention further discloses equipment for implementing the method. The multiple automatic spray coating machines and the multiple mechanism arms are arranged in the spray coating chamber, and therefore multicolor spray coating can be achieved, production cost is effectively reduced, spray coating quality of products is good, and spray coating efficiency of the products is high.

Owner:DONGGUAN GUANHUI HARDWARE

Folding type integrated table and chair for dinning

ActiveCN104223759ASave production materialsExquisite structureFoldable tablesStowable tablesHinge angleEngineering

The invention discloses a folding type integrated table and chair for dinning. One end of each vertical arm and one end of the corresponding moving arm are connected together by a ratchet wheel, so four independent arm-rest frames are formed; one moving arm is enabled to rotate from 180 degrees to 70 degrees by the ratchet wheel and is configured for fixing a clamping piece and a buckling shaft of a table board; one end of each pull rod is connected with a rotating stand; the other ends of every two pull rods are connected with a turning wheel; a pin key is arranged in the turning wheel; bevel edges of each support frame can be stretched and folded; cross edges of each support frame can move; vertical edges of each support frame are fixedly arranged on the inner sides of the corresponding vertical arms; sliding rails are configured on the corresponding cross edges; a seat board is arranged on the corresponding sliding rails; two reinforcing rods are connected with the left vertical arm and the right vertical arm; folding rods formed by the rotating stands, the pull rods and the turning wheel are connected with the front vertical arm and the rear vertical arm to form a square frame; two table boards are connected with the moving arms and are connected by loose hinges. The folding type integrated table and chair is ingenious in structure, and economic and practical.

Owner:浙江开洋木业有限公司

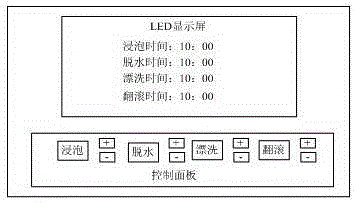

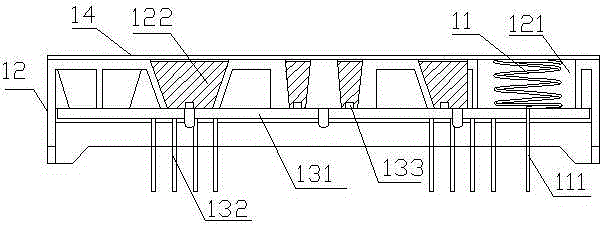

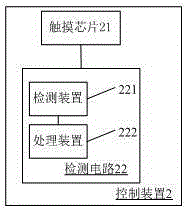

Touch LED display device and display equipment

ActiveCN105225613ASave production materialsEasy to operateElectronic switchingIdentification meansUser needsLED display

The invention relates to a touch LED display device and display equipment and belongs to the technical field of display. The touch LED display device comprises an LED display screen and a control device connected with the LED display screen, the LED display screen comprises touch spring sensors, a plastic shell and a PCB (printed circuit board) component, the lower end of each touch spring sensor is fixed on the PCB component and corresponds to the center of a through hole preformed in the plastic shell in position while the upper end of the same is flush with the upper surface of the through hole, the control device comprises a touch chip and a detection circuit connected with the touch chip, the touch chip is used for receiving touch signals sent by the touch spring sensors, and the detection circuit is used for sending corresponding control signals to the PCB component according to the touch signals. The touch spring sensors are arranged in the LED display screen, so that the problem of inconvenience in man-machine interaction due to the fact that a user needs to touch multiple touch buttons on a control panel for control when the LED display equipment is in use is solved, and effects of increasing operation forms and simplifying operation steps of the LED display equipment are realized.

Owner:ZHONGSHAN YOUYANG OPTOELECTRONICS TECH

Miniature intelligent label

ActiveCN102663486AIndependent contactless functionReduce volumeRecord carriers used with machinesCapacitanceEtching

The invention discloses a miniature intelligent label which is formed by a substrate, a chip and a package body. The substrate is square and is composed of a layer of thin insulating medium, a conductive pattern arranged at front and back faces of the insulating medium, a solder mask layer arranged at the front and back faces of the insulating medium and a surface of the conductive pattern, and a metallization hole which connects front conductive layer and back conductive layer. The chip is a dedicated chip of the intelligent label and is arranged at a part surface center area. The package body is formed by square resin molding material. The package body is arranged at an upper part of a substrate part surface, packages the chip and combines with the substrate to form a cuboid structure. The working frequency of the intelligent label is 13.56MHz, and by employing precision etching process, wire-to-wire capacitance between antenna adjacent windings and a plate capacitance resonant matching principle of front and back antenna windings, the packaging of a small intelligent label is realized.

Owner:SHANGHAI CHANGFENG SMART CARD

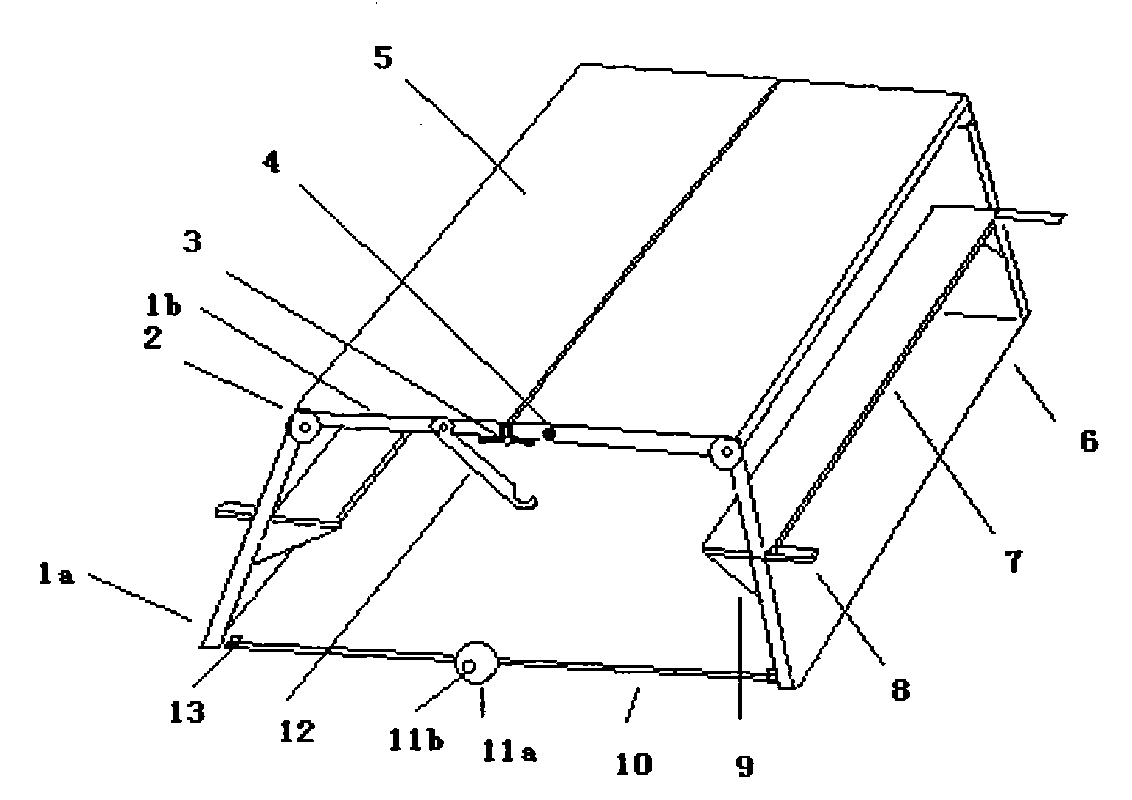

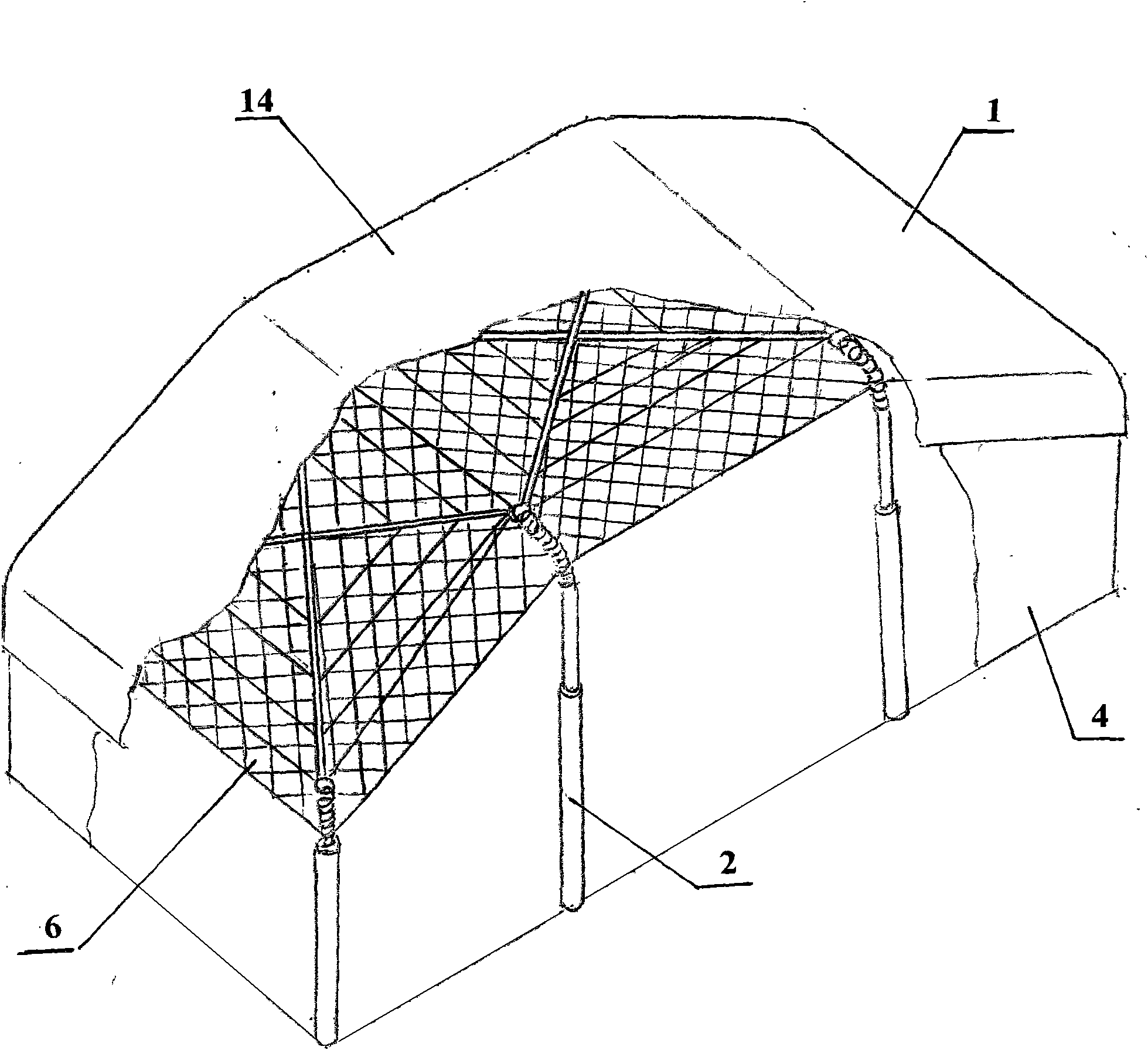

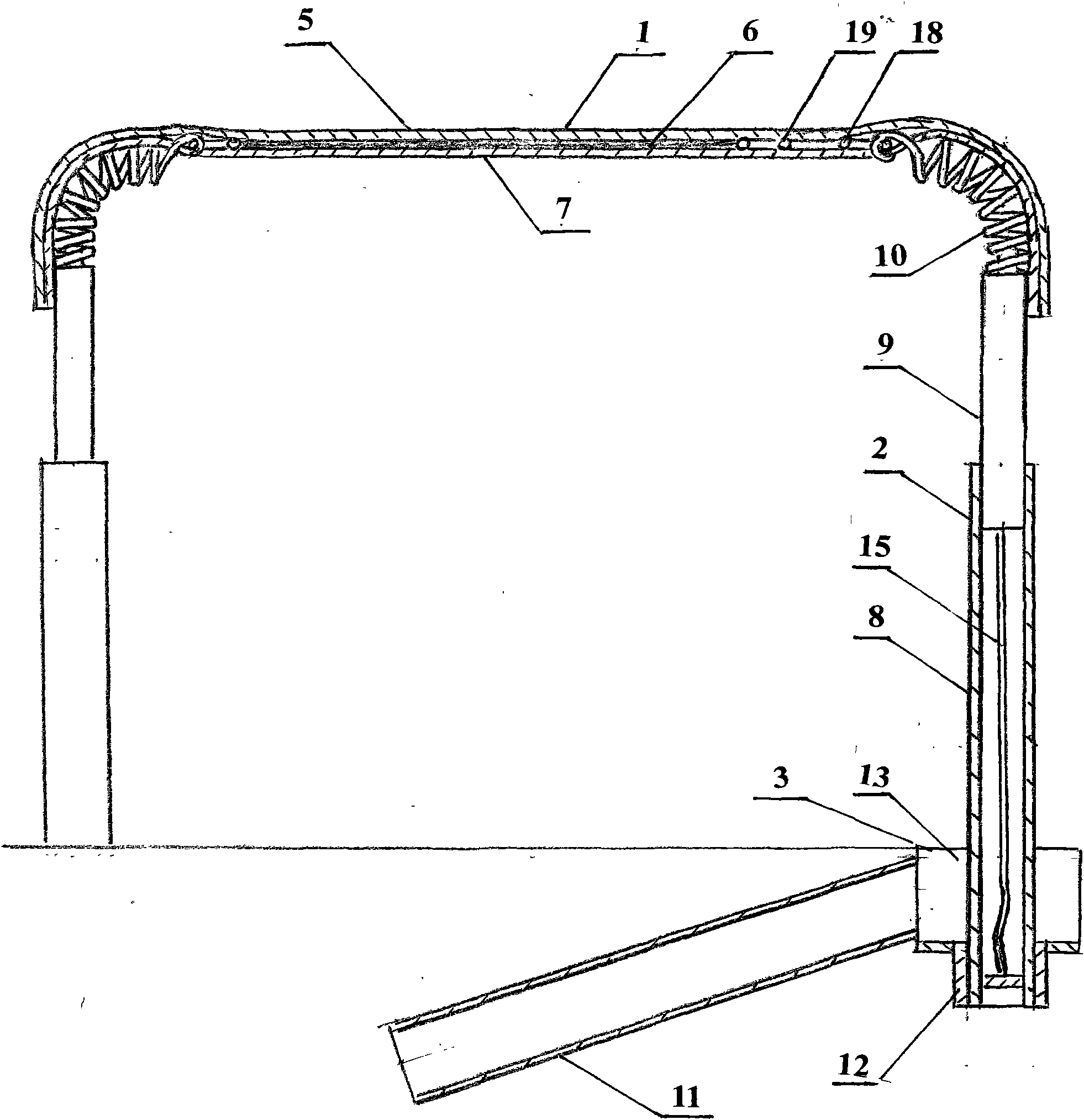

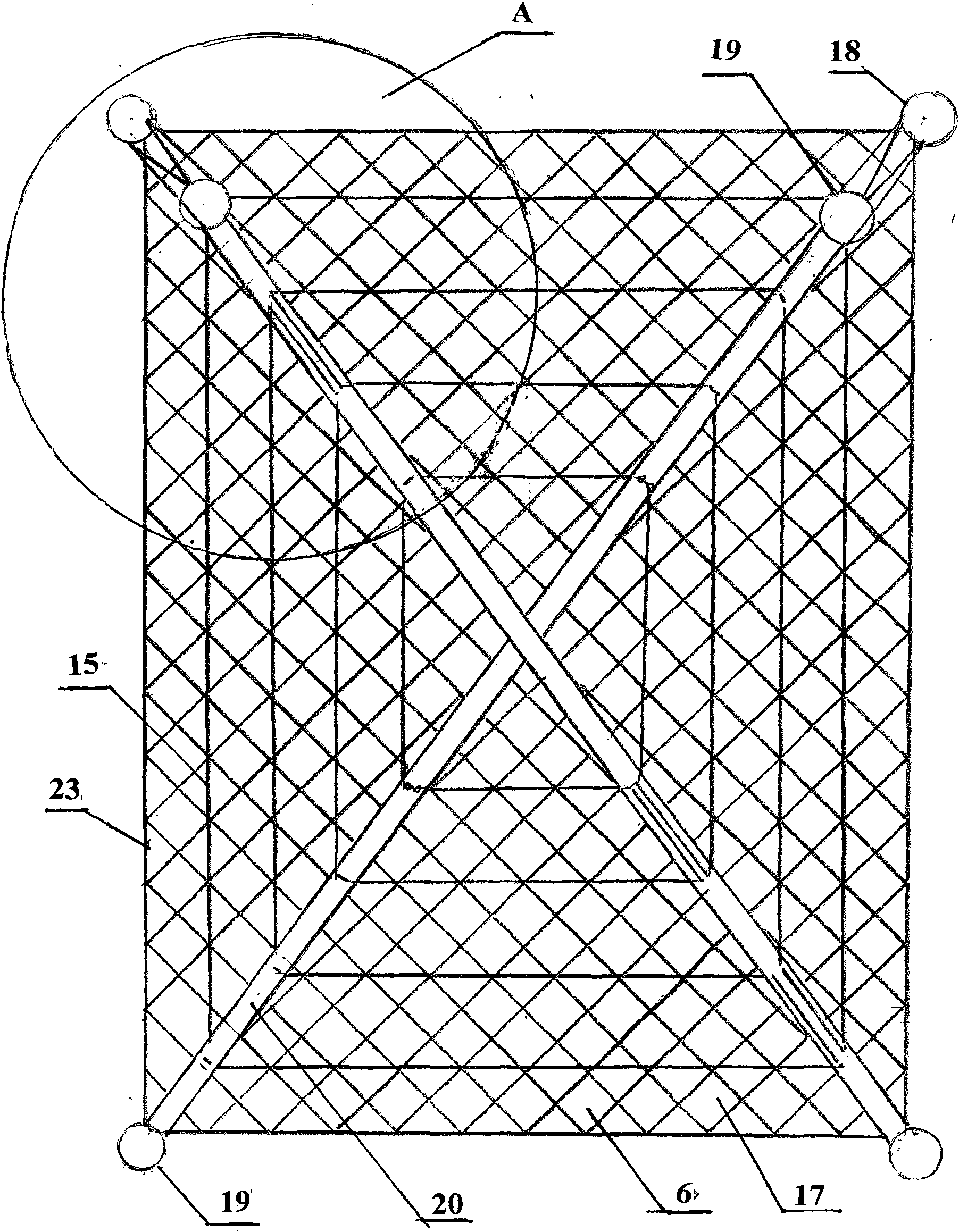

Prestress support cable mesh tent

InactiveCN101644111ASave production materialsLarge spanTents/canopiesPre stressPetroleum engineering

Owner:陈茂盛

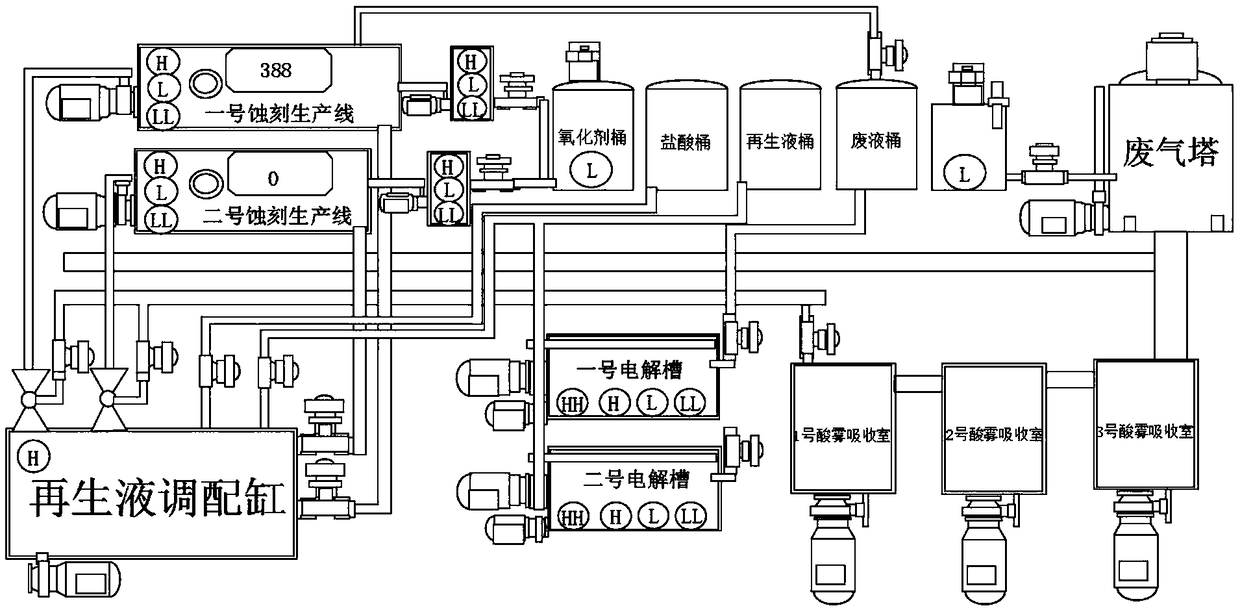

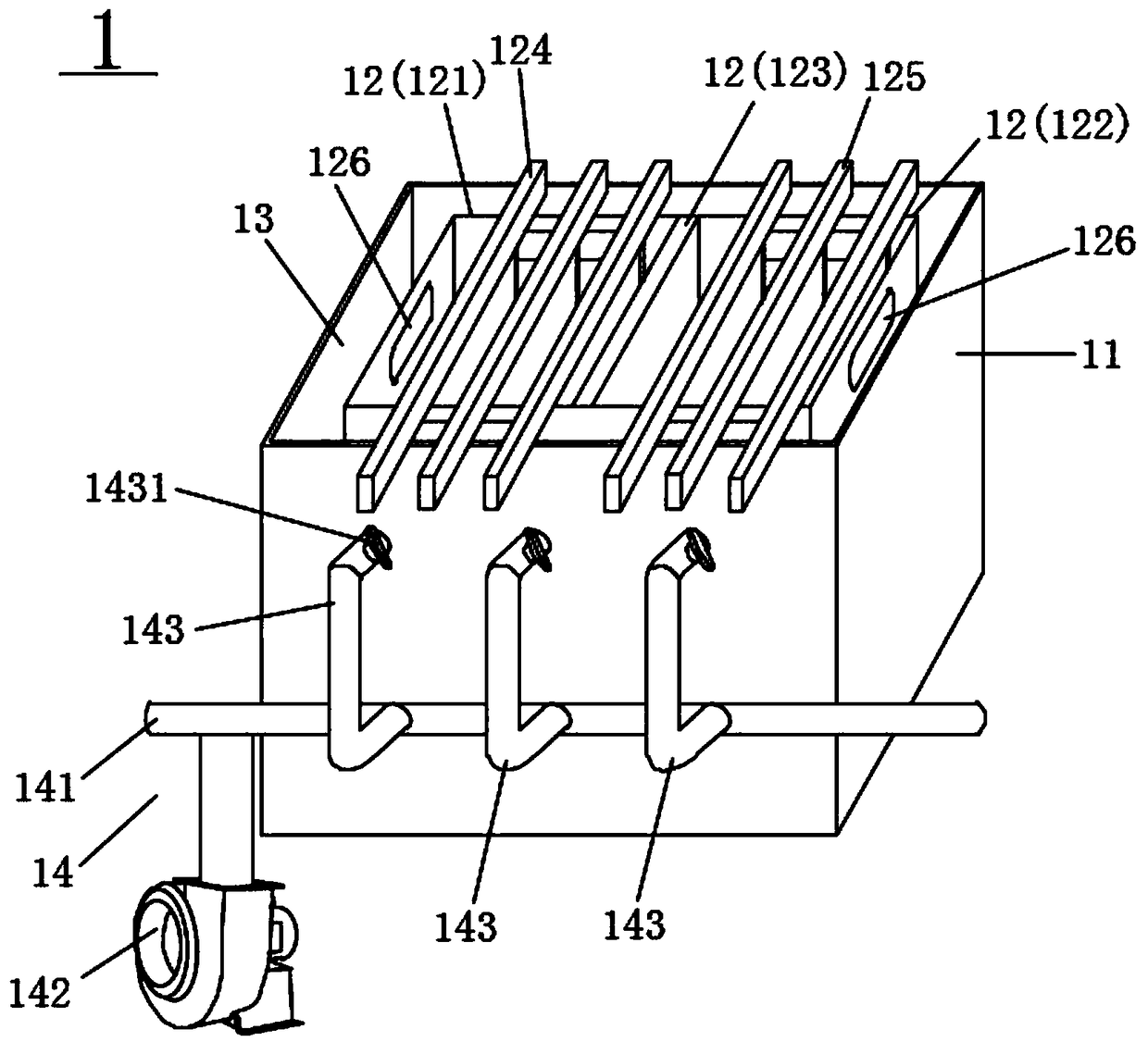

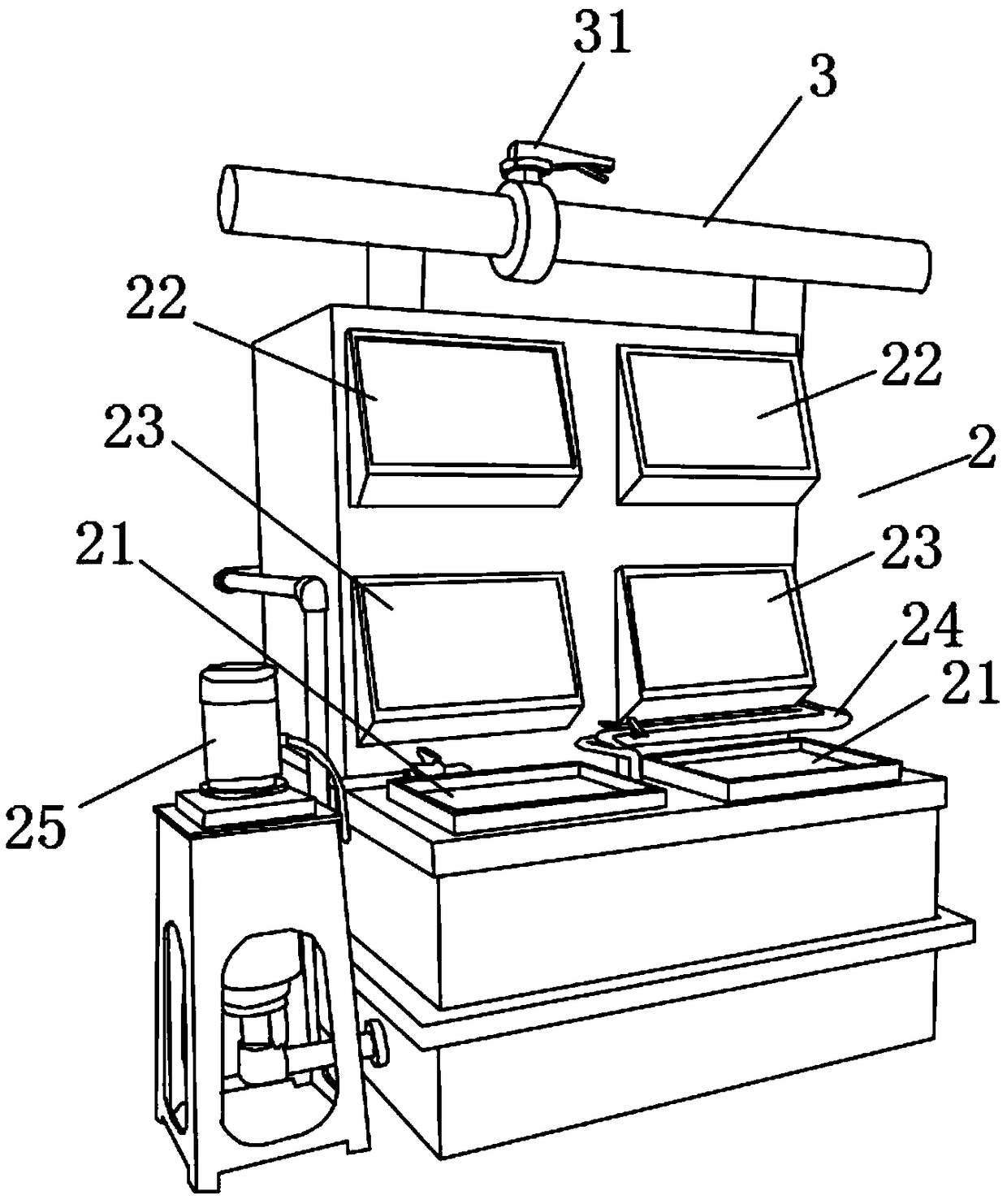

Acid etching liquid recycling system and method thereof

InactiveCN109023374ASave production materialsReduce manufacturing costPhotography auxillary processesProcess efficiency improvementIon-exchange membranesChemistry

The invention discloses an acid etching liquid recycling method which comprises the following steps of (1) prefabricating an acid etching liquid recycling system; (2) storing a waste etching liquor produced by an etching production line in a waste liquor barrel, and adding the waste etching liquor in the waste liquor barrel into an ion-exchange membrane electrolysis circulating device through an automatic-detection adding method; (3) electrolyzing the waste etching liquor through the ion-exchange membrane electrolysis circulating device so as to produce recycled liquid and elemental copper, storing the recycled liquid in a recycled liquid barrel, and moving out the elemental copper as a copper plate; and (4) adding an oxidizing agent, hydrochloric acid and the recycled liquid stored in therecycled liquid barrel into a recycled liquid blending monitoring device, detecting and blending the recycled liquid through multiple detectors in the recycled liquid blending monitoring device, enabling the oxidation reduction potential range of the recycled liquid to range from 480 to 520mv, enabling the copper concentration to range from 30 to 60g / L, and reflowing the recycled liquid into an etching production line so as to use. The invention further discloses an acid etching liquid recycling system applying the method.

Owner:德雅(深圳)环境科技有限公司

A method of manufacturing a PCB through utilization of 3D printing technology

InactiveCN105704934ASave human effortReduce manufacturing costConductive pattern formationElectricityWastewater

The invention provides a method of manufacturing a PCB through utilization of 3D printing technology. The method comprises the following steps: 1, a substrate is printed; 2, lines are printed; 3, the substrate is modified; 4, polishing, grinding and shaping are carried out; and 5, characters are printed. According to the method, lines are manufactured on the existing substrate, so that a local machine only needs to make the substrate and shape the substrate without artificial intervention in a production process; the manufacturing process can be automatically completed by a computer; manpower is saved; no waste water, exhaust gases, etc. will be generated in production; the production is environment-friendly and safe; production factories do not need to pay great amounts of water and electricity charges and expensive water treatment costs, so that production costs are effectively reduced and production materials are saved.

Owner:WEIJING PRECISION STEEL MOLD HUIZHOU CO LTD

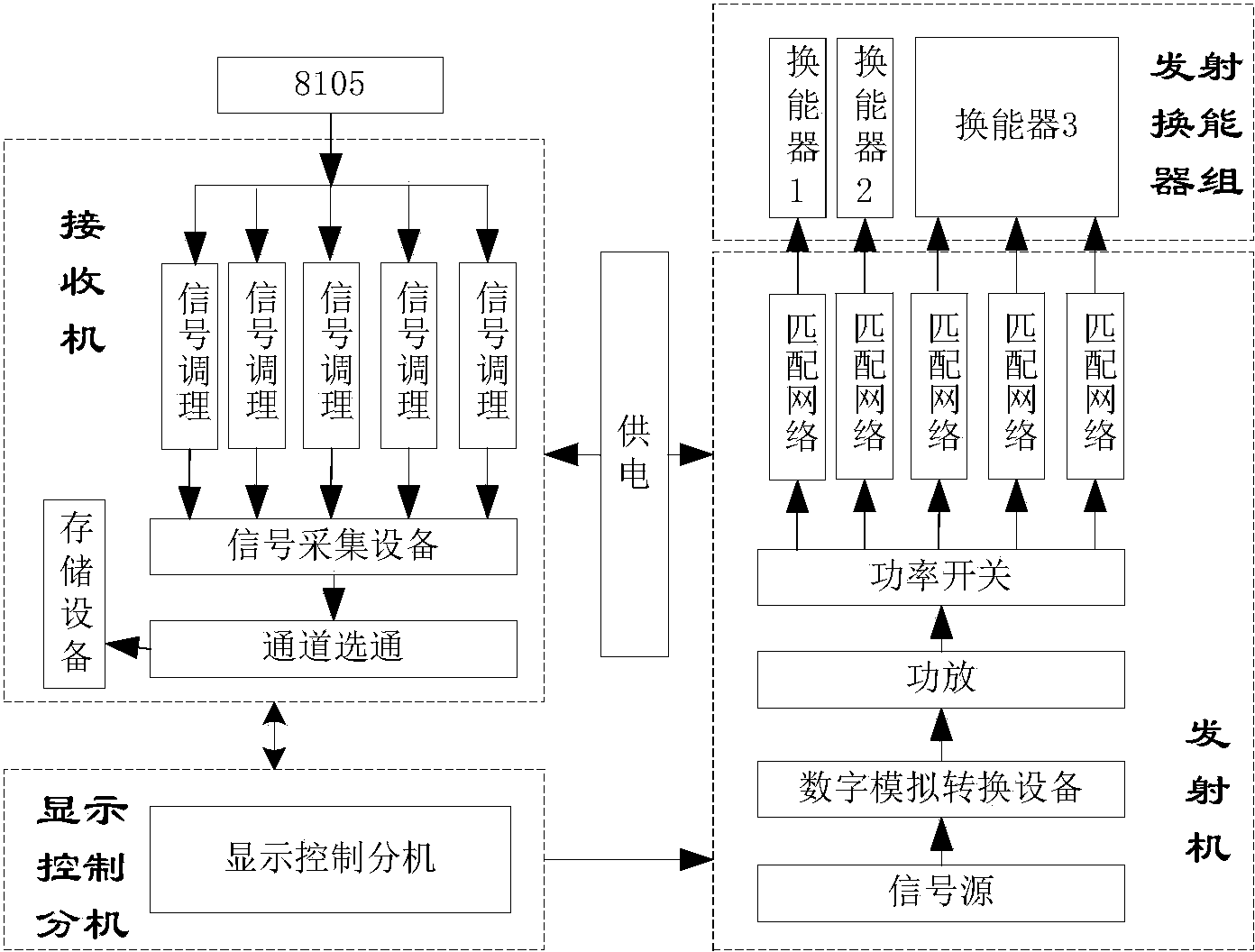

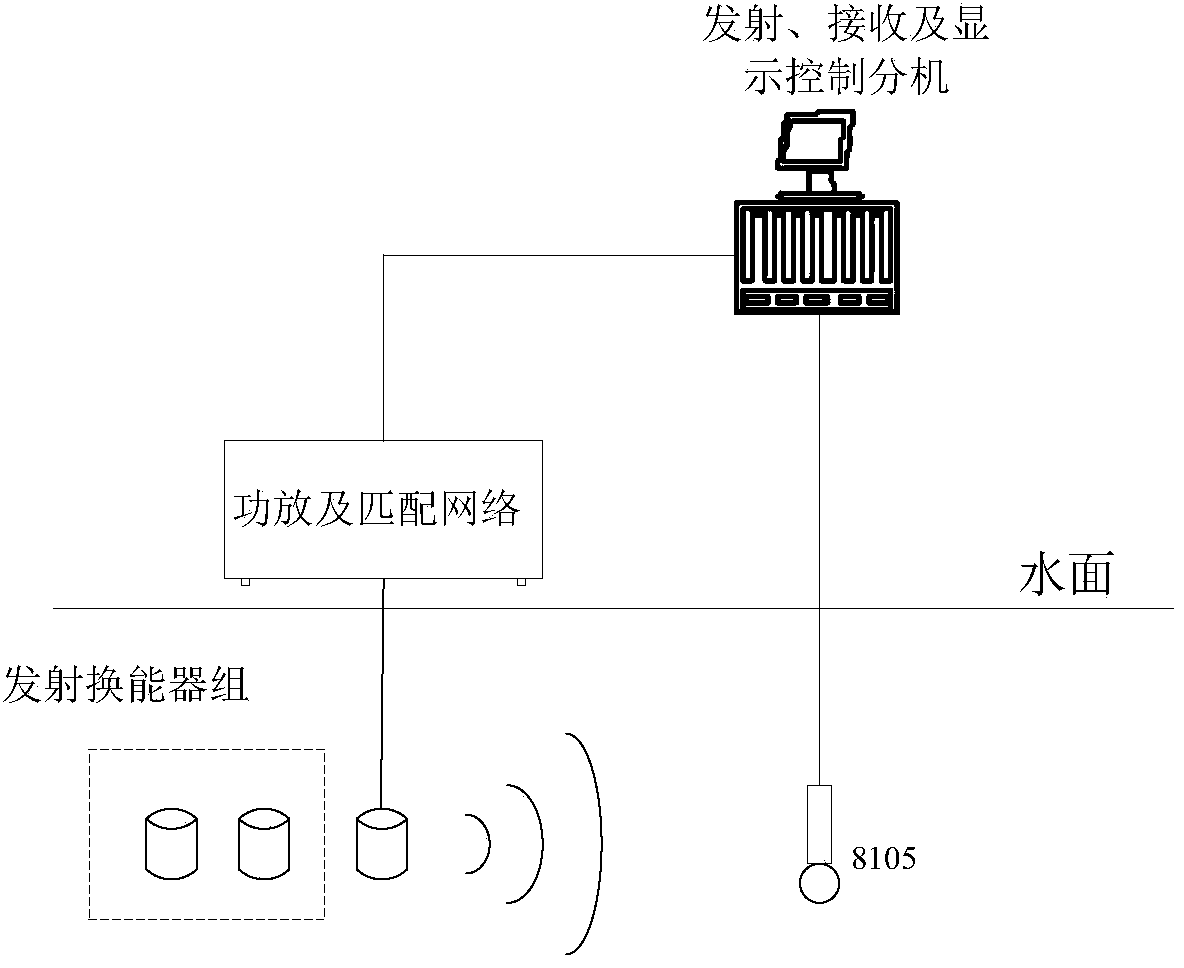

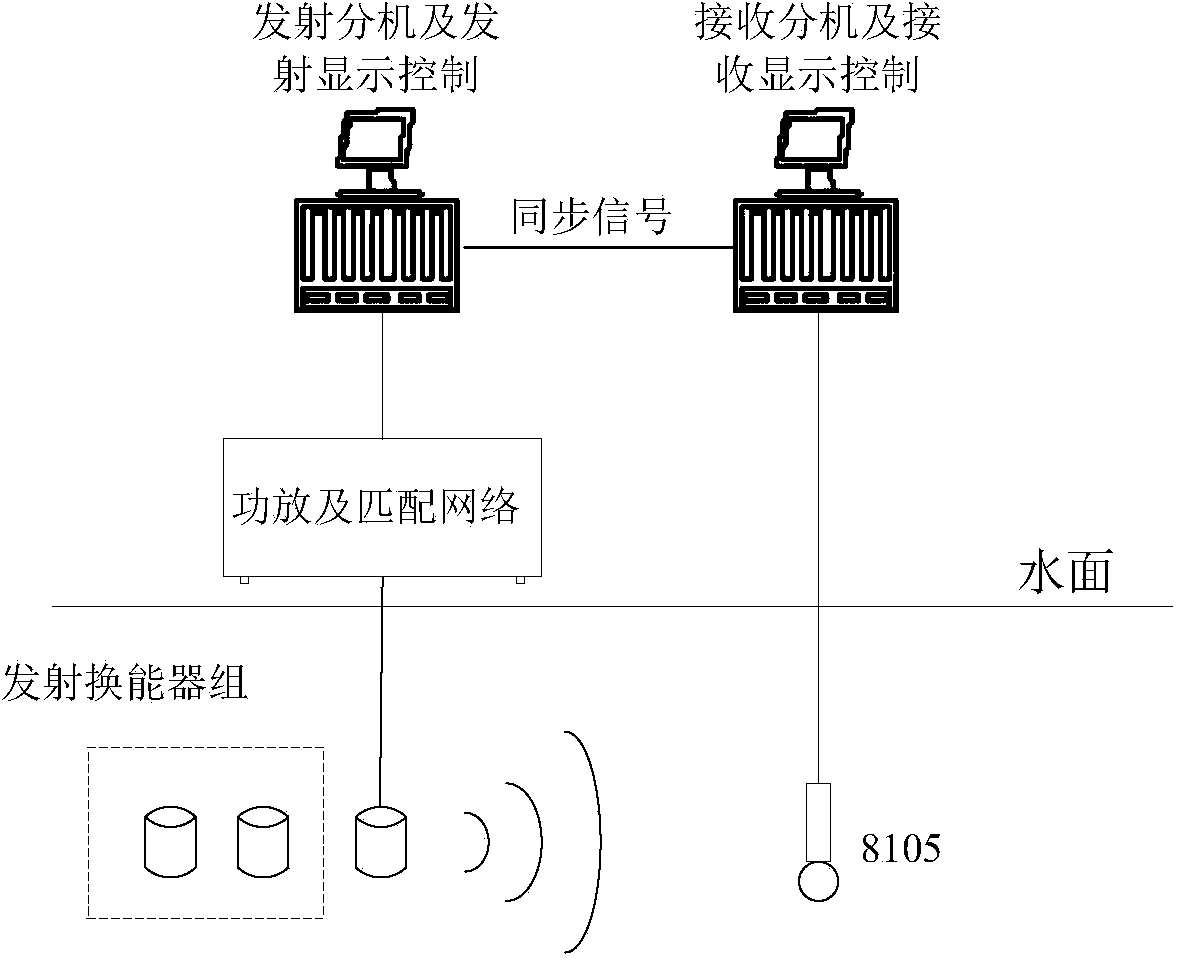

Common underwater acoustic measurement system

ActiveCN104375134AImprove general performanceEasy to carryWave based measurement systemsExtension setTransducer

The invention discloses a common underwater acoustic measurement system mainly composed of a transmitting transducer set, a transmitting extension set, a receiving extension set and a display control extension set. The display control extension set is connected with the transmitting extension set and the receiving extension set. The transmitting extension set is connected with the transmitting transducer set and used for driving the transmitting transducer set. The transmitting transducer set is used for finishing underwater launching of acoustic signals in a working frequency band. The transmitting extension set is used for finishing generation of underwater acoustic measurement signals and driving the transmitting transducer set, the receiving extension set is used for finishing receiving, conditioning, collecting and storing of the underground acoustic signals, and the display control extension set is used for finishing parameter setting, transmitting and receiving controlling, state monitoring, received waveform displaying and target strength calculating. The common underwater acoustic measurement system is high in universality and performance cost ratio and convenient to carry and use, the modular design is adopted, and subsystems can be independently used.

Owner:上海瑞洋船舶科技有限公司

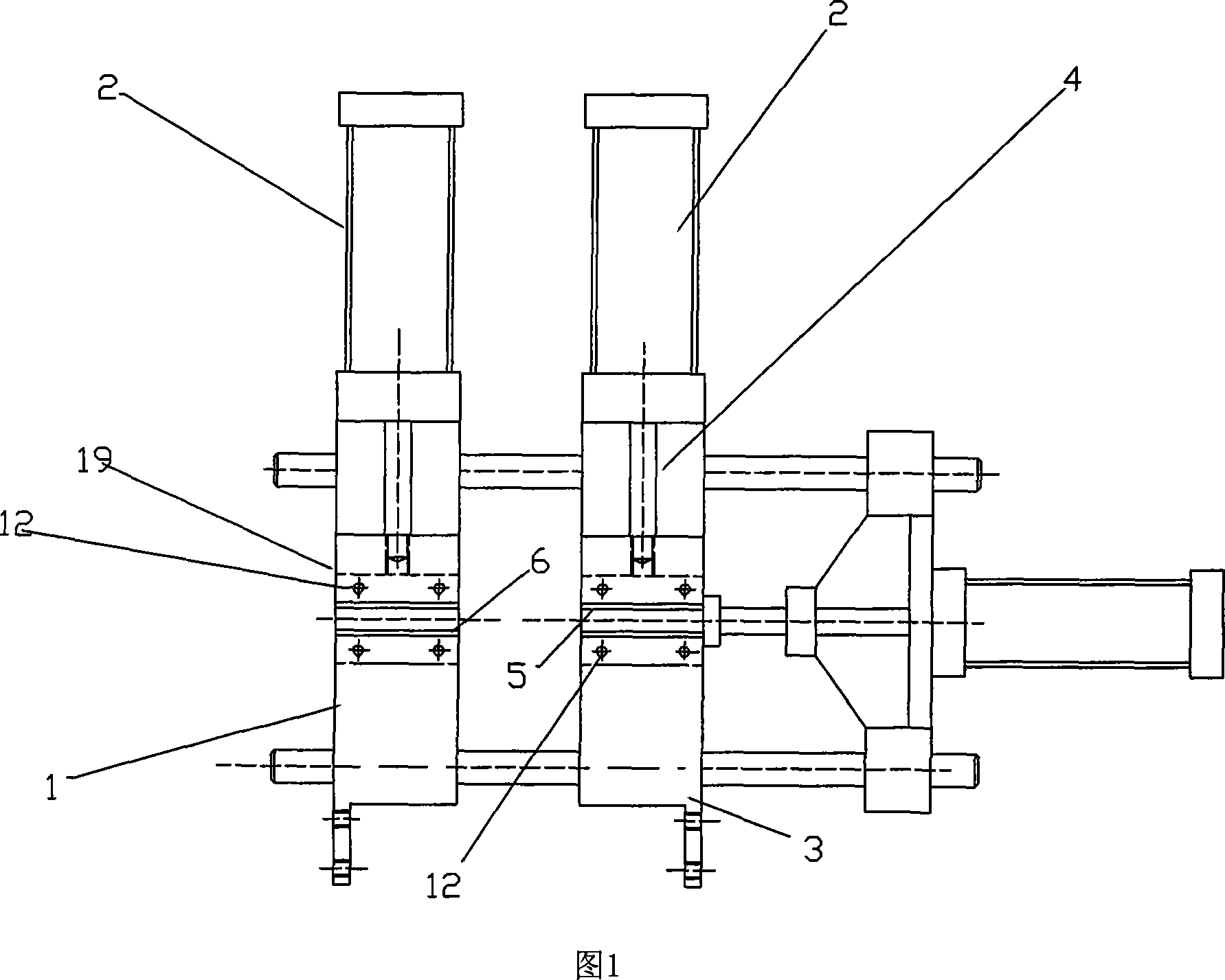

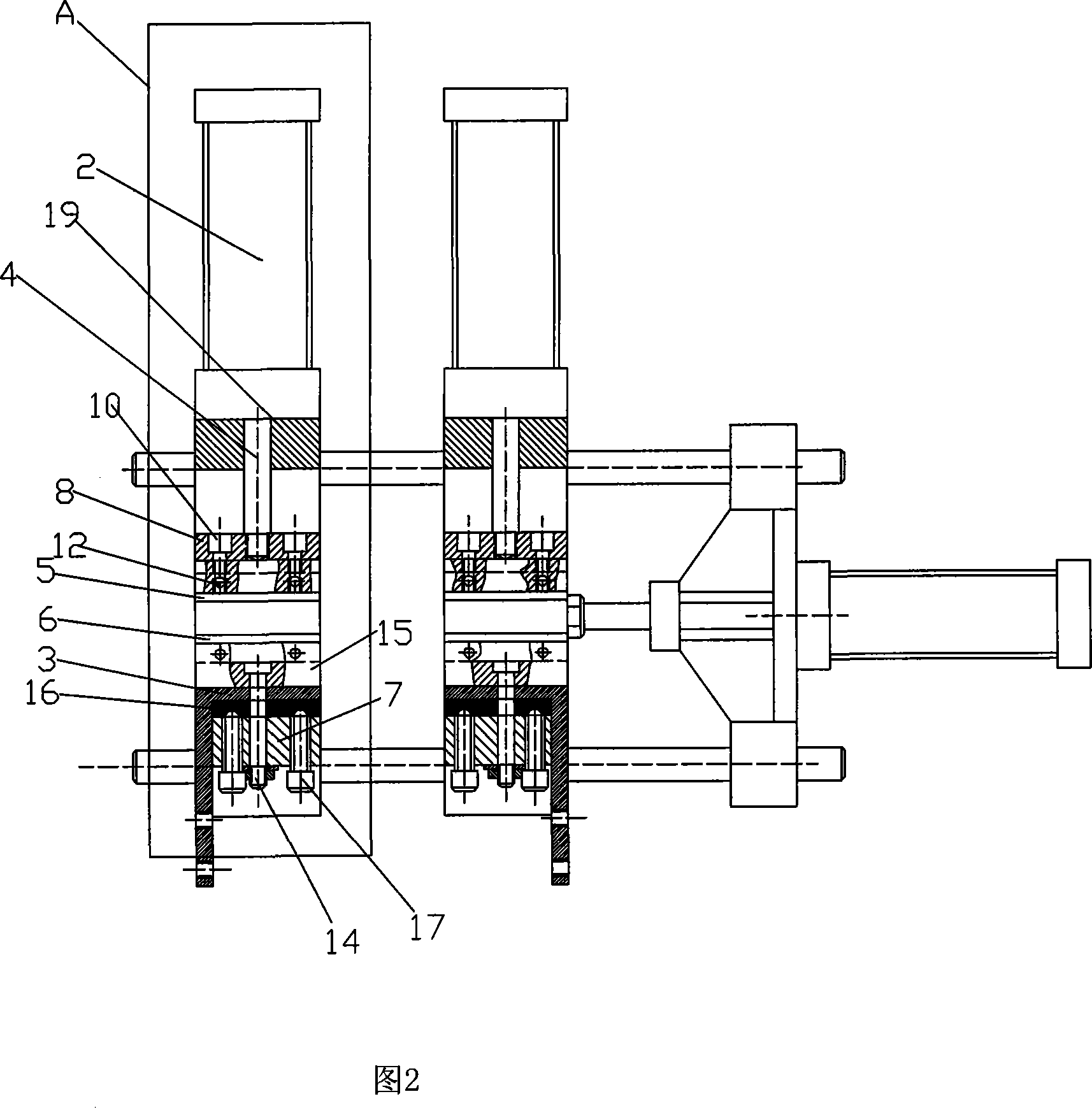

Inserted copper-aluminum pipe resistance welder

InactiveCN101073848AIncrease the freedom to adjust the structureSave production materialsResistance electrode holdersWelding/soldering/cutting articlesEngineeringCopper

The invention is concerned with the welder, especially the plug-in copper aluminium pipe resistance welding machine, includes the handpiece body, the tight cylinder, the electrode, the outputting line connecting piece, the tight cylinder axis, it is: sets the adjustable fixing piece of the top electrode between the bottom of the tight cylinder axis and the top electrode, sets the adjustable fixing piece of the bottom electrode between the bottom electrode and the bottom fixing block of the handpiece body.

Owner:张荣焕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com